-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

A-B 1794-IN106 Input/Output Analog Modules

-

General Electric 029.381208 Converteam Controller Module

-

Eaton XIOC-BP-3 Moeller 3-Signal Module Backplane

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

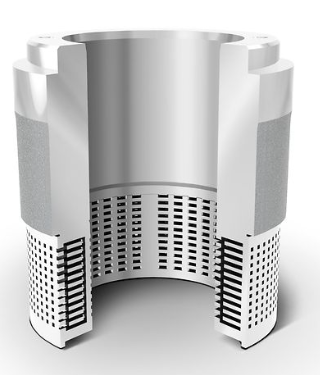

Emerson Fisher™ Whisper Trim™ I Cage

-

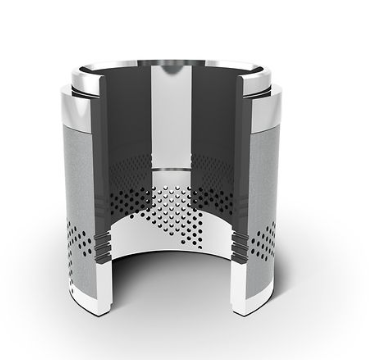

Emerson Fisher™ Whisper Trim™ III Cage

-

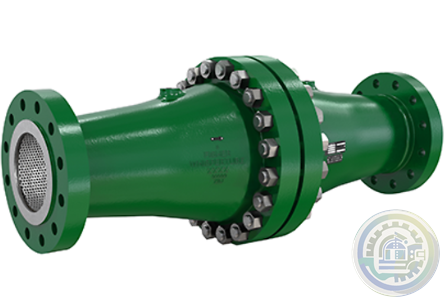

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

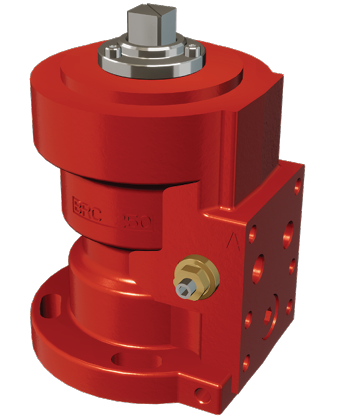

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

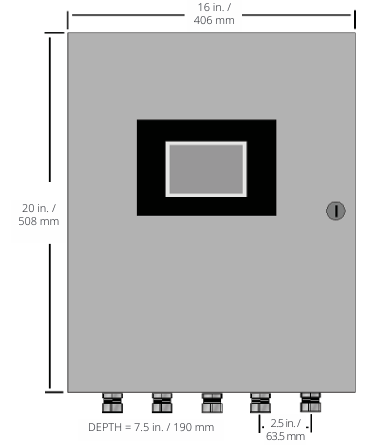

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

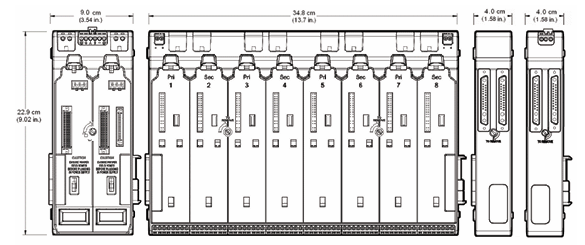

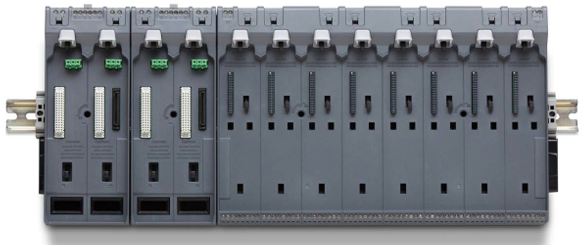

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

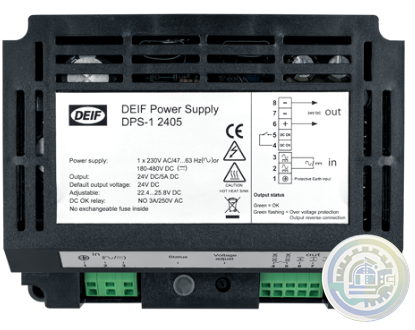

DEIF DPS-1 DC Power Supply

-

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

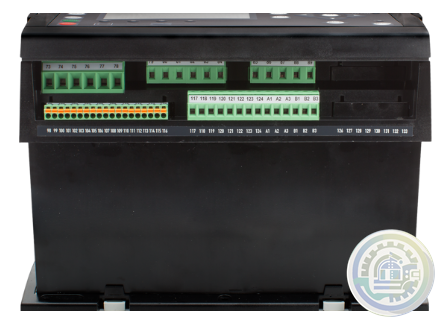

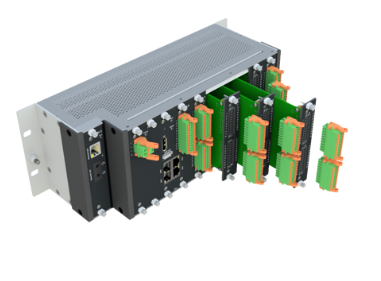

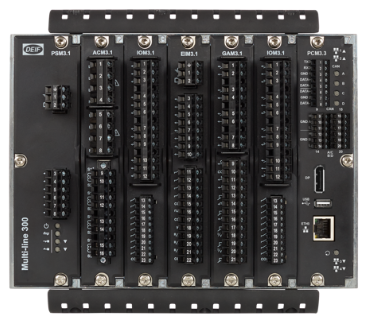

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

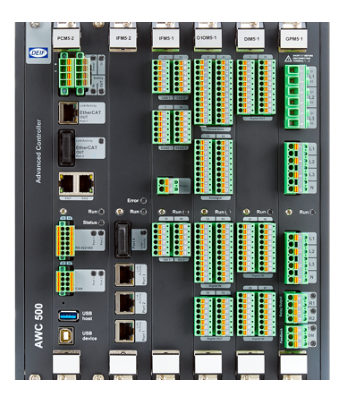

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

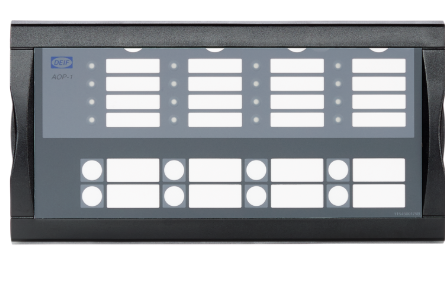

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

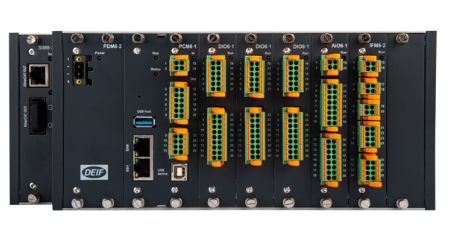

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

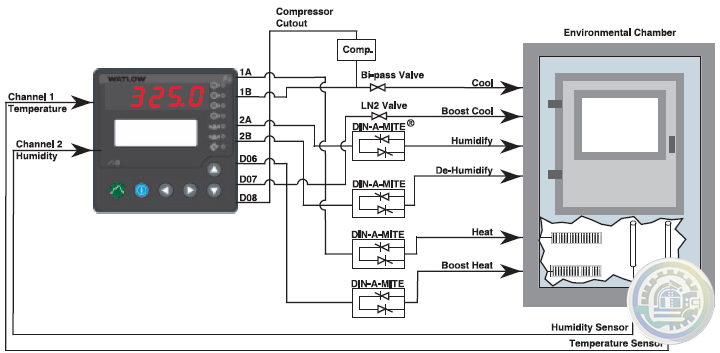

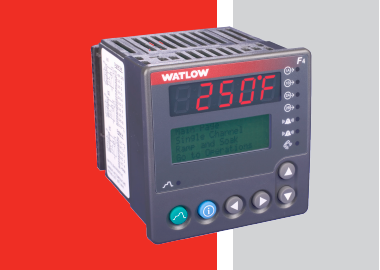

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

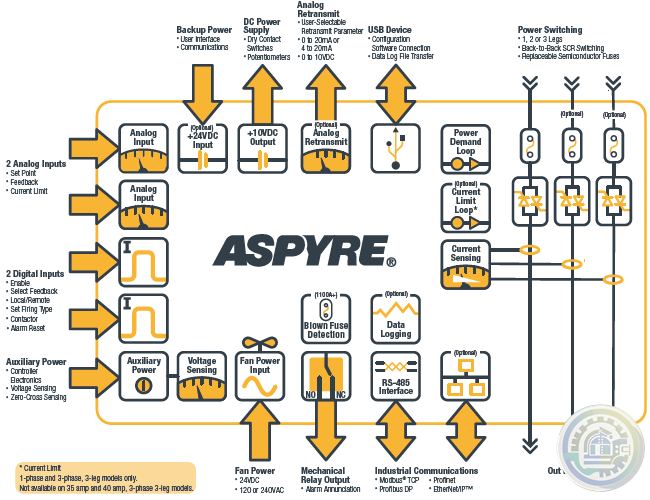

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

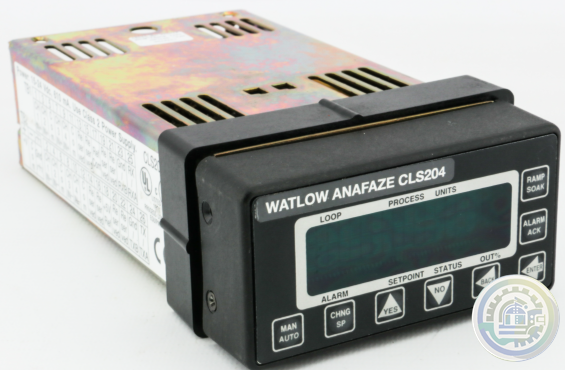

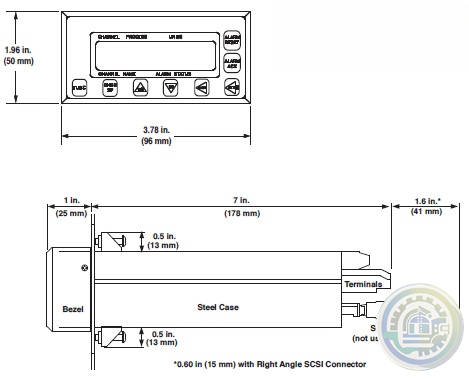

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

-

MOOG G123-825-001 Buffer Amplifier

-

Emerson AMS 3120 Bearing-Vibration Monitor

-

ABB SPC800VK01 Ability™ Symphony® Plus Hardware Selector

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

Common Industrial Protocol

(CIP) CIP™ is a messaging protocol for devices in industrial automation control systems.

CIP is the application layer for the EtherNet/IP network.

This protocol implements a relative path to send a message from the producing modules in a system to the consuming modules.

CIP uses the Producer/Consumer networking model instead of a source/ destination (Primary/Secondary) model.

The Producer/Consumer model reduces network traffic and increases speed of transmission.

In traditional I/O systems, controllers poll input modules to obtain their input status.

In the CIP system, digital input modules are not polled by a controller.

Installing the Motor

The S-Series and MTR-Series servo motors are designed for either vertical or horizontal

mounting and have a protection rating of IP65 (not including the connectors and shaft).

The motors should be mounted in a location where the environmental conditions

are within the specifications stated in Chapter 2. Use the following guidelines when mounting the motors:

• Observe the shaft radial and thrust load limits. Loads exceeding these limits will cause premature failure of the motor.

Excessive belt tension could cause bearing or shaft failure.

• Be sure to ground the motor using the ground wire in the motor power cable.

• Ensure that the motor cables are free from excessive stress, stretching, pinching or bending.

• To avoid damage, do not carry a motor by holding the cables or shaft.

• Do not apply excessive axial force or impact loads when installing the motor coupling or shaft pulley, or the encoder may be damaged.

• Install the motor in a location free from corrosive contaminants, dust, excessive water spray, or combustible gas.

• The shaft of the S-series servo motor is treated with grease (Shell Oil Alvania No. 2) for corrosion protection during storage.

Consider the effect of the grease on any plastic parts that are mated with the shaft.

• The optional servo motor brake should be used for holding stationary loads only.

Do not use this brake to stop a moving load, or reduced life or damage to the brake may occur.

Apply this brake only after the motor is stopped.

Common Industrial Protocol

(CIP) CIP™ is a messaging protocol for devices in industrial automation control systems.

CIP is the application layer for the EtherNet/IP network.

This protocol implements a relative path to send a message from the producing modules in a system to the consuming modules.

CIP uses the Producer/Consumer networking model instead of a source/ destination (Primary/Secondary) model.

The Producer/Consumer model reduces network traffic and increases speed of transmission.

In traditional I/O systems, controllers poll input modules to obtain their input status.

In the CIP system, digital input modules are not polled by a controller.

Instead, they produce their data either upon a change of state (COS) or at a requested packet interval (RPI).

The frequency of update depends upon the options that are chosen during configuration and where on the network the input module resides.

The input module, therefore, is a producer of input data and the controller is a consumer of the data.

The controller can also produce data for other controllers to consume.

The produced and consumed data is accessible by multiple controllers over the Logix backplane and over the EtherNet/IP network.

This data exchange conforms to the Producer/Consumer model.

A-B 1756-DMF30K MODULE ROCKWELL 1-AX DRVCTRLSF3000 CONFOR |

A-B 1756-DNB Module Rockwell Device Bridge/Scanner Module |

A-B 1756-EN2F Module Rockwell ControlLogix Ethernet |

A-B 1756-EN2T Module Rockwell CLX HI-CAP ENET/IP MODULE - TP |

A-B 1756-EN2TR MODULE ROCKWELL 2-PORT CLX HI-CAP ENET/IP MODULE - TP |

A-B 1756-EN2TXT MODULE Rockwell CLX ENET/IP MODULE - TP, X-ENVT |

A-B 1756-EN3TR Module Rockwell ControlLogix Ethernet |

A-B 1756-ENBT Module Rockwell ControlLogix Communication Control |

A-B 1756-HIST1G Module Rockwell Equipment History |

A-B 1756-HIST1G3277 Module SOF Module FT Device History |

A-B 1756-HIST2G Module Rockwell Equipment History |

A-B 1756-HIST2G3278 Module SOF Module FT Device History |

A-B 1756-HISTBETA Module Rockwell Equipment History |

A-B 1756-HSC Module Rockwell 2 CH/4 Output High Speed ??Counter |

A-B 1756-HYD02 Module Rockwell ControlLogix Analog Combination |

A-B 1756-IA16 module Rockwell ControlLogix 16-point DC output control |

A-B 1756-IA16I Module Rockwell ControlLogix Input Module |

A-B 1756-IA32 module Rockwell ControlLogix 32-point output control |

A-B 1756-IA8D module Rockwell ControlLogix 8 output control |

A-B 1756-IB16 module Rockwell ControlLogix 16-point output control |

A-B 1756-IB16D module Rockwell ControlLogix 16 output control |

A-B 1756-IB16I Module Rockwell ControlLogix Output Module |

A-B 1756-IB16IF module Rockwell ControlLogix 16-point digital output control |

A-B 1756-IB16ISOE Module Rockwell ControlLogix 16 Points |

A-B 1756-IB32 Module Rockwell ControlLogix 32 Points |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

-

Vibro-meter VM600-ABE042 204-042-100-011 Precision Control Module

-

Vibro-meter vmf-MPC4 200-510-111-034 200-510-070-113 Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved