-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

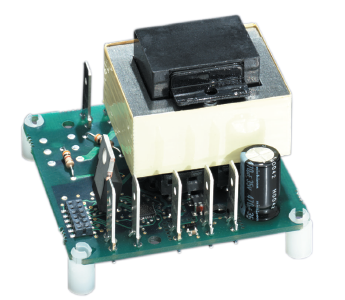

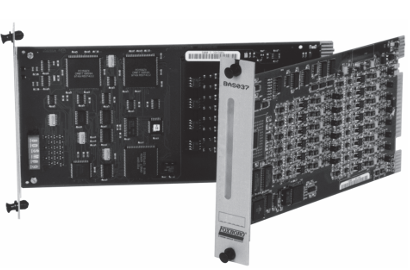

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

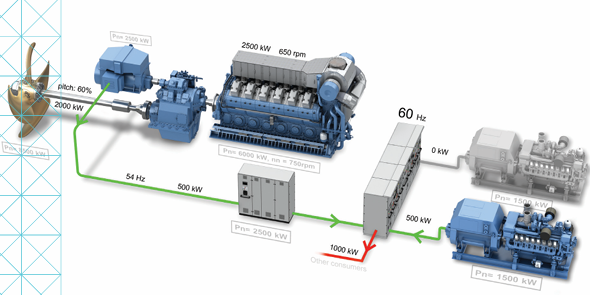

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

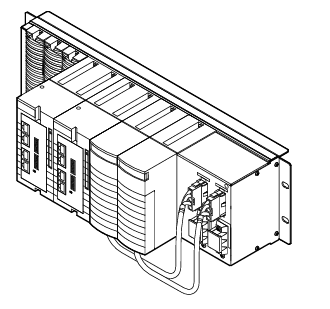

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

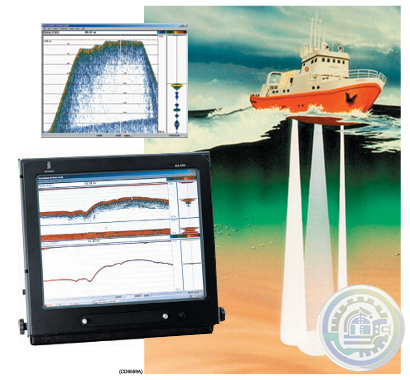

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

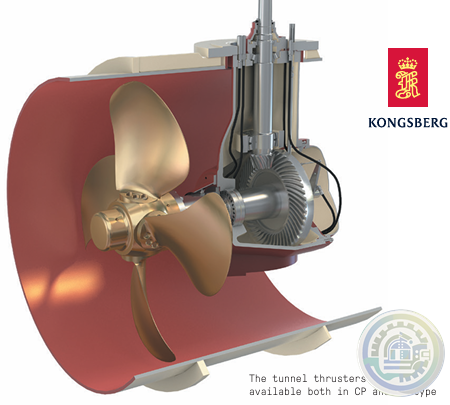

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

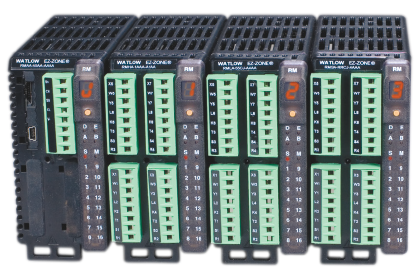

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

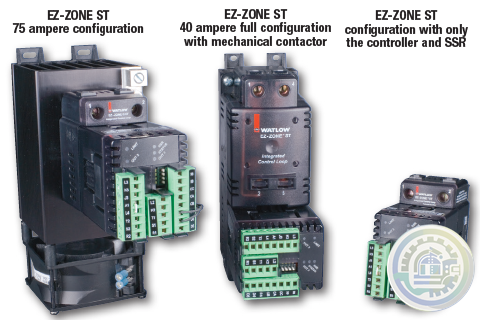

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

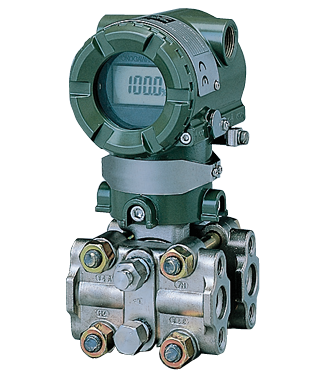

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

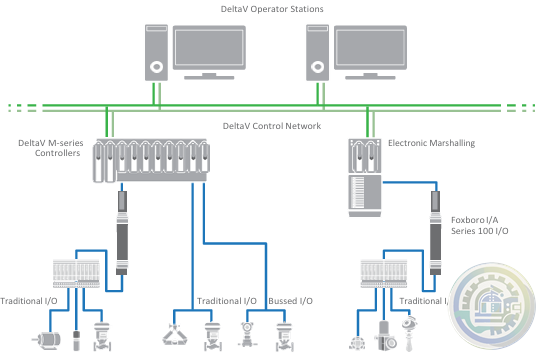

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

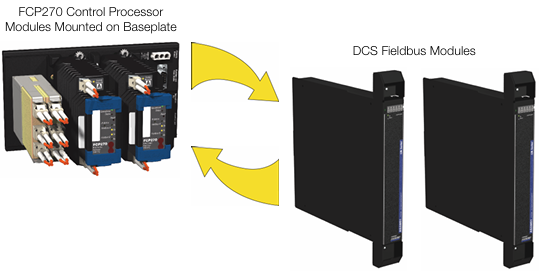

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

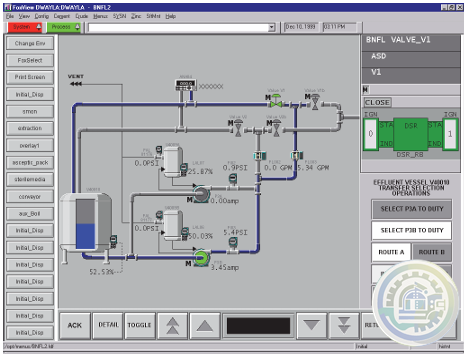

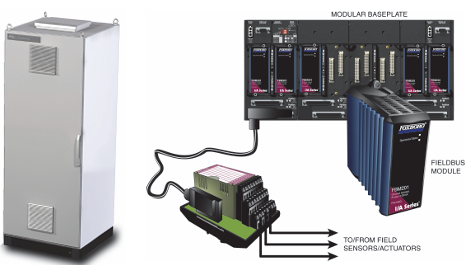

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

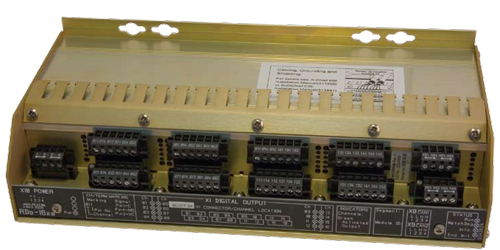

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

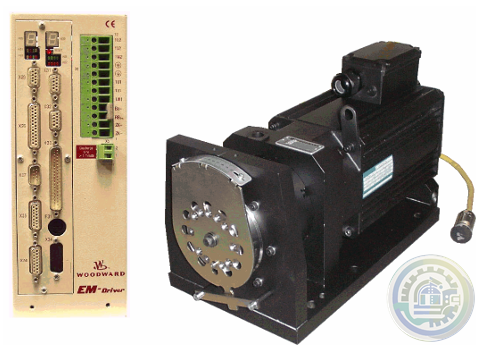

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

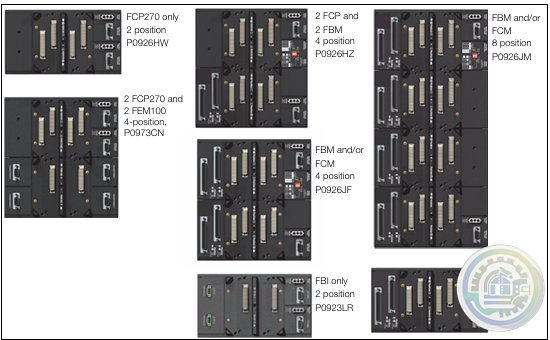

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

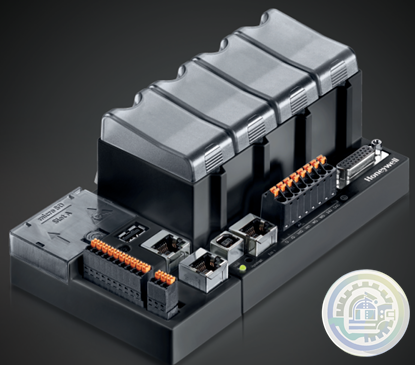

Honeywell ControlEdge™ PLC Modular Controllers

-

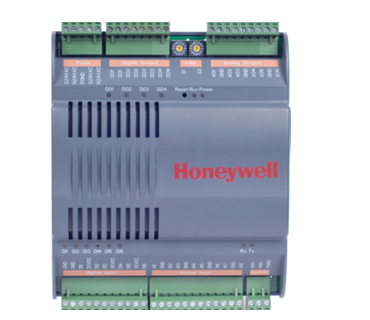

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

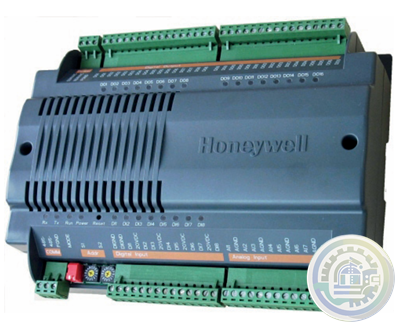

Honeywell ControlEdge™ HC900 How Does It Work?

-

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

A smartPAD cable reel – einfach, flexibel, sicher

Mit dem smartPAD cable reel bietet KUKA ein funktionales Rückzugssystem für das smartPAD Anschlusskabel.

Das System überzeugt durch einfache Handhabung und Montage und sorgt für eine sichere Arbeitsumgebung.

Ihre Vorteile

• Optimaler Schutz vor Beschädigung des smartPAD Kabels

• Erhöhte Arbeitssicherheit durch Vermeidung von Stolperfallen

• Flexible Montage durch Verlängerung des Anschlusskabels zum Schaltschrank

• Kurze Nachrüstzeit in der Anlage durch einfaches Umstecken des Kabels

Challenges in the Automotive Industry

The automotive industry is very dynamic and requires extreme flexibility from automotive manufacturers.

The growing global competition demands smart production systems, combined with flexible logistics systems.

They can be adapted quickly and thus also serve the ever-increasing demand for model diversity.

In addition to the installation, a simple operation of the system plays an important role.

Automotive manufacturers increasingly find that they have to expand their core competencies in areas ranging from automotive industry to mobility or even to re-define those areas.

They are only able to stand in the competition if they could cope with developments around Industrie 4.0. demographic change and data-driven production.

Solutions for the automotive industry

KUKA offers you the necessary configuration options to meet all the automotive challenges efficiently:

through adaptable, modular and automated production and logistics processes, we pave the way to sustainable success in the automotive industry.

The PC for KRC2 is the control PC of the robot controller.

With its fitted components, the PC performs all the functions of the robot controller.

Windows user interface with visual display and input

Program creation, correction, archiving, and maintenance

Sequence control

Path planning

Control of the drive circuit

Monitoring

Parts of the ESC safety circuit

Communication with external periphery (other controllers, host computers, PCs, network)

The KR C4 concept is revolutionary. For the first time, Robot and Motion Control

are seamlessly and interactively integrated with control processes for PLC, CNC

and Safety. With simple and flexible robot programming via inline forms and new

Spline motion programming, KR C4-based automation solutions are superior in

every way. Furthermore, the KR C4 features intelligent, flexible and scalable application potential.

High-end PLC support. The high-end SoftPLC option allows full access to the entire

controller I / O system and has a high runtime performance. It allows the I / O hand

ling of the robot, a complete robot cell or line of robots. In addition, variables such

as axis positions or velocities can be read and processed via function blocks.

More performance in CNC machining. The KUKA.CNC control option enables direct

programming and operation of KUKA robots via G-code. It can process even the

most complex programs from CAD / CAM systems and provides utmost accuracy

due to CNC path planning. This hugely simplifies the integration of robots into

an existing CNC environment. Thanks to the increasing number of robot-specific

functions in upstream CAD / CAM systems, the robot can play a direct role in

machining processes.

Fully integrated safety controller. The KR C4 seamlessly integrates the complete

safety controller into the control system without proprietary hardware. Safety

functions and safety-oriented communication are implemented via Ethernet-based

protocols. The safety concept uses multi-core technology and enables the dual

channel operation required for safety applications.

| KUKA | DC POWER SUPPLY 00-171-202 | ABB | 3BHB006309R0001 UNS 0882 A-P V1 power signal interface |

| KUKA | DSE-IBS3 | ABB | 3BHB006208R0001 UNS 0883 A-PV1 fast input and output port |

| KUKA | E93CE143I4B531 | ABB | 3BHE004385R0001 UNS 0884 A-P V1 current sensor |

| KUKA | E93DA113I4B53SERVO DRIVE ( CONDITION ) | ABB | 3BHB006943R0001 UNS 0885 A-Z V1 Converter Display |

| KUKA | E93DA123I4B53Servo Drive | ABB | 3BHB006943R0002 UNS 0885 A-Z,V2 Converter Display |

| KUKA | ECMAP0D3004BE53 KPP 600-20 0019825 | ABB | 3BHB002651R0001 UNS 0874 A-PV1 Control Panel |

| KUKA | ECMAP0D3004BE53KPP 600-20 | ABB | 3BHE004059R0104 SDCS-CON 2-21 Motherboard |

| KUKA | ECMAP1D3404BE53Servo Drive 00198260 | ABB | 3ADT315100R1012 SDCS-POW 4 internal power supply |

| KUKA | ECMAS3D2224BE53 KSP 600-3x20 00192 | ABB | 3BHE006422R0001 UNS2861 C-P, V1 HGC door control unit |

| KUKA | ECMAS3D2224BE53 KSP 600-3x20 | ABB | HIEE30511 1R0001 UNS 2860 B-P Chopper stage |

| KUKA | ECMAS3D4444BE53(Slightly Damaged) | ABB | 3BHE009319R0001 UNS 2881 B-P V1 measuring cell board |

| KUKA | ECMAS3D4444BE53Ser | ABB | 3BHE003855R0001 UNS 2882 A-P V1 Extended Door Controller |

| KUKA | ECMAS3D4444BE53Servo Drive 00198268 | ABB | 3BHB005922R0002 UNS 0880 A-PV2 converter interface |

| KUKA | ECMAS3D7774BE53KSP 600-3x64 | ABB | 3BHE035495R0020 UNS 0017 A-PV1 RF board |

| KUKA | EMI Filter KRC 2 32TDRT2-Version 3 | ABB | 3BHE035495R0022 UNS 0017 A-PV1 RF board |

| KUKA | Extension Lead 15m 00-127-948 | ABB | HIEE205010R0003 UNS 3020A-Z,V3 protection relay |

| GE | IS215AEPCH1C IS215AEPCH1F AEPC - 30Nm Air Distance Control (Center/Shaft) | GE | IS215AEPAH1A IS215AEPAH1C AEPA - 20Nm Air Distance Axle Control |

| GE | IS215AEPCH1A IS215AEPCH1D AEPC -20Nm Non-ESS Air Distance Center Control | GE | IS215WEPAH1A IS215WEPAH1B WEPA - 30Nm CANBus Air Distance Axle Control |

| GE | IS215AEPCH1B IS215AEPCH1E AEPC - 20Nm ESS Air Distance Center Control | GE | IS215WEPAH2A IS215WEPAH2B WEPA - 30Nm Non-CANBus Air Distance Axle Control |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved