-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

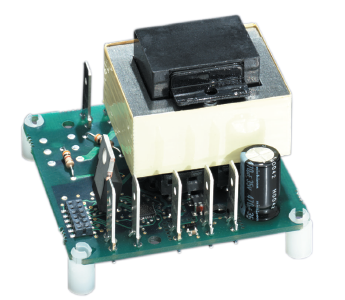

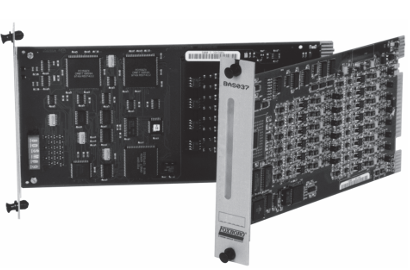

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

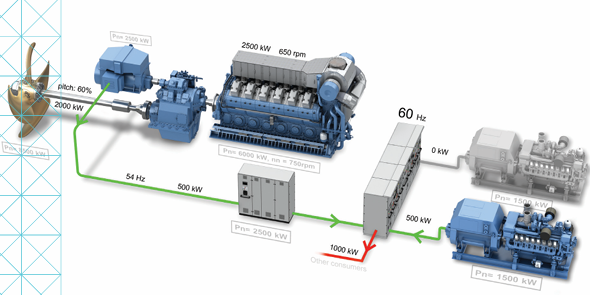

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

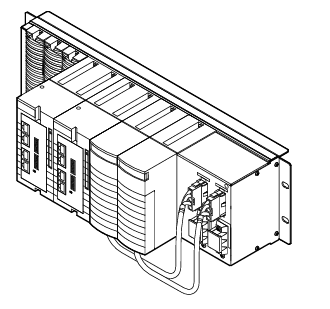

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

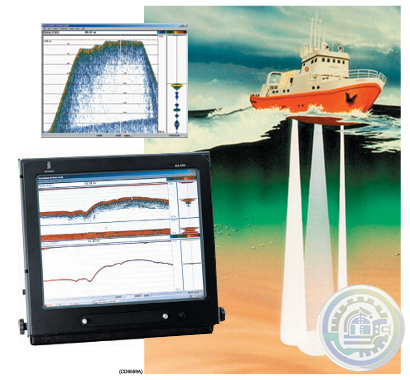

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

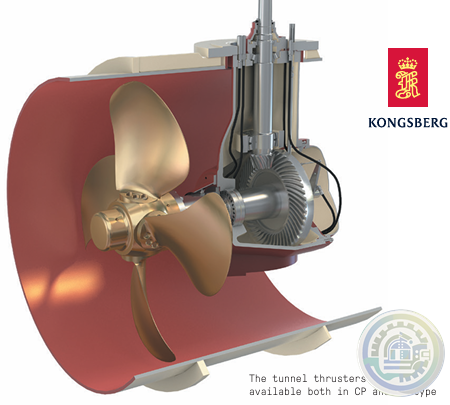

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

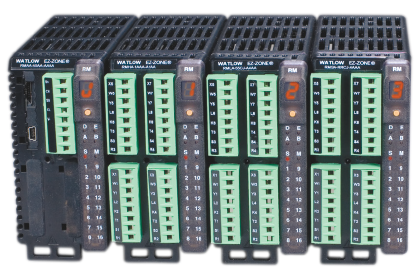

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

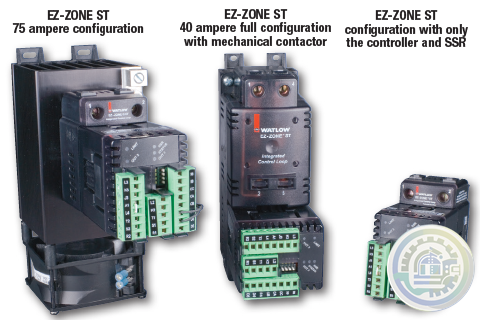

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

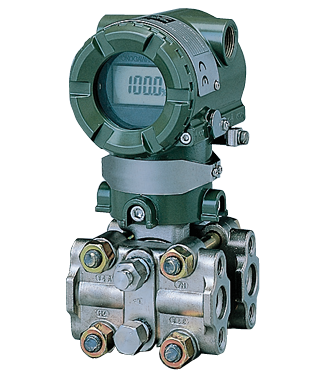

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

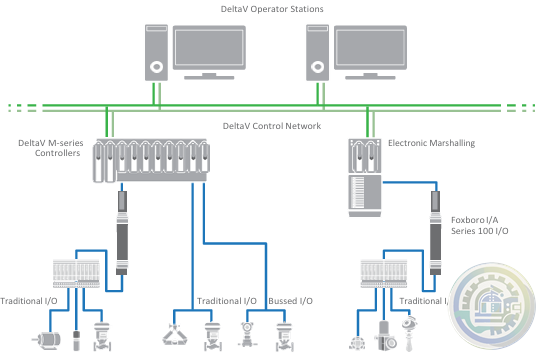

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

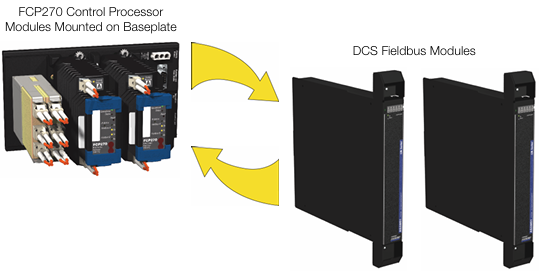

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

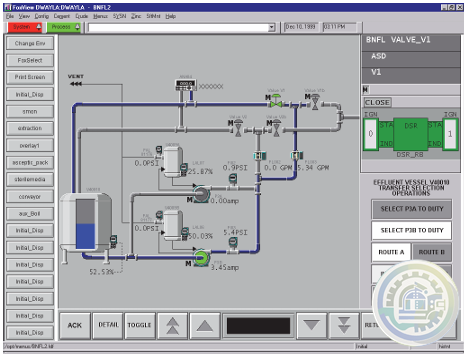

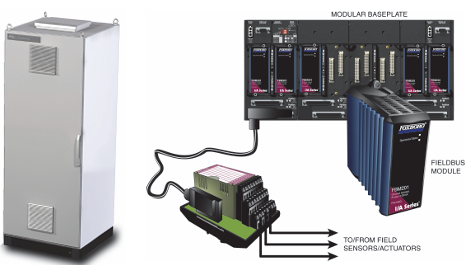

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

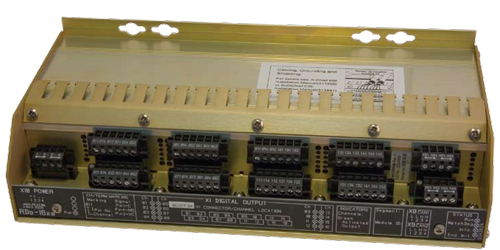

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

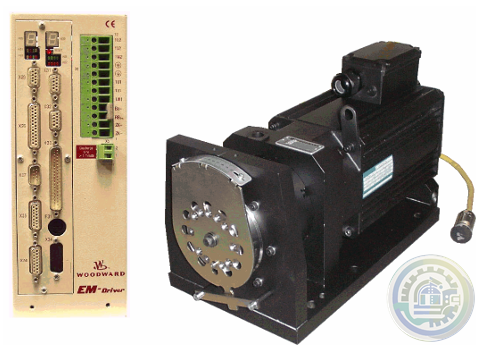

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

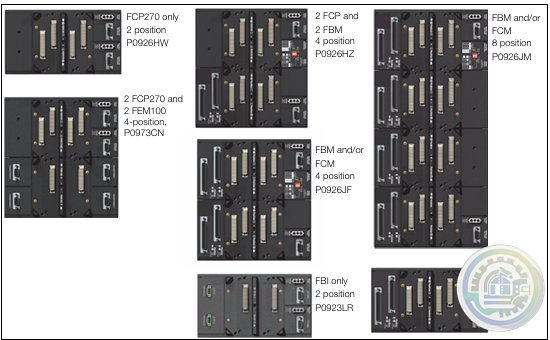

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

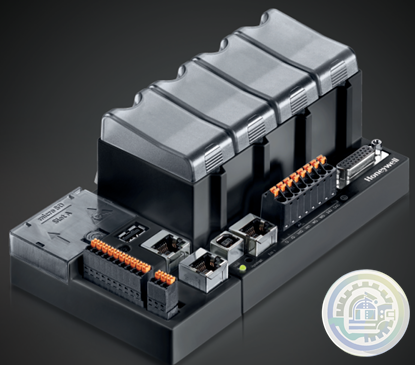

Honeywell ControlEdge™ PLC Modular Controllers

-

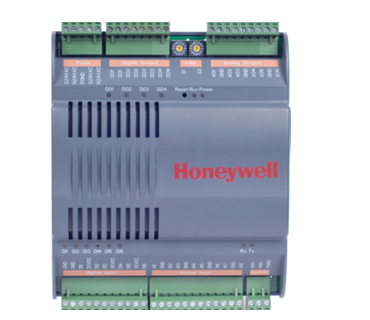

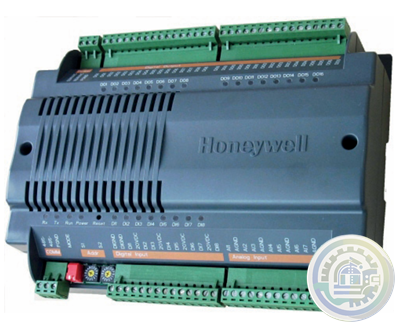

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Part Number is420ucsch1b Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VIe Function Module Availability In StockIS420UCSCH1B is a Quad Core Controller manufactured and designed by General Electric. It is a part of the Mark VIe Series used in GE Distributed Control Systems. It is a version of the quad-core controller that is used with the QNX Neutrino operating system. TMR, Simplex, and Dual redundancy are supported by the component. The QNX operating system is used in high-speed, highly reliable industrial applications. Another type of technology used on this controller is Embedded Field Agent (EMA) technology, which allows Predix cloud-based applications and possibly web applications to be applied over a stable connection, allowing real-time data to be delivered to the connecting controllers. IS420UCSCH1B Features The controller comes with 4 GB of DDR3-1333 SDRAM, which is a type of memory used in computers and other digital devices for high-speed data storage. The controller has 5 Ethernet ports, which allow it to connect to other devices and networks for data transfer and communication. The controller uses ControlST as its Human-Machine Interface (HMI), which is a software application used to interact with and control the device. The Mark VIe quad-core controller runs high-speed, high-reliability industrial applications using real-time hypervisor technology and QNX Neutrino, a real-time, multi-tasking operating system (OS). PredixTM cloud-based apps and/or locally hosted web applications are applied through a secure connection and delivered real-time data using embedded field agent (EFA) technology. A software package tailored to the UCSCH1x controller's use is preloaded. It leverages IONet interfaces as a turbine or balance of plant (BoP) controller and runs Mark VIe firmware and applications. Only supporting Mark controls I/O packs and controllers, IONet is a private special-purpose Ethernet. To synchronize the clocks of the I/O modules and controllers to within 100 microseconds, IEEE 1588 protocol is employed through the IONet interfaces. With the IONet connections, external data is transmitted to and from the controller's control system database. To the I/O modules, this also refers to process inputs and outputs. The UCSC controller lacks any application I/O, in contrast to conventional controllers that host application I/O on a backplane. Operation The operation of the system involves several key aspects, including the installation of the ToolboxST application, configuring the UDH network communication, and establishing the necessary IP address for communication with site HMIs. Here is an expanded explanation of these operations: ToolboxST Application Installation: To facilitate configuration and management tasks, the ToolboxST application is typically installed on a minimum 4 GB unencrypted flash drive. This flash drive serves as the storage medium for the application and contains the necessary files and settings. The ToolboxST application provides a user-friendly interface for configuring various aspects of the system, including network communication. UDH Network Configuration: The UDH (User Datagram Header) network is utilized for communication within the system. During the configuration process, the ToolboxST application is employed to define the communication parameters for the UDH network. This involves setting up network addresses, ports, protocols, and other relevant settings. The configuration ensures that the control module can establish reliable and secure communication with other devices and systems within the network. Default IP Address: By default, the control module is assigned the IP address 192.168.101.111. This IP address serves as the initial configuration for the module's network connectivity. However, it is important to note that this default IP address may need to be modified to match the specific requirements and setup of the site or network where the system is deployed. Configuring Relevant UDH IP Address: In order for the control module to effectively communicate with the site HMIs (Human-Machine Interfaces), it must be configured with the relevant UDH IP address. This IP address is specific to the UDH network and enables seamless communication between the control module and the site HMIs. Through the ToolboxST application, the control module's IP address can be customized and set to the appropriate value that aligns with the network configuration and addressing scheme of the site. Virtual Network The virtual network feature in controllers is a powerful capability provided by the hypervisor, enabling seamless communication and data exchange between virtual machines (VMs) running on the same physical machine or across multiple physical machines in the network. The virtual network functions similarly to a conventional Ethernet network, facilitating data transmission between VMs just as physical Ethernet networks facilitate data transfer between physical machines. Virtual network plays a crucial role in connecting different components of the system and enabling efficient data transfer. Specifically, it facilitates data exchange between the Embedded Field Agent (EFA) and the Mark VIe control, both of which run as separate VMs on the UCSCH1 controller. Here's how the virtual network enables data communication between the EFA and the Mark VIe control: EFA and Mark VIe Control VMs: In the UCSCH1 controller, the EFA and the Mark VIe control are both running as virtual machines (VMs) within the same hypervisor environment. Each VM operates independently, emulating separate computing environments within the same physical machine. Data Transfer through Virtual Network: When data needs to be exchanged between the EFA and the Mark VIe control, it is transmitted through the virtual network provided by the hypervisor. The virtual network efficiently routes the data between the two VMs, enabling seamless and fast communication. Connection to the Cloud: The EFA, being an essential component for remote monitoring and management, requires a connection to the cloud for data exchange with remote servers or cloud-based applications. This connection allows the EFA to send data to the cloud and receive commands or updates from the cloud-based systems. Physically Managed Switch for Network Division: To maintain proper network segregation and security, a physically managed switch is used to divide the networks. The physically managed switch creates distinct network segments, ensuring that the Mark VIe control, which contains sensitive control data, remains isolated from the cloud network. This network division helps protect critical control systems from potential external threats. By leveraging the virtual network, the controller achieves efficient and secure data communication between its different VMs, enabling seamless coordination and control of various components in the system. The integration of a physically managed switch adds an extra layer of security, ensuring the safety and integrity of critical control systems while allowing the EFA to establish connections with cloud-based systems for enhanced functionality and remote monitoring capabilities. Ethernet Ports/Controller Communications Support 3 IONet ports (R/S/T) for I/O module communications (simplex, dual, TMR, and Shared I/O supported). ENET 1 - EGD/UDH communications to ToolboxST PC, HMIs, UCSCS2A Safety controller, and GE PACSystems products. Modbus TCP Slave, Read/Write. ENET 2 - Secondary UDH communications, Modbus TCP Slave and OPC UA. IICS Cloud port for Embedded Field Agent (EFA). Module Ports The control module is equipped with various ports on its front and bottom panels, serving different purposes and enabling connectivity and functionality. Here is an expanded explanation of each port: Ethernet Ports: The front panel of the module features five Ethernet ports. These ports are used for establishing network connections and enabling communication with other devices or systems within the network. Predix Connectivity Port: Located on the bottom panel, this Ethernet port is specifically designated for connectivity to Predix, a cloud-based platform developed by GE. It facilitates data exchange and integration with Predix for enhanced monitoring and analytics capabilities. USB Ports: The module has two USB ports, which are primarily used for specific functions. These ports are typically utilized during the initial setup of the UDH (User Datagram Header) network IP address. Additionally, they can be utilized for a restore function, allowing for the restoration of the module's configuration or software. COM Port: The COM port is a serial communication port that employs an RJ-45 connector and operates at a speed of 115200 bits per second (bit/s). The configuration for this port is 8N1, which denotes eight data bits, no parity bit, and one stop bit. This port does not employ flow control and is commonly used by GE for troubleshooting purposes in the field. It supports the serial redirection of UEFI-setup, facilitating configuration adjustments and troubleshooting activities. Display Port: The module features a Display Port, although it is disabled after the system's startup. The Display Port is typically used to connect an external display device for video output, but its functionality is limited or deactivated once the module is operational. microSD Port: While the module includes a microSD port, it is not currently supported. The microSD port is designed to accommodate a microSD card, which can be utilized for storage purposes. However, in this particular system, the functionality of the microSD port is not enabled or actively supported. Product Attributes Altitude for Normal Operation: Designed to operate within an altitude range of 0-1000 meters. It can function reliably in environments with varying atmospheric pressure, ranging from 101.3 to 89.9 kilopascals (kPa). This attribute ensures that the module can maintain optimal performance even at different altitudes. Dimensions with Mounting: The module has specific dimensions when considering its mounting. It has a height of 8.03 inches, a depth of 5.99 inches, and a width of 2.17 inches when properly mounted. These dimensions provide guidance for installation and integration into the overall system architecture. HMI (Human-Machine Interface): Supports ControlST V07.00.00C or later as its human-machine interface. The HMI facilitates interaction between the module and the human operator, allowing for intuitive control, monitoring, and configuration of the system. Memory Type: The module is equipped with 4 GB DDR3-1333 SDRAM memory. This type of memory is commonly used for storing and processing data within the module. The 4 GB capacity provides sufficient space for efficient data management and enables the module to handle complex control algorithms and calculations effectively. Number of Ethernet Ports: Features a total of six Ethernet ports. Five of these ports are located on the front panel, providing convenient access for networking purposes. Additionally, one Ethernet port is available on the bottom of the module, specifically designed for Predix connectivity. These Ethernet ports facilitate seamless communication and data exchange between the module and other devices or systems within the network. NVSRAM (Nonvolatile Static Random-Access Memory): The module incorporates NVSRAM, which includes 3067 nonvolatile program variables, 64 totalizers, and 338 forces. NVSRAM allows the module to retain critical information, such as program variables and configuration settings, even during power outages or system failures. This attribute ensures data integrity and reliability, crucial for applications where data loss is not acceptable. Platform Configuration Supported Features: Supports EFA (Embedded Functionality Automation), Embedded EtherCAT (Ethernet for Control Automation Technology), and Embedded PPNG (Predix Process & Notification Gateway) as its platform configuration features. These advanced networking capabilities enhance the module's connectivity, compatibility, and overall performance in complex industrial control systems. Storage Temperature: The module is designed to withstand a wide range of storage temperatures, from -40 to 85 degrees Celsius. This attribute allows the module to be stored safely in environments with extreme temperature conditions, ensuring its durability and long-term reliability. Diagnostics The Control Module's circuit cards include system (software) limit checking, high/low (hardware) limit checking, and comprehensive diagnostics for abnormal hardware conditions. System limit checking consists of two limits for each analog input signal, which can be set with the I/O Configurator in engineering units for high/high, high/low, or low/low. Each input limit can be configured for latching/non-latching and enable/disable. System limit checking logic outputs are generated per frame and stored in the database (signal space) for use in control sequencing and alarm messages. Each analog input has high/low (hardware) limit checking, with typically two occurrences required before an alarm is triggered. These limits are not programmable and are chosen to be outside the normal control requirements range but within the linear hardware operational range (before the hardware reaches saturation). The software maintenance tools provide access to diagnostic messages for hardware limit checks and all other hardware diagnostics for the card (Control System Toolbox). In the database, each card has a composite logic output, and another logic output indicates a high/low (hardware) limit fault of any analog input or the associated communications for that signal. Characteristics HMI: ControlST - The human-machine interface (HMI) used in this system is ControlST. ControlST is a software or hardware component that allows users to interact with and control the system. Trip Solenoid Rating: 125 V dc - The trip solenoid used in the system has a rating of 125 volts direct current (V dc). The trip solenoid is an electromechanical device that is used to trip or close circuit breakers or other devices in response to specific conditions. Span: -8 mV to +45 mV - The span refers to the range of values that can be measured or controlled. In this case, the system has a span of -8 millivolts (mV) to +45 mV. This indicates that the system can measure or control signals within this voltage range. Power supply voltage: 28 V dc - The power supply voltage for the system is 28 volts direct current (V dc). This voltage is used to provide power to the various components of the system. Voltage Range: 18 - 32 VDC - The system operates within a voltage range of 18 to 32 volts direct current (VDC). This indicates that the system is designed to function properly within this voltage range. Platform Configuration Supported Features: EFA, Embedded EtherCAT, and Embedded PPNG - The platform configuration of the system supports several features, including EFA (Electronic Function Blocks), Embedded EtherCAT (Ethernet for Control Automation Technology), and Embedded PPNG (Powerful Programmable Numeric Gateway). These features enhance the system's capabilities and functionalities. NVSRAM: 3067 Nonvolatile Program Variables, 64 Totalizers, and 338 Forces - The system has NVSRAM (Nonvolatile Static Random Access Memory) that can store 3067 nonvolatile program variables, 64 totalizers, and 338 forces. NVSRAM is a type of memory that retains its stored information even when power is removed from the system. Number of Ethernet Ports: 6 - The system is equipped with six Ethernet ports. Ethernet ports are used for connecting the system to a network, allowing for communication with other devices or systems. Altitude for Normal Operation: 0-1000 m at 101.3 to 89.9 kPa - The system is designed to operate normally within an altitude range of 0 to 1000 meters. The atmospheric pressure range for normal operation is 101.3 to 89.9 kilopascals (kPa). HMI: ControlST V07.00.00C or Later - The specific version of the ControlST HMI used in the system is V07.00.00C or later. This indicates the minimum version requirement for compatibility and functionality with the system. Cable Separation and Routing When it comes to cable separation and routing in control systems, it is important to consider certain factors to ensure optimal system performance. One significant consideration is the prevention of electrical noise interference caused by different voltage levels in the cabling. Electrical noise can disrupt the operation of microprocessor-based control systems, leading to malfunctions or unreliable performance. To mitigate the risks associated with electrical noise interference, it is essential to follow proper guidelines and recommendations during the installation of cables. Before proceeding with the cable installation, it is advisable to consult the relevant manuals and documentation provided by the manufacturer or system designer. These manuals often contain specific instructions and precautions for cable installation in various scenarios. If the installation site presents unique circumstances or if the guidelines mentioned in the documentation cannot be met, it is crucial to seek further guidance or clarification. During the planning stages of system revamps or upgrades, adherence to level rules is highly recommended. Level rules refer to established standards and guidelines for cable separation and routing in control systems. These rules ensure that cables are appropriately organized and spaced to prevent interference and optimize system performance. By considering level rules during the planning process, the chances of a trouble-free installation and proper application of the control system are significantly increased. By following these guidelines and best practices, potential issues arising from electrical noise interference can be minimized. Proper cable separation and routing help maintain the integrity of the control system, ensuring reliable and efficient operation. It is important to prioritize these considerations during the design, installation, and maintenance phases to maximize the performance and longevity of the control system. Environment Features The Mark VIe control system cabinet should be installed in an environmentally controlled room or in the control room itself. The cabinet should be installed in a location where the floor surface allows for attachment in only one plane (a flat, level, and continuous surface). The mounting hardware is supplied by the customer. Lifting lugs are provided, and lifting cables must not exceed 45掳 from the vertical plane if used. Finally, the cabinet has a door handle that can be locked for security. Interconnecting cables can enter the cabinet from the top or bottom via removable access plates. Convection cooling of the cabinet necessitates the sealing of conduits to access plates. Furthermore, the temperature of the air passing through the conduit must be within the acceptable range. This is true for both the top and bottom access plates.Module manufactured by General Electric as part of the Mark VI/VIe Series used in gas turbine sppedtronic control systems

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved