-

Kongsberg TRX32 FILTER (303067B) | Elektro Marine

-

Kongsberg MRU-M-MB3 | Motion Reference Unit

-

Kongsberg TRX32 303088 | eight-channel I/O module

-

Kongsberg MRU2 Motion Reference Unit

-

KONGSBERG MRU-M-SU1 Industrial Measurement Unit

-

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

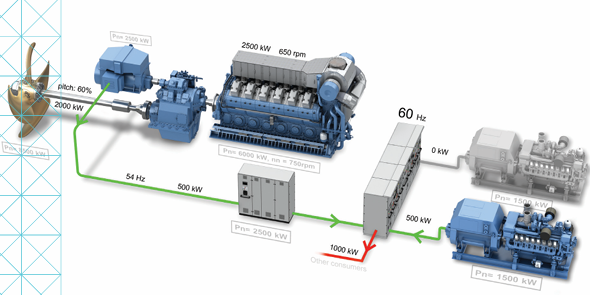

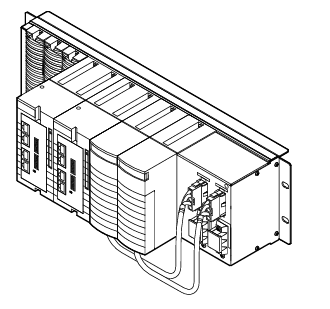

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

Kongsberg HiPAP 352P Portable acoustic positioning system

-

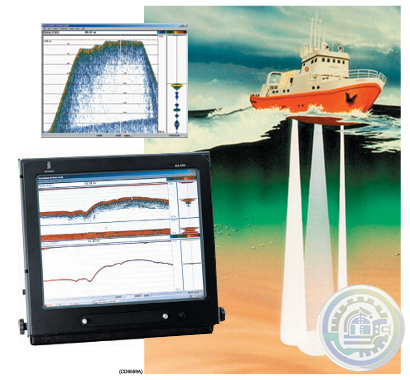

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

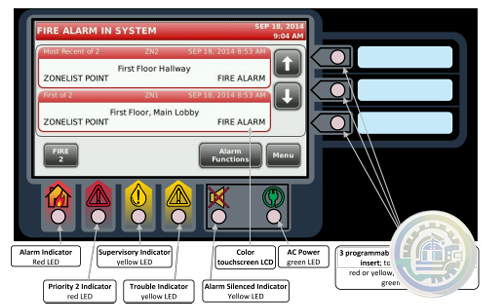

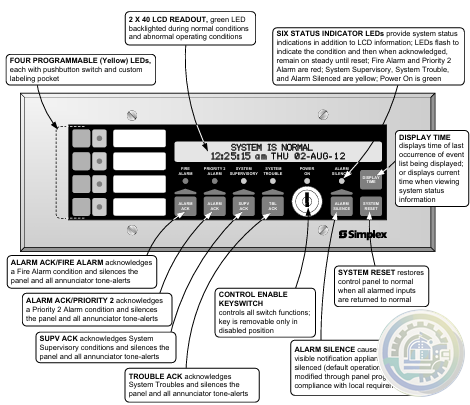

Kongsberg K-Chief 600 Alarm and Command Panel

-

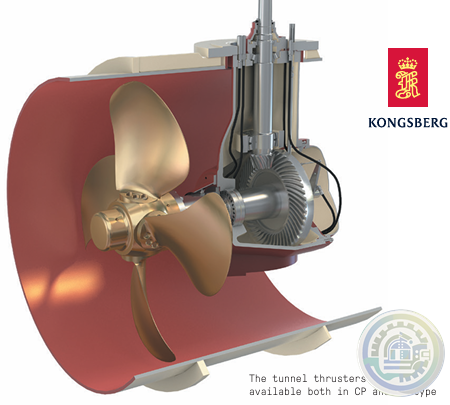

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

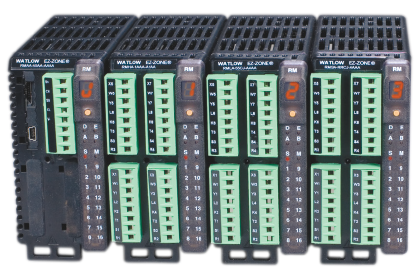

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

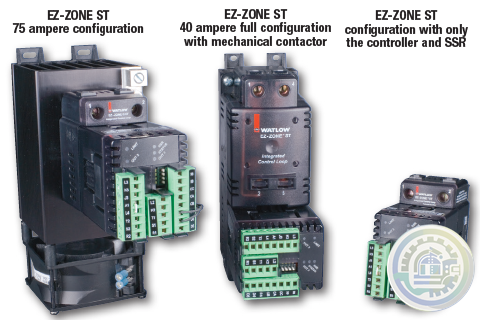

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

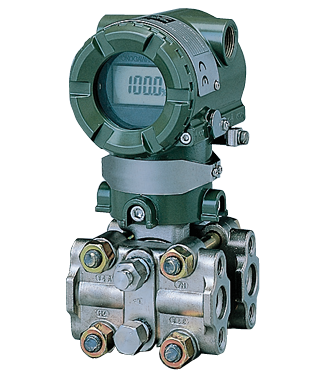

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

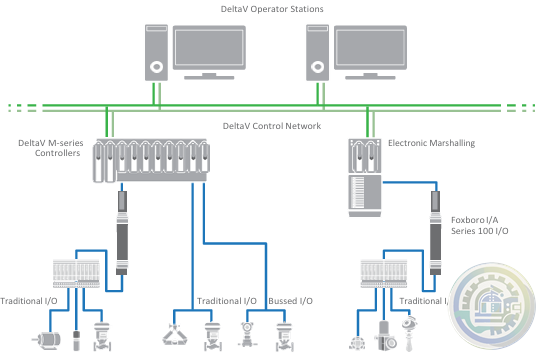

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

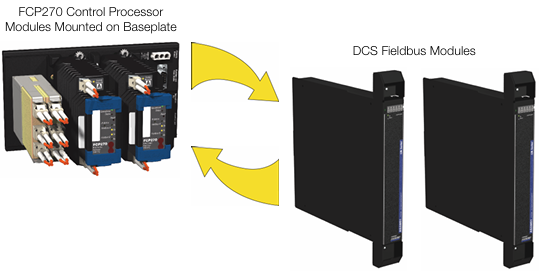

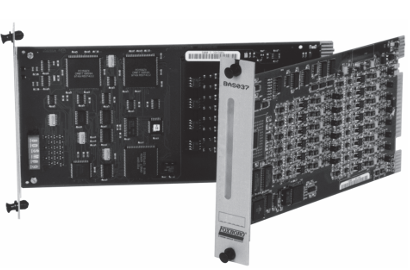

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

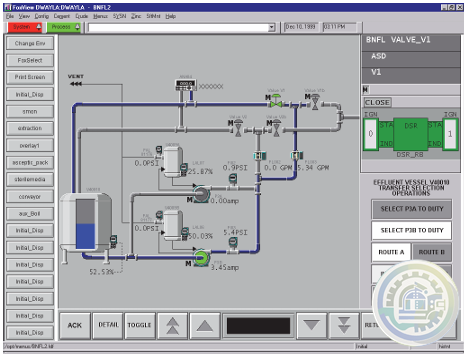

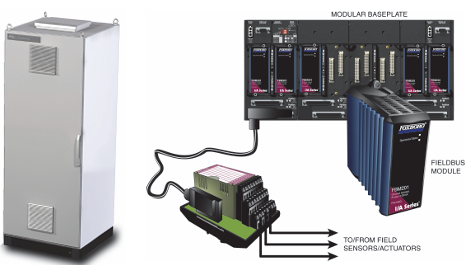

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

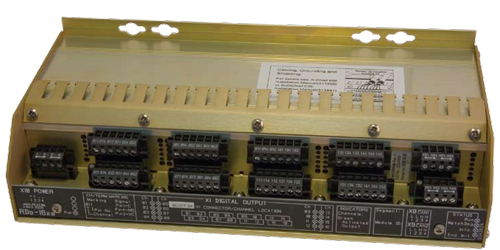

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

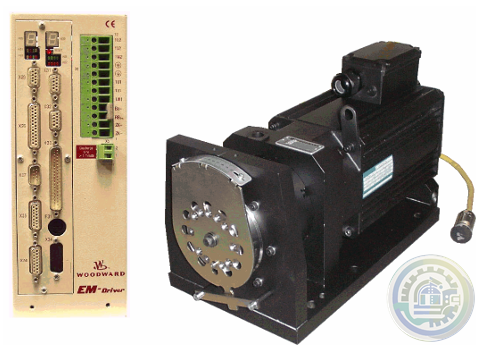

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

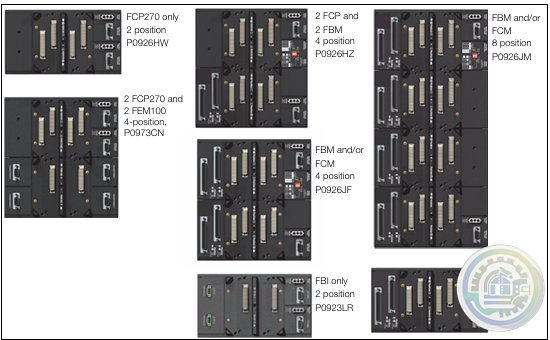

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

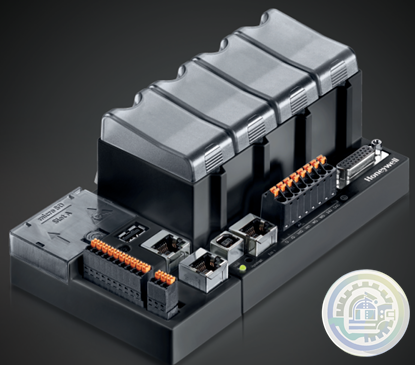

Honeywell ControlEdge™ PLC Modular Controllers

-

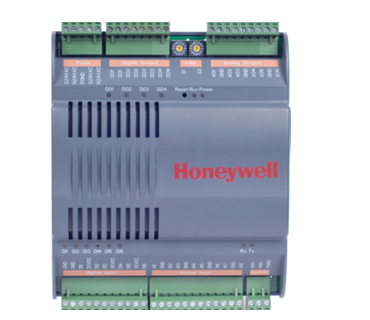

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

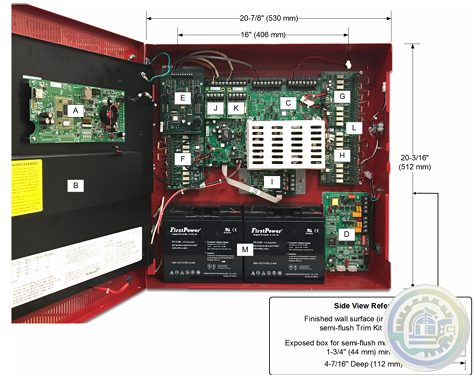

Honeywell ControlEdge™ HC900 How Does It Work?

-

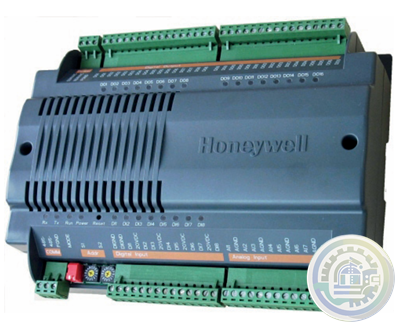

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

-

Honeywell E3Point Gas Detector

-

Honeywell 301C Controller

-

Honeywell 301IRF Refrigerant Gas Detector

-

Honeywell 301EM-20 Controller

-

Honeywell Series 3000 MkII

-

Honeywell XNX™ Universal Transmitter

-

Honeywell XNX Universal Transmitter

-

Honeywell MicroDock II Automatic Test and Calibration Station

-

Honeywell GasAlertMicro 5 Series Multi-Gas (1–5) Detectors

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Power requirements depend on the number and type of modules supplied for each system. For a system

with a single I/O chassis, size the input power source according to the rating of the MicroNet Plus power

supply to which the source is connected. Do not size the supply mains for the sum of the MicroNet Plus

power supply ratings when redundant supplies are used. MicroNet Plus supplies are redundant when

installed in the same chassis. Redundant supplies share the load between them equally, but each must

provide for full load in the event that one of the units is disabled. Table 4-3 gives the maximum overload

protection for supply mains connected to any single or redundant pair of MicroNet Plus main power

supplies. It is not recommended that both MicroNet Plus main power supplies of a redundant pair be

connected to a single source, since failure of that source would disable the system.

Application programming is done on the PCM112 using Woodward's MotoHawk application software tool.

MotoHawk is a rapid control system development tool that allows control engineers to quickly create control software directly in Simulink diagrams.

The software runs on any electronic control module that supports MotoHawk.

Working directly in the Simulink environment, application developers can convert application models

into files that can be programmed directly into Woodward production hardware in a single build step.

MotoHawk provides an advanced programming environment for users with control system expertise

but not necessarily specific embedded programming skills.

Once an application has been generated and loaded into the PCM112 controller via the CAN port, the

users can view variables and tune the controller using appropriate service interface tools such as Woodward's ToolKit or MotoTune.

Connections to other devices (such as diagnostic tools) are accomplished through other CAN ports available on the controller.

The required information flow is programmed into the controller via MotoTune or ToolKit.

The PCM112 controller consists of a rigid printed circuit board that is attached to an aluminum enclosure

using thermally conductive adhesive and then closed and sealed with an aluminum cover.

Connections to the controller are made via three automotive style sealed connectors.

The controller can be mounted directly to the engine or frame using vibration isolators.

The 8923-2241 includes the 1751-6685 module and mounting kit.

| Woodward | 8273-1013 | 2301E-ST – Steam Turbine Control 8273-1013 | |||

| Woodward | 8273-1014 | 2301E-ST – Steam Turbine Control, Hazardous Location Zone 2 8273-1014 | |||

| Woodward | 8237-2046 | 2301E-HT – Hydro Turbine Control (Francis), 24 VDC, Ordinary Location 8237-2046 | |||

| Woodward | 8200-1400 | 505HT – LVDC, Pelton Turbines 8200-1400 | |||

| Woodward | 8200-1401 | 505HT – HVAC/DC, Pelton Turbines 8200-1401 | |||

| Woodward | 8200-1402 | 505HT – LVDC, Francis / Kaplan Turbines 8200-1402 | |||

| Woodward | 8200-1403 | 505HT – HVAC/DC, Francis / Kaplan Turbines 8200-1403 | |||

| Woodward | 8269-1073 | 17” TouchPanel OCP – Includes RemoteView Software Program 8269-1073 | |||

| Woodward | 8928-5311 | RemoteView - Software License 8928-5311 | |||

| Woodward | 5404-1801 | Old 505 to New 505 Retrofit Wiring Kit 5404-1801 | |||

| Woodward | 8200-1500 | Peak200 – Bulkhead Mount, LV 8200-1500 | |||

| Woodward | 8200-1501 | Peak200 – Bulkhead Mount, HV 8200-1501 | |||

| Woodward | 8200-1502 | Peak200 – Bulkhead Mount, LV, ATEX Zone 2 8200-1502 | |||

| Woodward | 8200-1503 | Peak200 – Front Panel Mount, LV 8200-1503 | |||

| Woodward | 8200-1504 | Peak200 – Front Panel Mount, HV 8200-1504 | |||

| Woodward | 8200-1505 | Peak200 – Front Panel Mount, LV, ATEX Zone 2 8200-1505 | |||

| Woodward | 8200-1508 | Peak200 – Bulkhead Mount, HV, Class1 Div2 Haz. Loc. Compliant 8200-1508 | |||

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved