-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

A-B 4100-234-R Compact Motion Controller

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

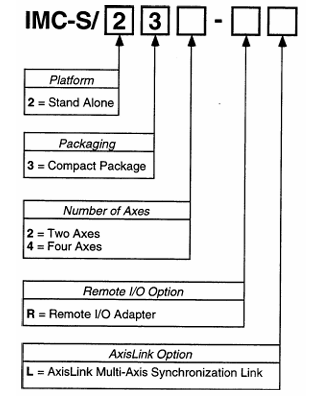

A-B IMC™ S Class Compact Motion Controllers Model Number Explanation

-

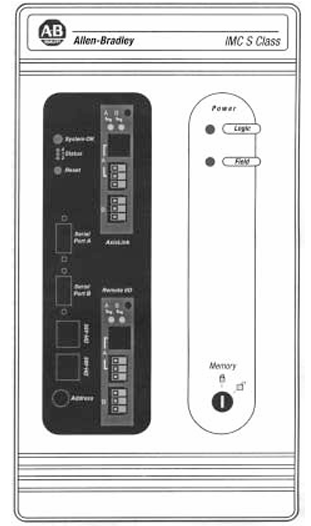

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models) Product Features

-

A-B IMC™ S Class Compact Motion Controllers (IMC-S/23x Models)

-

AIS810 ABB Ability™ System 800xA® hardware selector

-

NE810 ABB Ability™ System 800xA® hardware selector

-

ABB NE802 System 800xA hardware selector

-

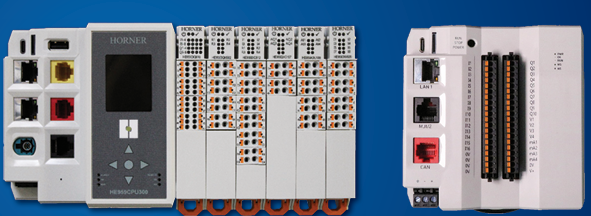

Horner OCS CPU Highly Expandable & Flexible Controller Solutions with OCS I/O Expansion

-

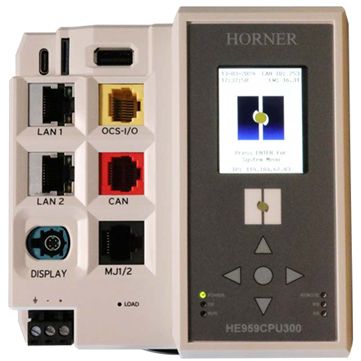

Horner CPU300 and HMI Connect Series Mounting Overview

-

Horner CPU300 and HMI Connect Series Features

-

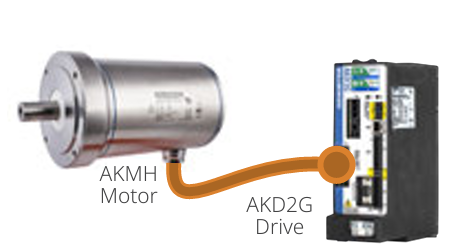

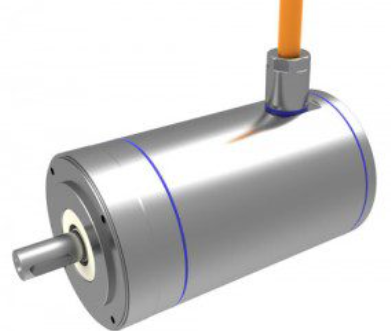

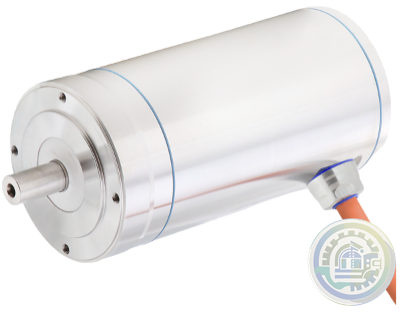

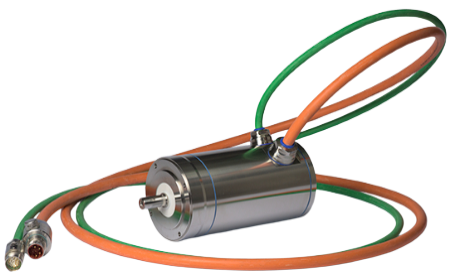

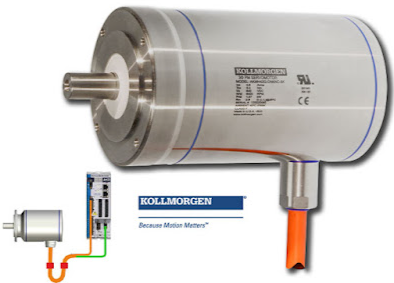

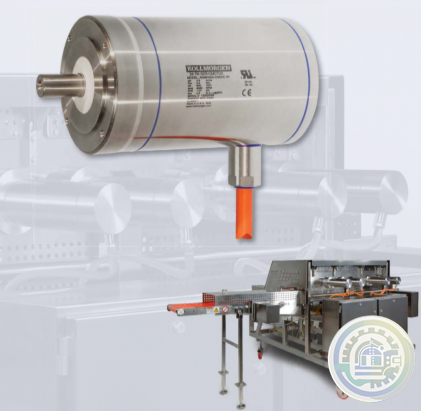

Kollmorgen AKMH™ Stainless Steel Washdown Motor Engineering Excellence

-

Kollmorgen AKMH™ Co-Engineered Solutions

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Modified Standard

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Brake Option

-

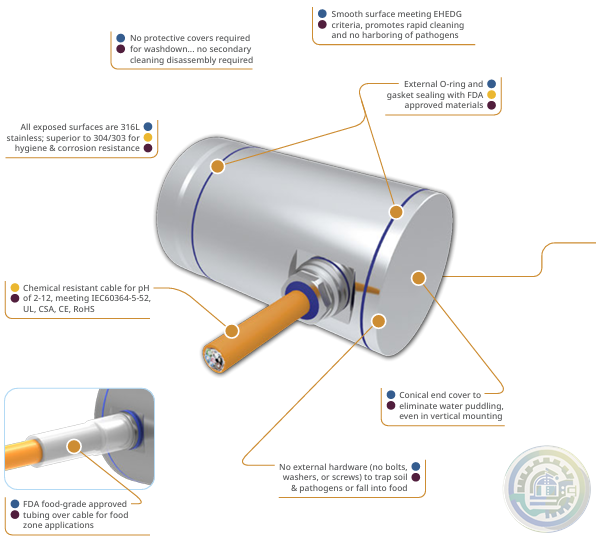

Kollmorgen AKMH™ Stainless Steel Washdown Motor Hygienic Design

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Protection Class

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Technical Guide

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Design Features

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits Highly configurable

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Benefits

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor Global Footprint

-

Kollmorgen AKMH™ Stainless Steel Washdown Motor

-

Kollmorgen AKMA™ Co-Engineered Solutions

-

Kollmorgen AKMA™ Universal Drive Solutions for Food,Beverage, and Pharmaceutical Industries

-

Kollmorgen AKMA™ Anodized Washdown Motor Features

-

Kollmorgen AKMA™ Anodized Washdown Motor Benefits

-

Kollmorgen AKMA™ Removing the Barriers of Design, Sourcing, and Time

-

Kollmorgen AKMA™ Anodized Washdown Motor

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Industry-leading

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Benefits

-

Emerson 00813-0100-0112 VersaMax Modular Input/Outputs and Controls Ease of Use

-

Emerson 00813-0100-0161 Compact Programmable Automation Controller Open communication

-

Emerson 00813-0100-0115 RXi - Industrial Monitor Designed for Visualisation

-

HIMA X-CPU 01 Processor Module Function

-

HIMA launches the fourth generation of its central module HIQuad X benefits

-

KEBA KeControl C5 - FE 560 Multi-protocol fieldbus expansion card

-

KEBA KeControl C5 - FE 571, FE 573 EtherCAT master expansion card

-

KEBA KeControl C5 - NE 551 Gbit Ethernet expansion card

-

KEBA KeDrive D3 controls – D3-DU 3x5 Control modules with built-in safety control

-

KEBA KeDrive D3 controls - D3-DU 3x0 Control modules

-

KEBA KeControl C1 Control modules

-

KEBA KeControl C5 - CP 5x0 Control modules

-

KEBA KeControl C5 - CP 50x Controls / Control units

-

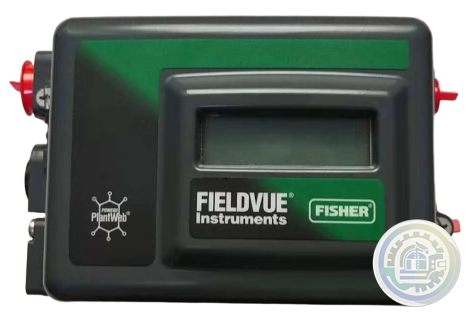

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Performance

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Value

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Features

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller

-

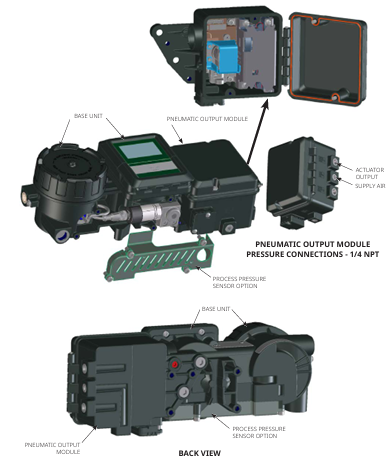

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Device Alerts

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Value

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Features

-

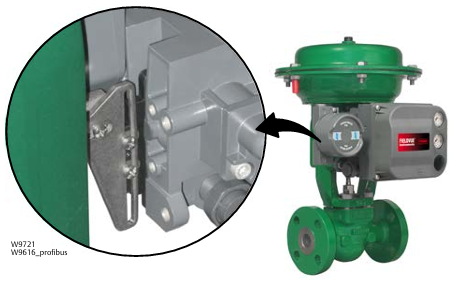

Emerson Fisher DVC6200 Digital Valve Controller Features

-

Emerson Fisher DVC6200 Digital Valve Controller Specifications

-

Emerson Fisher DVC6200 Digital Valve Controller

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Instrument Shutdown

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller General Information

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Restart Control Mode

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Detailed Setup

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller

-

Kongsberg RDIO400 Remote Digital Inputs and Outputs Technical Specifications

-

Emerson CSI A6120 Enclosure Seismic Vibration Monitor Features

-

Kongsberg RL542A Radio Link Features

-

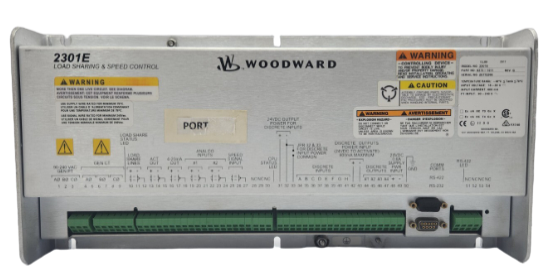

Woodward 2301E Digital Load Sharing and Speed Controller four modes of operation

-

ABB AC 800PEC High Performance Control System Modular structure

-

ABB AC 800PEC High Performance Control System Aluminium applications

-

GE IC693CMM321 Ethernet Interface Module Board Indicators

-

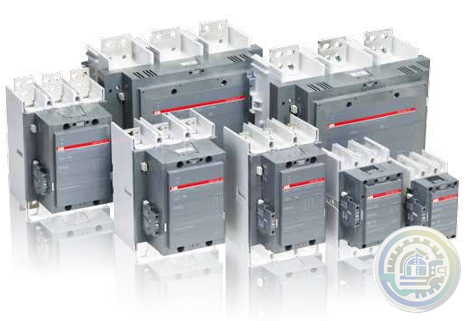

ABB Preventive maintenance for AF1350 ... AF2650 contactors Benefits

-

ABB DC switching contactors, type GAF A compact contactor up to 1000 V DC Features

-

Kongsberg RMP420-Remote Multipurpose Input/Output

-

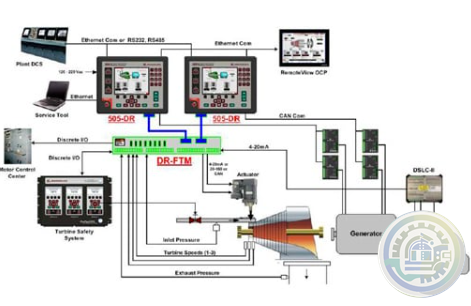

Woodward 505DR Dual Redundant Turbine Controller Control specifications

-

Woodward 505DR Dual Redundant Turbine Controller Communication

-

Woodward 505DR Dual Redundant Turbine Controller Description

-

Emerson M-Series DC to DC System Power Supplies Product Description

-

ABB M4M Network Analyser Transmission method

-

ABB FAU 810 Flame Analyser Unit Remote Monitoring

-

Honeywell 91MCE Series MICRO SWITCH Miniature Compact Limit Switches Features

-

MOOG Dual PWM Amplifier G123-814 Wiring

-

MOOG Dual PWM Amplifier G123-814 Applying this amplifier

-

Emerson A6410 Dual Channel Valve and Enclosure Expansion Monitor Features

-

Emerson A6630 Temperature Monitor Machine Monitoring System sensor types

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive main application scenarios

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive applications

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive

-

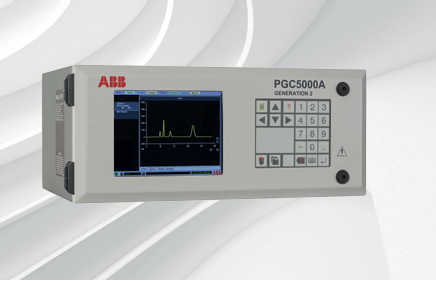

ABB PGC5000 Temperature programmed gas chromatograph Gas Control

-

ABB PGC5000 Temperature programmed gas chromatograph Safety area classification

-

ABB PGC5000 Temperature programmed gas chromatograph Introduction

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Application flexibility

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Features

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller

-

ABB Time Synchronization in PGC5000 Series Data System

-

ABB VistaSTAR with PGC5000 Version 4 Data System Interface

-

ABB PGC5000 Series gas chromatographs ATEX Directive

-

ABB PGC5000 Series gas chromatographs PGC Certification

-

ABB PGC5000 Series gas chromatographs Introduction

-

Honeywell BW™ ICON Multi-Gas Detector FEATURES AND BENEFITS

-

HONEYWELL BW™ RIGRAT Transportable Multi-gas Area Monitor FEATURES AND BENEFITS

-

HONEYWELL BW™ SOLO Repairable Single Gas Detector FEATURES

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System User Experience

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System Flexible Capabilities

-

ABB ACS800-07 (+V992) is a cabinet-mounted drive Controls of the supply unit

-

Emerson A6110 Shaft Relative Vibration Monitor Features

-

GE Multilin 489 Generator Protection System SR Series Relays features

Current Location:

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

69

Product parameters

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Feature

Bently Nevada 128015-05 - Relay Module

Introducing the Bently Nevada 128015-05, a top-of-the-line industrial monitoring and protection system designed for the power industry, petrochemical plants, and general automation applications. Known for its reliability and precision, this model is a trusted choice for engineers and maintenance professionals worldwide.

Introducing the Bently Nevada 128015-05, a top-of-the-line industrial monitoring and protection system designed for the power industry, petrochemical plants, and general automation applications. Known for its reliability and precision, this model is a trusted choice for engineers and maintenance professionals worldwide.Key Features:

1) Advanced Monitoring Capabilities: The Bently Nevada 128015-05 is equipped with state-of-the-art monitoring sensors and software that provide real-time data on machinery health and performance. This enables early detection of potential issues before they escalate into costly failures.

2) High Accuracy Vibration Analysis: With its high-resolution vibration analysis capabilities, this model can detect even the slightest changes in machinery vibration levels, allowing for proactive maintenance and minimizing downtime.

3) Flexible Configuration Options: The 128015-05 offers customizable configuration options to suit the specific needs of different industrial environments. Users can easily adjust parameters and set alerts based on their unique monitoring requirements.

4) Remote Monitoring and Diagnostics: This model comes with remote monitoring capabilities, allowing users to access critical data and diagnostics from anywhere in the world. This feature is especially beneficial for companies with multiple facilities or remote operations.

5) Easy Integration: The Bently Nevada 128015-05 seamlessly integrates with existing industrial control systems, making it a cost-effective solution for upgrading monitoring capabilities without the need for a complete system overhaul.

Typical Usage Scenarios:

1) Power Industry: The 128015-05 is widely used in power plants to monitor turbines, generators, and other key equipment. Its advanced monitoring capabilities help ensure uninterrupted power generation and prevent costly downtime.

2) Petrochemical Plants: In petrochemical plants, this model is used to monitor pumps, compressors, and other critical machinery to ensure safe and efficient operation. Early detection of equipment issues can prevent accidents and environmental hazards.

3) General Automation: The 128015-05 is also suitable for general automation applications, such as manufacturing facilities and industrial processes. Its high accuracy vibration analysis helps optimize production efficiency and maintain equipment reliability.

Basic Advantages:

1) Prevents Costly Downtime: Early detection of equipment issues allows for timely maintenance, reducing the risk of unexpected breakdowns and costly downtime.

2) Increases Equipment Reliability: The Bently Nevada 128015-05 helps extend the lifespan of machinery by providing continuous monitoring and proactive maintenance.

3) Enhances Safety: By monitoring critical equipment parameters, this model helps prevent accidents and ensures a safe working environment for personnel.

Related Models:

1) Bently Nevada 126615-01

2) Bently Nevada 129529-0025-01

3) Bently Nevada 135137-01

4) Bently Nevada 133388-02

5) Bently Nevada 149716-01

6) Bently Nevada 3500/40-03-01

7) Bently Nevada 140734-02

8) Bently Nevada 3500/45-03-00

9) Bently Nevada 128702-01

10) Bently Nevada 129525-0100-02

In conclusion, the Bently Nevada 128015-05 is a reliable and advanced monitoring system designed to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. With its high accuracy vibration analysis, remote monitoring capabilities, and customizable configuration options, this model is a valuable asset for ensuring equipment reliability, safety, and efficiency in industrial settings.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

69

How to install and debug this product? Matters needing attention

Open the manual and programming software, use the new version, upload the data and programs, save the computer, continue downloading! For details, please consult the technical service provider!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Where can I download the manual and programming software?

Product official website, official hotline and contact sales or technical engineers.

Is it in stock or need to be ordered?

There will generally be inventory, but it does not rule out that the website inventory has been sold and not updated. Please consult customer service.

Can you provide technical service?

Need to see the product type and site conditions, equipment damage, humanities and other factors, please inform us, we will provide you with a suggestion!

Where can I order this series?

Please see the contact information of the website, official channels, and consulting customer service! Thank you for your cooperation!

Do you have product selection list and pre-sale service?

It can be downloaded from local agents, technical service companies, and the official website (pdf). Some special products are excluded. Please contact us as appropriate.

Let's Communicate

Call the enterprise hotline customer service consultant is waiting for you online

wechat/whatsapp:

+86-181-4410-0983

Contact Business

Talk to a customer service consultant now about what you need to know

Positive message

Leave us a message and a customer service consultant will contact you within 24 hours

Wechat

Whatsapp

Email: kongjiangauto@163.com

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved