Johnson Controls Smart Equipment™ Control

Introduction

This document is designed to assist and guide a trained technician or engineer to diagnose and

troubleshoot the Smart Equipment Controller alarms. When troubleshooting always use Johnson

Controls and industry safety standards.

Preliminary checks

No power

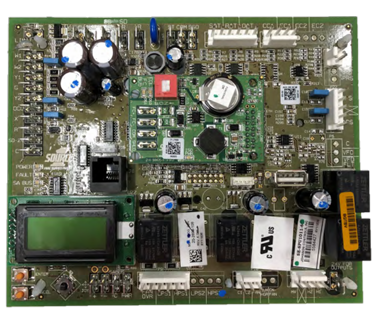

The Smart Equipment™ Control (SEC) board requires 24 VAC to operate. If no power is provided then

no alarms are active, the LCD screen is blank, and the unit does not function at all.

1.on the upper left hand of the board using the voltmeter.--

If no voltage is present, check the wiring diagram and trace where the 24 VAC power is

lost.

If voltage is present and no power is indicated on the SEC board through the LCD

display or power LED indicator, replace the board.

2.Check for optional components such as the phase monitor in the circuit. If there is a red light

visible on the phase monitor, this indicates that the board is not receiving power. Swap the

incoming voltage going to the unit, not the voltage within the unit.

Heating alarms

HS1 lockout due to limit switch

The HS1 Lockout occurs due to a loss of 24 VAC to the SEC board LIMIT terminal. The LIMIT circuit

will have two or more limit switches wired in series. One switch is an automatic limit switch and

the other is a manual limit switch. If the SEC board recognizes three limit switch trips in one hour a

hard lockout of unit operation occurs and no operation occurs other than blower operation.

If a HS1 Lockout occurs complete the following steps:

1. Use a volt meter to check that 24 VAC power is present at the LIMIT terminal located on at the

upper left corner of the SEC board.

a. If no voltage is present, check the wiring diagram and trace where the 24 VAC power

is lost.

b. If voltage is present, continue to Step 2.

2. Determine if a limit switch is open and check the possible cause of the limit trip.

3. Check the circuit wiring for damage or a loose connection.

4. Check if the limit switch is faulty. If the switch is tripping without reaching tripping

temperature, this can indicate a faulty LIMIT switch.

5. Check that all the filters are clean.

6. Check for correct air flow according to the unit installation manual. Return static should not

be higher than 0.2 in. w.c. Factory equipment should be air balanced to operate in a cfm

range from 350 cfm to 450 cfm per ton.

Note:

a. If the unit AHU or RTU is a VAV application during the heating operation, the fan

should run at an adequate speed to allow correct air flow that will prevent the

unit from tripping on HS1 lockout. This means in most cases the VAV boxes must

be open when a call for heat is commanded.

b. On occasions where the system has two transformers, proper low voltage

phasing must be verified or HS1 could occur.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

Foxboro P0960AH-0C I/A Series Z-Bus Connector

-

Foxboro P0960AH I/A Series Z-Bus Connector

-

Foxboro P0950CA Centralized and Distributed Control Module

-

Foxboro P0926KL Control Module

-

Foxboro P0926KK Control Module

-

Foxboro P0926CC High-Performance Industrial Module

-

Foxboro P0924AW Wireless Pressure Transmitter

-

Foxboro P0916NK HDLC Cable Brand

-

Foxboro P0916JP I/A Series Module

-

Foxboro P0916GG Precision Control

-

Foxboro P0916DV Fieldbus Extension Cable

-

Foxboro P0916DB I/A Series Module

-

Foxboro P0914ZM Identification Module

-

Foxboro P0902YU Information Processing & Display Module

-

Foxboro P0902BM I/O Module

-

Foxboro P0901XT Fieldbus JR45 Termination Assembly

-

Foxboro P0901VK Precision Control

-

Foxboro P0800DV Fieldbus Extension Cable

-

Foxboro P0800DO Digital Output Module

-

Foxboro P0800DG Standard Communication Protocol Module

-

Foxboro P0800DB Control Module

-

Foxboro P0800CE Industrial Control Module

-

FOXBORO P0700WB Industrial Control Module

-

FOXBORO P0500WX Control System Module

-

Foxboro P0500RU FBM3A/33A Termination Assembly 3 Wire

-

Foxboro FBM205 Input Interface Module

-

Foxboro FBM202 Input Interface Module

-

Foxboro FBM18 Input Interface Module

-

Foxboro FBM12 Input Interface Module

-

Foxboro FBM10 Input Interface Module

-

Foxboro FBM07 Input Interface Module

-

Foxboro FBM04 Input Interface Module

-

Foxboro FBM02 Input Interface Module

-

Foxboro CP30 CP30B Control Processors Brand

-

Foxboro AD202MW Pressure transmitter

-

Foxboro A431:A593 P0924TR Analog Input Interface Module

-

Johnson Controls MS-NAE5520-1 Supports a LONWORKS trunk

-

Johnson Controls MS-NAE5513-1 Supports two N2 or two BACnet MS/TP (RS-485) trunks

-

Johnson Controls MS-NAE5511-1 Supports two N2 or two BACnet MS/TP (RS-485) trunks

-

Johnson Controls MS-NAE5510-1U Supports two N2 or two BACnet MS/TP (RS-485) trunks

-

Johnson Controls MS-NAE5510-0U Supports two N2 or two BACnet MS/TP (RS-485) trunks

-

Johnson Controls MS-NCE2560-0 NCE2560 Network Control Engine

-

Johnson Controls MS-VMA1930-0 Integrated VAV Controller

-

Johnson Controls ACC-TBKINOUT-0 Input and Output terminal block replacement kit

-

Johnson Controls ACC-TBKPWFCSA-0 Power, FC Bus, and SA Bus terminal block replacement kit

-

Johnson Controls TL-BRTRP-0 Portable BACnet/IP to MS/TP Router

-

Johnson Controls Y65T42-0 Transformer, 120/208/240 VAC Primary to 24 VAC Secondary

-

Johnson Controls Y65T31-0 Transformer, 120/208/240 VAC Primary to 24 VAC Secondary

-

Johnson Controls Y65A13-0 Transformer, 120 VAC Primary to 24 VAC Secondary

-

Johnson Controls Y64T15-0 Transformer, 120/208/240 VAC Primary to 24 VAC Secondary

-

Johnson Controls ZFR-USBHA-0 ZFR USB Dongle provides a wireless connection through CCT

-

Johnson Controls WRZ-7860-0 Refer to the WRZ-7860 Receiver

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Johnson Controls AS-CBLTSTAT-0 Cable adapter for connection to 8-pin TE-6700 Series sensors

-

Johnson Controls NS Series Network Sensors

-

Johnson Controls NS-ATV7003-0 Handheld VAV Balancing Tool

-

Johnson Controls MS-FCP-0 License enabling Metasys Equipment Controller

-

Johnson Controls TL-CCT-0 License enabling Controller

-

Johnson Controls M4-XPM18000-0 18-point Input Expansion Module

-

Johnson Controls M4-XPM09090-0 18-point Input/Output Expansion Module

-

Johnson Controls M4-XPM04060-0 10-point Input/Output Expansion Module

-

Johnson Controls M4-CGM04060-0 10-point General Purpose Application MS/TP Controller

-

Johnson Controls M4-CVM03050-0P VAV Box Controller with position feedback

-

Johnson Controls M4-CVM03050-0 VAV Box Controller

-

Johnson Controls M4-CGM09090-0 General Purpose Application Controller

-

EPRO PR6423/003-030-CN Industrial Vibration Sensor

-

EPRO CON021 Eddy Current Signal Converter

-

EPRO MMS6120 Dual Channel Temperature Monitor

-

EPRO PR6424/012-000 Eddy Current Sensor

-

EPRO PR6424/013-130+CON021 Eddy Current Sensor

-

EPRO PR6424/014-040 Eddy Current Sensor

-

EPRO PR6423/001-000 Eddy Current Sensor

-

EPRO PR6423/010-000-CN Eddy Current Sensor

-

EPRO CON011 9200-00001N Eddy Current Signal Converter

-

EPRO MMS6120 9100-00002-10 Dual Channel Temperature Monitor

-

EPRO MMS6120 9100-00002C-08 Dual Channel Temperature Monitor

-

EPRO PR9376/010-011 Hall Effect Speed/Proximity Sensor

-

EPRO CON011 9200-00001 Eddy Current Signal Converter

-

EPRO PR9268/300-000 Electrodynamic Velocity Sensor

-

EPRO MMS3120/022-000 9100-03047-01 industrial control module

-

EPRO MMS6823R 9100-00001-06 Displacement Monitor Module

-

EPRO PR6423/10R-030-CN 8mm Eddy Current Sensor

-

EPRO PR6423/002-030-CN+CON021 Industrial Vibration Sensor

-

EPRO PR9376/20 Hall Effect Speed/Proximity Sensor

-

Epro MMS6823 Data Acquisition Module

-

EPRO PR6423/002-001-CN Industrial Vibration Sensor

-

EPRO RSM020 940860010250 Controller board

-

EPRO RSM020 Controller board

-

EPRO SDM010 Factory specific piezoelectric vibration monitor

-

Woodward 3522-1004 EM-80/EM-300 Actuator System

-

Woodward 3522-1009 EM-80/EM-300 Actuator System

-

Honeywell M7410F1000 Cartridge Globe Valve Actuator

-

Honeywell M7410F3006 Cartridge Globe Valve Actuator

-

Honeywell M6410A3017 Cartridge Globe Valve Actuator

-

Honeywell M6410A1029 Cartridge Globe Valve Actuator

-

Honeywell R8242A Contactor

-

Honeywell R6410A Valve Actuator

-

Honeywell ML6474 Damper Actuator, 132 lb-in

-

Honeywell ML6464 Damper Actuator, 66 lb-in

-

Honeywell ML6185 Damper Actuator SR 50 lbin

-

Honeywell ML6161 Damper Actuator, 35 lb-in

-

Honeywell ML684 Versadrive Valve Actuator

-

Honeywell PVB0000AS Spyder BACnet controller

-

Honeywell PUB4024S Spyder BACnet controller

-

Bently CBBL0026 Carrying case for the kit

-

Bently PLSA0241 South Africa/india - Category D powerplug

-

Bently MAGFO104 Accelerometer magnetic base

-

Bently CBVB0032 SCOUT instrument carrying bag

-

Bently CBCCO027 Coiled cable

-

Bently ACCLO547 Straight accelerometer

-

Bently 10005-02 SCOUT programmed USB thumb drive

-

Bently 108M3239 SCOUT100-Extwo-channel portable datacollector

-

Honeywell N-ADV-PCA-DEMO Demo License for Advanced Controller

-

Honeywell N-ADV-134-H-C Niagara Device with 1+3 Ethernet interfaces

-

Honeywell N-ADV-133-H-C Niagara Device with 1+3 Ethernet interfaces

-

Honeywell N-ADV-133-H-BWW-D Niagara Advanced Plant Controller with BLE & WiFi (Rest of World)

-

Honeywell N-ADV-133-H-BWW-C Niagara Advanced Plant Controller with BLE & WiFi (Rest of World)

-

Honeywell N-ADV-133-H-BWA-D Niagara Advanced Plant Controller with BLE & WiFi (Americas)

-

Honeywell N-ADV-133-H-BWA-C Niagara Advanced Plant Controller with BLE & WiFi (Americas)

-

Honeywell N-ADV-133-H-BWA Niagara Advanced Plant Controller with BLE & WiFi (Americas)

-

Honeywell N-ADV-133-H-B-C Niagara Advanced Plant Controller

-

Honeywell N-ADV-112-H-C N-ADV DEVICE 1+1ETH & 2RS485

-

Honeywell N-ADV-10000-255PCA Optimizer Advanced Controller License for 200 Devices

-

Honeywell N-ADV-05000-255PCA Optimizer Advanced Controller License for 100 Devices

-

Honeywell N-ADV-0255P-UP PBUS UPGRADE 255 PTS

-

Honeywell N-ADV-01250-255PCA Optimizer Advanced Controller License for 25 Devices

-

Honeywell N-ADV-0100P-UP PBUS UPGRADE 100 PTS

-

Honeywell N-ADV-00500-100PCA Optimizer Advanced Controller License for 10 Devices

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Woodward 3522-1004 EM-80/EM-300 Actuator System

-

Woodward 3522-1009 EM-80/EM-300 Actuator System

-

3HAC044168-001/06 ABB Pcb Circuit Board

-

ABB FGM1190-97 With vertical female thread connection

-

ABB FGM1190-98 With flanged connection in accordance with DIN or ASME

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved