-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

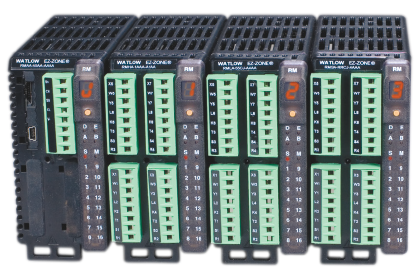

Watlow EZ-ZONE® RM Modular Controller Family

-

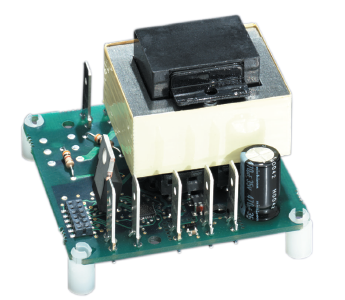

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

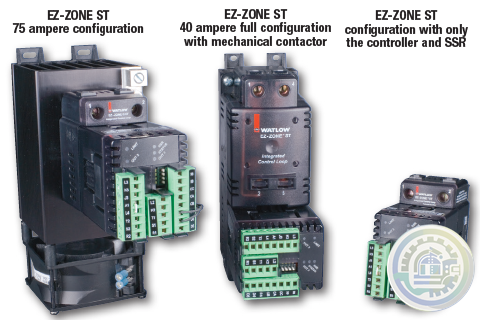

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

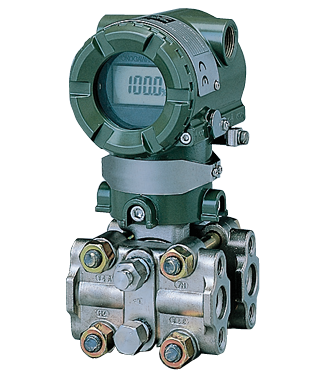

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

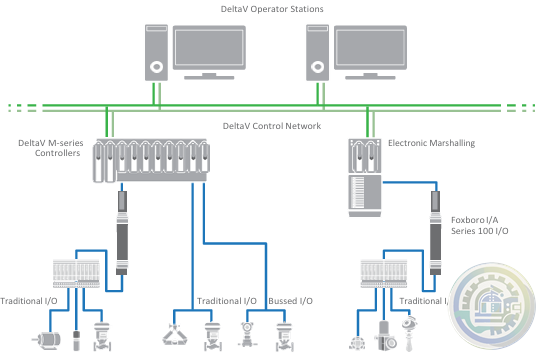

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

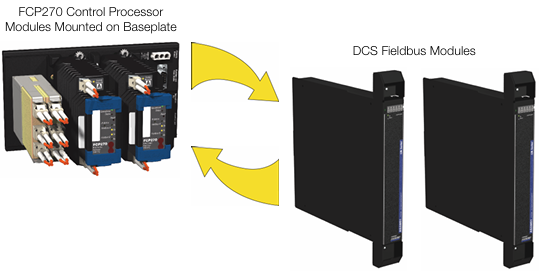

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

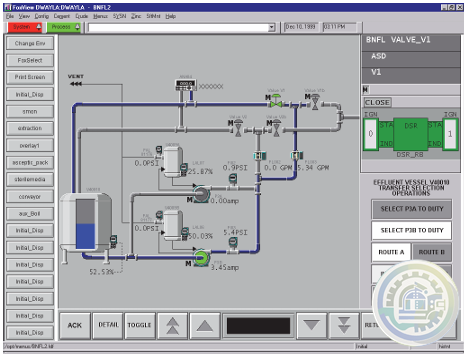

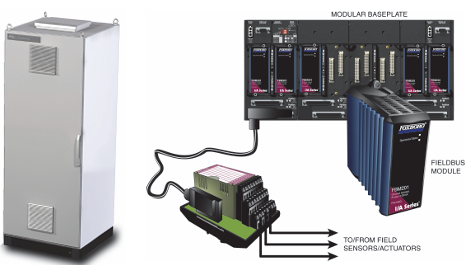

Foxboro Evo™ Process Automation System

-

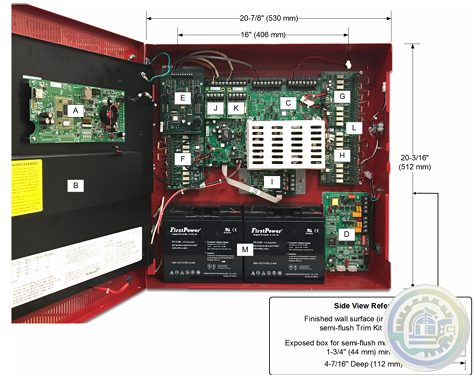

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

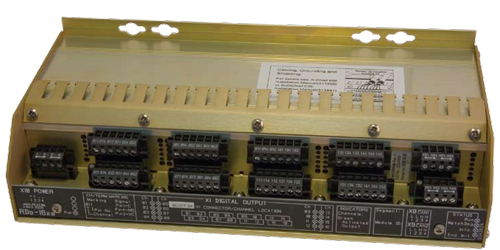

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

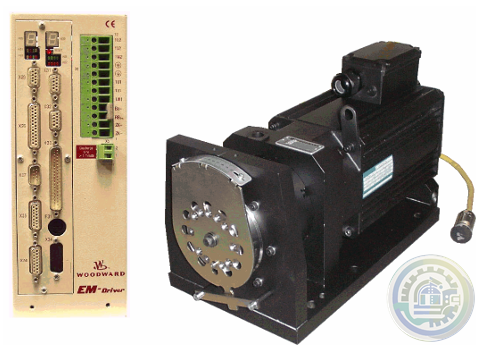

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

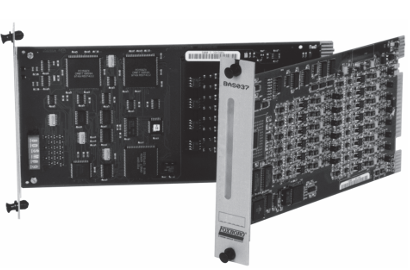

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

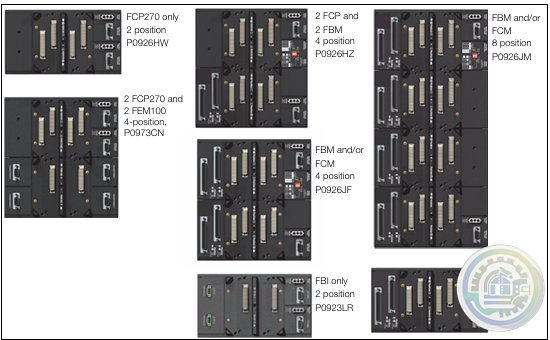

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

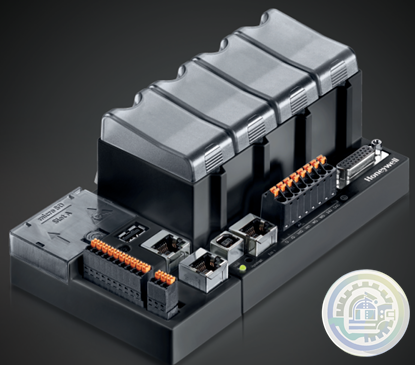

Honeywell ControlEdge™ PLC Modular Controllers

-

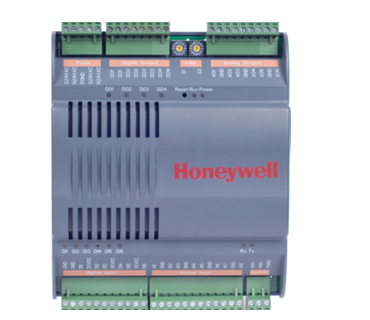

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

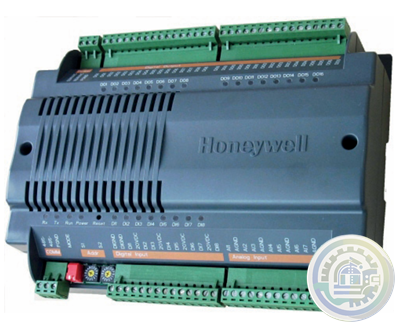

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

-

Honeywell E3Point Gas Detector

-

Honeywell 301C Controller

-

Honeywell 301IRF Refrigerant Gas Detector

-

Honeywell 301EM-20 Controller

-

Honeywell Series 3000 MkII

-

Honeywell XNX™ Universal Transmitter

-

Honeywell XNX Universal Transmitter

-

Honeywell MicroDock II Automatic Test and Calibration Station

-

Honeywell GasAlertMicro 5 Series Multi-Gas (1–5) Detectors

-

Honeywell GasAlertMax XT II Multi-Gas (1–4) Detector

-

Honeywell GasAlertQuattro Multi-Gas (1–4) Detector

-

Honeywell BW Clip4 Multi-Gas (4) Detector

-

Honeywell BW™ MicroClip Series Multi-gas detectors

-

Honeywell GasAlertMicroClip Series Multi-Gas (1–4) Detector

-

Honeywell GasAlert Extreme Single-Gas Detector

-

Honeywell IntelliDoX Automated instrument management system

-

Honeywell BW Clip Series Single-Gas Detectors

-

Honeywell GasAlertMicro 5 Series multi-gas detectors

-

Honeywell GasAlert Extreme single gas detector

-

Honeywell GasAlertMax XT II

-

Honeywell MicroDock II Automated Instrument Docking Station

-

Honeywell BW™ Max XT II Multi-Gas Detector

-

Honeywell QRAE 3 Wireless 4-Gas Monitor

-

Honeywell BW™ Max XT II Multi Gas Detector

-

Honeywell Satellite XT

-

Honeywell WEB-8000 Controller

-

Honeywell Spyder™ Model 7 VAV controller

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

The FCP280 performs regulation, logic, timing and sequence control,

as well as data acquisition, alarm detection and alarm notification.

Acquisition, alarm detection and alarm notification.

Process variables are controlled using time-proven algorithms

(mathematical calculations that perform specific functions).

These algorithms are contained in functional control blocks that are configured

by the field process engineer to implement the desired control strategy.

The versatility of the algorithms, combined with the variety of available FBMs,

provides control capabilities suitable for a wide range of process applications.

From simple feedback and cascade loops to highly complex feed-forward,

non-linear and complex characteristic control schemes,

a variety of control strategies can be easily implemented.

The FCM has a rugged extruded aluminium enclosure that provides physical protection for the circuitry.

Enclosures specifically designed for the installation of FBMs and FCMs provide varying degrees

of environmental protection for the FCM, up to harsh environments (Class G), in accordance with ISA Standard S71.04.

The FCM can be removed/replaced from the base plate without power failure.

six light-emitting diodes (LEDs) on the front of the FCM.

Six light-emitting diodes (LEDs) on the front of the FCM are used to indicate the status of

network activity with the modular fieldbus and fibre-optic link, as well as the operational status of the FCM.

Figure 1 shows an example of a redundant configuration where the baseboards

(containing the FCM) are connected point-to-point via fibre optic cable.

The cabling configuration shows a single fibre optic segment connecting two substrates.

However, up to three fibre segments can be used to connect four baseboards (maximum).

The maximum fibre cabling distance between any two base stations is 10 km (using FCM2F10s (RH916TQ)).

The total fibre optic cabling distance (all cable segments) between base stations does not exceed 20 km (10.42 miles).

Deif PPM-3 SG Protection And Power Management

DEIF | PPU300 | ML300 | MULTI-LINE 300 | 921002392.10 | DISPLAY UNIT

DEIF AGC Plant Management Genset Controller 920025558.10

Deif PPM/DGM Protection And Power Management 100099054.280

DEIF PPM-3 DG PROTECTION AND POWER MANAGEMENT COMPLETE SET

DEIF AGC-4 Controller with DU-2/MKIII DisplayAutomatic Gen-set controller 24VDC

DEIF DELOMATIC-3 DGU 3 Control Panel 1044220060E 1044220070E 1044220080E

DEIF AGC-4 Controller with DU-2/MKIII DisplayAutomatic Gen-set controller 24VDC

NEW DEIF AGC 252 advanced Genset Controller 2912420010.39 Options -C2-H2-N-I1

NEW DEIF AGC 252 advanced Genset Controller 2912420010.39 Options -C2-N

Deif OPM-1 Output Module 1044220080E

DEIF DELOMATIC 4 DGU 0001 CONTROLLER

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved