-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

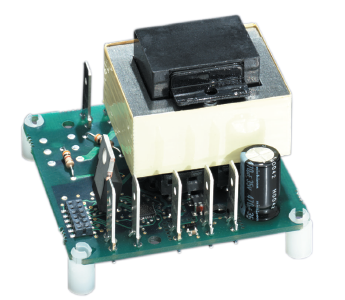

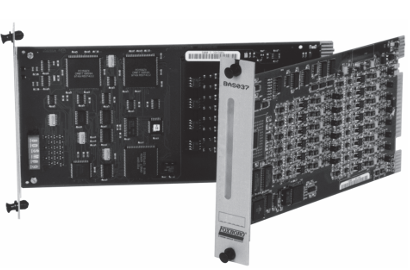

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

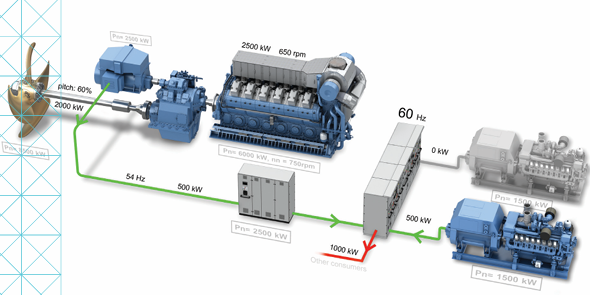

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

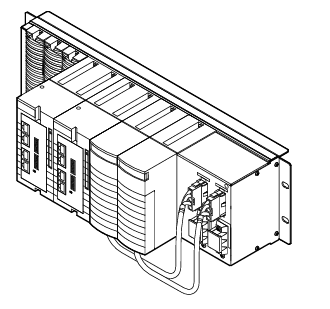

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

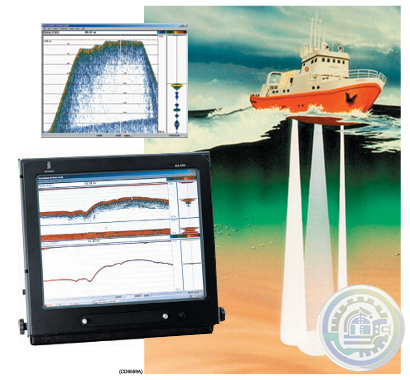

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

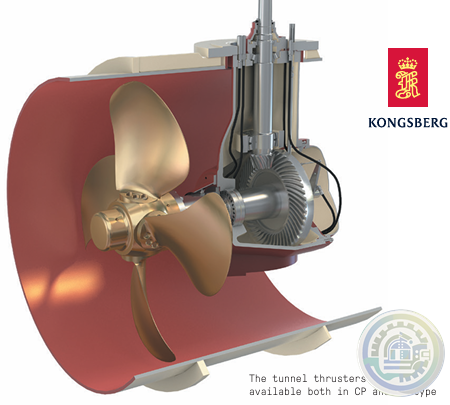

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

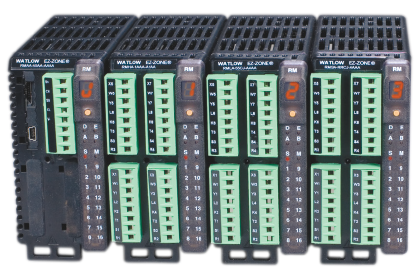

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

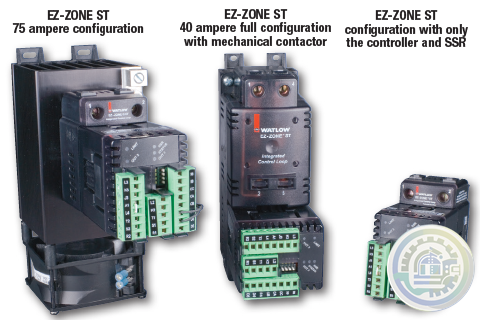

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

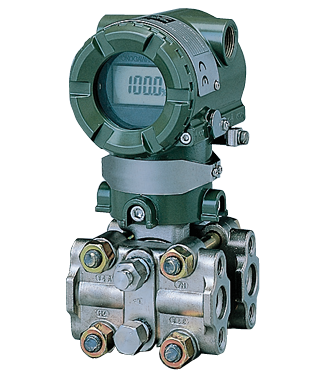

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

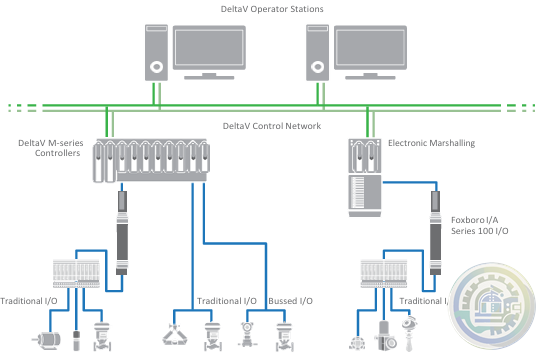

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

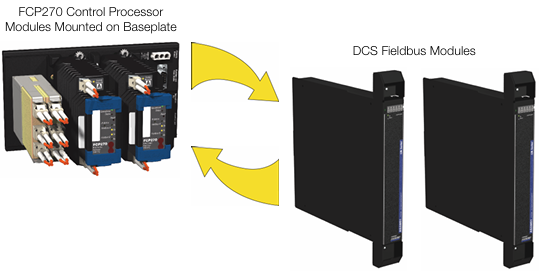

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

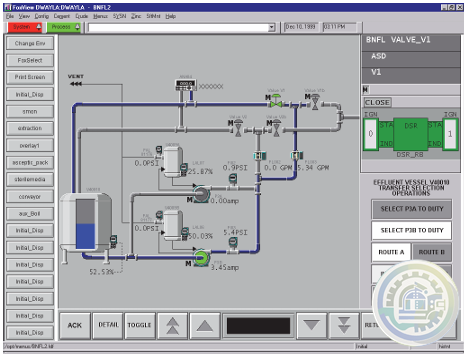

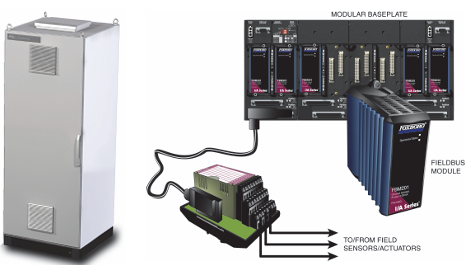

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

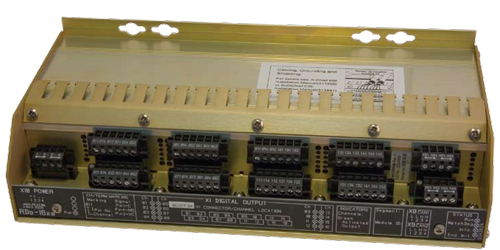

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

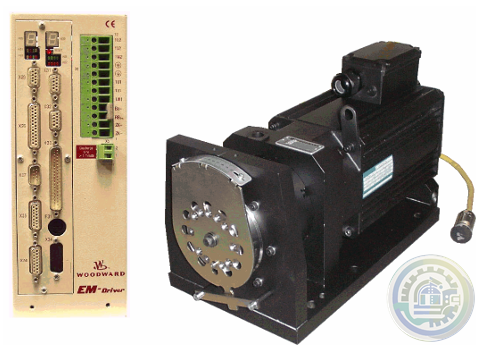

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

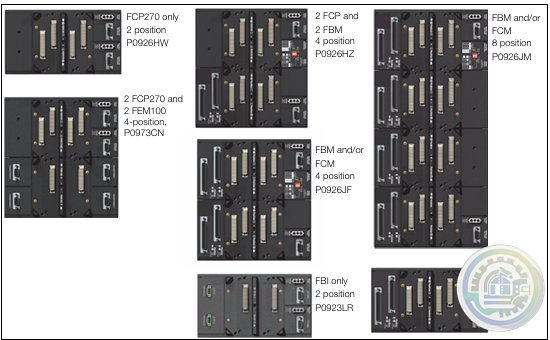

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

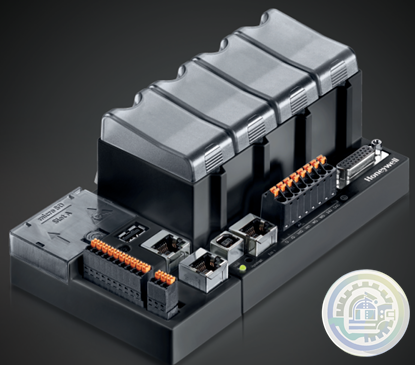

Honeywell ControlEdge™ PLC Modular Controllers

-

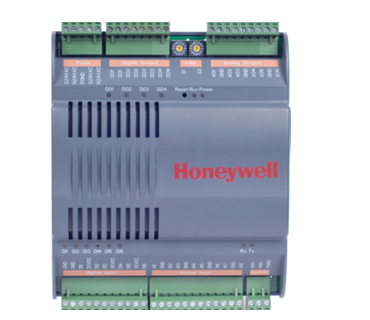

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

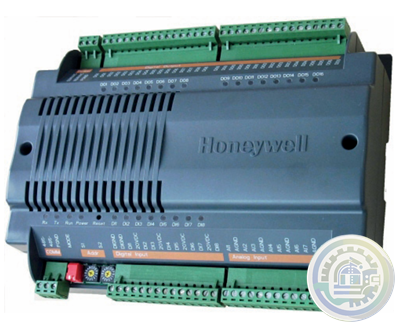

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Part Number IS215VPROH1B Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI Function Module Availability In StockThe IS215VPROH1B is a Turbine Protection Board designed for the Mark VI system. The Turbine Protection Board (VPRO) and its associated terminal boards (TPRO and TREG) provide an independent emergency overspeed protection system. The protection system consists of three redundant VPRO boards in a module separate from the turbine control system, which control the trip solenoids via TREG. VPRO also has an Ethernet connection for IONet communications with the control modules. FUNCTIONAL DESCRIPTION The VPRO board in Protection Module P performs the emergency trip function. Up to three trip solenoids can be connected between the TREG and TRPG terminal boards TREG supplies the positive side of the 125 V dc to the solenoids, while TRPG supplies the negative side. Either board has the ability to trip the turbine. VPRO offers emergency Overspeed protection as well as emergency stop functions. It is in charge of TREG's 12 relays, nine of which form three groups of three to control the three trip solenoids. VPROH1A has been replaced by the functionally equivalent VPROH1B. VPROH1A and VPROH1B support a second TREG board that is powered by VPRO connector J4. IS215VPROH1B Installation To install the VPRO board Turn off the VME I/O processor rack. Insert the VPRO board and use your hands to push the top and bottom levers in to seat the edge connectors. Tighten the captive screws on the front panel's top and bottom.

Power up the VME rack and check the diagnostic lights at the top of the front panel Cable connections to the TPRO and TREG terminal boards are made at the VPRO front panel connectors J3, J4, J5, and J6. To secure the cables, these are latching connectors. J7 is a 125 V dc power connector. Refer to the section on diagnostics in this document for more information. You may need to update the VPRO firmware to the most recent version. IS215VPROH1B Operation The main purpose of the protection module is to protect the turbine from emergency overspeed (EOS) using three VPRO boards. VPRO also has backup synchronization check protection, three analog current inputs, and nine thermocouple inputs, which are primarily intended for gas turbine exhaust over-temperature protection. With three completely separate and independent VPRO boards named R8, S8, and T8, the protection module is always triple redundant (originally named X, Y, and Z). While the turbine is running, any of these boards can be powered down and replaced without jeopardizing the protection system. Each board has its own I/O interface, processor, power supply, and Ethernet communications to the controller (IONet). The communications allow the controller to send test commands to the protection module and monitor EOS system diagnostics in the controller and on the operator interface. The VPRO board, which serves as the system's heart, is where communications take place.

The VPRO board has a VME interface for programming and testing in a VME rack; however, when plugged into the protection module, the backplane is neutralized, removing any continuity between the three independent sections. Speed Control and Overspeed Protection Six passive, magnetic speed pickups are used to implement speed control and overspeed protection. The controllers monitor the first three, which use the median signal for speed control and primary overspeed protection. The second three are connected to the R8, S8, and T8 VPROs in the protection module separately. On the TPRO terminal board, nine passive magnetic speed pickups or active pulse rate transducers (TTL type) are provided, with three monitored by each of the R8, S8, and T8 VPROs. The application software has separate overspeed trip settings for the primary and emergency overspeed trip limits, and a second emergency overspeed trip limit must be programmed into the I/O configurator to confirm the EOS trip point. Interface To Trip Solenoids The trip system combines the controller's Primary Trip Interface with the protection module's EOS Trip Interface. To interface with the hydraulics, three separate, triple redundant trip solenoids (also known as Electrical Trip Devices - ETDs) are used. The TRPG and TREG terminal boards are linked by the ETDs. From the turbine control, a separately fused 125 V dc feeder is provided for each solenoid, which energizes in the run mode and de-energizes in the trip mode. Backup Synch Check Protection The Protection Module includes backup synch check protection. The generator and bus voltages are supplied by two single-phase potential transformers (PTs) with secondary outputs of 115 V rms. Between the PTs and the turbine control, the maximum cable length is 100 meters of 18 AWG twisted, shielded wire. Each PT is magnetically isolated, with a rated barrier of 1,500 V rms and a circuit load of less than 3 VA. Synchronization algorithms are based on phase lock loop techniques. At nominal voltage and 50/60 Hz, the phase error between the generator and bus voltages is less than +/-1 degree. The measured frequency is within 0.05% of the input frequency and supports a frequency range of 45 to 66 Hz. Diagnostics Three LEDs at the top of the VPRO front panel indicate status. The normal RUN condition is a flashing green, while the FAIL condition is a solid red.TEL:+8618144100983

The third LED is STATUS, which is normally off but displays a steady orange if the board has a diagnostic alarm condition. VPRO performs diagnostic checks and generates faults in the following ways: Feedback from the trip relay driver and contacts Solenoid voltage and source of solenoid voltage Economizer relay driver and contact feedbacks Relay driver and coil K25A Contact feedback and servo clamp relay driver All analog inputs have high and low limits. If any of the above signals fails, a composite diagnostic alarm L3DIAG VPROR, S, or T is generated. Individual diagnostic signals can be latched and then reset with the RESET DIA signal if they become healthy. Features The Board protects against backup synch checks and detects speed differences. The thermocouple and analog inputs are both supported by the board. Two circuit boards are stacked one on top of the other in this module.

The top board, an IS200VPRW, is inserted into standoffs and connects to the lower board by four screw connections. Integrated circuits, a transformer, multiple transistors, as well as resistors, capacitors, and diodes, are all present on the board. Carbon composite material is sometimes used to make resistors. There are various inductor coils on the board, as well as numerous connectors, including plugs. A heat sink can be found on the right front side. The module's bottom board has two backplanes. There are capacitors and resistors, as well as many integrated circuits, in it. Oscillating chips are included in this category. The top board's standoffs are set towards the board's margins. The module uses the TREG board to regulate trip solenoids. The controller's application software is used to start tests on these trip solenoids. These can also be tripped manually. A faceplate is included with the board. LED indicators, a power switch, cable connectors, and Ethernet connectors are all found on the faceplate. Screws attach this faceplate to the boards.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved