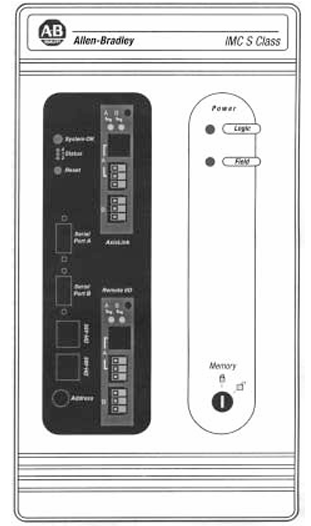

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models) Product Features

Product Features

• Powerful graphical software development system (GML) with

real-time debugging makes application programming easy and fun.

• State-of-the-art Intel i960 RISC microprocessor.

• Completely digital—no potentiometers or other adjustments

required; will not drift with time, temperature or humidity.

• Multitasking operating system allows simultaneous execution of

up to 10 tasks for efficient utilization.

• Electronic gearing for synchronization of any axis to another at a

programmable ratio. Ratio may be specified as a floating point

number or integer fraction (1⁄3. 3⁄10. etc.).

• Electronic cam for coordinated motion profiles on one or more

axes. Profiles may be position versus time or slave axis position

versus master axis position.

• Sophisticated phase shift and advance/retard capabilities for

electronic gears and cams allow complex motions to be easily

programmed.

• Auto-registration and auto-correction make high-speed

registration applications easy.

• Exclusive Imaginary Axis provides additional command-only

axis for precise generation of master motion in master-slave

applications or correction moves in registration and

synchronization applications.

• Concurrent, independent, or synchronous motion on all axes.

Interpolated motion on up to three axes.

• Wide position, speed, acceleration, and deceleration ranges for

precise control.

• Separately programmable acceleration and deceleration rates for

maximum versatility.

• Trapezoidal, parabolic, and S-curve velocity profiles.

• Rotary mode with electronic unwind allows unlimited position

range for rotary axes.

• Motion merge function allows seamless transition between all

types of motion.

• Most motion parameters (including master axis for electronic

gears and cams) can be changed on-the-fly with no delays.

• Powerful floating-point math capabilities including

transcendental functions (sin, cos, log, etc.).

• Sophisticated Nested Digital Serve Control Loop with automatic

servo setup for quick and easy servo tuning.

• Isolation of all external connections from the microprocessor

logic for reliable performance.

• 4 MHz maximum feedback count rate allows high speed

operation without sacrificing resolution.

• Encoder loss detection protects operators and machinery from

damage in the event of encoder feedback failure.

• Isolated 16-bit DACs for smooth motion. Software offset

correction eliminates drift with analog servo drives.

• Field-configurable servo outputs allow independent selection of

±10V or ±150 mA signal format for each axis.

• Programmable position lock and position error tolerances for

servo fault protection.

• Programmable directional software travel limits for enhanced

overtravel protection.

• Velocity feedforward to reduce following error.

• Four optically isolated inputs for a home switch, positive and

negative overtravel switches, and a drive fault signal for each axis.

• Relay-contact drive enable output for each axis.

• Optically isolated high-speed position registration input for each

axis for position synchronization and registration applications.

• CPU watchdog with front-panel LED indicator for fail-safe protection.

• AxisLink option allows real-time axis coordination between

controllers for distributed, multi-axis systems.

• Non-volatile storage (write-locked battery-backed RAM) of

application program, setup parameter and default variable values.

• Memory Lock keyswitch on front panel prevents accidental or

unauthorized changes to application program, setup parameters,

and default variable values.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

- Alfa Laval

-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

METSO D201505 / D201463 network controller

-

METSO ntel D33025 Motherboard

-

METSO ACN MR D201463 DCS Controller

-

METSO ACN MR D201505R DCS Controller

-

METSO ACN MR D201380 DCS Controller

-

METSO ACN MR D201139 DCS Controller

-

METSO ACN MR D202214 DCS Controller

-

METSO ACN MR D202275 DCS Controller

-

Metso D201376 Industrial Analog Input Module

-

Metso D201134 Process Control Module

-

Metso d200175 ver: 2.04 personality module

-

Metso D200137 ACN RT Node with D200175

-

METSO ACN CS CONTROLLER D201925 VER 2.15

-

METSO D100644 Electrical Automation Module

-

Kollmorgen CB06560 PRD-B040SAIB-62 Control Module

-

Servostar 310 Kollmorgen Servo Amplifier

-

Kollmorgen S20330-SRS Digital AC Servo Drives

-

Kollmorgen S22460-SRS Digital AC Servo Drives

-

Kollmorgen S70602-NANANA S700 Servo Driver

-

BJRL-20012-110001 Kollmorgen Goldline Smart Drives

-

Kollmorgen SAM-DA-400-07B-P4N-F SAM Servo Amplifiers

-

Kollmorgen CP320260 Servo Drive

-

Kollmorgen S72402-NANANA - AC servo drives

-

Kollmorgen E33NRHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen S20360-SRS Servo Drive

-

Kollmorgen E33NCHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen CR06200-000000 Servo Drive

-

Kollmorgen DIGIFAS7201 Digital Industrial Servo

-

CB06251 Kollmorgen Servo Drive

-

Kongsberg TRX32 FILTER (303067B) | Elektro Marine

-

Kongsberg MRU-M-MB3 | Motion Reference Unit

-

Kongsberg TRX32 303088 | eight-channel I/O module

-

Kongsberg MRU2 Motion Reference Unit

-

KONGSBERG MRU-M-SU1 Industrial Measurement Unit

-

Kongsberg RMP201-8 Versatile Remote Input/output System

-

Kongsberg dPSC 8100183 Dual Process Segment Controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA PW482-10 S2 Power Supply Module

-

Yokogawa SCP451-11 S1 Processor Module

-

YOKOGAWA SR1030B62 High-Frequency Module

-

Yokogawa CP451-50 S2 Processor Module

-

YOKOGAWA AAI143-H50 Analog I/O Modules

-

YOKOGAWA AMM42 2-Wire Transmitter Input Multiplexer Module

-

SDV144-S63 | Yokogawa | Digital Input Module

-

Yokogawa AIP830-111 Operation Keyboard for Single loop Operation

-

Yokogawa S9361DH00 Control Module / Terminal Board

-

Yokogawa ATK4A-00/S1 KS Cable Interface Adapter

-

YOKOGAWA PW701 Power Supply Module

-

YOKOGAWA Dual-Redundant V-Network Router AVR10D-A22010

-

YOKOGAWA PW441-10 Communication Module

-

YOKOGAWA VI451-10 S2 Communication Module

-

Yokogawa VC401-10 Coupler Modules

-

Yokogawa ALP121 PROFIBUS-DP Communication Module

-

Yokogawa NFAI841-S00/A4S00 Analog Input/Output Module

-

YOKOGAWA AIP591 Transceiver Control Module

-

YOKOGAWA AIP578 Transceiver Control Module

-

YOKOGAWA PW501 Power Supply Unit Brand

-

Yokogawa YNT511D-V42 Bus Repeater Module

-

YOKOGAWA AIP171 Transceiver Control Module

-

YOKOGAWA VI702 Vnet/IP Interface Card

-

2302-32-VLE-2 YOKOGAWA Data Acquisition Module

-

Yokogawa ATK4A-00 16-Channel KS Cable Interface Adapter

-

YOKOGAWA ALR121-S00 Serial Communication Module

-

CP461-50 | Yokogawa | Processor Module

-

Yokogawa AIP121-S00 Control Module

-

YOKOGAWA UR1800 Wireless Communication Module

-

Yokogawa| LC82 *A Redundant RL-Bus Interface Card

-

YOKOGAWA ST6 Industrial Control Module

-

YOKOGAWA ANR10D ER Bus Node Unit

-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

YOKOGAWA VO/E2/TCDM24/L8 High-Precision Temperature Controller

-

YOKOGAWA 16137-119 Process Control Module

-

YOKOGAWA 16114-500 I/O Module for Process Control Systems

-

Yokogawa PSCDM024DCBAN - Critical Discrete Module

-

YOKOGAWA 16137-151 Digital Input Module

-

YOKOGAWA 16137-188 Digital Input Module

-

YOKOGAWA 16137-222 Digital Input Module

-

YOKOGAWA 16137-223 Digital Input Module

-

YOKOGAWA 16137-153 Digital Input Module

-

Watlow SUB21/IV10 0-10 V input adaptor

-

Watlow ITOOLS/NONE/USB U SB configuration kit

-

Watlow CTR500000/000 100 A Current transformer

-

Watlow CTR400000/000 50 A Current transformer

-

Watlow CTR200000/000 25 A Current transformer

-

Watlow CTR100000/000 10 A Current transformer

-

Watlow SUB35/ACCESS/249R.1 2.49R Precision resistor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved