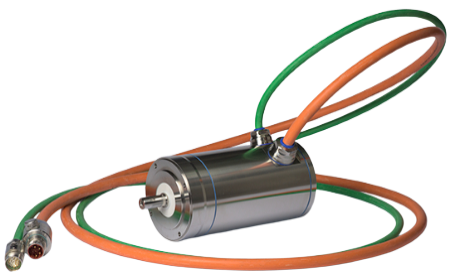

Kollmorgen AKMH™ Stainless Steel Washdown Motor Hygienic Design

AKMH™ Hygienic Design Guide

Hygienic Design

The Food and Drug Administration (FDA) is an agency of the United States Department of Health and Human Services.

The FDA is responsible for protecting and promoting public health through the regulation and supervision of food safety,

vaccines, biopharmaceuticals, blood transfusions, medical devices and other products.

The “European Hygienic Engineering and Design Group” (EHEDG) is a European-based non-government organization

devoted to the advancement of hygienic design and food engineering. European legislation requires that handling,

preparation, processing, packaging, etc. of food is done hygienically, with hygienic machinery in hygienic premises (the food

hygiene directive, the machine directive and the food contact materials directive).

Certifications: UL, CE, RoHs, BISSC, NSF, USDA, FDA, EAC, designed to EHEDG guidelines, according to DIN EN ISO 14159

and DIN EN 1672-2

Surface: Stainless steel 316L/1.4404. roughness < 0.8 μm

Immunity: Against tested industrial cleaning agent, corrosion-proof

Degree of Protection: IP69K

Mounting Screw*: Stainless steel 316L/1.4404. sealant FDA 21 CFR 175.300

O-Ring: EPDM or Viton, FDA 21 CFR 177.2600

Shaft: Stainless steel 316L/1.4404

Rotary Shaft Seal: Mineral filled PTFE, single lip, mineral: FDA 21 CFR 175.300. PTFE: FDA 21 CFR 177.1500

Shaft Center Screw*: Stainless steel 1.4404. sealant FDA 21 CFR 175.300

Bearing Grease: Food-grade as per FDA 21 CFR 178.3570

Cable Gland: Stainless steel 1.4404. Silicone seal FDA 21 CFR 177.2600

Cable Tube: Silicone FDA 21 CFR 177.2600

Name Plate: Laser marked in housing

Size: AKMH2 to AKMH6

Tested properties with respect to cleaning agents

The testing lab of ECOLAB Deutschland GmbH tested the resistance of the external surfaces to the following industrial

cleaning agents:

» P3-topactive DES

» P3-topax 12

» P3-topax 56

» P3-topax 66

» P3-topax 990

In the process, the surfaces were immersed in the respective cleaning agent at 21°C temperature for 28 days. This

corresponds to approx. 2.500 cleaning cycles with 15-minute contact each with the cleaning agent or 1.500 cleaning cycles

with cleaning and subsequent disinfection. Due to the possible relaxation after each treatment in practice the chemical

attack would be even lower.

Kollmorgen can only give a guarantee for the motor’s lifecycle if the tested cleansing agents are used. Contact Kollmorgen

Customer Support for information on motor use with alternative cleaning agents.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

-

Kongsberg RCU502I 421768 Remote Control Unit (Modular I/O Processor)

-

ABB AC 800PEC PC D237 3BHE028915R0101 / PC D237 A101 CONTROLLER BOARD

-

ABB GVC704AE01 5SHX1060H0001 3BHB003230R0101 Medium voltage inverter

-

ABB Process Panel PP245 3BSC690126R2 PP245B

-

GE Mark VIe & VIeS IS230PCAAH1B - Core Analog I/O Module

-

GE Mark VIe & VIeS IS230PCAAH1A Core Analog I/O Module

-

Emerson PMCSPANA/IH PMC Carrier Installation and Use Manual

-

Emerson PMCSPAN26E-010 Secondary PMC expansion

-

Emerson PMCSPAN26E-002 Primary PMC expansion

-

Emerson PMCSPAN16E-010 Secondary PCI expansion

-

Emerson PMCSPAN16E-002 Primary PCI expansion

-

A-B 1783-HMS4C4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-RA5TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-CMS10DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-HMS8S4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-CMS6B Stratix 5200 Ethernet Managed Switches

-

A-B 1783-RA5TGW Stratix 4300 Remote Access Routers

-

A-B 1783-RA2TGWC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US5TG/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGW Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US6T2F/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5TG Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2TG2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US6T2TG2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US4T1H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US14T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US7T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-RA2TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US16T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US7T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGB Stratix 4300 Remote Access Routers

-

A-B 1783-LMS5 Stratix 2500 Ethernet Lightly Managed Switches

-

A-B 1783-US7T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US8T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US8TG2GX Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T 5 Port Unmanaged Switch

-

MOOG D138-002-002 Industrial Control Module

-

MOOG D138-003-001 Industrial Control Module

-

MOOG CA98502-001 Accessories for Ruggedized Motion Controller

-

MOOG D691-078D servo valve

-

MOOG CA65866-001 MSD Motion Controller

-

MOOG C43148-001 QD10 16/16 Digital l/0 module

-

MOOG D138-002-012 Main control unit

-

MOOG CA94286-001 Accessories for Ruggedized Motion Controller

-

MOOG D136-001-008 MSCI MSD Motion Controller

-

MOOG B95906-001 MSCI Motion Controller

-

MOOG B95865-001 CAN Termination Resistors

-

MOOG QEBUS-CAN Module

-

MOOG D136-003-001 Interfaces of Ruggedized Motion Controller

-

MOOG RDI0 16/16 Digital Module

-

MOOG D136-003-004 Interfaces of Ruggedized Motion Controller

-

MOOG D391-001-003 MSD MOTION CONTROLLER

-

MOOG D138-002-003 Industrial Control Module

-

MOOG MSC-R-10 16/8 Digital and PT100 Module

-

MOOG CB08987-001 Ruggedized Motion Controller

-

MOOG RDISP 22 Operator Panel DISPLAYS

-

MOOG D136-003-002 Interfaces of Ruggedized Motion Controller

-

MOOG CA65865-001 MSCl Motion Controller

-

MOOG B95863-001 CAN Connection Cables

-

MOOG QA10 16/4 Analog Module

-

MOOG D136-006-001 EtherCAT slave interface

-

MOOG D391-001-001 MSD MOTION CONTROLLER

-

MOOG D136-003-005 Interfaces of Ruggedized Motion Controller

-

MOOG D137-004-003 TFT Touch screen display

-

MOOG D138-002-003 Industrial Control Module

-

MOOG D138-003-010 Industrial Control Module

-

MOOG CB03223-001 Accessories for Ruggedized Motion Controller

-

MOOG B95864-001 CAN Termination Resistors

-

MOOG QD10 16/16 Digital Module

-

MOOG D391-001-002 MSD MOTION CONTROLLER

-

MOOG D138-001-010 Industrial Control Module

-

MOOG D138-001-005 Industrial Control Module

-

MOOG D138-001-002 Industrial Control Module

-

MOOG D138-001-001 Industrial Control Module

-

MOOG D137-002-001 Digital I/O modules

-

MOOG QEBUS-CAN Extension module

-

MOOG D137-001-010 Connection modules

-

MOOG D137-001-004 Digital I/O modules for E-Bus

-

MOOG D137-001-007 Digital extension module

-

MOOG G391-001-001 MSD Motion Controller

-

MOOG D138-002-001 Motion Controller

-

MOOG D137-004-004 TFT Touch screen display

-

MOOG D136-002-005 Ruggedized Motion Controller Interface

-

MOOG D137-001-006 Digital extension module

-

MOOG D136-002-004 Ruggedized Motion Controller Interface

-

MOOG D137-004-006 TFT Touch screen display

-

MOOG G391-001-002 MSD Motion Controller

-

MOOG D137-004-005 TFT Touch screen display

-

MOOG D137-001-005 Digital extension module

-

MOOG D136E001-001 Programmable Processor Module

-

MOOG D138-006-001 operation panel

-

MOOG G122-829-001 Programmable Processor Module

-

MOOG G761-3002B Industrial servo valves

-

MOOG T161-902A-00-B4-2-2A Servo Controller

-

MOOG M128-010-A001B DC Power Module

-

MOOG G391-001-003 MSD Motion Controller

-

MOOG D138-002-002 Motion Controller

-

MOOG D137-001-011 Digital extension module

-

MOOG D136-002-003 Ruggedized Motion Controller Interface

-

MOOG D136-002-002 Ruggedized Motion Controller Interface

-

MOOG D136-001-008a Ruggedized Motion Controller Interface

-

MOOG D136-001-007 Ruggedized Motion Controller Interface

-

MOOG D136-001-001 Ruggedized Motion Controller Interface

-

MOOG 914-GBE Gigabit Ethernet (GbE) Media Converter

-

MOOG 914-0300-00 ADVANCED MODULAR MULTIPLEXER SYSTEM

-

ABB UCD224A103 digital input/output module

-

ABB PDD205A0121 power distribution device

-

ABB PDD205A1121 power distribution device

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved