-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

A-B 4100-234-R Compact Motion Controller

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

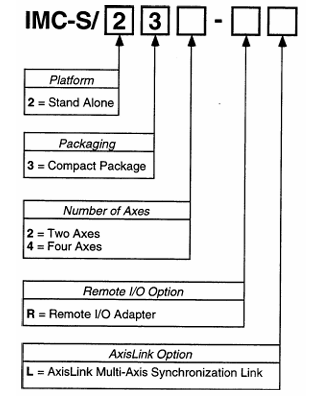

A-B IMC™ S Class Compact Motion Controllers Model Number Explanation

-

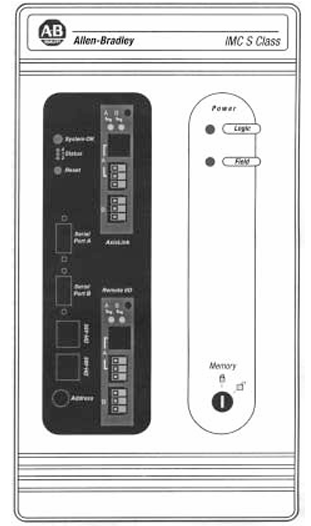

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models) Product Features

-

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models)

-

AIS810 ABB Ability™ System 800xA® hardware selector

-

NE810 ABB Ability™ System 800xA® hardware selector

-

ABB NE802 System 800xA hardware selector

-

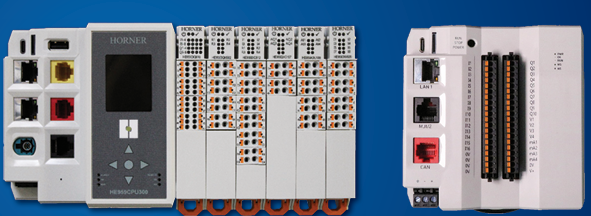

Horner OCS CPU Highly Expandable & Flexible Controller Solutions with OCS I/O Expansion

-

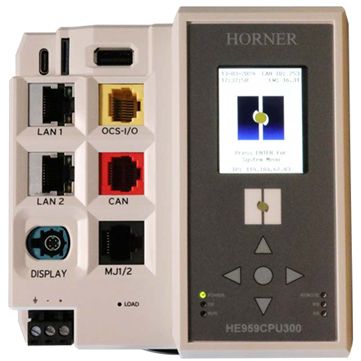

Horner CPU300 and HMI Connect Series Mounting Overview

-

Horner CPU300 and HMI Connect Series Features

-

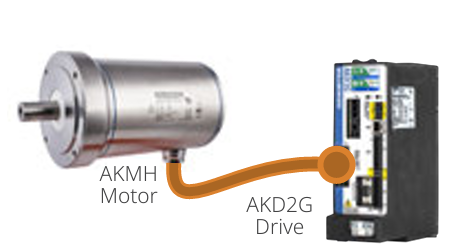

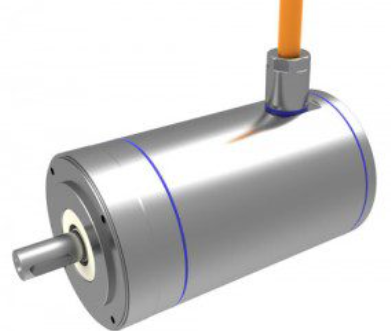

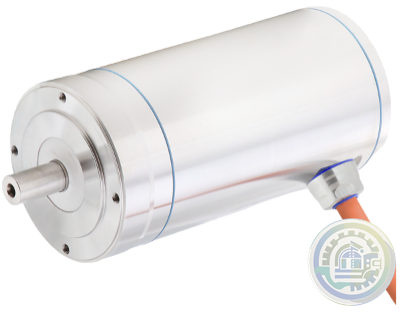

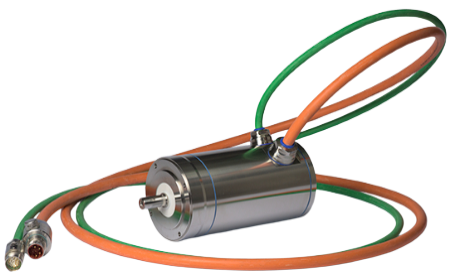

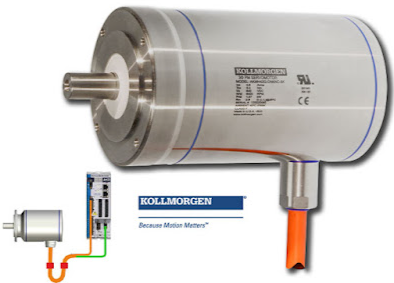

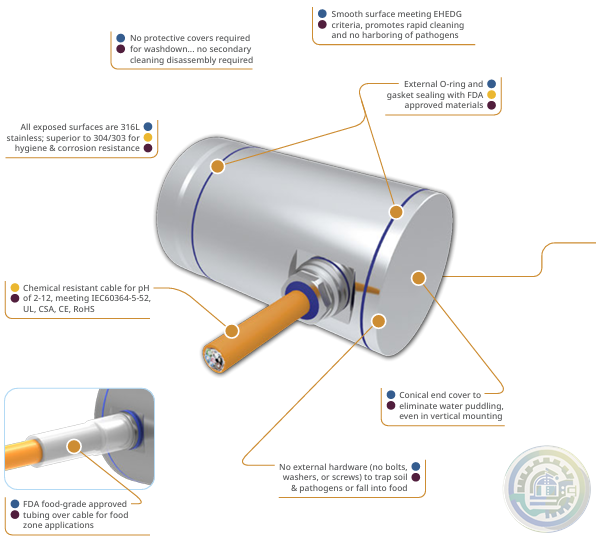

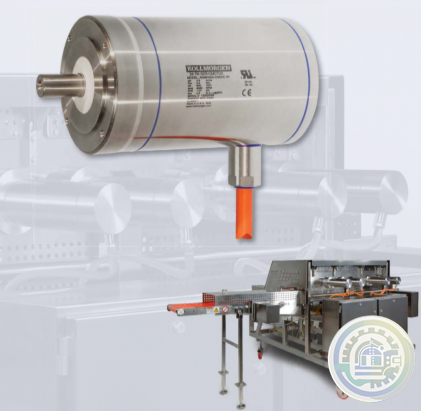

Kollmorgen AKMH™ Stainless Steel Washdown Motor Engineering Excellence

-

Kollmorgen AKMH™ Co-Engineered Solutions

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Modified Standard

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Brake Option

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Hygienic Design

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Protection Class

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Technical Guide

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Design Features

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits Highly configurable

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Global Footprint

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor

-

Kollmorgen AKMA™ Co-Engineered Solutions

-

Kollmorgen AKMA™ Universal Drive Solutions for Food,Beverage, and Pharmaceutical Industries

-

Kollmorgen AKMA™ Anodized Washdown Motor Features

-

Kollmorgen AKMA™ Anodized Washdown Motor Benefits

-

Kollmorgen AKMA™ Removing the Barriers of Design, Sourcing, and Time

-

Kollmorgen AKMA™ Anodized Washdown Motor

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Industry-leading

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Benefits

-

Emerson 00813-0100-0112 VersaMax Modular Input/Outputs and Controls Ease of Use

-

Emerson 00813-0100-0161 Compact Programmable Automation Controller Open communication

-

Emerson 00813-0100-0115 RXi - Industrial Monitor Designed for Visualisation

-

HIMA X-CPU 01 Processor Module Function

-

HIMA launches the fourth generation of its central module HIQuad X benefits

-

KEBA KeControl C5 - FE 560 Multi-protocol fieldbus expansion card

-

KEBA KeControl C5 - FE 571, FE 573 EtherCAT master expansion card

-

KEBA KeControl C5 - NE 551 Gbit Ethernet expansion card

-

KEBA KeDrive D3 controls – D3-DU 3x5 Control modules with built-in safety control

-

KEBA KeDrive D3 controls - D3-DU 3x0 Control modules

-

KEBA KeControl C1 Control modules

-

KEBA KeControl C5 - CP 5x0 Control modules

-

KEBA KeControl C5 - CP 50x Controls / Control units

-

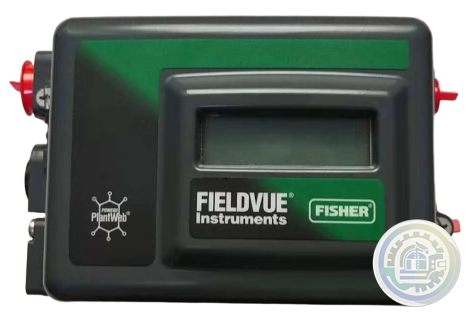

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Performance

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Value

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Features

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller

-

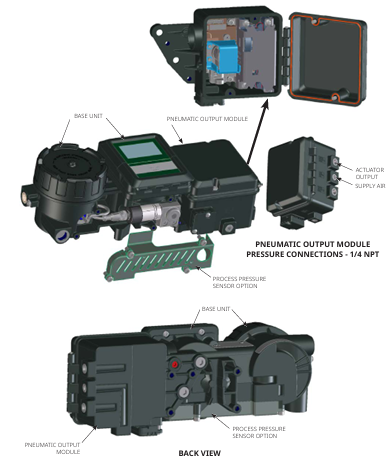

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Device Alerts

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Value

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Features

-

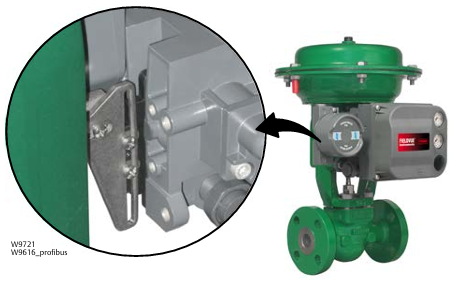

Emerson Fisher DVC6200 Digital Valve Controller Features

-

Emerson Fisher DVC6200 Digital Valve Controller Specifications

-

Emerson Fisher DVC6200 Digital Valve Controller

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Instrument Shutdown

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller General Information

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Restart Control Mode

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Detailed Setup

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller

-

Kongsberg RDIO400 Remote Digital Inputs and Outputs Technical Specifications

-

Emerson CSI A6120 Enclosure Seismic Vibration Monitor Features

-

Kongsberg RL542A Radio Link Features

-

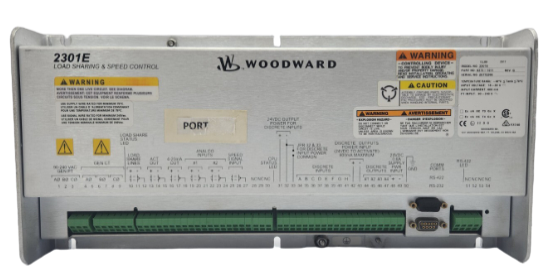

Woodward 2301E Digital Load Sharing and Speed Controller four modes of operation

-

ABB AC 800PEC High Performance Control System Modular structure

-

ABB AC 800PEC High Performance Control System Aluminium applications

-

GE IC693CMM321 Ethernet Interface Module Board Indicators

-

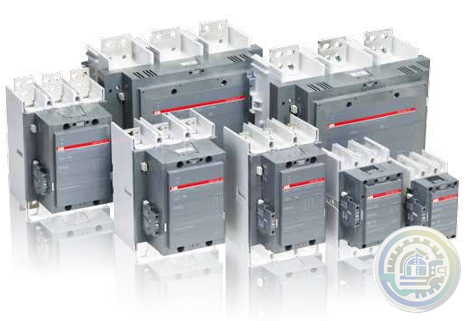

ABB Preventive maintenance for AF1350 ... AF2650 contactors Benefits

-

ABB DC switching contactors, type GAF A compact contactor up to 1000 V DC Features

-

Kongsberg RMP420-Remote Multipurpose Input/Output

-

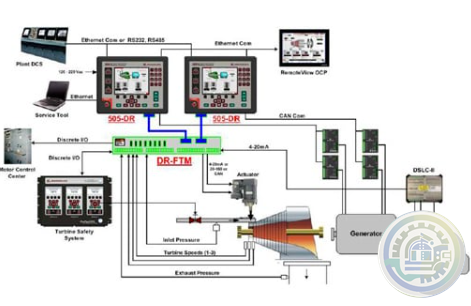

Woodward 505DR Dual Redundant Turbine Controller Control specifications

-

Woodward 505DR Dual Redundant Turbine Controller Communication

-

Woodward 505DR Dual Redundant Turbine Controller Description

-

Emerson M-Series DC to DC System Power Supplies Product Description

-

ABB M4M Network Analyser Transmission method

-

ABB FAU 810 Flame Analyser Unit Remote Monitoring

-

Honeywell 91MCE Series MICRO SWITCH Miniature Compact Limit Switches Features

-

MOOG Dual PWM Amplifier G123-814 Wiring

-

MOOG Dual PWM Amplifier G123-814 Applying this amplifier

-

Emerson A6410 Dual Channel Valve and Enclosure Expansion Monitor Features

-

Emerson A6630 Temperature Monitor Machine Monitoring System sensor types

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive main application scenarios

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive applications

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive

-

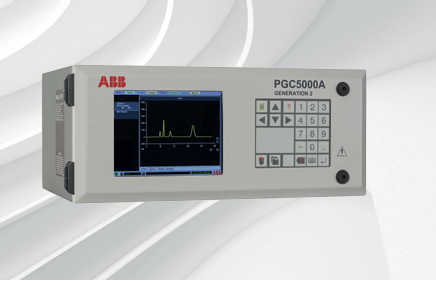

ABB PGC5000 Temperature programmed gas chromatograph Gas Control

-

ABB PGC5000 Temperature programmed gas chromatograph Safety area classification

-

ABB PGC5000 Temperature programmed gas chromatograph Introduction

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Application flexibility

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Features

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller

-

ABB Time Synchronization in PGC5000 Series Data System

-

ABB VistaSTAR with PGC5000 Version 4 Data System Interface

-

ABB PGC5000 Series gas chromatographs ATEX Directive

-

ABB PGC5000 Series gas chromatographs PGC Certification

-

ABB PGC5000 Series gas chromatographs Introduction

-

Honeywell BW™ ICON Multi-Gas Detector FEATURES AND BENEFITS

-

HONEYWELL BW™ RIGRAT Transportable Multi-gas Area Monitor FEATURES AND BENEFITS

-

HONEYWELL BW™ SOLO Repairable Single Gas Detector FEATURES

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System User Experience

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System Flexible Capabilities

-

ABB ACS800-07 (+V992) is a cabinet-mounted drive Controls of the supply unit

-

Emerson A6110 Shaft Relative Vibration Monitor Features

-

GE Multilin 489 Generator Protection System SR Series Relays features

Current Location:

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

66

Product parameters

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Feature

### ABB DC562: The Pinnacle of Performance in Automation Solutions

The **ABB DC562** is engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. With its robust design and unparalleled performance metrics, the DC562 stands out as a reliable solution for a variety of industrial needs.

**Key Technical Features**

The ABB DC562 boasts an impressive input/output capacity, supporting a wide range of signal types and communication protocols. With a durable construction designed to withstand harsh environmental conditions, this model ensures longevity and minimal maintenance requirements. The performance metrics of the DC562 include high processing speeds, enabling real-time data acquisition and processing, which is crucial for applications that require immediate response times. Its advanced diagnostic capabilities facilitate proactive maintenance, reducing downtime and enhancing operational efficiency.

The device features a modular design, allowing for easy upgrades and scalability to accommodate future technological advancements. Its compatibility with various ABB automation products ensures seamless integration into existing systems, making it a versatile choice for engineers and project managers alike.

In the power industry, the ABB DC562 excels in monitoring and controlling critical infrastructure. For instance, it can be utilized in substations to manage electrical loads, ensuring stable power distribution. In the petrochemical sector, the DC562 is instrumental in controlling complex processes, such as refining and chemical production, where precise control and reliability are paramount. For general automation, it serves as a central hub for managing and coordinating multiple automated systems, optimizing production efficiency across various plants.

**Comparison with Other Models**

When comparing the ABB DC562 with other models in the ABB lineup, such as the **ABB REL670** and **ABB SDCS-MEM-8**, a few distinct advantages emerge. While the REL670 focuses primarily on protection and control applications, the DC562 offers a broader range of functionalities suitable for diverse operational needs. Additionally, the SDCS-MEM-8, although powerful in control tasks, may not provide the same level of input/output flexibility as the DC562. This makes the DC562 a more adaptable choice for organizations looking to streamline multiple processes under one cohesive system.

**Complementary ABB Models**

The ABB DC562 can seamlessly integrate with various other models from the ABB portfolio, enhancing its capabilities. For instance, when paired with the **ABB 3BHE001787P0003** for advanced data communication, users can benefit from enhanced connectivity. The **ABB 3BHB009182P0001** provides a robust interface that complements the DC562’s processing power, while the **ABB 3BSE050092R20** offers additional input/output options for more complex applications.

Furthermore, integrating the **ABB DO561** allows for improved data logging and monitoring, essential in high-stakes environments like power generation. The **ABB 1SFA619403R5022** enhances the DC562’s overall automation capabilities, providing additional layers of control.

By leveraging complementary models such as the **ABB 3BHE020959R0127** and **ABB TA525**, users can create a comprehensive automation ecosystem tailored to their specific operational needs. The versatility of the ABB DC562 ensures it functions effectively in conjunction with these models, resulting in a cohesive and efficient automation solution.

The **ABB DC562** is engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. With its robust design and unparalleled performance metrics, the DC562 stands out as a reliable solution for a variety of industrial needs.

**Key Technical Features**

The ABB DC562 boasts an impressive input/output capacity, supporting a wide range of signal types and communication protocols. With a durable construction designed to withstand harsh environmental conditions, this model ensures longevity and minimal maintenance requirements. The performance metrics of the DC562 include high processing speeds, enabling real-time data acquisition and processing, which is crucial for applications that require immediate response times. Its advanced diagnostic capabilities facilitate proactive maintenance, reducing downtime and enhancing operational efficiency.

The device features a modular design, allowing for easy upgrades and scalability to accommodate future technological advancements. Its compatibility with various ABB automation products ensures seamless integration into existing systems, making it a versatile choice for engineers and project managers alike.

In the power industry, the ABB DC562 excels in monitoring and controlling critical infrastructure. For instance, it can be utilized in substations to manage electrical loads, ensuring stable power distribution. In the petrochemical sector, the DC562 is instrumental in controlling complex processes, such as refining and chemical production, where precise control and reliability are paramount. For general automation, it serves as a central hub for managing and coordinating multiple automated systems, optimizing production efficiency across various plants.

**Comparison with Other Models**

When comparing the ABB DC562 with other models in the ABB lineup, such as the **ABB REL670** and **ABB SDCS-MEM-8**, a few distinct advantages emerge. While the REL670 focuses primarily on protection and control applications, the DC562 offers a broader range of functionalities suitable for diverse operational needs. Additionally, the SDCS-MEM-8, although powerful in control tasks, may not provide the same level of input/output flexibility as the DC562. This makes the DC562 a more adaptable choice for organizations looking to streamline multiple processes under one cohesive system.

**Complementary ABB Models**

The ABB DC562 can seamlessly integrate with various other models from the ABB portfolio, enhancing its capabilities. For instance, when paired with the **ABB 3BHE001787P0003** for advanced data communication, users can benefit from enhanced connectivity. The **ABB 3BHB009182P0001** provides a robust interface that complements the DC562’s processing power, while the **ABB 3BSE050092R20** offers additional input/output options for more complex applications.

Furthermore, integrating the **ABB DO561** allows for improved data logging and monitoring, essential in high-stakes environments like power generation. The **ABB 1SFA619403R5022** enhances the DC562’s overall automation capabilities, providing additional layers of control.

By leveraging complementary models such as the **ABB 3BHE020959R0127** and **ABB TA525**, users can create a comprehensive automation ecosystem tailored to their specific operational needs. The versatility of the ABB DC562 ensures it functions effectively in conjunction with these models, resulting in a cohesive and efficient automation solution.

In conclusion, the **ABB DC562** is an exceptional choice for organizations within the power industry, petrochemical sector, and general automation. Its technical features, superior performance metrics, and compatibility with a range of ABB automation products make it an invaluable asset for any industrial application. By choosing the DC562, companies can achieve enhanced reliability, efficiency, and scalability in their automation processes.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

66

How to install and debug this product? Matters needing attention

Open the manual and programming software, use the new version, upload the data and programs, save the computer, continue downloading! For details, please consult the technical service provider!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Where can I download the manual and programming software?

Product official website, official hotline and contact sales or technical engineers.

Is it in stock or need to be ordered?

There will generally be inventory, but it does not rule out that the website inventory has been sold and not updated. Please consult customer service.

Can you provide technical service?

Need to see the product type and site conditions, equipment damage, humanities and other factors, please inform us, we will provide you with a suggestion!

Where can I order this series?

Please see the contact information of the website, official channels, and consulting customer service! Thank you for your cooperation!

Do you have product selection list and pre-sale service?

It can be downloaded from local agents, technical service companies, and the official website (pdf). Some special products are excluded. Please contact us as appropriate.

Let's Communicate

Call the enterprise hotline customer service consultant is waiting for you online

wechat/whatsapp:

+86-181-4410-0983

Contact Business

Talk to a customer service consultant now about what you need to know

Positive message

Leave us a message and a customer service consultant will contact you within 24 hours

Wechat

Whatsapp

Email: kongjiangauto@163.com

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved