-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

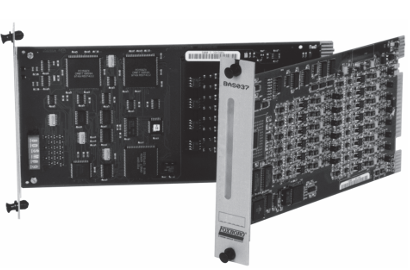

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

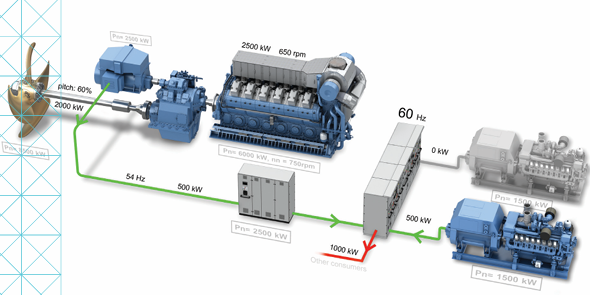

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

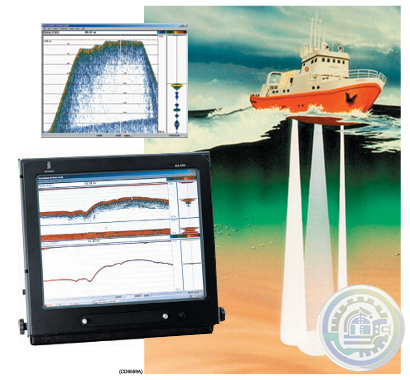

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

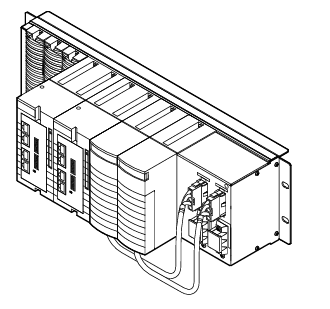

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

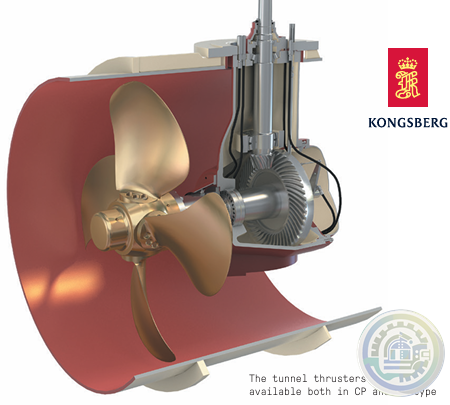

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

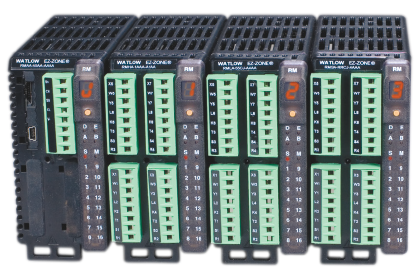

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

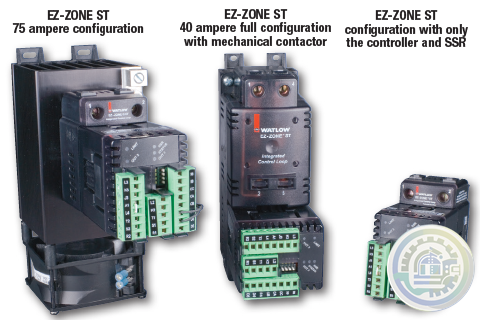

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

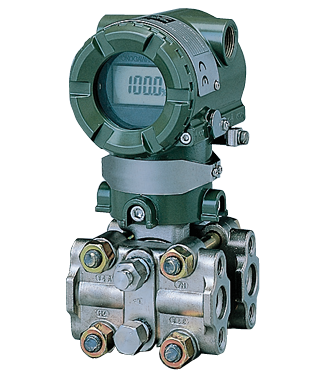

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

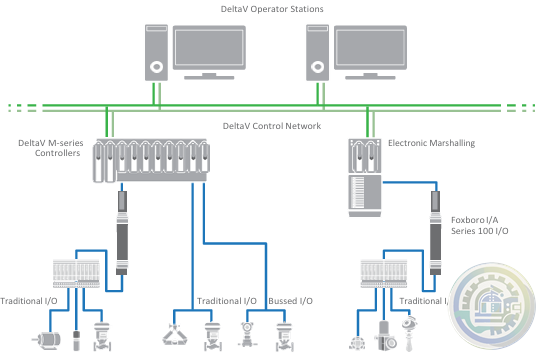

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

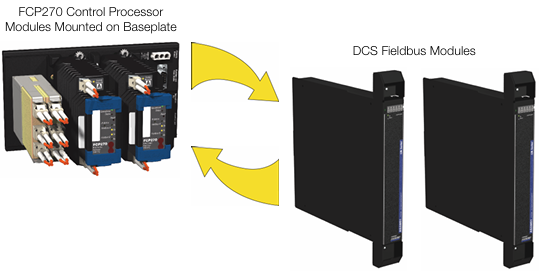

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

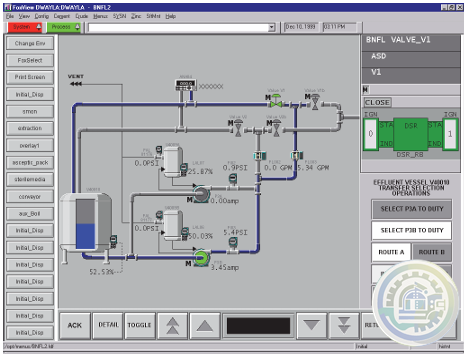

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

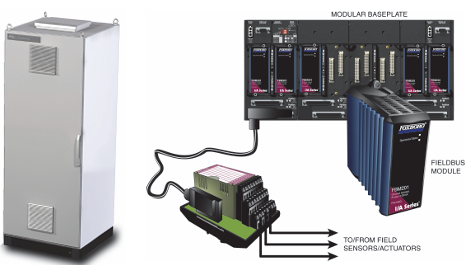

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

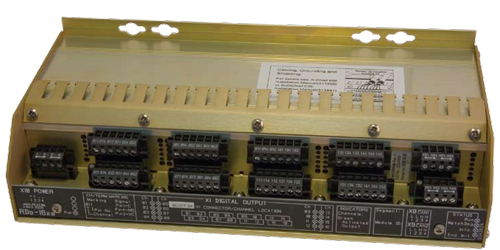

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

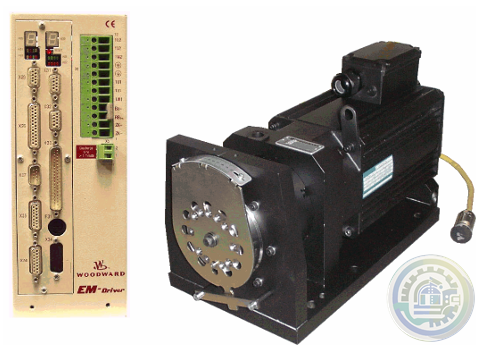

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

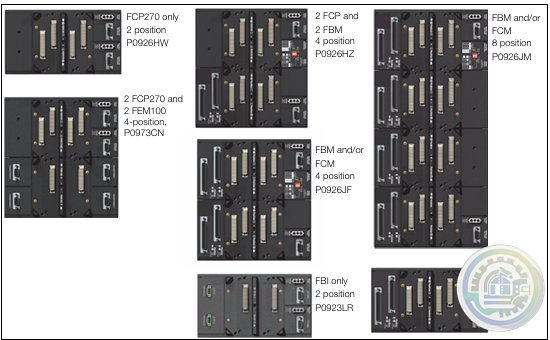

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

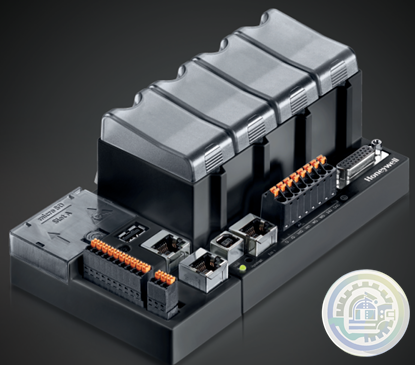

Honeywell ControlEdge™ PLC Modular Controllers

-

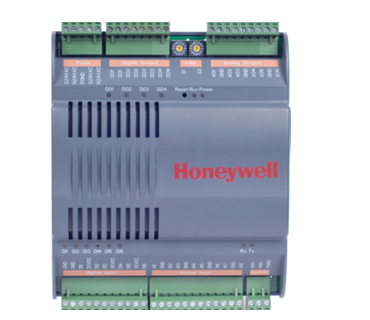

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

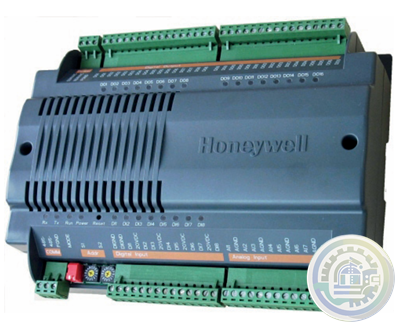

Honeywell ControlEdge™ HC900 How Does It Work?

-

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Challenges in the Automotive Industry

The automotive industry is very dynamic and requires extreme flexibility from automotive manufacturers.

The growing global competition demands smart production systems, combined with flexible logistics systems.

They can be adapted quickly and thus also serve the ever-increasing demand for model diversity.

In addition to the installation, a simple operation of the system plays an important role.

Automotive manufacturers increasingly find that they have to expand their core competencies in areas ranging from automotive industry to mobility or even to re-define those areas.

They are only able to stand in the competition if they could cope with developments around Industrie 4.0. demographic change and data-driven production.

Solutions for the automotive industry

KUKA offers you the necessary configuration options to meet all the automotive challenges efficiently:

through adaptable, modular and automated production and logistics processes, we pave the way to sustainable success in the automotive industry.

Our services and expertises

The KPP can additionally contain axis amplifiers for one to three axes. The drive interface on the connector panel is not included.

KUKA offers a range of production machines with which you can integrate standardized systems and components into customized production processes.

Depending on the specific requirements, automation components and function packages can be implemented directly in your production system or slightly modified.

Whether you need modern and efficient foundry equipment or machines for connecting various material combinations -

All these components have one thing in common: they are tried-and-tested products that are cost-effective and easy to integrate.

Highly dynamic. the KR 1000 titan handles the heaviest workpieces and components precisely and safely.

KUKA at the Battery Show Europe in Stuttgart

Modern technologies and processes such as friction stir welding are playing an increasingly important role in the complex production of electric vehicles and their batteries.

KUKA has been supporting customers here for decades with comprehensive industry and technology expertise.

At the Battery Show Europe in Stuttgart, the largest event for battery and electric vehicle technology in Europe,

industry experts and leading manufacturers will be talking about the latest developments.

KUKA will also be there from June 18 - 20. 2024 in hall 9. booth D20.

Robot-Store provides used or new industrial robot spares for KUKA robot, FANUC robot, ABB robot, MOTOMAN robot, and other manufacturers.

In addition, our expert will help to identify the parts you need If you are not sure which parts to quote.

Most of the robot parts have a unique number that will tell us exactly the robot spares you require for your robot.

The KUKA Power Pack is the drive power supply of the robot controller and generates the intermediate

circuit voltage with which the internal drive controllers and external drives are supplied.

The KPP can additionally contain axis amplifiers for one to three axes. The drive interface on the connector panel is not included.

Tailor-made services: from preventive maintenance to performance checks

Successful production is reliant on availability, output and quality of automation.

We can offer you a flexible range of services all over the world with measures tailored to

your individual needs to ensure that your machines and systems have the highest possible uptime.

With our various service level agreements, we offer everything from regular inspections and a technical hotline

to maintenance and extended warranties.

You can also benefit from our repair and replacement concepts,

the KUKA spare parts finder and a detailed analysis and performance check for your robot system.

KUKA is also responsible for the entire friction stir welding

In friction stir welding or FSW welding, a rotating, pin-like tool is guided between the contact surfaces of the component.

The frictional heat causes the material to plasticize, and the parts are joined together.

Even difficult-to-weld or dissimilar materials such as aluminum can be welded together with magnesium, copper, or steel.

This process consumes less energy and material and does not require shielding gas or flux cored wire as in conventional processes.

FSW welding is used in a wide variety of industries that have special requirements for welding seams,

be it battery containers, side walls of high-speed trains or tank structures of rockets.

In addition to the growth market of e-mobility, the technology is therefore also used in the aviation and electrical industries, for example.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved