ABB A future-proof approach to modernizing industrial automation

Executive summary

Aging automation systems pose significant challenges for industrial plant managers

due to their inability to keep up with technological advancements, leading to inefficiencies,

increased unplanned maintenance costs, and heightened risk of compliance issues.

Traditionally, upgrading these systems involved a costly and disruptive "rip and replace" approach.

However, a more sustainable and cost-effective strategy is now available through modular, phased

upgrades, emphasizing minimal operational disruption.

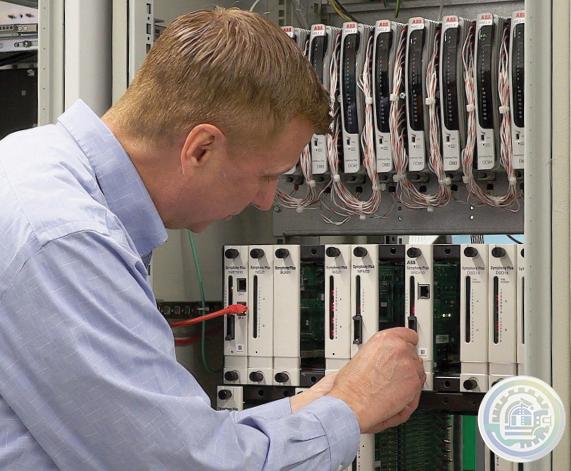

ABB Ability Symphony Plus SDe introduces a space-fit solution that allows for incremental, in

place upgrades. This method retains existing infrastructure such as cabinets, cables, and field

wiring, significantly reducing downtime and environmental impact by minimizing hardware

waste. The focus is on replacing or upgrading only the components that add direct value, such as

controllers and I/O modules, which also helps in reducing power consumption and enhancing

energy efficiency.

The transition to a modern Ethernet-based communication backbone in place of proprietary

systems further future-proofs plants, facilitating easier upgrades and integration with other

enterprise systems. This network-centric approach allows for more flexible and scalable plant

operations, adapting to changing needs without extensive re-engineering.

By adopting these innovative solutions, industrial plants achieve a more manageable and cost-

effective upgrade process, maintaining control over their life cycle planning, minimizing risks, and

ensuring continuous improvement in operational efficiency and compliance. This strategy not only

protects the plants' investments in automation but also aligns with broader sustainability and

efficiency goals.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

Johnson Controls Simplex S2081-0006 Battery and Battery Cabinet Reference for 4100ES

-

Johnson Controls Simplex 4100-1273 Phone Class A Adapter Module

-

Johnson Controls Simplex 4100-1272 Phone Module with 3 Class B phone NACs

-

Johnson Controls Simplex 4100-1271 Remote Master Telephone

-

Johnson Controls Simplex 4100-1255 3-8 Channel Operator Interface Modules

-

4100-1254 2 Channel (full audio)

-

Johnson Controls Simplex 4100-1253 1.5 Channel (audio + mike)

-

Johnson Controls Simplex 4100-1252 1 Channel (audio or mike)

-

Johnson Controls Simplex 4100-1244 Remote Microphone (mike) Module

-

Johnson Controls Simplex 4100-1292 Panel Mounted LCD Annunciator

-

Johnson Controls Simplex 4100-9611 Basic Remote Annunciator Panel

-

Johnson Controls Simplex 4100-9610 Remote Annunciator Panel

-

Johnson Controls 4100-5102 Simplex 4100-5102 Expansion Power Supply

-

Johnson Controls WRG1830/ZFR183x Pro Wireless Field Bus System

-

Johnson Controls FX-ZFR1810-0 Temperature Sensors

-

Johnson Controls MS-FIT100-0 Field Inspection Tool

-

Johnson Controls ACC-TBKPWFCSA-0 Power, FC Bus, and SA Bus terminal block replacement kit

-

Johnson Controls ACC-TBKINOUT-0 Input and Output terminal block replacement kit

-

Johnson Controls FX-PCA4911-0 28-Point PCA with Integral Real-Time Clock, 24 VAC

-

ACC-USBLON-0 | Johnson Controls | SNx Accessories

-

LC-ATC1510-0 | Johnson Controls | 15-points Advanced Terminal unit Controller

-

Johnson Controls ZFR-HPSST-0 Wireless System Survey Tool

-

Johnson Controls WRZ-SST-120 Wireless System Survey Tool

-

Johnson Controls WRZ-7860-0 Thermostat

-

Johnson Controls NS-WALLPLATE-0 Network Sensor Wall Plate

-

Johnson Controls AS-CBLTSTAT-0 Cable adapter for connection to 8-pin TE-6700 Series sensors

-

Johnson Controls FX-DIS1710-0 Local Controller Display

-

Johnson Controls F4-CGM09090-0 18-point General Purpose Application MS/TP Controller

-

Johnson Controls F4-CGM04060-0 10-point General Purpose Application MS/TP Controller

-

Baldor KPD-TS12C-30E 12.1" color TFT touch screen with serial interface and Ethernet

-

Baldor KPD-TS10C-30E 10" color TFT touch screen with serial interface and Ethernet

-

Baldor KPD-TS05C-30E 5.6" color TFT touch screen with serial interface and Ethernet

-

Baldor KPD-TS05C-30 5.6" color TFT touch screen with serial interface

-

Baldor KPD-TS05M-10 5.6" monochrome touch screen with serial interface

-

Baldor KPD-TS03M-10 3.9" monochrome touch screen with serial interface

-

Baldor KPD-KG420-30 4x20 character/graphic display, 12 function keys, serial interface

-

Baldor KPD-KG420-20 4x20 character/graphic display, serial interface

-

Honeywell MS-1030H-BT Microset Intelligent Wall Sensor

-

Honeywell FLEX001WBRC7S1 FLEX Room Monitor

-

Honeywell AWM92200V Airflow Sensors

-

Honeywell AWM92100V Airflow Sensors

-

Honeywell MCSP-A Digital Current Sensor

-

Honeywell CTP-10-050-VDC-001 Analog Current Sensor

-

Honeywell P7640A1034 Differential Air Pressure Transducer

-

Honeywell TR40-H-CO2 Sylk Wall Module Sensor

-

Honeywell TR40-CO2 Sylk Wall Module Sensor

-

Honeywell TR40-H Sylk Wall Module Sensor

-

Honeywell TR40 Sylk Wall Module Sensor

-

Honeywell C7041F2006 20K Temperature Sensor

-

Honeywell C7041R2018 20K Temperature Sensor

-

Honeywell C7041R2000 20K Temperature Sensor

-

Honeywell C7041J2007 20K Temperature Sensor

-

Honeywell C7041B2013/U20K Temperature Sensor

-

Honeywell C7770A1040/U 20K Temperature Sensor

-

Honeywell C7041B2005/U 20K Temperature Sensor

-

Honeywell 50053060-001 Duct Mount Sensor Offset bracket

-

Honeywell C7250A1001 20K Duct Mount, Outdoor Temperature Sensor

-

Honeywell C7400S1000 Duct Mount Temperature

-

Honeywell STRN-CRK-01 Crank Arm Kit for Direct Coupled Actuator

-

Honeywell MS7503A2030 Economizer Actuator, Direct Coupled

-

Honeywell M7215A1008 Economizer Actuator

-

Honeywell 209541B FTT Network Termination Device

-

Honeywell WPM-8000 LCBS Gateway

-

Honeywell LGW1000 LCBS Gateway

-

Honeywell YCRL6438SR1000 LCBS Controller

-

Honeywell WRECVR Receiver only

-

Honeywell TR23-WS Wireless sensor only

-

Honeywell TR21-WS Wireless sensor only

-

Honeywell TR23-WK Wireless sensor/receiver kit with override/knob setpoint

-

Honeywell TR21-WK Wireless sensor/receiver kit

-

Honeywell CC-PWRB01 24 Vdc, 20 A fully redundant Power Supply

-

Honeywell CC-PWRR01 24 Vdc, 20 A fully redundant Power Supply

-

Honeywell CC-PWRN01 Power Supply

-

Honeywell CC-MCAR01 IOTA Channel

-

Honeywell CC-MCHN01 Aluminum channels that provide a mounting medium for the IOTA Channel

-

ABB FGM1190-97 With vertical female thread connection

-

ABB FGM1190-98 With flanged connection in accordance with DIN or ASME

-

ABB FGM1190-87 With pipe fitting in accordance with DIN 2950

-

Bently TTL70259 LEMO-BNCTTLTach/Keyphasorcable

-

Bently MAGF0104 Accelerometermagneticbase

-

Bently DCCA0041 DCcaradapter

-

Bently CABU0213 USBdatatransfercable

-

Bently ACCL0561 Right-angledaccelerometer

-

Bently ACCL0547 Straightaccelerometer

-

Bently 108M4049-02 SCOUTprogrammedUSBthumbdrive

-

Bently 108M3240 SCOUT140-Exfour-channelportable datacollector

-

Bently 100M5828 SCOUT/Vb Series Hard Case

-

Bently VBMR0222 Stainless safety rings (1 pair)

-

Bently DTC70262 Neoprene dust cover

-

Bently BATT0575 Battery pack ATEX

-

Bently MAGM0064 Accelerometer magnetic base Male connection

-

Bently KTTC0331 Triaxial sensor kit

-

Bently AP3500S2-Z1 Low frequency accelerometer

-

Bently AP3500T2-Z1 Low frequency accelerometer

-

Bently AM3100T2-Z2 General purpose accelerometer

-

Bently AS3100S2-Z2 General purpose accelerometer

-

Bently SUNW0401 Network upgrade

-

Bently CLK20399 Aditional L2 user activation

-

Bently DGLU0219 Dongle for software seat or license mobility

-

Bently 3071/01 System 1 software

-

Bently 108M4069 Laser TachZone 2 rated

-

Bently 108M4067 Arpl15 Oring

-

Bently 108M4066 Circlips-20Mm Stainless

-

Bently 108M4064 Laser Tacho Holder

-

Bently CBBLO026 Carrying casefor the kit

-

Bently CB5R0025 Sensor Cable Five meters, red

-

Bently CB5G0024 Sensor CableFive meters,green

-

Bently MAGA0063 Laser magneticstand

-

Bently CBL50216 Laser cable Five meters

-

Bently 113M5529-01 Reflective tapeOne roll, 60 cm

-

Bently LASA0315 LaserZone 2 rated

-

Bently 110M8172-012 LEMO-BNC TTLTach/Keyphasor cable

-

Bently 108M4045 SCOUT quick start guide

-

Bently PLEU0229 Europe - Category Cpower plug

-

Bently PLHK0245 Hong Kong/UK Category-G power plug

-

Bently PLAU0228 Australia/New Zealand /China - Category Mpower plug

-

Bently PLSAO241 South Africa/India -Category D power plug

-

Bently PLUS0230 USA/Canada - CategoryA power plug

-

Bently 109M2384-01 Neck strap with SensorKeeper

-

Bently MVBX0250 Reference_Guide

-

Bently 113M5585 Accelerometermagnetic base

-

Bently CBVB0032 carrying bag

-

Bently CBTB0278 SCOUT instrument

-

Bently CBCC0027 or138M7748 Triple BNC adapter

-

Bently CABUO213 Transducer cable

-

Bently 110M8172-012 USB data transfer cable

-

Bently CABB0560 BNC to BNC Cable,1meter

-

Bently 108M4044 AC power adapter

wechat/whatsapp:

Email: kongjiangauto@163.com

-

ABB FGM1190-97 With vertical female thread connection

-

ABB FGM1190-98 With flanged connection in accordance with DIN or ASME

-

ABB FGM1190-87 With pipe fitting in accordance with DIN 2950

-

ABB DRIVEMONITOR VERSION 4000 DRIVE MODULE RBOX316-ABB-00

-

ABB VACUUM CONTACTOR VSC7 SCO IEC 60470 400A 3POLE 220-250V 50/60Hz

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved