Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

The DIN rail mounted Fieldbus Module baseplate

provides a convenient, secure facility for the mounting

of DIN rail mounted Fieldbus Modules (FBMs) and

Fieldbus Communications Modules (FCMs). Its eight

mounting positions can accommodate up to eight

FBMs or a combination of FBMs and FCMs.The

baseplate also provides the necessary connectors for

redundant power, redundant module Fieldbus, and

termination cables.

PLUG-IN MODULES

The DIN rail mounted FBMs accommodated by the

baseplate are compact, plug-in modular assemblies

used to interface field devices with the host control

station. The FCMs, having the same form factor as

the FBMs, perform signal interface functions.

For example, FCM10Es are used to interface the

Ethernet trunk Fieldbus with the 2 Mbps module

Fieldbus, and FCM2Fs are used for fiber optic

communications extensions between baseplates. The

FBMs and FCMs plug onto the baseplate by means

of their two, 48-pin connectors, and each is fastened

in place by two screws.

BASEPLATE MOUNTING

The baseplate is available in two basic mounting

configurations — horizontal DIN rail mount or vertical

DIN rail mount. Either of these configurations can be

employed internal to, or external to an enclosure;

however, in all cases the DIN rail must be amply

supported, whether by means of metal braces, a

backplate, or a supporting wall.

In addition to DIN rail mounting of the baseplate, a

mounting kit is available for mounting the baseplate

horizontally in a standard, 483 mm (19 in) rack. The

kit provides a 25.4mm (1 in) mounting depth, to meet

clearance requirements at the front of the 19-inch

rack.

BASEPLATE IMPLEMENTATION

A grouping of up to four baseplates per FCM (pair)

can be connected together, for mounting of up to 32

modules (30FBMs and 2 FCMs). Multiple groups of

baseplates can be connected to the Ethernet trunk

Fieldbus, either directly (via Ethernet connectors) or

through one or more multiport fiber optic converters

(hubs). (Refer to PSS 21H-2W1 B3 for information on

the various DIN rail mounted FBM subsystem

communication topologies). Module Fieldbus

interconnection between baseplates is made by

shielded twisted-pair cable for local configurations

and/or by fiber optic cable for remote configurations.

Using fiber optic topologies (refer to

PSS21H-2W1B3), baseplates can be separated up

to 10 km (6.2 mi).

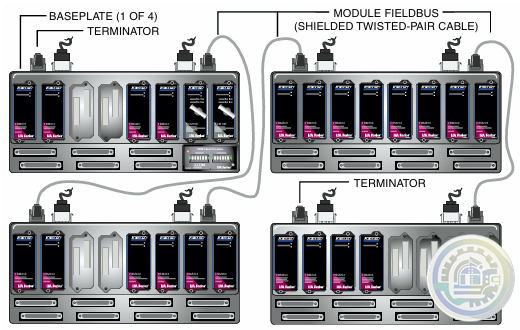

Figure 1 shows baseplate implementation using only

shielded twisted-pair cable connections. This

configuration is used when the four (maximum)

baseplates are mounted in the same general location.

Using shielded twisted-pair cable, the baseplates can

be interconnected up to 60 m (196 ft) total cable

distance. Shielded twisted-pair cables are available in

lengths of 0.25 m (10 in), 1 m (3.3 ft), 3 m (9.9 ft), 5 m

(16.5 ft), 10 m (33 ft), 20 m (66 ft), 30 m (99 ft) and

60m (198 ft), allowing placement of the baseplates

(up to four in a group) in one or more enclosures.

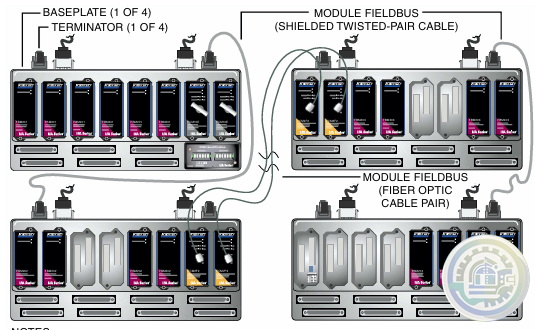

Figure 2 shows how baseplate implementation can be

extended using fiber optic cabling. In this

configuration, up to three module Fieldbus segments

can be fiber optic, allowing the baseplates to be

dispersed over a wider area. The FCM2Fs provide

three different fiber optic cabling distances between

baseplates: 2km (1.24 mi), 4 km (2.48 mi), or 10km

(6.2 mi). Refer to PSS21H-2Y3 B3 for additional

information on baseplate implementation using this

configuration.

Figure 3 shows the key elements of a typical baseplate.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

CTI 2532 - 16-point Form-A Relay Output Module

-

CTI 2573-MOD - Serial Interface Adapter w/MODBUS

-

CTI 2572-B - Fast Ethernet TCP/IP Adapter

-

CTI 2513 - 24VDC Power Supply

-

CTI 2512-A - 75W AC PS w/redundancy support

-

CTI 2512 - 75-watt AC Power Supply

-

CTI 2500-RIO-B - RS485 RBC

-

CTI 2500-RBC - Profibus RBC

-

CTI 2500-R11-A - Eleven-slot redundant base

-

CTI 2500P-R8 - Eight-slot base

-

CTI 2500P-ACP1 Application Coprocessor module

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500-C200 CPU with 256K User Memory

-

B&R 8LSA46.R0045D000-0 Servo Motor

-

B&R 5PC910SX02-00 REV:K6 Power Supply Module

-

B&R 7EX470.50-1 2003 CAN bus controller

-

B&R 5AC600.GPI0-K05 slot interface module

-

B&R 5AC600.FLAP-K11 slot interface module

-

B&R 5PP120.1214-37A Power Panel

-

B&R 5AP1130.156C-000 Automation Panel

-

B&R 3IF661.9 2005 interface module

-

B&R 5DLSD3.1000-00 Automation Panel link module

-

B&R 5AP933.215C-00 Automation Panel

-

B&R 8AC110.60-2 ACOPOS plug-in module

-

B&R 8AC120.60-1 ACOPOS plug-in module

-

B&R 5AP920.1505-01 Automation Panel

-

B&R 7DO135.70 Digital Output Module

-

B&R 7DI140.70 Digital Input Module

-

B&R 7AO352.70 Analog Output Module

-

B&R AO352 Analog Output Module

-

B&R AT664 Analog Input Module

-

B&R AT664 Analog Input Module

-

B&R DO135 Digital Output Module

-

B&R 4P3040.00-490 Power Panel

-

B&R X20CP1486 high-performance CPU

-

B&R 5CFCRD.0064-03 CompactFlash 64 MB Western Digital (SLC)

-

B&R X20BM15 Bus Module

-

B&R MDA115-0 MULTI digital output module

-

B&R MCGE31-0 Power Supply Module

-

B&R HCMCO3MC-1A Network Controller Module

-

B&R HCMARC-0CT Network Controller Module

-

B&R ECPP40-01 Industrial Controller Module

-

B&R ECPNC3-1 11150168481 Process Control Module

-

B&R 2DS100.60-1 PLC Module/Rack

-

B&R 2CP100.60-1 PLC Module/Rack

-

B&R 2BM100.9 Analog Input Module

-

Honeywell FC-TSAI-1620M Field termination assembly module

-

J-MHM10 YAMATAKE HONEYWELL INTERFACE MODULE

-

Honeywell 51401437-301 Dual Channel Safety Relay Module

-

Honeywell 51404203-002 Universal Board

-

Foxboro Suite™ DCSandI/A Series® Tools Q0301JL

-

HIMA F7130A 984713060 specialized power supply module

-

HIMA H41q-HS B4237-1 997104237 control module

-

HIMA K9202 996920202 high-reliability relay module

-

HIMA H4135 992413502 Safety Relay Module

-

HIMA Z7149 Digital Output Module

-

HIMA H51q-H B5233-2 997235233 control module

-

HIMA X-DO1201 985210204 Digital Output Module

-

HIMA X-BLK01 632590802 Blanking Module for I/O Slots

-

HIMA X-DI1601 985210222 Digital Input Module

-

HIMA LM002_MAX 985020002 Digital Output Module

-

HIMA X-FAN1003 993201013 | Redundant Cooling Fan Module

-

HIMA K9203 996920302 Communication Adapter

-

H51q-HRS B5233-2 997205233 HIMA safety system module

-

HIMA K9203A 996920360 Cooling Fan Module

-

HIMA H51q-HS B5233-1 997105233 Central Rack System

-

HIMA F8621A 984862160 Communication Module

-

HIMA F7131 981713102 High-Current DC/DC Power Supply Module

-

HIMA ELOPII Industrial Control Module

-

HIMA F8620/11 Central Processing Unit

-

X-FAN 18 03 HIMA substrate fan

-

HIMA K9202B Industrial Safety Module

-

HIMA BV7046-4 Digital Output Module

-

F30 010 20 OS-REV.V6.46/V11.28 HIMatrix Safety-Related Controller

-

HIMA F2DO801 Digital Output Module

-

HIMATRIX F3001020 | HIMA Safety-Related Controller

-

HIMA Z7116/3236/C5 Connection Module

-

HIMA F3DIO20/802 982200442 Digital Input Module

-

HIMA 80105 984080105 versatile communication module

-

HIMA X-DO2401 985210203 Digital Output Module

-

HIMA X-DI3201 985210201 Digital input module

-

F8651X HIMA Analog Input Module

-

HIMA F8650E CPU Module Brand

-

HIMA safety-related F2DO1601 remote I/O

-

HIMA F-PWR02 power buffer module

-

HIMA EABT3 B9302 997009302 Communication Module

-

HIMA K1412B 996141261 H51q-HRS B5233-2 997205233 System Rack Assembly

-

HIMA K7214 996721402 Power Distribution Module

-

HIMA TM202-A00-B00-C00-D00-E00-G00 Controller Module

-

HIMA TM521-A02-B00-C02-D00-E01-G00-I0-M1 Controller Module

-

HIMA TM591-B00-G00 Controller Module

-

HIMA KFD2-STC4-Ex1 transmitter power supply

-

HIMA KFD2-STC4-Ex1 transmitter power supply

-

HIMA SB3073-EX isolation safety barrier

-

HIMA KFD2-VR4-Ex1.26 voltage repeater

-

HIMA F3236 984323602 | sensor | Safety relay

-

HIMA F8652E 984865264 | Safety Controller Module

-

HIMA F8627 984862702 Safety-Related CPU module

-

HIMA Z7130 Safety Instrumented System

-

Hima H6200A Transmitter Circuit

-

Foxboro 9720052-XXX Field Termination Guide for Tricon Systems

-

Foxboro 9791007-XXX Technical Product Guide for Tricon Systems

-

Foxboro ISA-S71.04-1985 Environmental Conditions for Process Measurement and Control Systems

-

Foxboro PSS 21H-2X66 B4 G66 Tricon Termination Enclosure

-

Foxboro PSS 21H-2X62 B4 G62 and G72 Tricon System and Termination Enclosures

-

Foxboro PSS 21H-2X61 B4 G61 Tricon Termination Enclosure

-

Foxboro PSS41H-2G66 G66Tricon Termination Enclosure

-

Foxboro PSS41H-2G62 G62and G72Tricon System and Termination Enclosures

-

Foxboro PSS41H-2G60 G60Tricon System Enclosure

-

Foxboro P0971DP RTD Input-Output Module or Card

-

Foxboro P0970VB Precision Industrial Control Module

-

Foxboro P0970EJ-DNBX Dual NodeBus Extended Module

-

Foxboro P0970BP RS-423 (Internal) Cable Assembly

-

Foxboro P0970BC-DNBI Dual Mode Bus Interface Module

-

Foxboro P0961EF-CP30B Display Panel

-

Foxboro P0961CA Fiber Optic LAN Module

-

Foxboro P0961BD-GW30B Gateway Processor GW30B Module

-

Foxboro P0961BC-CP40B Control Processor

-

Foxboro P0960JA-CP40 Control Processor 40 Module

-

Foxboro P0926TM Modular I/O PLC Module Brand

-

Foxboro P0916BX Termination Assembly

-

Foxboro P0916AW Advanced Control Module

-

Foxboro P0916AG Compression Term Assembly

-

Foxboro P0916AE Compression Terminal Base

-

Foxboro P0912CM Dual Coax Cable

-

Foxboro P0912CB Precision Control Module

-

Foxboro P0911VJ Control Module

-

Foxboro P0911QC-C Industrial Control Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Woodward 3522-1004 EM-80/EM-300 Actuator System

-

Woodward 3522-1009 EM-80/EM-300 Actuator System

-

3HAC044168-001/06 ABB Pcb Circuit Board

-

ABB FGM1190-97 With vertical female thread connection

-

ABB FGM1190-98 With flanged connection in accordance with DIN or ASME

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved