-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

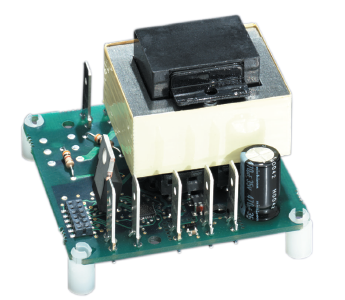

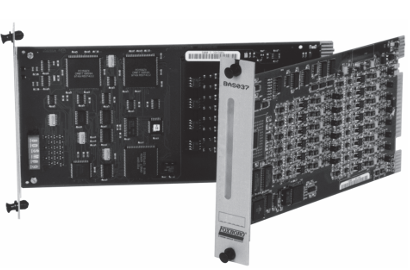

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

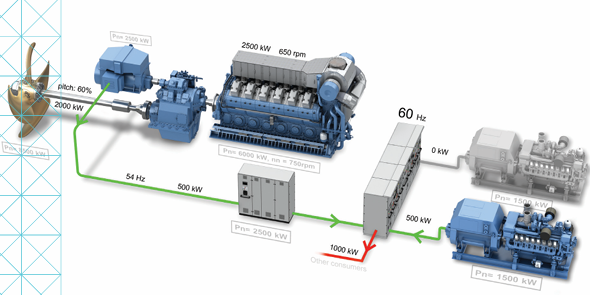

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

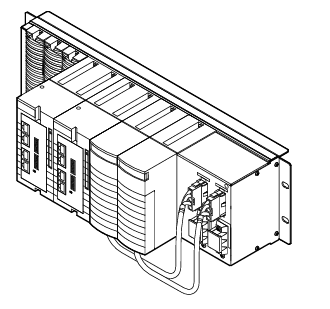

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

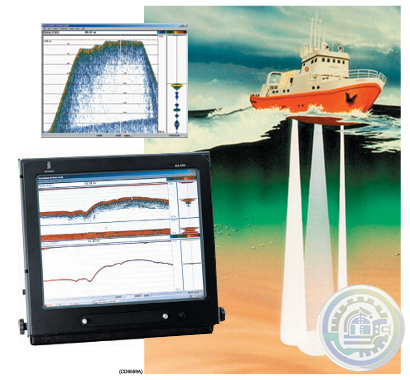

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

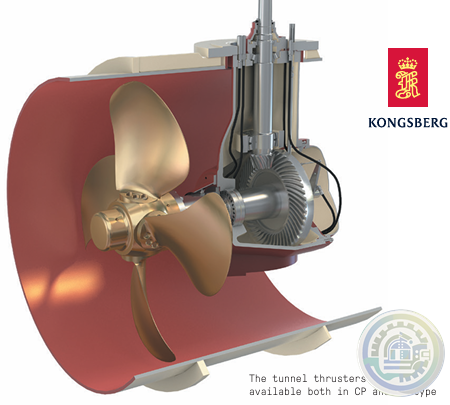

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

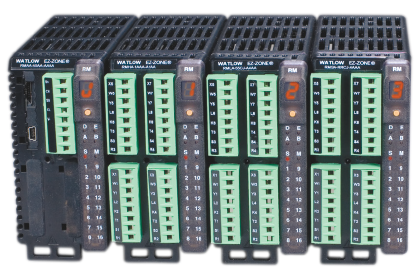

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

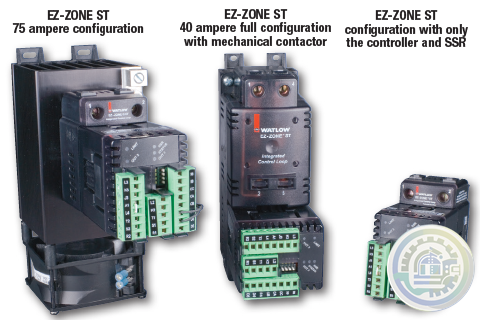

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

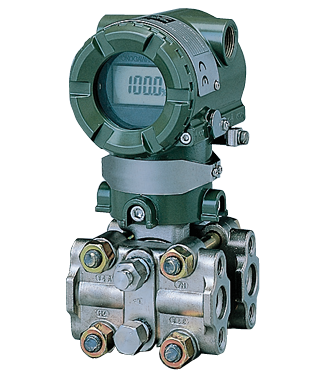

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

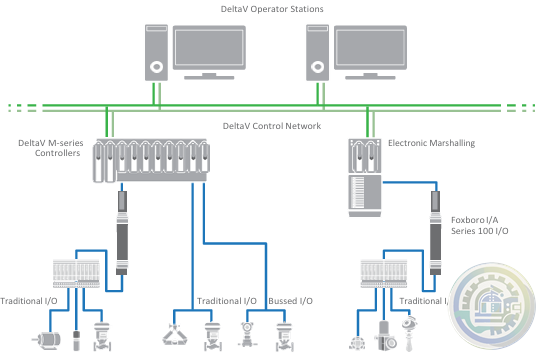

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

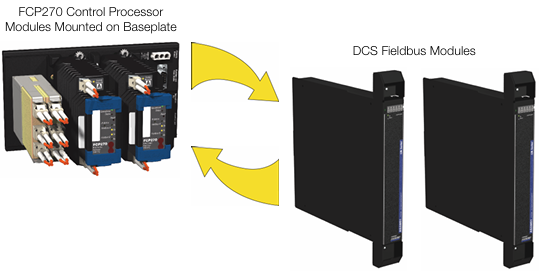

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

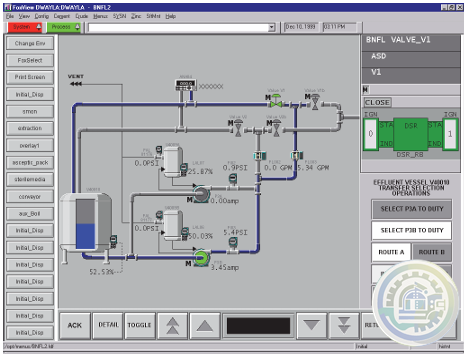

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

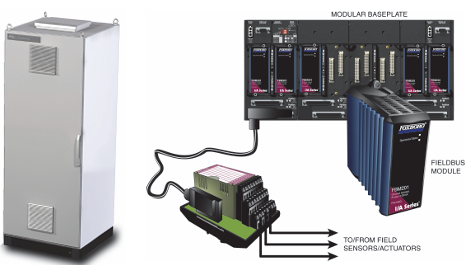

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

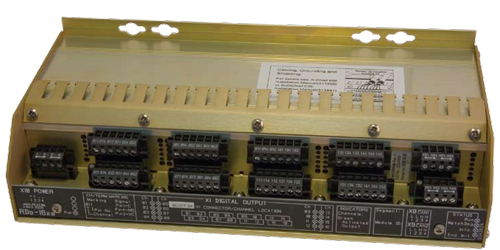

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

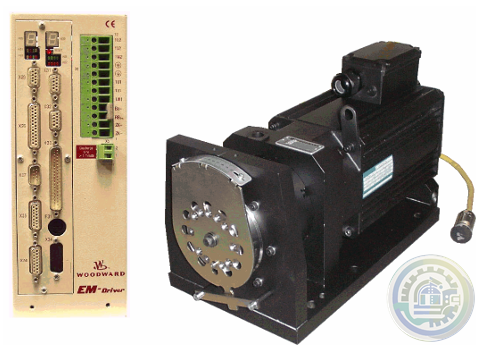

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

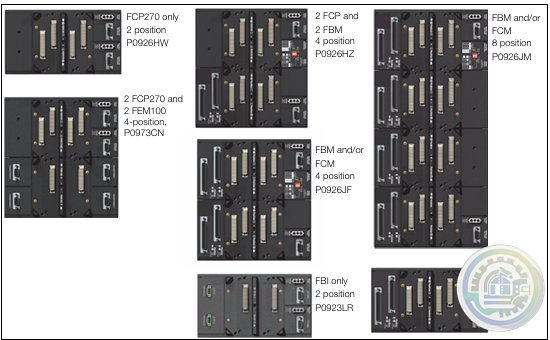

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

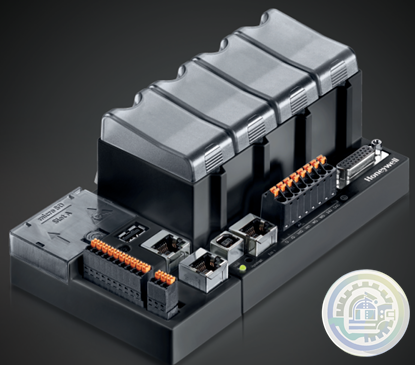

Honeywell ControlEdge™ PLC Modular Controllers

-

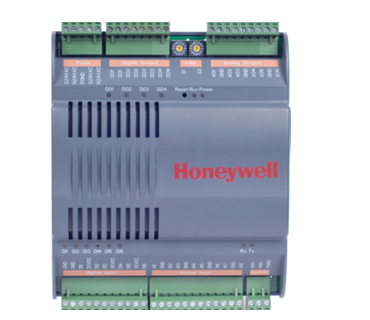

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

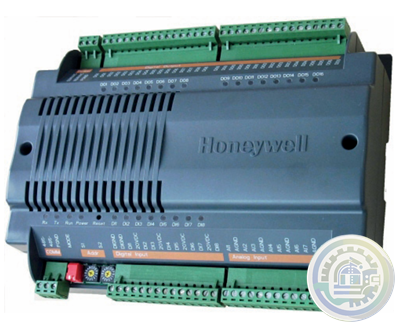

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

Current Location:

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

62

Product parameters

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Feature

SEW DFS56L/TF/RH1M/KK - Drive system module

SEW DFS56L/TF/RH1M/KK - Drive system module

### SEW DFS56L/TF/RH1M/KK: Powering the Future of Automation

The SEW DFS56L/TF/RH1M/KK stands out in the realm of industrial automation, offering exceptional capabilities tailored for demanding applications in the power industry, petrochemical sector, and general automation. This robust model is engineered to deliver superior performance with a focus on durability, efficiency, and operational reliability.

#### Key Technical Features

The SEW DFS56L/TF/RH1M/KK boasts an impressive input/output capacity, ensuring seamless integration into complex systems. With its high-performance metrics, this model operates efficiently under varying loads, providing consistent output even in challenging environments. The unit is designed to withstand harsh conditions, featuring advanced protection against dust and moisture, making it an ideal choice for industrial settings where reliability is non-negotiable.

Durability is a cornerstone of the DFS56L/TF/RH1M/KK, with components that resist wear and tear, thus extending the service life of the product. The advanced thermal management system ensures that the unit maintains optimal operating temperatures, reducing the risk of overheating and subsequent failures. Performance metrics such as rapid response times and high cycle rates position the DFS56L/TF/RH1M/KK as a leader in automation technology.

#### Real-World Usage Scenarios

The versatility of the SEW DFS56L/TF/RH1M/KK shines through in various real-world applications. In the power industry, it excels in controlling and monitoring electrical systems, ensuring efficient energy distribution and management. In the petrochemical sector, the DFS56L/TF/RH1M/KK is instrumental in automating processes such as refining, where precision and reliability are crucial. Its application in general automation allows for seamless integration into manufacturing lines, improving productivity and operational efficiency.

For instance, in a petrochemical plant, the SEW DFS56L/TF/RH1M/KK can coordinate multiple systems, from pumps to conveyors, ensuring optimal workflow and minimal downtime. Similarly, in power generation facilities, it can manage load balancing and system diagnostics, enhancing overall operational stability.

#### Comparison with Other SEW Models

When comparing the SEW DFS56L/TF/RH1M/KK to other models in the SEW lineup, such as the SEW 531X305NTBANG1 and SEW DS200DMCBG1AKG, its unique advantages become apparent. While the 531X305NTBANG1 offers robust performance for specific automation tasks, the DFS56L/TF/RH1M/KK provides a more versatile solution capable of handling diverse applications in various industrial sectors. Additionally, the SEW DS200DMCBG1AKG, known for its precision, lacks the broad application spectrum of the DFS56L/TF/RH1M/KK.

#### Complementary Models

The SEW DFS56L/TF/RH1M/KK complements a range of other SEW automation products to create a cohesive operational ecosystem. For instance, integrating with the SEW IOP302 enables enhanced data collection and analysis, while the SEW 216EA61B offers robust electrical connections for reliable power management. The SEW MU-GAIH14 can be used alongside the DFS56L/TF/RH1M/KK to enhance control capabilities in complex automation tasks.

Additionally, the SEW IC693MDL930LT and SEW IC200MDL640K serve as excellent expansion modules, enhancing the functionality of the DFS56L/TF/RH1M/KK in larger systems. The SEW 5531S and SEW 336A3435ALGO1 can provide additional feedback and control, optimizing the performance of the entire system. Meanwhile, the SEW PFSK164 3BSE021180R1 and SEW DS200SHCAG1B can be integrated for specialized applications, ensuring that the DFS56L/TF/RH1M/KK remains at the forefront of automation technology.

In conclusion, the SEW DFS56L/TF/RH1M/KK is a powerful and reliable choice for industries seeking to enhance their automation capabilities. With its impressive specifications, durability, and real-world application performance, it solidifies its position as a leader in SEW automation products, particularly in the power industry, petrochemical sector, and general automation environments.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

62

How to install and debug this product? Matters needing attention

Open the manual and programming software, use the new version, upload the data and programs, save the computer, continue downloading! For details, please consult the technical service provider!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Where can I download the manual and programming software?

Product official website, official hotline and contact sales or technical engineers.

Is it in stock or need to be ordered?

There will generally be inventory, but it does not rule out that the website inventory has been sold and not updated. Please consult customer service.

Can you provide technical service?

Need to see the product type and site conditions, equipment damage, humanities and other factors, please inform us, we will provide you with a suggestion!

Where can I order this series?

Please see the contact information of the website, official channels, and consulting customer service! Thank you for your cooperation!

Do you have product selection list and pre-sale service?

It can be downloaded from local agents, technical service companies, and the official website (pdf). Some special products are excluded. Please contact us as appropriate.

Let's Communicate

Call the enterprise hotline customer service consultant is waiting for you online

wechat/whatsapp:

Contact Business

Talk to a customer service consultant now about what you need to know

Positive message

Leave us a message and a customer service consultant will contact you within 24 hours

Wechat

Whatsapp

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved