-

Bently Nevada 2300/20-CN Monitor with 4-20ma Outputs

-

Bently Nevada 2300/20-RU 2300 Vibration Monitor

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

A-B 4100-234-R Compact Motion Controller

-

Bently Nevada ORBIT 60 SERIES Dynamic Input Modules Connectors

-

Bently Nevada ORBIT 60 SERIES Dynamic Input Modules Description

-

Bently Nevada Orbit 60 Series Robust cybersecurity

-

Bently Nevada ORBIT 60 SERIES System Overview

-

Bently Nevada ORBIT 60 SERIES System Overview Datasheet

-

Bently Nevada ORBIT 60 SERIES

-

Bently Nevada 2300 Vibration Monitor Series Benefits

-

Bently Nevada 2300 Vibration Monitor Series Key Features

-

Bently Nevada 2300 Vibration Monitor Series Description

-

Bently 2300/25 2300 Vibration Monitor Key Features

-

Bently 2300/20 and 2300/25 2300 Vibration Monitors Features

-

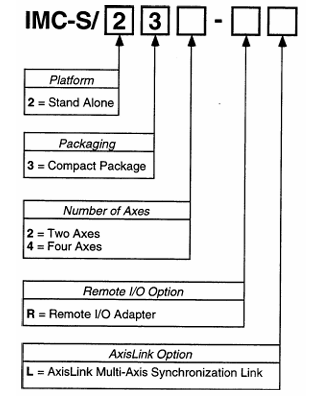

A-B IMC™ S Class Compact Motion Controllers Model Number Explanation

-

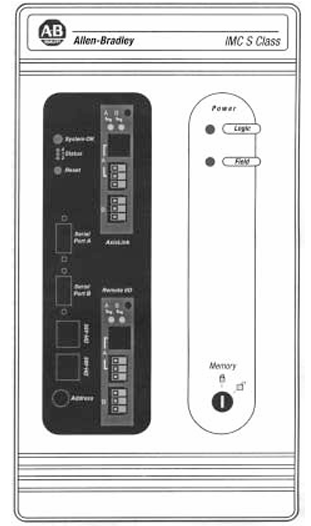

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models) Product Features

-

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models)

-

AIS810 ABB Ability™ System 800xA® hardware selector

-

NE810 ABB Ability™ System 800xA® hardware selector

-

ABB NE802 System 800xA hardware selector

-

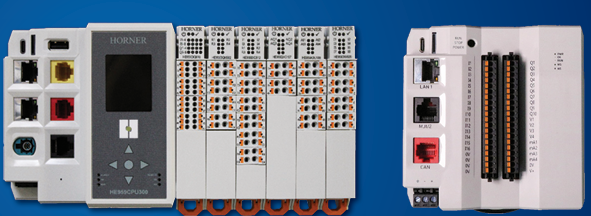

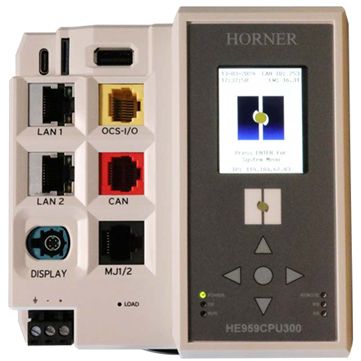

Horner OCS CPU Highly Expandable & Flexible Controller Solutions with OCS I/O Expansion

-

Horner CPU300 and HMI Connect Series Mounting Overview

-

Horner CPU300 and HMI Connect Series Features

-

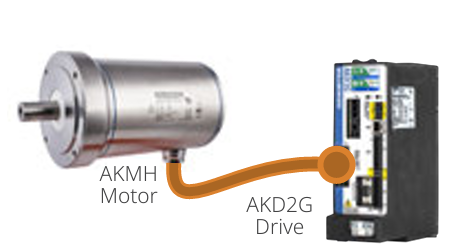

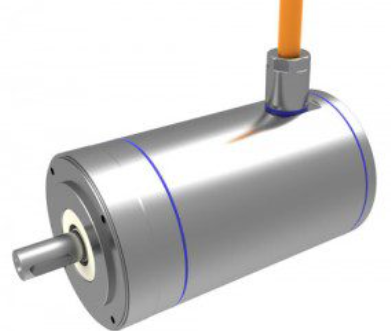

Kollmorgen AKMH™ Stainless Steel Washdown Motor Engineering Excellence

-

Kollmorgen AKMH™ Co-Engineered Solutions

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Modified Standard

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Brake Option

-

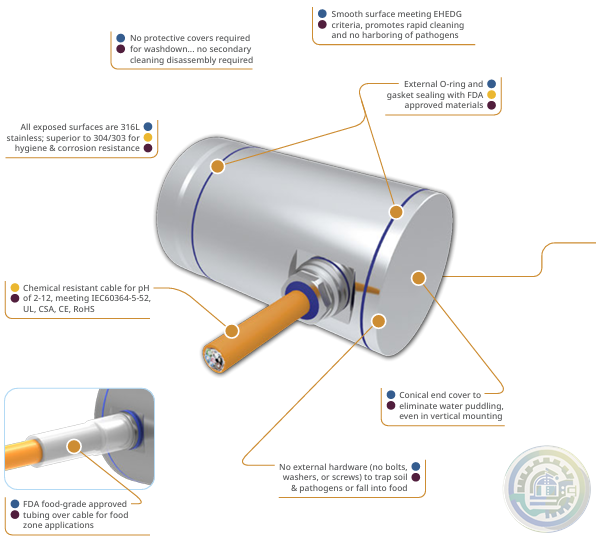

Kollmorgen AKMH™ Stainless Steel Washdown Motor Hygienic Design

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Protection Class

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Technical Guide

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Design Features

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits Highly configurable

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Global Footprint

-

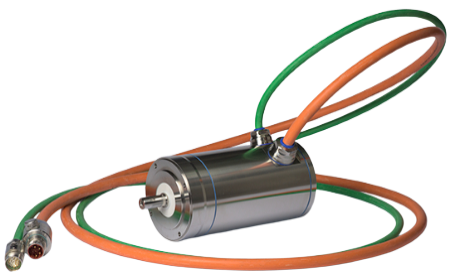

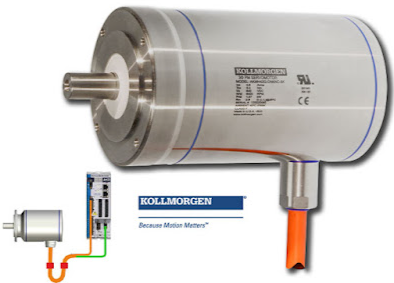

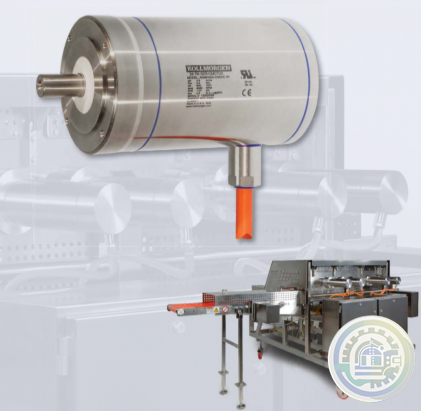

Kollmorgen AKMH™ Stainless Steel Washdown Motor

-

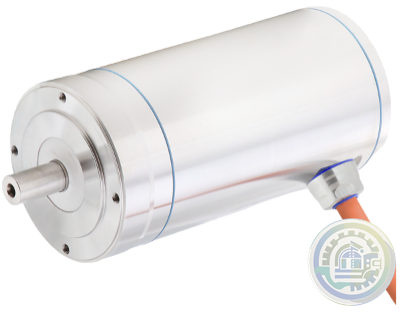

Kollmorgen AKMA™ Co-Engineered Solutions

-

Kollmorgen AKMA™ Universal Drive Solutions for Food,Beverage, and Pharmaceutical Industries

-

Kollmorgen AKMA™ Anodized Washdown Motor Features

-

Kollmorgen AKMA™ Anodized Washdown Motor Benefits

-

Kollmorgen AKMA™ Removing the Barriers of Design, Sourcing, and Time

-

Kollmorgen AKMA™ Anodized Washdown Motor

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Industry-leading

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Benefits

-

Emerson 00813-0100-0112 VersaMax Modular Input/Outputs and Controls Ease of Use

-

Emerson 00813-0100-0161 Compact Programmable Automation Controller Open communication

-

Emerson 00813-0100-0115 RXi - Industrial Monitor Designed for Visualisation

-

HIMA X-CPU 01 Processor Module Function

-

HIMA launches the fourth generation of its central module HIQuad X benefits

-

KEBA KeControl C5 - FE 560 Multi-protocol fieldbus expansion card

-

KEBA KeControl C5 - FE 571, FE 573 EtherCAT master expansion card

-

KEBA KeControl C5 - NE 551 Gbit Ethernet expansion card

-

KEBA KeDrive D3 controls – D3-DU 3x5 Control modules with built-in safety control

-

KEBA KeDrive D3 controls - D3-DU 3x0 Control modules

-

KEBA KeControl C1 Control modules

-

KEBA KeControl C5 - CP 5x0 Control modules

-

KEBA KeControl C5 - CP 50x Controls / Control units

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Performance

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Value

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Features

-

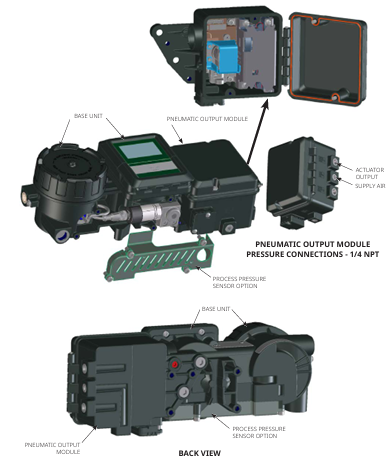

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Device Alerts

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Value

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Features

-

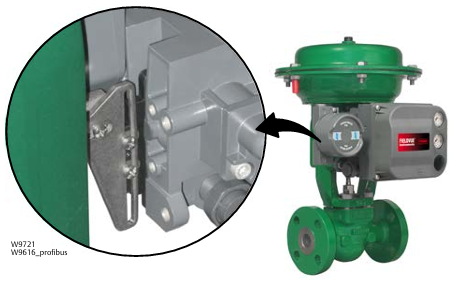

Emerson Fisher DVC6200 Digital Valve Controller Features

-

Emerson Fisher DVC6200 Digital Valve Controller Specifications

-

Emerson Fisher DVC6200 Digital Valve Controller

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Instrument Shutdown

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller General Information

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Restart Control Mode

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Detailed Setup

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller

-

Kongsberg RDIO400 Remote Digital Inputs and Outputs Technical Specifications

-

Emerson CSI A6120 Enclosure Seismic Vibration Monitor Features

-

Kongsberg RL542A Radio Link Features

-

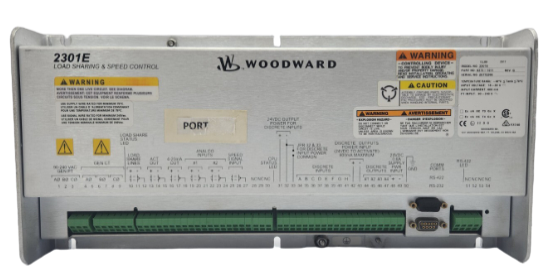

Woodward 2301E Digital Load Sharing and Speed Controller four modes of operation

-

ABB AC 800PEC High Performance Control System Modular structure

-

ABB AC 800PEC High Performance Control System Aluminium applications

-

GE IC693CMM321 Ethernet Interface Module Board Indicators

-

ABB Preventive maintenance for AF1350 ... AF2650 contactors Benefits

-

ABB DC switching contactors, type GAF A compact contactor up to 1000 V DC Features

-

Kongsberg RMP420-Remote Multipurpose Input/Output

-

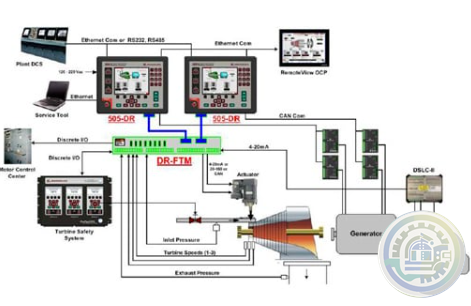

Woodward 505DR Dual Redundant Turbine Controller Control specifications

-

Woodward 505DR Dual Redundant Turbine Controller Communication

-

Woodward 505DR Dual Redundant Turbine Controller Description

-

Emerson M-Series DC to DC System Power Supplies Product Description

-

ABB M4M Network Analyser Transmission method

-

ABB FAU 810 Flame Analyser Unit Remote Monitoring

-

Honeywell 91MCE Series MICRO SWITCH Miniature Compact Limit Switches Features

-

MOOG Dual PWM Amplifier G123-814 Wiring

-

MOOG Dual PWM Amplifier G123-814 Applying this amplifier

-

Emerson A6410 Dual Channel Valve and Enclosure Expansion Monitor Features

-

Emerson A6630 Temperature Monitor Machine Monitoring System sensor types

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive main application scenarios

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive applications

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive

-

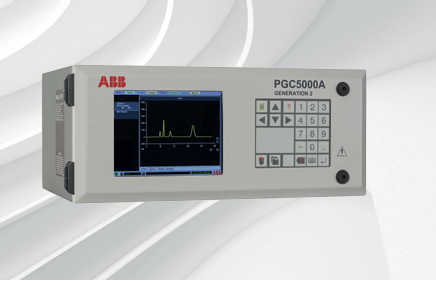

ABB PGC5000 Temperature programmed gas chromatograph Gas Control

-

ABB PGC5000 Temperature programmed gas chromatograph Safety area classification

-

ABB PGC5000 Temperature programmed gas chromatograph Introduction

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Application flexibility

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Features

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller

-

ABB Time Synchronization in PGC5000 Series Data System

-

ABB VistaSTAR with PGC5000 Version 4 Data System Interface

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

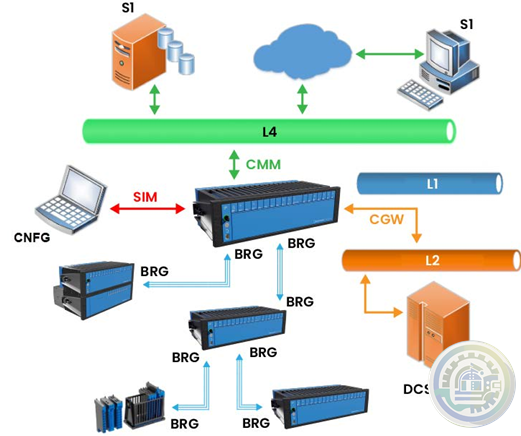

Overview

PAC8000 Hybrid Control provides a fully integrated solution for process control,

logic automation and strategy development.

PAC8000 Hybrid Control provides a process engineer with the tools to design, implement, document,

and maintain a process control system using advanced control strategies.

PAC8000 Hybrid Control consists of a number of open system components.

The PAC8000 Hybrid Workbench is an integrated development environment that centralizes and coordinates project data including instrument indexes,

control strategies (process and logic) and project management.

It configures the control logic and generates an export database to create the operator (HMI) database.

A rugged field-mountable Control Platform, consisting of the PAC8000 Hybrid controller (8521- HC-MT) and the 8000 Process I/O system.

PAC8000 Controllers are used in conventional distributed control architectures,

with the I/O modules connected directly to the Controllers.

The same I/O modules may be used in remote IO architectures.

Benefits of PAC8000 Controllers

• Controller Options PAC8000 Controllers include a Process Controller featuring DCS style function block programming,

a Logic Controller with 61131-style PLC programming, and a Hybrid Controller that provides the capabilities of both.

An RTU Controller is also available, providing DNP3 communication.

The SIL 2 SafetyNet Controller is also part of the PAC8000 family.

• I/O Modules A broad range of PAC8000 I/O modules are available to meet the needs of different applications.

All modules provide comprehensive diagnostic information.

Analog and discrete output modules are typically 8-channel, with 8-, 16- or 32-channel discrete input modules.

Up to 64 modules can be mounted on each node.

• Environmental and Hazardous Area Operation PAC8000 can go where other products cannot.

They can be field mounted and will operate under the following conditions:

• -40°C to +70°C operating range

• ISA Level G3 corrosive atmospheres • 30g shock and 5g vibration

• Class I, Division 2 and Zone 2 hazardous areas, with I/O field wiring including intrinsically safe (Exi) and increased safety (Exe) options.

Open communications

MTL Open System Technologies products are just that - open. SafetyNet nodes

communicate with one another, with standard MOST nodes, historian and asset

management packages and with HMI packages over a fault tolerant Ethernet LAN,

running at up to 100 Mbit/s.

PAC8000 delivers full-specification performance in a broad range of harsh process environment conditions; extreme

temperatures, humidity or corrosives and conditions subject to shock and vibration.

In ATEX environments, PAC8000 also excels.

All components can be installed and maintained in Zone 2/Division 2 hazardous areas.

The I/O includes modules that can be connected directly to Intrinsically Safe (Exi) or Increased Safety (Exe) field wiring.

PAC8000 provides comprehensive diagnostic data on controllers, Bus Interface Modules (BIM),

I/O modules, field wiring and field instruments, allowing users to respond to issues quickly and effectively.

Features

PAC8000 I/O is a completely modular I/O solution for both general purpose and hazardous area applications. It offers a wide variety of I/O functions, and has an open architecture that allows communication with a variety of different field-buses by selecting the appropriate type of Bus Interface Module (BIM) or Controller.

Field terminals (one per I/O module) snap onto the carrier and accept field wiring without the need for additional terminals or connections. They can be changed easily if damaged in the field. A comprehensive mechanical keying system ensures that equipment safety is maintained.

Carriers form PAC8000s physical and electrical backbone by providing a mounting onto a flat panel or T- or G-section DIN rail. They support and interconnect the BIM or Controller, power supplies, I/O modules and field terminals, and carry the address, data and power lines of the internal Railbus

Returns commoned internally

Pulse counting option

24 V dc bussed field power required

GE 8709-CA-08 I/O Carrier, 8 module with earth bar |

GE 8720-CA-04 4 module Intrinsically Safe carrier |

GE 8710-CA-04 4 module carrier |

GE 8723-CA-RB Railbus isolator carrier |

GE 8711-CA-NS Node services carrier, screw terminal LAN |

GE 8724-CA-PS Intrinsically Safe module power supply carrier |

GE 8712-CA-NS Node services carrier, Profibus-DP LAN |

GE 8725-CA-RB Railbus isolator carrier with PFM |

GE 8715-CA-BI BIM only carrier for Profibus & MODBUS LANs |

GE 8727-CA-08 8 module Intrinsically Safe carrier |

GE 8717-CA-PS Carrier for 8910-PS-DC |

GE 8729-CA-08 Intrinsically Safe Carrier, 8 module, 64-address system |

GE 8020-CE-RH R-HAND EXT. CARRIER |

GE 8044-CC-20 Carrier extension cable, 2.0m |

GE 8021-CE-LH Carrier extender, left hand |

GE 8080-FC-10 16-pin cable for 8618 (1m) |

GE 8030-CE-RH Intrinsically Safe Carrier extender, right hand |

GE 8081-FC-20 16-pin cable for 8618 (2m) |

GE 8031-CE-LH Intrinsically Safe Carrier extender, left hand |

GE 8082-FC-30 16-pin cable for 8618 (3m) |

GE 8034-CC-12 Intrinsically Safe Carrier Extension Cable set, 1.2m |

GE 8085-FC-10 20 + 24 pin cables for 8619 (1m) |

GE 8041-CC-35 Carrier extension cable, 0.35m |

GE 8086-FC-20 20 + 24 pin cables for 8619 (2m) |

GE 8042-CC-85 Carrier extension cable, 0.85m |

GE 8087-FC-30 20 + 24 pin cables for 8619 (3m) |

GE 8413-FK-DN 8913/4 PS DIN Rail Mounting Kit |

GE 8913-PS-AC 5A 12VDC & 5A 24VDC A/C Input P/S |

GE 8414-FK-SU 8913/4 PS Surface Mounting Kit |

GE 8914-PS-AC 10A 24VDC A/C Input P/S |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved