-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

A-B 1794-IN106 Input/Output Analog Modules

-

General Electric 029.381208 Converteam Controller Module

-

Eaton XIOC-BP-3 Moeller 3-Signal Module Backplane

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

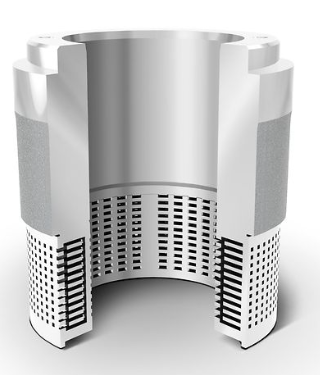

Emerson Fisher™ Whisper Trim™ I Cage

-

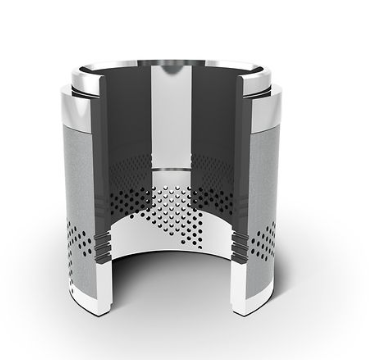

Emerson Fisher™ Whisper Trim™ III Cage

-

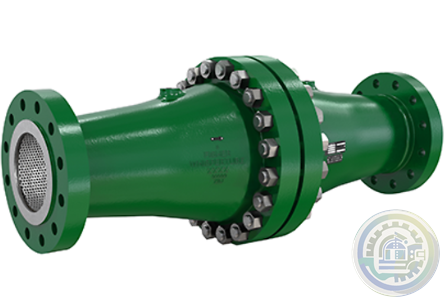

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

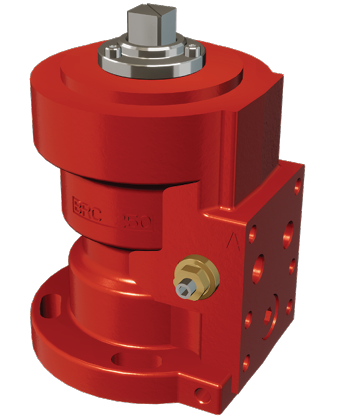

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

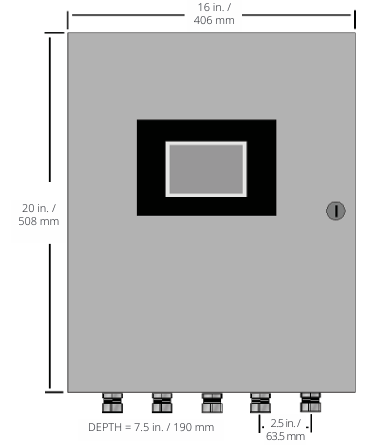

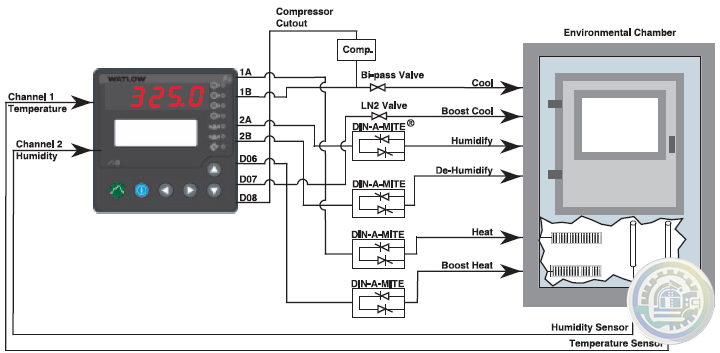

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

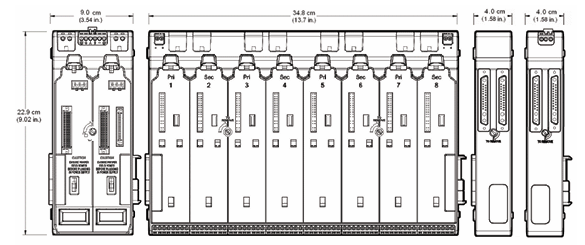

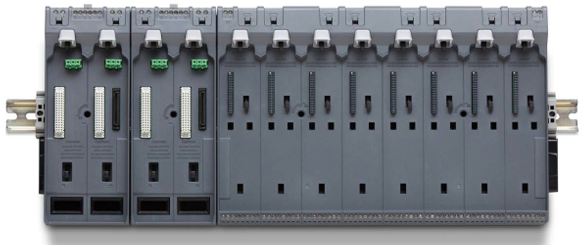

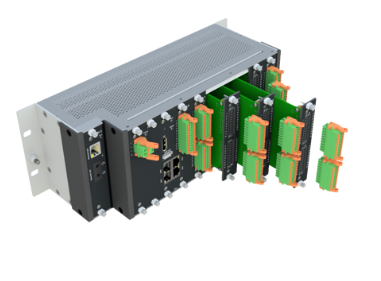

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

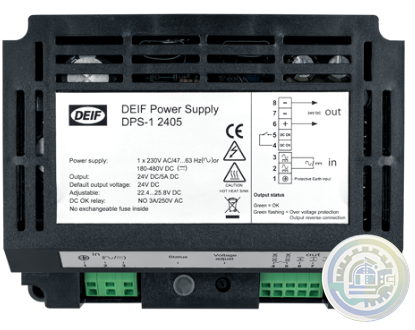

DEIF DPS-1 DC Power Supply

-

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

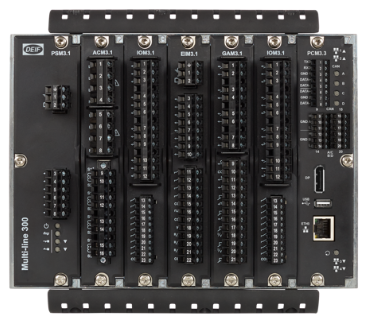

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

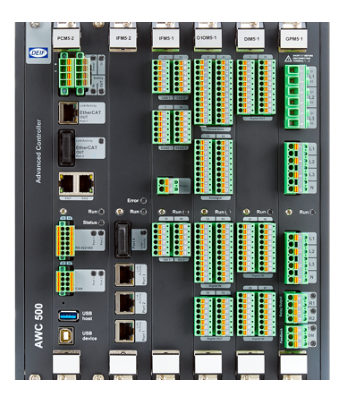

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

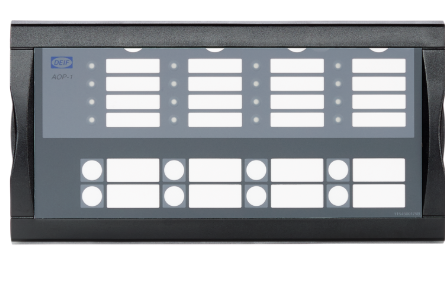

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

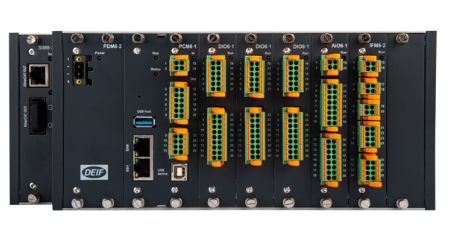

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

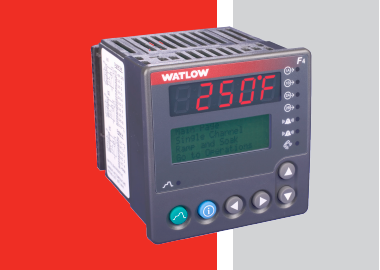

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

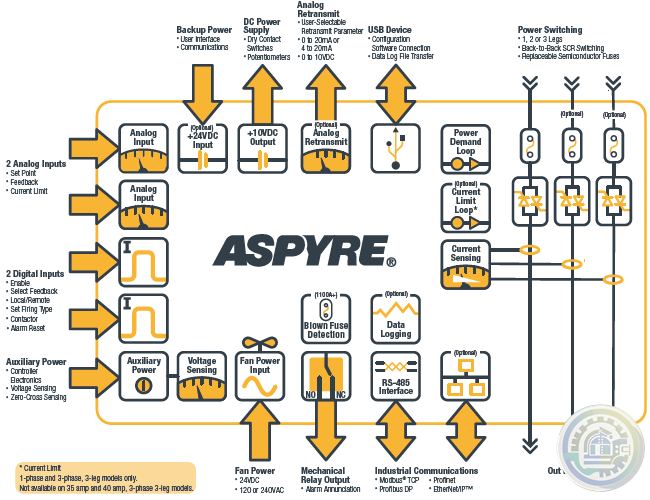

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

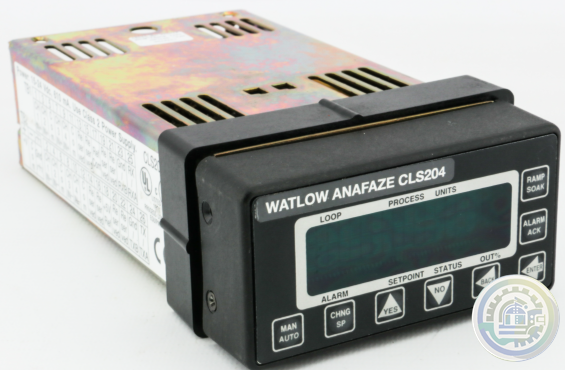

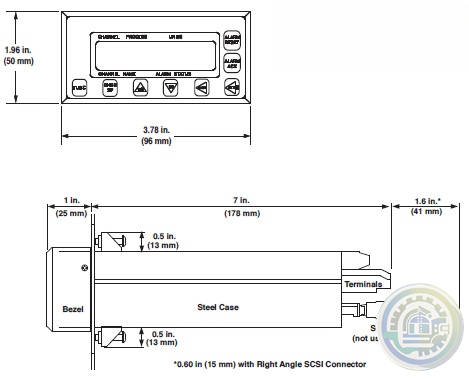

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

-

MOOG G123-825-001 Buffer Amplifier

-

Emerson AMS 3120 Bearing-Vibration Monitor

-

ABB SPC800VK01 Ability™ Symphony® Plus Hardware Selector

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

Barrel Control

Select barrel control for multiple–zone applications in which there is

thermal conduction between the zones. Injection molding and

extrusion are good example applications because they use multiple

heater bands (zones) mounted on one thermal conductor (the metal

barrel). The barrel conducts heat between different zones. If you

select barrel control, also select between inner and outer zones (word

1, bit 13 for channel 1). A barrel loop is autotuned as the temperature

rises from a cold start to a temperature setpoint during startup.

Non–barrel control

Select non–barrel control for applications with independent loops and

no thermal conduction between zones. If you select non–barrel

control, the inner/outer zone selection doesn’t apply.

Switching the barrel control

For some applications, even though the loops are independent with

no thermal conduction between zones, barrel control might provide

better performance than non–barrel control. If a loop has any of these

characteristics, you might want to use barrel control if the:

• time constant is greater than 10 - 30 seconds

• loop has a problem of overshooting the setpoint

• loop output is saturating (CV is at 100%) for a significant duration

Output response

When the slot for this module is disabled, configuration words in the

SLC processor’s output image table are held in their last state and not

transferred to the module. When the slot is re–enabled, output image

table words are transferred to the module during the subsequent scan.

Installing and Wiring

This document gives you information about:

• avoiding electrostatic damage

• compliance with European Union directive

• determining the module’s chassis power requirement

• planning for sufficient enclosure depth

• choosing a module slot in a local I/O chassis

• installing the module

• wiring the module

TC Break Control

Word 4 or O:e.8 for Channel1

If a loop input circuit becomes open (open wire) the loop can not

measure temperature. In automatic mode, the lack of temperature

feedback makes it impossible to control the temperature. To guard

against this condition, the BTM module provides TC break detection.

When a break is detected, the module responds in one of these ways:

• disables the loop

• forces CV to this (TC Break Control) value (word 4 for loop 1)

• forces the CV to the manual %–output value (O:e.8 for loop 1)

Once the thermocouple break has been repaired you must disable the

loop and then re-enable it (through the input image table O:e.0/0 loop 1).

Module Addressing

When you enter the module ID in processor configuration (off-line),

the processor automatically reserves the required number of I/O

image table words. In the figure below, that section of the I/O image

table is designated by “slot e”. Its location in the I/O image table is

determined by the module’s slot location “e” in the I/O chassis. Slot

location “e” is a required addressing unit when referring to the

module in ladder logic. For the sample program’s data table layout

A-B | 1746-FIO4I module Rockwell SLC analog combination |

A-B | 1746-FIO4V module Rockwell SLC analog combination |

A-B | 1746-HCA Module MOT Module Cable Communication Test |

A-B | 1746-HSCE Module Rockwell SLC Analog Combo |

A-B | 1746-HSCE2 Module Rockwell SLC Analog Combination |

A-B | 1746-HSTP1 Module Rockwell SLC 1 Axis Module |

A-B | 1746-IA16 module Rockwell SLC 16 digital input |

A-B | 1746-IA4 Module Rockwell SLC 4 Digital Inputs |

A-B | 1746-IA8 Module Rockwell SLC 8 digital inputs |

A-B | 1746-IB16 module Rockwell SLC 16 digital input |

A-B | 1746-IB32 module Rockwell SLC 32 digital input |

A-B | 1746-IB8 Module Rockwell SLC 8 digital inputs |

A-B | 1746-IC16 module Rockwell SLC 16 digital input |

A-B | 1746-IG16 Module Rockwell SLC 16 Digital Inputs |

A-B | 1746-IH16 module Rockwell SLC 16 digital input |

A-B | 1746-IM16 module Rockwell SLC 16-point digital input |

A-B | 1746-IM4 Module Rockwell SLC 4 digital inputs |

A-B | 1746-IM8 module Rockwell SLC 8 digital inputs |

A-B | 1746-IN16 Module Rockwell SLC 16-point digital input |

A-B | 1746-INT4 Module Rockwell SLC 4-Point Thermocouple |

A-B | 1746-IO12 Module Rockwell SLC 12 Point Combo |

A-B | 1746-IO12DC Module Rockwell SLC 12 Point Combo |

A-B | 1746-IO4 Module Rockwell SLC 4 Point Combo |

A-B | 1746-IO8 Module Rockwell SLC 8 Point Combo |

A-B | 1746-ITB16 module Rockwell SLC 16 digital input |

A-B | 1746-ITV16 module Rockwell SLC 16 digital input |

A-B | 1746-IV16 Module Rockwell SLC 16 Digital Inputs |

A-B | 1746-IV32 Module Rockwell SLC 32 Digital Inputs |

A-B | 1746-IV8 Module Rockwell SLC 8 Digital Inputs |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

-

Vibro-meter VM600-ABE042 204-042-100-011 Precision Control Module

-

Vibro-meter vmf-MPC4 200-510-111-034 200-510-070-113 Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved