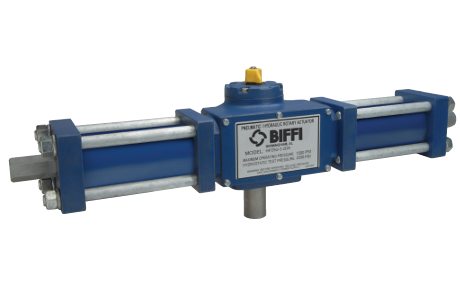

BIFFI Morin HP Series Model High Pressure Actuators

General Application

Morin Actuators are designed for on/off or modulating control of any

quarter-turn ball, butterfly, rotary plug or damper style valve application.

Technical Data

Supply pressure: Maximum operating pressure 400 to 2250 psig or as

specified by nameplate.

Maximum shell pressure 2250 psig or as specified by nameplate.

Supply medium: Any gas or hydraulic fluid compatible with materials

of construction.

Temperature rating:

Standard range: -20 to 210 °F

Optional range: -65 to 300 °F

Angular rotation: 90° ± 8°

Installation

The actuator is factory lubricated and does not normally require periodic lubrication

while in service. The actuator can be mounted parallel or perpendicular to pipeline.

The actuator can be installed in any convenient position including vertical, horizontal

or upside down.

A. Bolt mounting bracket to actuator hand tight. Do not tighten yet.

B. Install coupling on valve. Be sure rotary stops on valve are removed or

adjusted to allow actuator stops to do the stopping.

C. Install actuator and bracket to valve being sure to leave all fastener

connections hand tight. If possible, stroke valve and actuator to a half open

position 45° and physically shift actuator back and forth until coupling and

all fasteners are relaxed then tighten all bolts and nuts. This procedure will

accurately align valve stem to actuator output shaft and prolong valve stem

seal life.

D. Cycle valve/actuator assembly and observe for smooth operation.

E. Adjust travel stops for perfect alignment in both open and closed positions.

F. Tubing Connections – Tubing connections for the hydraulic supply are to be

attached as shown in Figures 1. 2 and 3. Note that on a two cylinder actuator,

the inboard end cap (adaptor) is vented and must not be connected to the

hydraulic or high-pressure gas supply.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

- Alfa Laval

-

HITACHI LYA210A Thermocouple Analog Input Module

-

Hitachi LYD105A Digital Control Board

-

HITACHI LYA010A AC Drive Inverter

-

HITACHI 2-822037-A Relay output module

-

CTI 2500P-WB-RMP2 Workbench IDE, Annual Maintenance Reinstatement if expired 1-2 yr

-

CTI 2500P-WB-RMP1 Workbench IDE, Annual Maintenance Reinstatement if expired less than 1 yr

-

CTI 2500P-WB-AMP2 Workbench IDE, Annual Maintenance, 2yr

-

CTI 2500P-WB-AMP1 Workbench IDE, Annual Maintenance, 1yr

-

CTI 2500P-WB-USB-S6 Workbench IDE, Subscription License, 6 mos

-

CTI 2500P-WB-USB-S3 Workbench IDE, Subscription License, 3 mos

-

CTI 2500P-WB-USB-PR Workbench IDE, Standard License

-

CTI 2500-OPC KEPServerEX OPC and Communications Server (Kepware)

-

CTI 2500-FASTRAK-S PLC WorkShop Suite by FASTRAK

-

CTI 2559-FPC 40-Position Screw-Terminal Connector with cold-junction compensation for 2559-TC

-

CTI 2500-RFC PLC to RF Modem Cable

-

CTI 2505 - Vibration Sensor Interface Module

-

CTI 2554-A - 4-Channel Isolated High-speed Counter Module

-

CTI 2553-A - 2-Channel Mag Meter Input Module

-

CTI 2559-TC - 8-Channel Thermocouple Input Module

-

CTI 2559-RTD - 8-Channel RTD Input Module

-

CTI 2557 - 16-Channel RTD Input Module

-

CTI 2552-A - 8-Channel Isolated RTD Input Module

-

CTI 2551-A - 8-Channel Isolated Thermocouple Input Module

-

CTI 2560-A - 8-Channel Isolated Analog Output Module

-

CTI 2558 - 8-Channel Analog Input Module

-

CTI 2555-A - 16-Channel Analog Input Module

-

CTI 2550-A - 8-Channel Isolated Analog Input Module

-

CTI 2501 - 8in/4Out Analog Module

-

CTI 2534-8-point Form-C Relay Output Module

-

CTI 2530-8-point Form-C Relay Output Module

-

CTI 2599-8/16/32-point 11-240 VAC Output Module

-

CTI 2598-8 - 8-point 11-240 VAC Output Module

-

CTI 2597-8/16/32-point 11-125 VDC Output Module

-

CTI 2596-8 - 8-point 11-125 VDC Output Module

-

CTI 2595 - 16-point TTL/Word Output Module

-

CTI 2591-EF - 16-point Isolated 11-146 VDC Output w/ front panel accessible fuses

-

CTI 2591-A - 16-point Isolated 11-146 VDC Output

-

CTI 2590-EF / 2591-EF 16-Point Isolated Discrete Output Modules

-

CTI 2590-A - 16-point Isolated 20-132 VAC Output

-

CTI 2589-B - 8/16/32-point Universal Input Module

-

CTI 2588-8 - 8-point Universal Input Module

-

CTI 2585 - 16-point TTL/Word Input Module

-

CTI 2581 - 16-point Isolated 12-56 VDC Input Module

-

CTI 2577 - Profibus DP Slave Adapter

-

CTI 2576 - DeviceNet Scanner Module

-

Foxboro 0399143 SY-0301060R SY-1025115C/SY-1025120E Control Module

-

Foxboro 873EC-JIPFGZ electrochemical analyzer

-

Foxboro FCP280 RH924YA Field Control Processor

-

Foxboro P0916PH P0916JS Industrial Control Module

-

Foxboro P0916PH P0916AL Voltage Monitor Module

-

Foxboro 870ITEC-AYFNZ-7 Temperature Transmitter

-

Foxboro FBM207 P0914TD Voltage Monitor

-

Foxboro P92 Control Module

-

Foxboro FBM240 Discrete Output and Discrete Input Module

-

Foxboro FBM208 Discrete I/O Module

-

Foxboro FBM201D Analog Input Interface module

-

Foxboro FBM201E Analog Input Interface module

-

Foxboro P0923ZJ Control Module

-

Foxboro P0923NG Control Module

-

Foxboro P0923DB Series Alarm Cable

-

Foxboro P0916KN Precision Control Module

-

Foxboro P0916KM I/A Series Control Module

-

Foxboro P0916VM I/A Series Control Module

-

Foxboro P0916WE Control Module

-

Foxboro P0916VB Termination Cable

-

Foxboro P0916VL Interface Module

-

Foxboro P0916VC Control Module

-

Foxboro P0916WG Control Module

-

Foxboro P0972ZQ Precision Control Module

-

Foxboro P0973BU Fiber Optic Jumper Cable

-

Foxboro P0926MX Splitter/Combiner Kit

-

Foxboro AD908CC Ethernet Module

-

Foxboro AD908JQ Function Module

-

Foxboro AD908AE Communication Processor

-

Foxboro AD908AC Programming & Monitoring Device

-

Foxboro AD916CC analog input module

-

Foxboro P0917XV Compression Termination

-

Foxboro FBM206 Input Interface Module

-

Foxboro P0961BS Buss Connector

-

Foxboro FBM216 Input Interface Module

-

Foxboro p0903nu 1X8 Cell Sub Assembly

-

Foxboro P0911SM Industrial Control Module

-

Foxboro CM902WM I/A Series Industrial Power Module

-

Foxboro CM902WL I/A Series Industrial Power Module

-

Foxboro P0972VA Address Translation Station

-

Foxboro P0916Js Terminal Block Brand

-

Foxboro FBM203 Input Interface Module

-

Foxboro P081000000FF IPM02 Power Supply/Switching Board

-

Foxboro ZCP270 Control Processor Module

-

Foxboro PO961BC/ CP40B Industrial Control Module

-

Foxboro PO916JS Control Module

-

Foxboro PO911SM Field bus module

-

Foxboro P0972PP-NCNI Network Interface Module

-

Foxboro P0971XU I/A Series Control Module

-

Foxboro P0971QZ Control Module

-

Alfa Laval i-OC-XL Modular composite boiler

-

Alfa Laval i-OC-L Modular composite boiler

-

Alfa Laval i-OC-M Modular composite boiler

-

Alfa Laval i-OC-S Modular composite boiler

-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

METSO D201505 / D201463 network controller

-

METSO ntel D33025 Motherboard

-

METSO ACN MR D201463 DCS Controller

-

METSO ACN MR D201505R DCS Controller

-

METSO ACN MR D201380 DCS Controller

-

METSO ACN MR D201139 DCS Controller

-

METSO ACN MR D202214 DCS Controller

-

METSO ACN MR D202275 DCS Controller

-

Metso D201376 Industrial Analog Input Module

-

Metso D201134 Process Control Module

-

Metso d200175 ver: 2.04 personality module

-

Metso D200137 ACN RT Node with D200175

-

METSO ACN CS CONTROLLER D201925 VER 2.15

-

METSO D100644 Electrical Automation Module

-

Kollmorgen CB06560 PRD-B040SAIB-62 Control Module

-

Servostar 310 Kollmorgen Servo Amplifier

-

Kollmorgen S20330-SRS Digital AC Servo Drives

-

Kollmorgen S22460-SRS Digital AC Servo Drives

-

Kollmorgen S70602-NANANA S700 Servo Driver

-

BJRL-20012-110001 Kollmorgen Goldline Smart Drives

-

Kollmorgen SAM-DA-400-07B-P4N-F SAM Servo Amplifiers

-

Kollmorgen CP320260 Servo Drive

-

Kollmorgen S72402-NANANA - AC servo drives

-

Kollmorgen E33NRHA-LNN-NS-00 Precision Motion Control Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved