-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

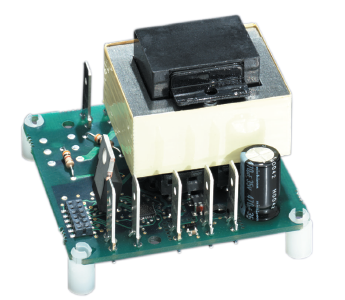

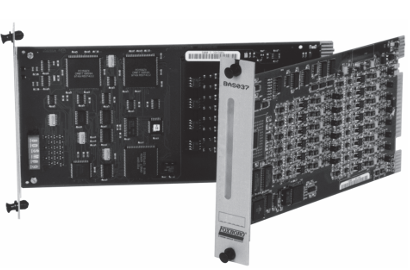

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

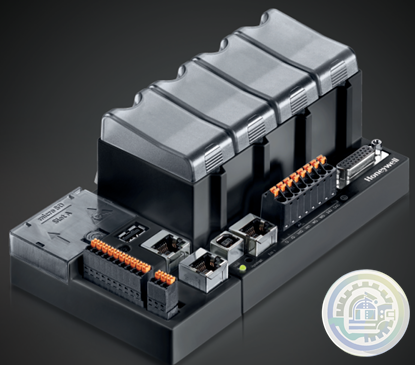

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

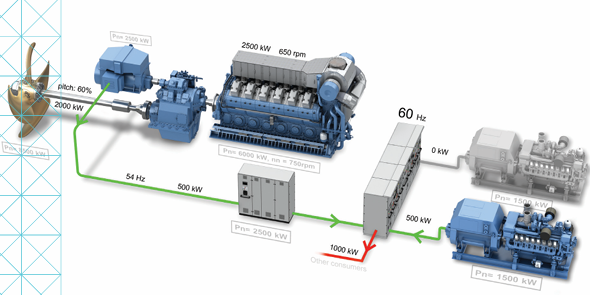

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

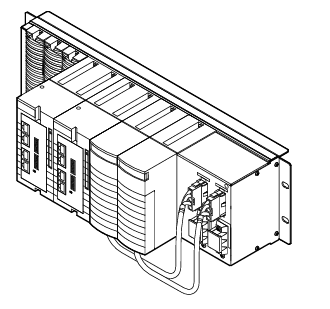

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

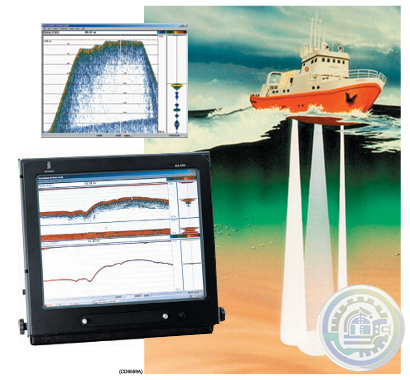

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

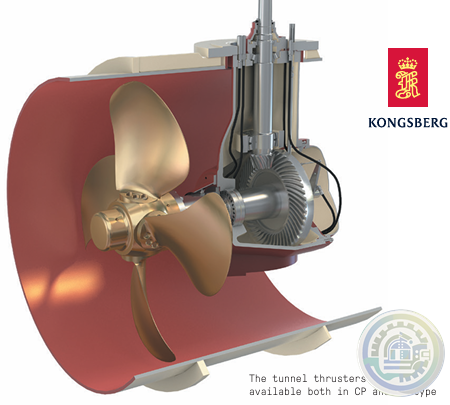

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

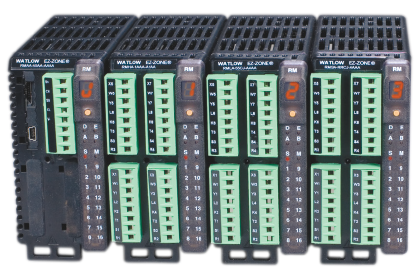

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

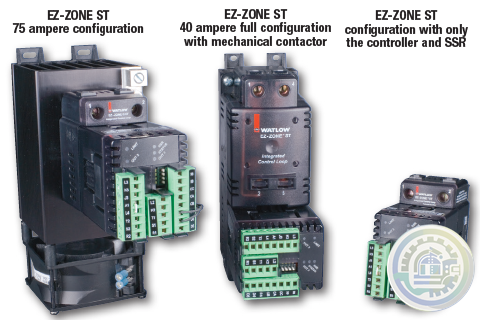

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

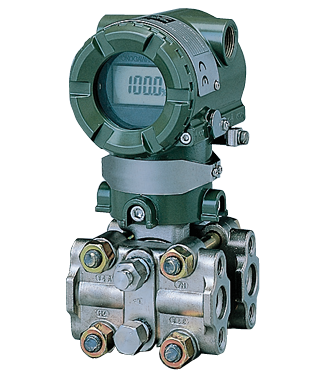

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

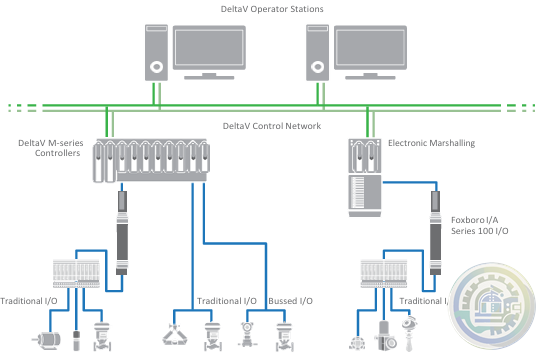

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

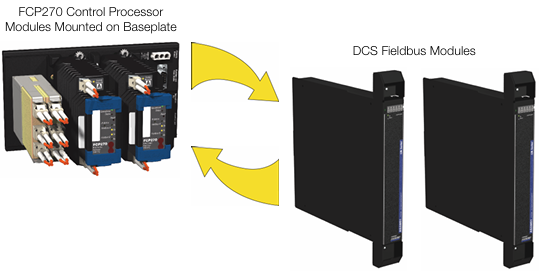

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

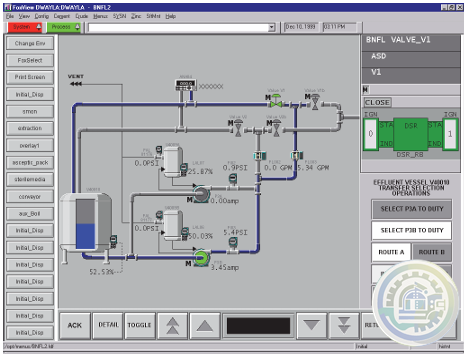

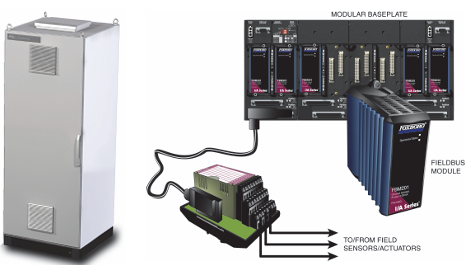

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

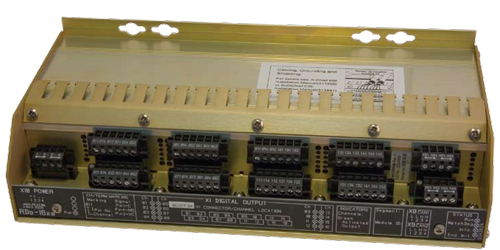

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

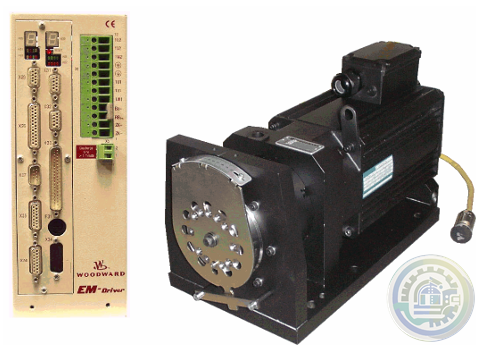

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

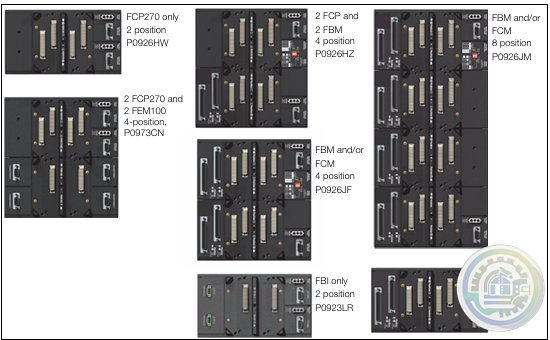

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

Honeywell ControlEdge™ PLC Modular Controllers

-

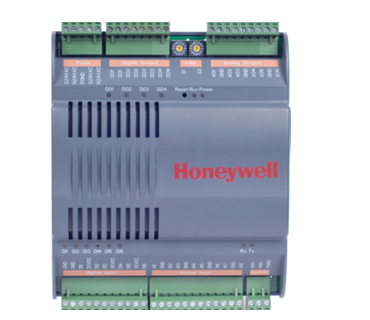

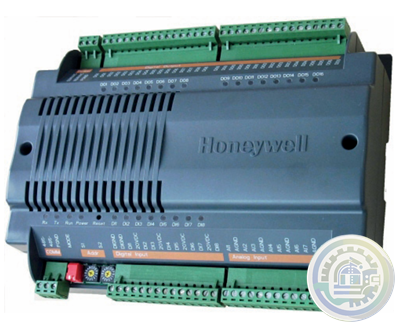

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Part Number DS215SLCCG1AZZ01B Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In StockDS215SLCCG1AZZ01B is a LAN Communications Card developed by GE. It is a part of Mark V control system. It has circuits for communications with the drive or exciter that are both isolated and non-isolated. The programmer module is connected to the 16-position alphanumeric display (and display controller, U18). The KPPL connector receives the programmer module, which is mounted to the SLCC. The LAN Control Processor, U1, is the main microprocessor (LCP). Two replaceable EPROMs contain the LCP software (U6 and U7). U8 and U9 supply the LCP-specific Memory. Communication between the LCP and the Drive Control Processor (DCP) on the Drive Control Card occurs via 3PL and dual-ported RAM (U5). Dual-ported RAM [DPR] is RAM set up as memory arrays that two microprocessors may access both independently and concurrently. Mark V improves unit reliability even further by employing three redundant control processors. This triple modular redundant (TMR) design can safely operate, control, and protect a unit in the event that one of its control processors or control processor components fails.

The TMR design allows for the shutdown and repair of a single control processor without shutting down the turbine. Board Connections Five connectors (marked _PL) connect to the other controller boards, external signals, and the network. These are the connectors to other boards: 2PL Connector: This connector is responsible for connecting 5, 15, and 24 V dc input/output (I/O) signals between various components. The Power Supply/Interface Board (IMCP, DCI, SDCI, or DCFB), the Drive Terminal Board or Simple Drive Terminal Board, and the Drive Control Card establish connections using this connector. It enables the exchange of power and I/O signals required for communication and coordination between these boards. 3PL Connector: The 3PL connector is used to connect the inputs from the Drive Control Card. It allows the Drive Control Card to transmit input signals to the SLCC, enabling communication and coordination between these two components. It relies on these inputs to perform its control functions effectively. 10PL Connector: This connector serves as the interface for input/output (I/O) signals between the LAN I/O Terminal Board and the Card. It enables communication between the LAN card and the LAN I/O Terminal Board, facilitating the exchange of data and signals over the network. This connector plays a vital role in integrating the LAN Card into the networked system and allows for remote monitoring and control capabilities. ARCPL Connector: The ARCPL connector establishes input/output (I/O) connections between the DLAN (Distributed Local Area Network) and ARCNET signals and the Card. This connector allows for the transmission of signals related to DLAN and ARCNET protocols, enabling communication with other devices or systems utilizing these protocols. It provides connectivity options for specific network configurations or protocols employed in the system. KPPL Connector: The KPPL connector facilitates input/output (I/O) connections between the Programmer Module keypad and the Card. It enables the exchange of data and signals between the card and the Programmer Module keypad. This connector allows the user to input commands, configurations, or other instructions through the keypad, which are then processed and executed. Board Mounting Features four standoffs that serve as mounting points. Standoffs are small supports or spacers that elevate and secure the board in a fixed position. These standoffs provide stability and ensure proper alignment between the module and the surrounding components or enclosure. Includes a connector labeled KPPL, which is designed to accept a programmer module plug. The programmer module plug is a specific type of connector that allows for communication and interaction. When the programmer module plug is connected to the KPPL connector, it establishes a physical and electrical connection between the LAN Card and the programmer module. Covered by the keypad and cover module. This module is specifically designed to provide a protective enclosure and to house the keypad interface. The keypad allows users to input commands, configurations, or other instructions, facilitating control and interaction with the module. The cover module is shielded from external elements and provides a secure housing for the keypad and other components. Application Data Includes configurable hardware that must be set correctly for the application: Berg-type Hardware Jumpers: The configurable hardware includes Berg-type hardware jumpers, which are identifiable by the JP nomenclature. These jumpers are physical connectors that can be manually adjusted or moved to establish or break connections on the device. The JP nomenclature provides a standardized way of labeling and identifying these jumpers. Wire Jumpers: In addition to the hardware jumpers, the device also utilizes wire jumpers, which are identified by the WJ nomenclature. Wire jumpers consist of physical wires that are used to create connections between specific points on the device. Similar to hardware jumpers, wire jumpers offer flexibility in configuring the device's circuitry. Software The LAN Control Processor (LCP) software contained in EPROMs U6 and U7 cannot be configured in the field. The EPROMs U6 and U7 can be replaced and moved from one board to another. When ordering replacement boards. The EPROMs from the old board must be transferred to the new board. When replacing an SLCC (or LCC) and the EPROMs are required, specify it to ensure that both EPROMs are included. The use of software-implemented fault tolerance (SIFT) technology in the Mark V TMR control system. Based on separate inputs, each control processor in a TMR control panel determines its own control and protection functions. The control processors vote on the inputs used to make these decisions individually. If one control processor fails to correctly read an input, the erroneous value is out-voted. Software Design The exciter application program is made up of useful software modules that work together as building blocks to meet system demands. Variables are kept in random-access memory (RAM), whereas block definitions and configuration information are saved in read-only memory (ROM) (RAM). The code is executed by microcontrollers. Traditional analog controls are simulated by the exciter application program. The program makes use of an open architecture system and a library of pre-existing building blocks. Each block serves a specific purpose, such as signal level detectors, function generators, proportional integral (PI) regulators, AND gates, and function generators. Time synchronization Time synchronization allows for the accurate synchronization of all Mark V control panels on the Stagelink with a global time source (GTS), such as an IRIG-B time code signal or periodic pulse inputs. This enables the GTS to set the time clocks of all computers with operator interfaces. The rest of the plant's equipment, including the DCSs, should be synchronized to this common GTS. Power Requirements The Mark V panel can accept power from a variety of sources. Before entering the Mark V panel, each power input source (dc and two alternating current sources) should be fed through its own external 30 A 2 pole thermal magnetic circuit breaker. A 125 V dc source and/or up to two 120/240 V ac sources can be used as power sources. Each core in the panel has its own power supply board, which is powered by a 125 V dc panel distribution bus. Characteristics Critical Communication: Turbine control systems require highly reliable and low-latency communication to ensure the safe and efficient operation of the turbine. LAN Communications Cards are specifically engineered to meet these stringent communication requirements. Redundancy: Redundancy is often a critical feature in turbine control systems to ensure continued operation even in the event of hardware failures. LAN Communications Cards may support features like dual NICs (Network Interface Cards) or redundant network paths to enhance system reliability. Industrial-Grade: Turbine control environments can be harsh, with factors like temperature variations, vibrations, and electromagnetic interference. LAN Communications Cards used in such systems are typically built to withstand these harsh conditions and are designed to be rugged and durable. Protocol Support: Turbine control systems may use specific communication protocols or standards. LAN Communications Cards are designed to support these protocols, ensuring seamless integration with the control system and other devices on the network. Security: Security is a paramount concern in critical systems like turbine control. These cards may include security features such as hardware encryption, firewall capabilities, and support for secure communication protocols to protect against unauthorized access or tampering. Monitoring and Diagnostics: Advanced LAN Communications Cards for turbine control systems often include diagnostic and monitoring features. These features allow for real-time monitoring of network performance and card health, aiding in the early detection of issues. Integration with SCADA Systems: Turbine control systems are often part of larger Supervisory Control and Data Acquisition (SCADA) systems. LAN Communications Cards facilitate the seamless integration of turbine data into the SCADA network, allowing for centralized monitoring and control.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved