-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

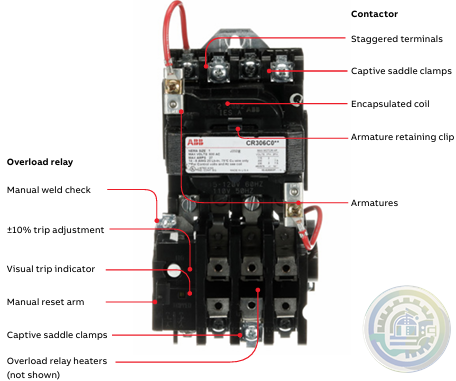

ABB REF610B11LCNP Feeder Protection and Control

-

A-B 1794-IN106 Input/Output Analog Modules

-

General Electric 029.381208 Converteam Controller Module

-

Eaton XIOC-BP-3 Moeller 3-Signal Module Backplane

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

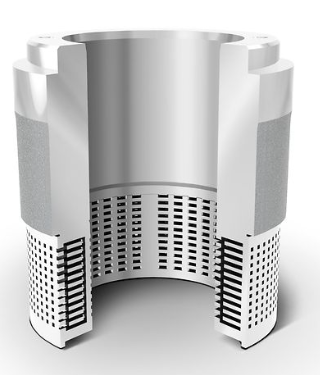

Emerson Fisher™ Whisper Trim™ I Cage

-

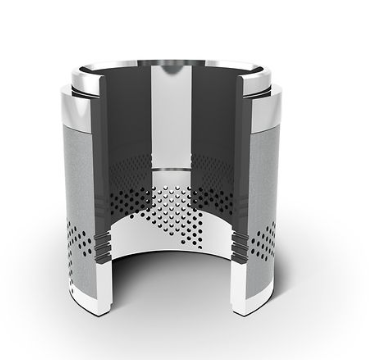

Emerson Fisher™ Whisper Trim™ III Cage

-

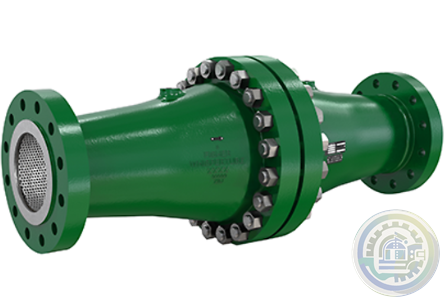

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

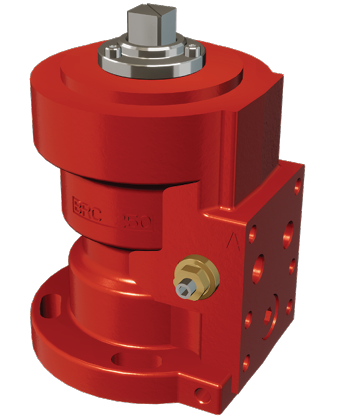

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

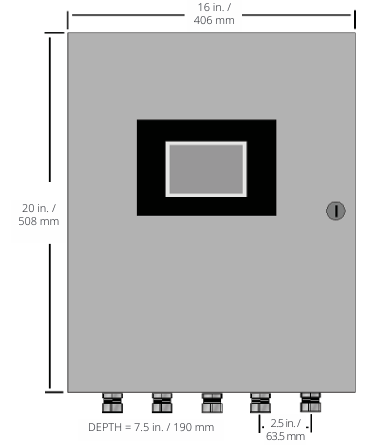

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

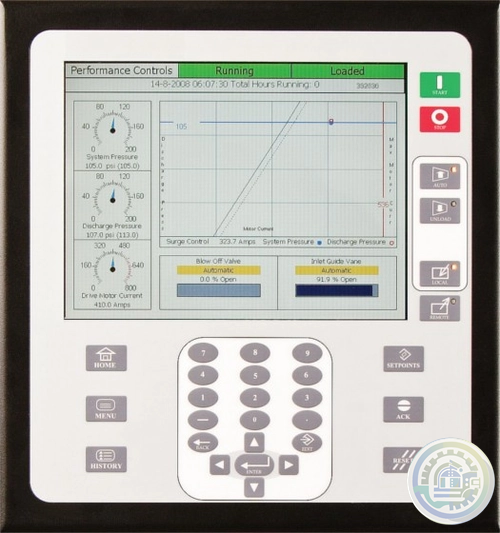

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

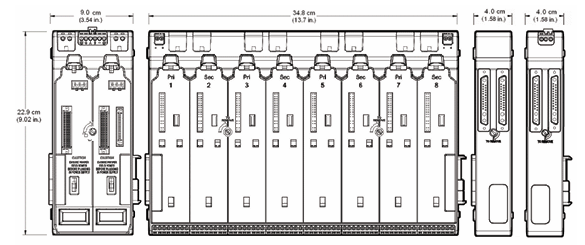

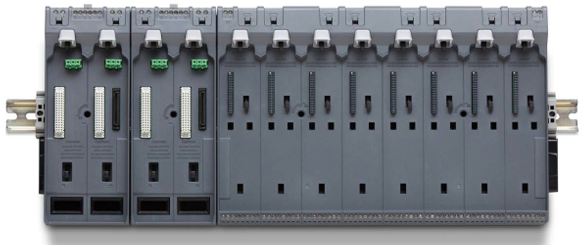

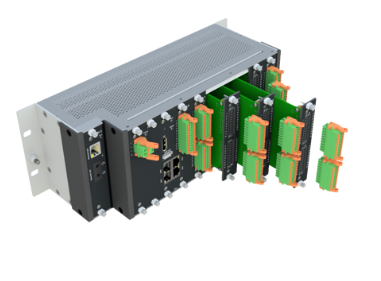

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

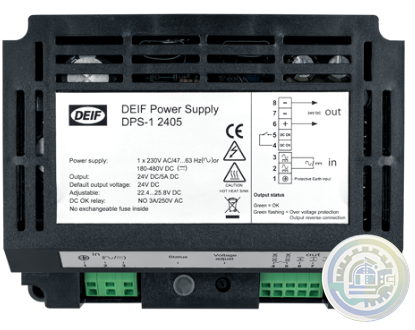

DEIF DPS-1 DC Power Supply

-

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

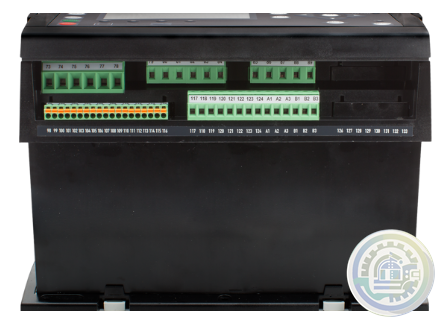

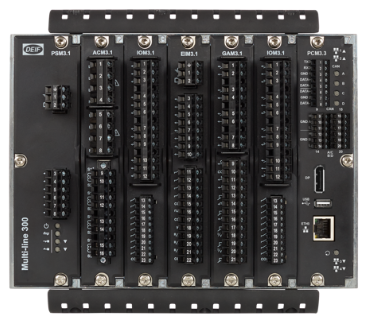

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

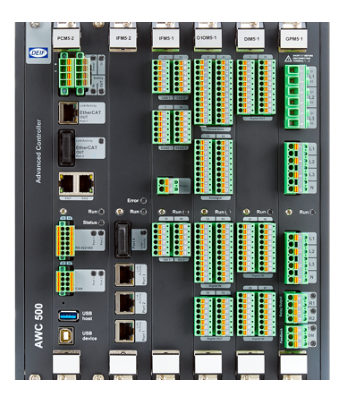

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

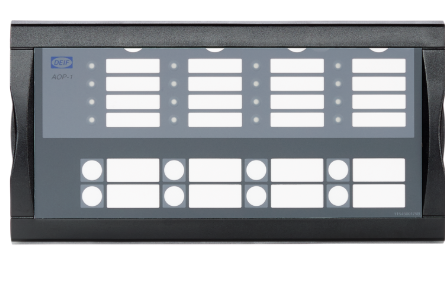

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

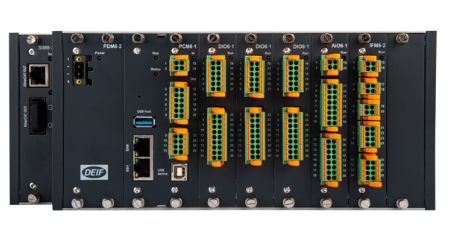

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

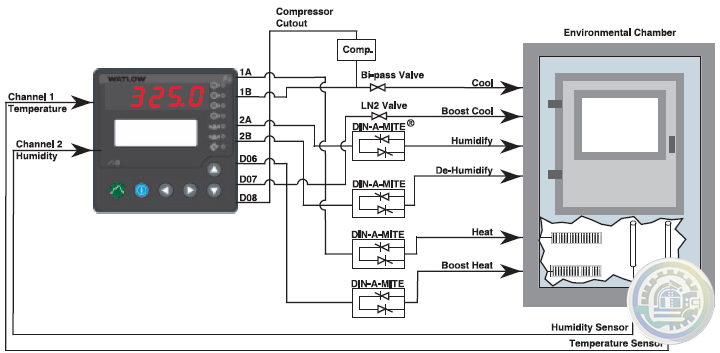

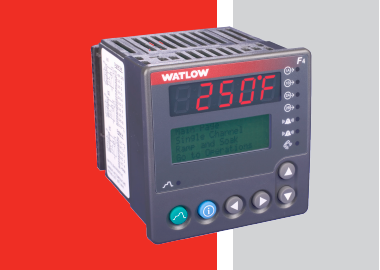

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

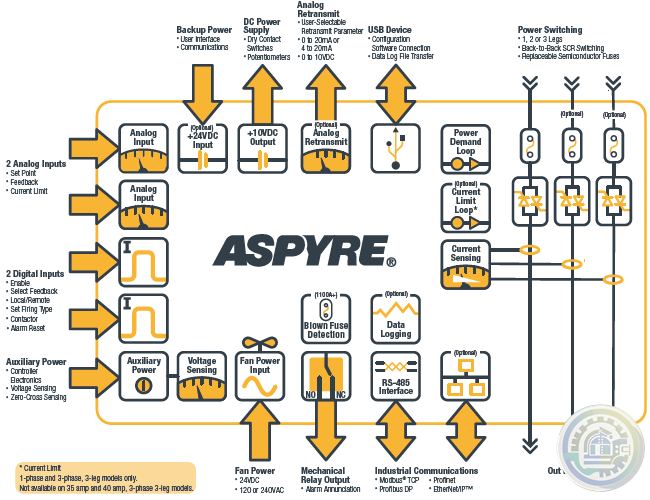

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

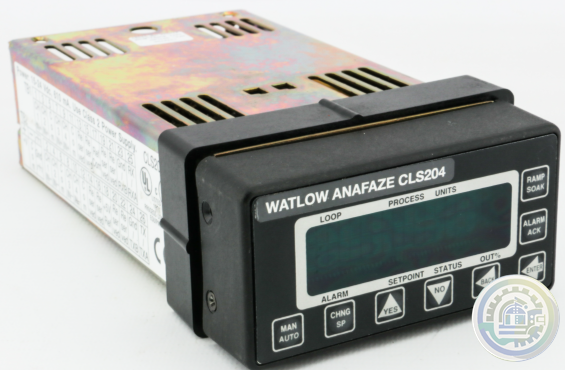

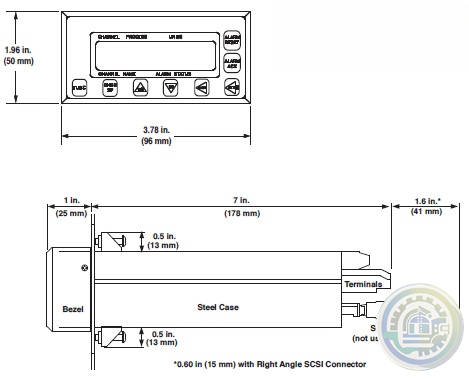

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

-

MOOG G123-825-001 Buffer Amplifier

-

Emerson AMS 3120 Bearing-Vibration Monitor

-

ABB SPC800VK01 Ability™ Symphony® Plus Hardware Selector

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

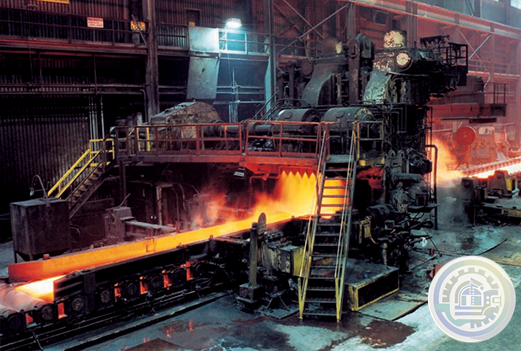

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

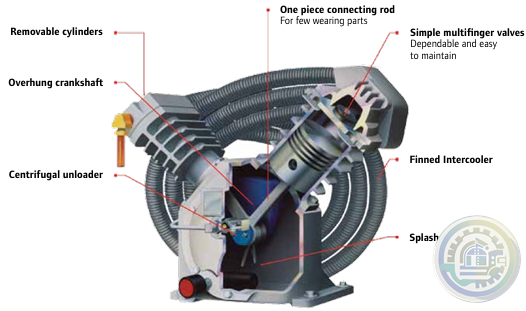

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Description

The autonomous KMR iiwa robot is HRC-capable and mobile.

It combines the strengths of the sensitive LBR iiwa lightweight robot with those of a mobile, autonomous platform.

The KMR iiwa is location-independent and highly flexible – the perfect basis for meeting the requirements of Industrie 4.0.

KMR iiwa: autonomous and extremely flexible

The PC for KRC2 is the control PC of the robot controller.

With its fitted components, the PC performs all the functions of the robot controller.

Windows user interface with visual display and input

Program creation, correction, archiving, and maintenance

Sequence control

Path planning

Control of the drive circuit

Monitoring

Parts of the ESC safety circuit

Communication with external periphery (other controllers, host computers, PCs, network)

KUKA Remote Service

Our KUKA Remote Service provides you with online support in analyzing and rectifying faults and servicing your system.

This service has the highest level of security as every single item of data is encrypted in line with the current state of the art.

Individual service agreements

With the maximum availability of your robots, systems, cells and equipment in mind, we offer service packages that are tailored to your specific requirements:

KMR stands for KUKA Mobile Robotics.

The KMR iiwa is a combination of the sensitive LBR iiwa lightweight robot and a mobile, flexible platform.

As the name and the individual components already suggest, the KMR iiwa stands out with its high degree of mobility and flexibility.

Manufacturing processes are changing constantly. This is why mobile robot systems must be very adaptable.

Maximum mobility and autonomous working methods optimize your production significantly.

The industrial production of wafers requires sensitive, intelligent and clean automation solutions.

We offer the KMR iiwa CR specifically for the safe handling of sensitive components such as wafers.

The solution consists of a combination of a cleanroom cobot and a mobile platform.

The robot's patented gripper is specially designed for safe handling in cleanroom environments.

In addition, continuous production is ensured without interrupting battery charging.

The mobile solution is based on inductive charging technology so that the platform passes over

a charging station during the pick-and-place process and is then charged during the process – without any loss of time.

Maintenance management with custom-tailored agreements

Tailor-made combo agreement (service level and maintenance management)

The KR C4 concept is revolutionary. For the first time, Robot and Motion Control

are seamlessly and interactively integrated with control processes for PLC, CNC

and Safety. With simple and flexible robot programming via inline forms and new

Spline motion programming, KR C4-based automation solutions are superior in every way.

Furthermore, the KR C4 features intelligent, flexible and scalable application potential.

High-end PLC support. The high-end SoftPLC option allows full access to the entire

controller I / O system and has a high runtime performance. It allows the I / O hand

ling of the robot, a complete robot cell or line of robots. In addition, variables such

as axis positions or velocities can be read and processed via function blocks.

More performance in CNC machining. The KUKA.CNC control option enables direct

programming and operation of KUKA robots via G-code. It can process even the

most complex programs from CAD / CAM systems and provides utmost accuracy

due to CNC path planning. This hugely simplifies the integration of robots into

an existing CNC environment. Thanks to the increasing number of robot-specific

functions in upstream CAD / CAM systems, the robot can play a direct role in

machining processes.

KUKA PM6-850 PM6850 POWER SUPPLY |

KUKA RDW-04 Board 71-039-2771039271 |

KUKA robot ARM LBR iisy s |

KUKA Robot Central Hand ZH 200 IV 0 |

KUKA robot control control panel 24V 1A |

KUKA Robot ESC-CIV Modules 00-106-290 |

KUKA Robot K C2 00123102 00-123-102 |

KUKA Robot K C2 121154 00-121-154 |

KUKA Robot K C2 _ PC PROGRAMMING UN |

KUKA robot KR C KRCteach counterpart |

KUKA Robot KRCAmplifier FE2069-001-124_ 69001124 |

KUKA robot KRC2 KCP2 00-110-185 N 1911 |

KUKA Robot Panel KCP KR C69-000-398 24V 0 |

KUKA Robot SmartPAD Quantec KRC4 KCP4 00-168-334 |

KUKA Robot VKCP2 Tech Counterpart VKCP2 00-107-264 |

Kuka Robotics GmbH K C2 00115489 Industrial Automat |

KUKA Safety PCB 00-128-234 0018 incl |

KUKA SERVO CONTROL CONTROLLER PM6-600 ART |

KUKA Servo Drive - E93DA222I4B53- KSD1-08 |

KUKA Servo Drive 00-122-284 E93DA222I4B53 |

KUKA Servo drive KSD1-16 E93DA55214B538 |

KUKA Servo Motor 1FK6100-8AF91-1ZZ9-Z_ 69-225-463 |

KUKA SERVO MOTOR 1FK7034-5AZ91-1ZZ9-Z MISSING ELBOW |

KUKA Servo Motor 1FK7103-5AY71-1SY3-Z S81_ 00-188-018 |

KUKA Servo Pack ECMBS3D4444BE531 |

KUKA Siemens Servo Motor 1FK6032-6AK71-1ZZ9-Z S36_ 69-225- |

KUKA vap133-atx_ 01051810 MOTHERBOARD |

KUKA VKCP2-PV00-163-784 _ 6 MONTHS WARRA |

KUKA VKRC4 PANEL 00-312-962 SN_ 0000178 |

KUKA X2X300-108-883 Extension Cable 35m |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

-

Vibro-meter VM600-ABE042 204-042-100-011 Precision Control Module

-

Vibro-meter vmf-MPC4 200-510-111-034 200-510-070-113 Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved