-

Bently TTL70259 LEMO-BNCTTLTach/Keyphasorcable

-

Bently MAGF0104 Accelerometermagneticbase

-

Bently DCCA0041 DCcaradapter

-

Bently CABU0213 USBdatatransfercable

-

Bently ACCL0561 Right-angledaccelerometer

-

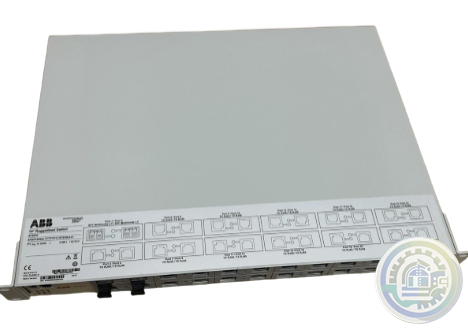

ABB TB825 (Multi Mode) System 800xA hardware selector

-

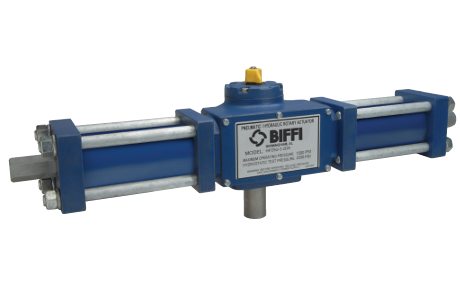

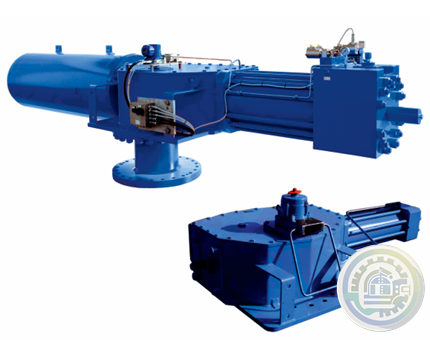

BIFFI Morin HP Series Model High Pressure Actuators

-

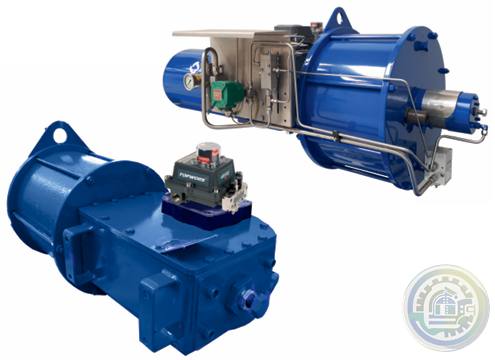

BIFFI GPo Gas-hydraulic actuator

-

BIFFI PHW Power Hand Wheel series

-

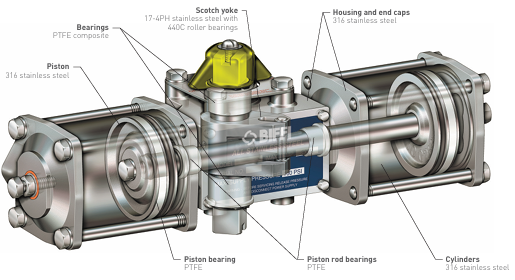

BIFFI MORIN S SERIES DESIGNED WITH A HEART OF STAINLESS STEEL

-

BIFFI MORIN S SERIES ACTUATORS

-

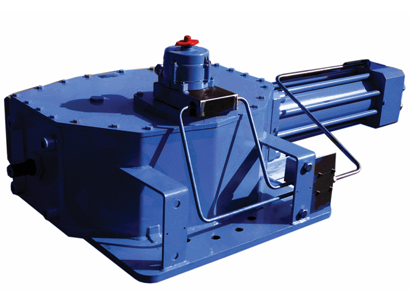

BIFFI ALGA Double-Acting Pneumatic Actuator Version: Base and with Manual Operator Actuators

-

BIFFI ALGA/ALGAS/ALGAS-QA Pneumatic Actuators

-

BIFFI Morin Series A, B, C and S Scotch Yoke Actuators

-

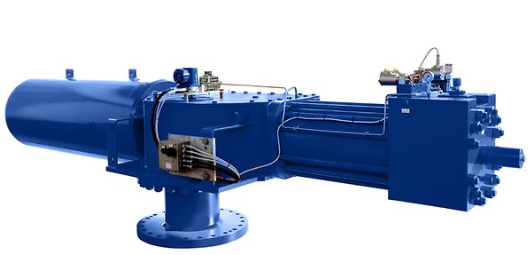

BIFFI OLGA-H High-Pressure Double-Acting Hydraulic Actuator

-

BIFFI OLGA-H/OLGAS-H/OLGAS-H-QA High Pressure Hydraulic Actuators

-

BIFFI OLGA/OLGAS Hydraulic Actuators

-

Hitachi Energy S10V Programmable Controller

-

Hitachi Energy Programmable Controller S10VE

-

Bently Nevada SCOUT240-IS Hardware Features

-

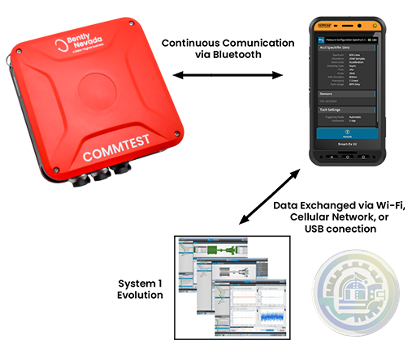

Bently Nevada COMMTEST240 Hardware Features

-

Bently Nevada COMMTEST220 ANDCOMMTEST240 Portable Data Collectors

-

Bently Nevada vb8 Portable Data Collector, Analyzer and Balancer

-

Bently Nevada vb7 Portable Data Collector, Analyzer and Balancer

-

Bently Nevada vb6 Portable Vibration Data Collector

-

Bently Nevada vb5 Portable Data Collector

-

Bently Nevada vb and SCOUT100 Series

-

Bently Nevada SCOUT100-Ex Easy, efficient two-channel vibration analyzers

-

Bently Nevada SCOUT200* series Portable data collection for condition monitoring

-

Bently Nevada™ Scout™ SCOUT140EX Vibration Data Collector,Analyzer and Balancer

-

Eaton MTL Megablock range of wiring hubs

-

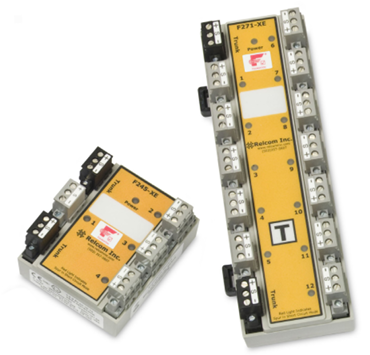

Eaton F2xx-XE Megablock Series

-

Eaton MTL intrinsically safe fieldbus barriers

-

Eaton MTL FS32 fieldbus trunk and spur surge protection

-

Eaton MTL FS32 rangeSurge protection for fieldbus components

-

Eaton MTL FP32 fieldbus trunk and spur surge protection - DIN rail

-

Eaton The FBT-6 is connected to the network

-

Eaton The FBT-6 checks for any device not responding to a LAS pass token

-

Eaton MTL FBT-6 Fieldbus diagnostic monitor

-

Eaton DIN-rail mounted Fieldbus Terminators

-

Eaton MTL Fieldbus Software Tools

-

Eaton F11 Fieldbus Power Hub

-

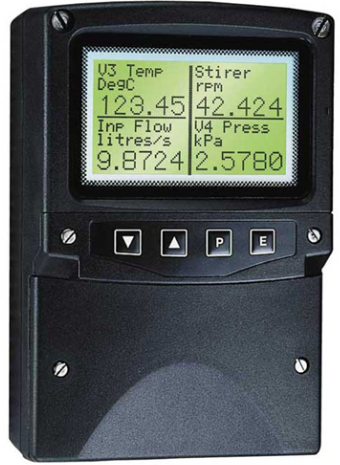

Eaton MTL fieldbus displays

-

MTL F809F-Plus fieldbus diagnostics module

-

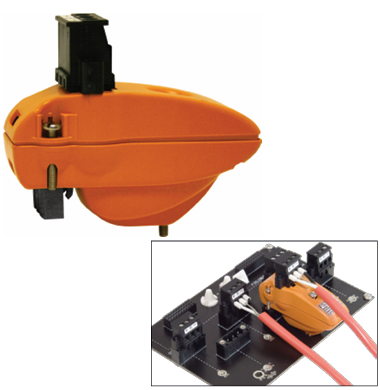

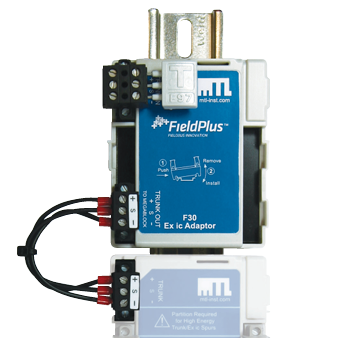

Eaton F30 Ex ic Adaptor Accessory for F300 range of Megablock Wiring Hubs

-

Eaton AS-I Megablocks Passive hubs for AS-i bus networks

-

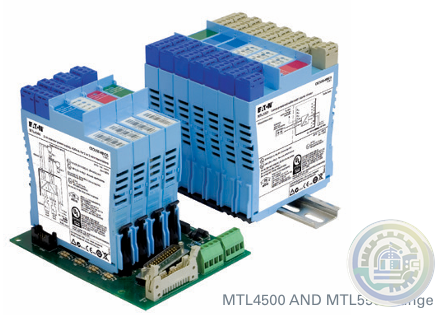

Eaton Analogue Input Modules with passive input for 4-wire transmitters

-

Eaton Analogue Input module types MTLx541A/MTLx541AS

-

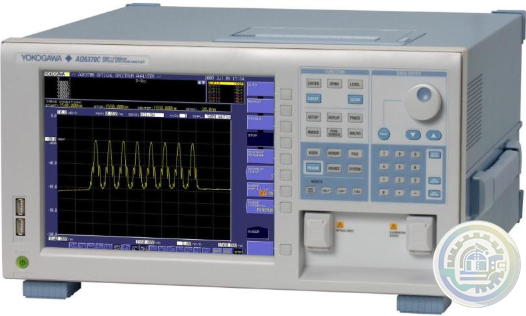

YOKOGAWA AQ6370C Various Analysis Functions

-

YOKOGAWA AQ6370C Optical Spectrum Analyzer

-

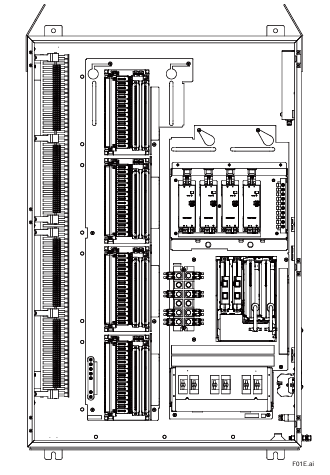

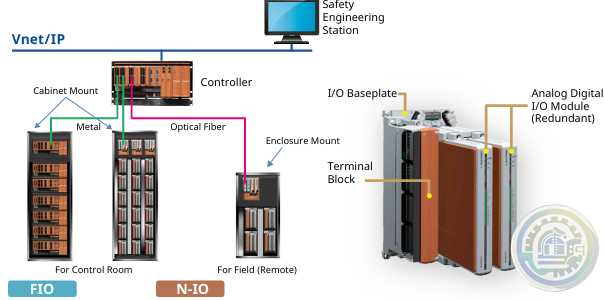

YOKOGAWA N-IO field enclosure (System Models: A2ZN70D, A2ZN60D)

-

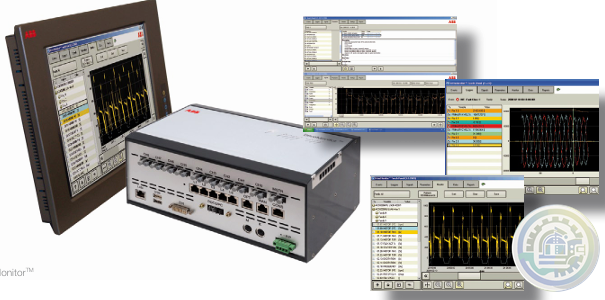

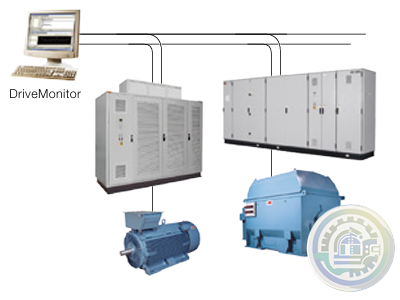

ABB What is DriveMonitor™?

-

ABB DriveMonitor™ Relax, we are always on site with you

-

ABB Remote Service for Medium Voltage Drives DriveMonitor™

-

ABB DriveMonitor hardware and optional touch screen display

-

ABB DriveMonitor For system monitoring, analysis and troubleshooting

-

ABB DriveMonitor 4000 Version

-

YOKOGAWA ProSafe-RS N-IO (Network I/O) Safety Instrumented System

-

YOKOGAWA CENTUM VP Integrated Production Control System

-

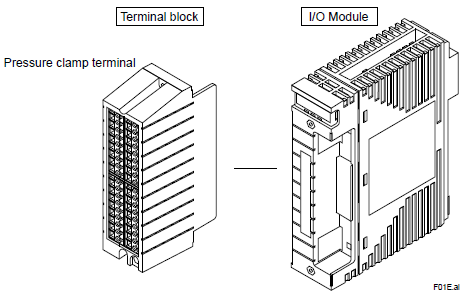

YOKOGAWA Terminal Block (for I/O Modules with Built-In Barrier and FIO)

-

YOKOGAWA AIP830 Operation Keyboard for Single-loop Operation

-

YOKOGAWA YTA710 Temperature Transmitter

-

YOKOGAWA YTA610 Temperature Transmitter

-

YOKOGAWA YTA310, YTA320 Temperature Transmitter

-

YOKOGAWA YTA110 Temperature Transmitter

-

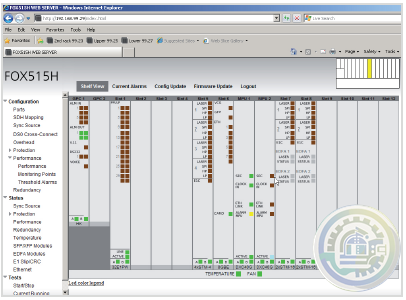

Hitachi Energy FOX515H Flexible Network Management

-

Hitachi Energy FOX515H is a member of Hitachi Energy’s comprehensive

-

Hitachi Energy FOX515H High capacity backbone platform

-

Hitachi Energy FOX605 Full support for native Ethernet and MPLS-TP

-

Hitachi Energy FOX605 Future-proof, long-term support of proven technologies

-

Hitachi Energy FOX605 Utility access multiplexer

-

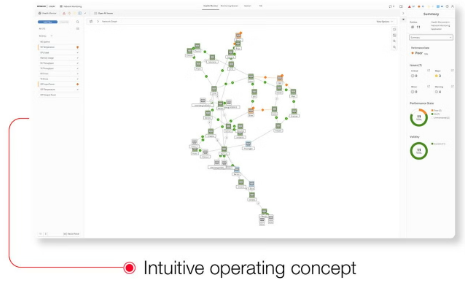

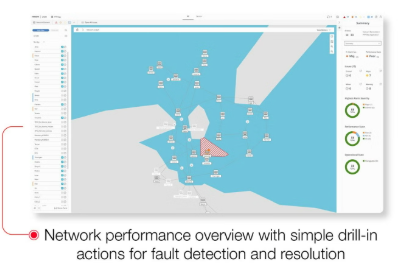

Hitachi Energy Configuration Management with FOXMAN-UN

-

Hitachi Energy FOXMAN-UN Network Management System for Wired Communications

-

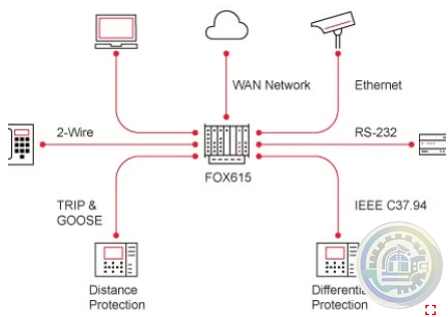

Hitachi Energy FOX615 the utility communication solution

-

Hitachi Energy Longevity: Investment cycles in utilities are much longer than those in the public telecom sector

-

Hitachi Energy Ready for the challenges of tomorrow FOX615

-

Hitachi Energy FOX615 Key highlights

-

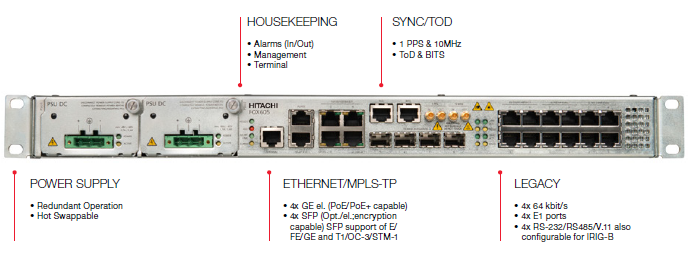

Hitachi Energy FOX610 Compact Ethernet/MPLS-TP Multiplexer

-

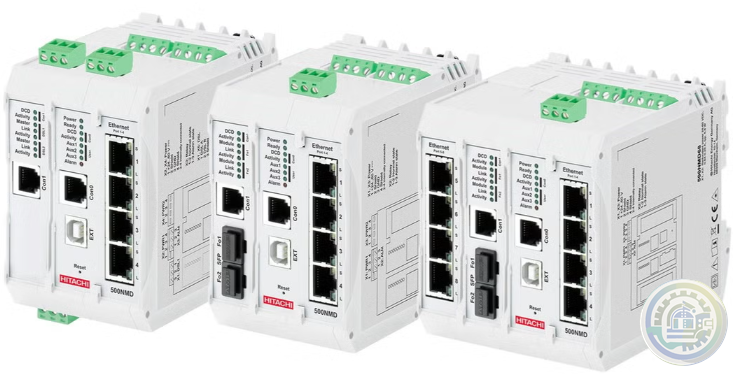

Hitachi Energy EDS500 series Connectivity, guaranteed

-

Siemens Communications processor CP 1628

-

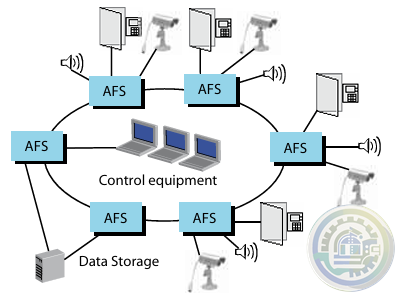

ABB Typical Applications for AFS

-

ABB AFS Technical solution-In-plant communication

-

ABB FOX Switch (AFS) Family for utility applications

-

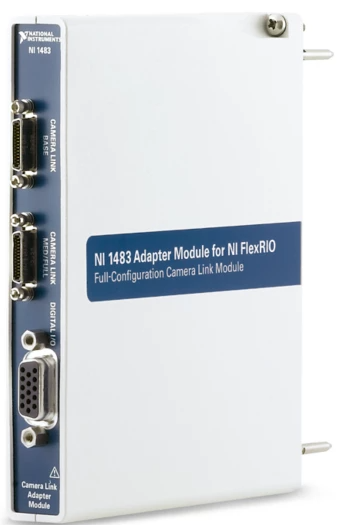

NI 1483 Adapter Module for NI FlexRI0

-

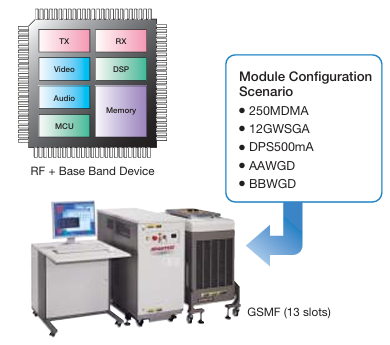

NI 5791R RF Transceiver Adapter Module

-

NI VXIpc-871B Pentium VXI Controller, 1.266 GHz

-

ABB Data sheet AFS670/675

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

ABB AFS670/675 19" Switch

-

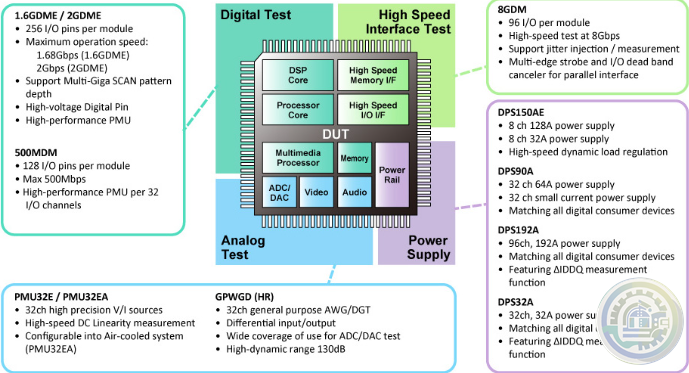

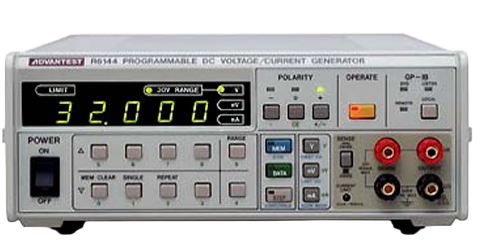

Advantest PMU Module

-

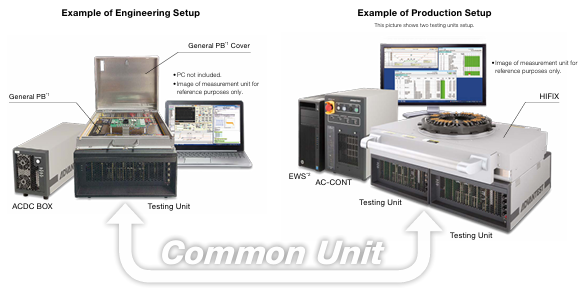

Advantest Parallel Test Solution for Multiple Market Segments

-

Advantest M4841 Dynamic Test Handler

-

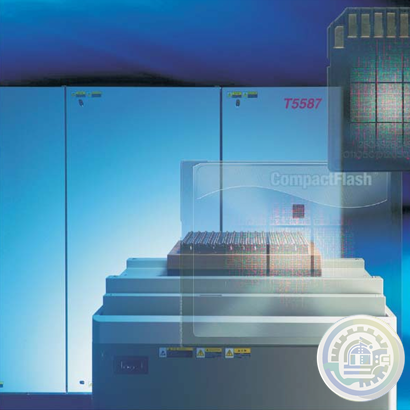

Advantest T5587 Memory Test System

-

Advantest T5833 Memory Test System

-

Advantest T5503HS Test System

-

Advantest T5588 Memory Test System

-

Advantest V93000 Smart Scale™ Test Platform

-

Advantest T6373 LCD Driver Test System

-

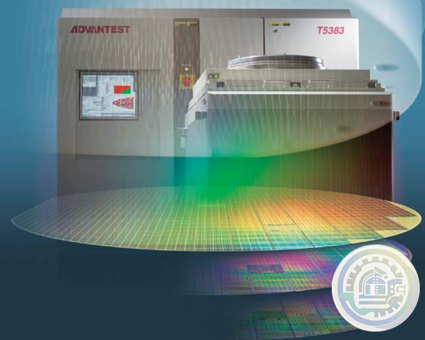

Advantest T5383 Memory Test System

-

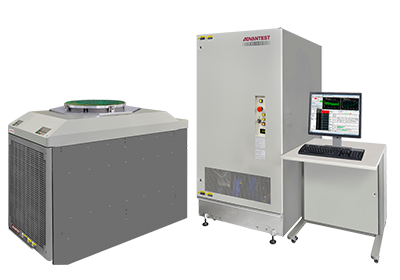

Advantest T5503 256-DUT Parallel Test Capacity for Mass Production Test of High Speed DDR3-SDRAM Memory Devices

-

Advantest The EVA100 Software GUI is extremely intuitive

-

Advantest The EVA100 automatically creates graphs of DUT characteristics

-

Advantest EVA100 Product Features

-

Advantest EVA100 Evolutionary Value Added Measurement System

-

Advantest T6391 Tester for Display Driver ICs

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

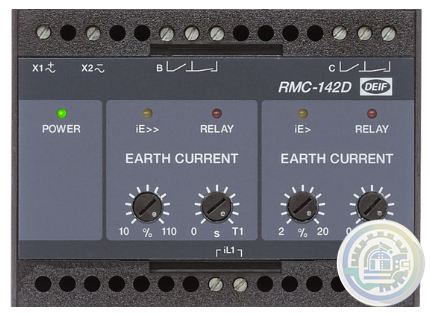

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

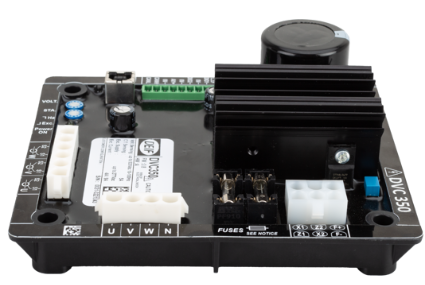

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Plant-wide scalability

Ability to scale connectivity beyond 3500 and the control

system to monitor more machinery leveraging other Bently

Nevada online, scanning, or portable devices in the same

System 1 platform.

Comprehensive diagnostic HMI implementation

Standardized & holistic machinery configurations based on

Bently Nevada best practices for vibration and process data.

Standard data connectivity (OPC, 3500. etc.) for overall machine

and key sub-systems (vibration, lube, seal, surge, etc.).

Optional hosted and/or remote monitoring

Access to Bently Nevada machinery experts through

standardized remote monitoring.

Flexible

The 3500 Series features the industry’s most extensive

selection of machinery measurement parameters combined

with software configuration for virtually all monitor options.

Local or remote mounted displays are available, or you can

operate the 3500 without a display. The result is unparalleled

flexibility to address almost any application.

3701 ADAPT ESD Overview

Typical (and recommended) applications of the ADAPT ESD will use a triple modular

redundant architecture. In this configuration, each processor module physically

connects to an array of 32 input channels, 12 of which are configurable as discrete

inputs or 4-20 mA analog inputs, as well as two speed inputs. The Bently Nevada

Monitor Configuration software allows you to configure large combinations of

logic blocks in order to manage the system trip logic. This logic dictates how the trip

mechanisms for the system are driven. The ADAPT ESD system can drive 12 independent

trip relays. Of the 12 relays, six of these signals can optionally be configured for

two-out-of-three, (2oo3), voting. In the 2oo3 arrangement, the system activates a

relay only when any two of the three CPU modules drive to trip. In independent mode,

or one-out-of-one voting, any single CPU that drives to trip will cause an assigned relay

to activate on the corresponding output card. For the highest safety, the system should

be configured in “de energize to trip”, or “normally energized” mode so that loss of

power will not result in a machine running unmonitored.

| Bently 1-536067-4 TE Connectivity AMP Connectors |

| Bently 128277-01 Vibration Monitoring Module |

| Bently 124761-01 Power Supply Module |

| Bently 3500/45 176449-04 Position Monitor |

| Bently 149986-01E 16-Channel Relay Module |

| Bently 330180-X1-CN 3300 XL 8 mm Proximity Transducer System |

| Bently 1900/65A 172323-01 Vibration Monitoring Controller |

| Bently 1900/65-00-01-03-01-01 General Purpose Equipment Monitor |

| Bently 9200-01-01-10-00 Seismoprobe Velocity Transducers |

| Bently 3500/15 114M5330-01 AC and DCPower Supplies |

| Bently 3701/55 289761-01 ADAPT (ESD) Emergency Shutdown Device |

| Bently 3500/42M 140734-99 Proximitor Seismic Monitor |

| Bently 3701/55 323174-01 ADAPT (ESD) Emergency Shutdown Device |

| Bently 3500/93 135785-02C Backlit Display Unit |

| Bently 330876-03-50-00-00 Proximity Probe / Armored High-Temperature FluidLoc Cable |

| Bently 1900/65A-00-01-01-01-01 General Purpose Equipment Monitor |

| Bently 163179-02 2024 temperature module |

| Bently 3500/54-03-00 Dual channel overspeed detection module |

| Bently 1900/65A-01-01-03-00-01 General Purpose Equipment Monitor |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

ABB DRIVEMONITOR VERSION 4000 DRIVE MODULE RBOX316-ABB-00

-

ABB VACUUM CONTACTOR VSC7 SCO IEC 60470 400A 3POLE 220-250V 50/60Hz

-

ALSTOM MCRI1 - MODULE BOARD FOR SETTING SETTINGS AND CURRENT REGULATION

-

ALSTOM BCEA1 - TERMINAL BOARD OF 8 ANALOGUE INPUT SIGNALS

-

ALSTOM E64L1- LOGIC INFORMATION ACQUISITION BOARD

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved