-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

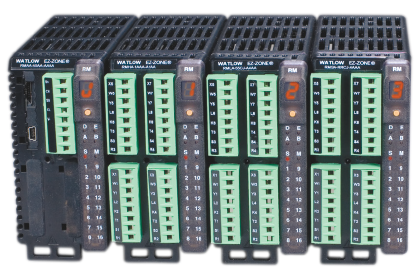

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

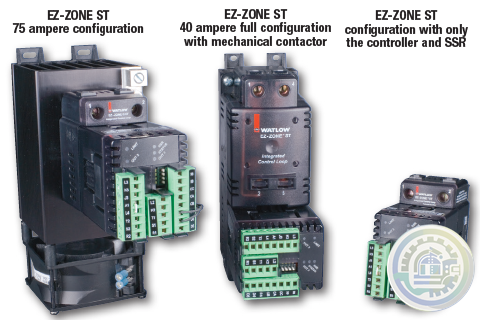

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

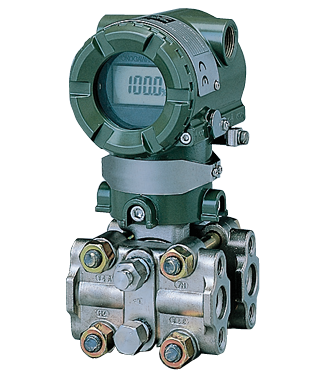

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

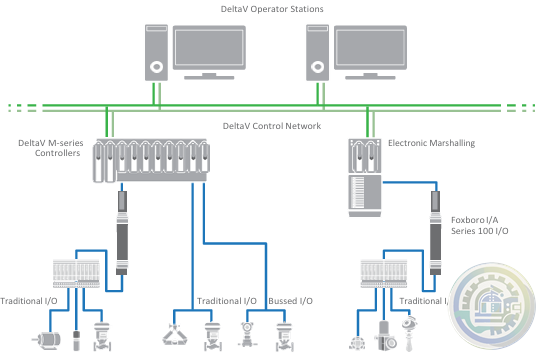

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

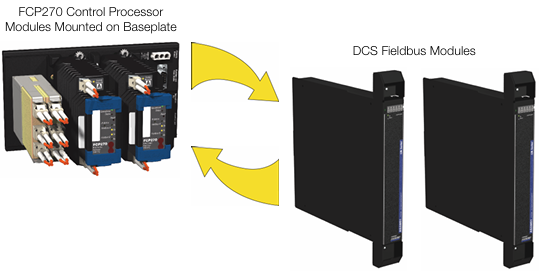

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

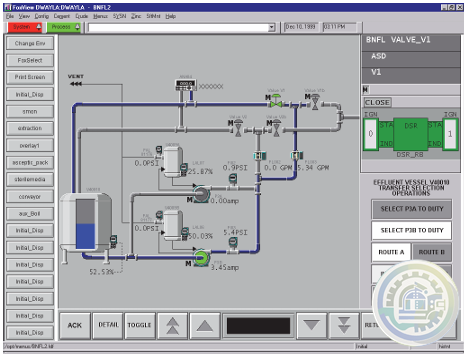

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

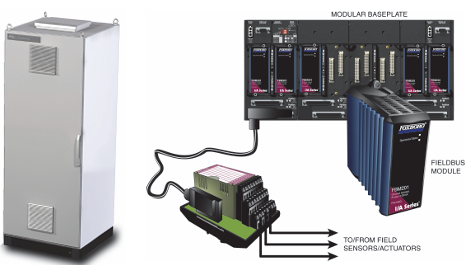

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

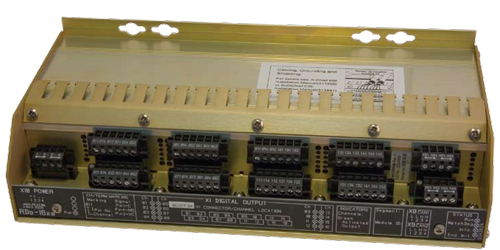

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

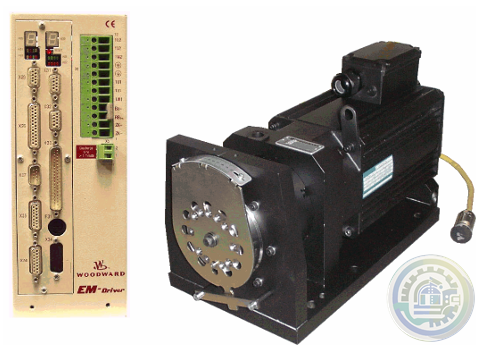

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

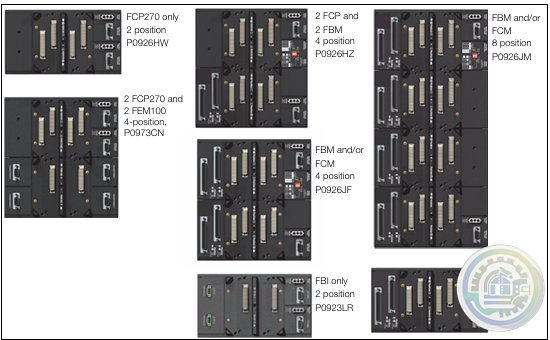

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

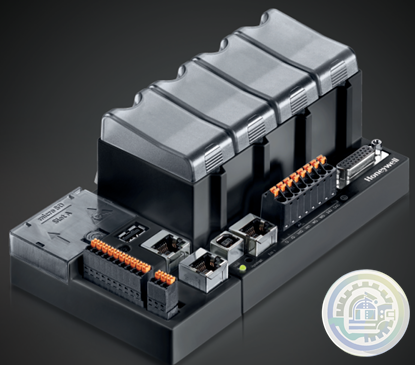

Honeywell ControlEdge™ PLC Modular Controllers

-

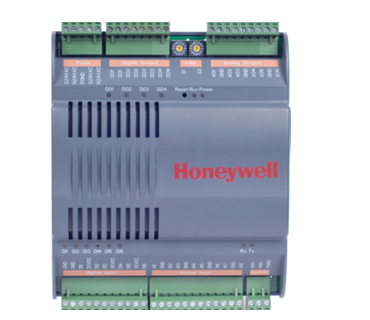

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

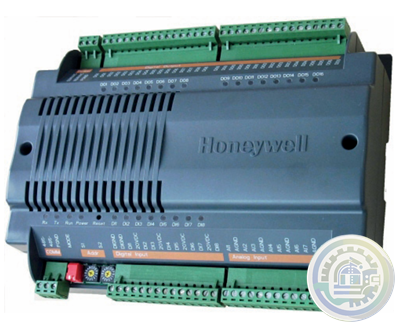

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

-

Honeywell E3Point Gas Detector

-

Honeywell 301C Controller

-

Honeywell 301IRF Refrigerant Gas Detector

-

Honeywell 301EM-20 Controller

-

Honeywell Series 3000 MkII

-

Honeywell XNX™ Universal Transmitter

-

Honeywell XNX Universal Transmitter

-

Honeywell MicroDock II Automatic Test and Calibration Station

-

Honeywell GasAlertMicro 5 Series Multi-Gas (1–5) Detectors

-

Honeywell GasAlertMax XT II Multi-Gas (1–4) Detector

-

Honeywell GasAlertQuattro Multi-Gas (1–4) Detector

-

Honeywell BW Clip4 Multi-Gas (4) Detector

-

Honeywell BW™ MicroClip Series Multi-gas detectors

-

Honeywell GasAlertMicroClip Series Multi-Gas (1–4) Detector

-

Honeywell GasAlert Extreme Single-Gas Detector

-

Honeywell IntelliDoX Automated instrument management system

-

Honeywell BW Clip Series Single-Gas Detectors

-

Honeywell GasAlertMicro 5 Series multi-gas detectors

-

Honeywell GasAlert Extreme single gas detector

-

Honeywell GasAlertMax XT II

-

Honeywell MicroDock II Automated Instrument Docking Station

-

Honeywell BW™ Max XT II Multi-Gas Detector

-

Honeywell QRAE 3 Wireless 4-Gas Monitor

-

Honeywell BW™ Max XT II Multi Gas Detector

-

Honeywell Satellite XT

-

Honeywell WEB-8000 Controller

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Application programming is done on the PCM112 using Woodward's MotoHawk application software tool.

MotoHawk is a rapid control system development tool that allows control engineers to quickly create control software directly in Simulink diagrams.

The software runs on any electronic control module that supports MotoHawk.

Working directly in the Simulink environment, application developers can convert application models

into files that can be programmed directly into Woodward production hardware in a single build step.

MotoHawk provides an advanced programming environment for users with control system expertise

but not necessarily specific embedded programming skills.

Once an application has been generated and loaded into the PCM112 controller via the CAN port, the

users can view variables and tune the controller using appropriate service interface tools such as Woodward's ToolKit or MotoTune.

Connections to other devices (such as diagnostic tools) are accomplished through other CAN ports available on the controller.

The required information flow is programmed into the controller via MotoTune or ToolKit.

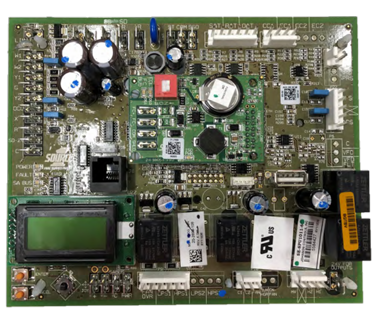

The PCM112 controller consists of a rigid printed circuit board that is attached to an aluminum enclosure

using thermally conductive adhesive and then closed and sealed with an aluminum cover.

For redundant operation, the control can use any combination of power supplies.

The power supplies can only be installed into slots PS1 (power supply #1) and PS2 (power supply #2). If

redundant power supplies are not needed, blanking plates must be installed in the slots not being used.

Branch circuit fuses, circuit breakers, and wiring must meet appropriate codes and authorities having

jurisdiction for the specific country (CE, UL, etc.). See Table 4-3 for maximum recommended fuse or

breaker ratings. Do not connect more than one main power supply to any one fuse or circuit breaker. Use

only the wire sizes specified in Table 4-3. which meet local code requirements. Time delay fuses or circuit

breakers must be used to prevent nuisance trips.

In the event that on supply needs to be replaced, the recommended method for changing

Power Modules is with the power off (to the module being removed and the module being inserted).

The system will tolerate this “cold swap” method without failure.

Woodward THICK DROP, 7/8' MALE TO PIGTAIL, (3M) 5417-1119

Woodward THICK DROP, 7/8" MALE TO PIGTAIL, (6M) 5417-1281

Woodward MICRONET DROP, M12 FEMALE TO 7/8' MALE, (0.5M) 5417-1120

Woodward MICRONET DROP, 7/8' MALE TO M12 FEMALE, (1M) 5417-1127

Woodward MICRONET DROP, 7/8' MALE TO M12 FEMALE, (2M) 5417-1128

Woodward MICRONET DROP, 7/8" MALE TO M12 FEMALE, (3M) 5417-1245

Woodward MID DROP, 7/8' MALE TO PIGTAIL, (1M) 5417-1142

Woodward MID DROP, 7/8' MALE TO PIGTAIL, (2M) 5417-1143

Woodward MID TRUNK CABLE (0.5M) 5417-1145

Woodward MID TRUNK CABLE (6M) 5417-1150

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

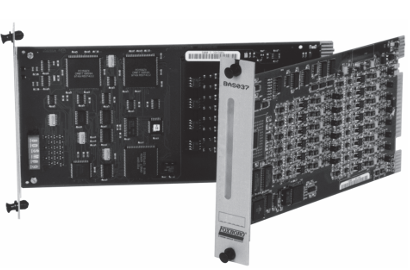

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved