-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

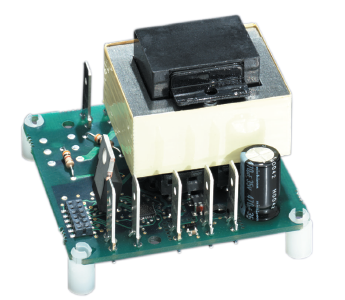

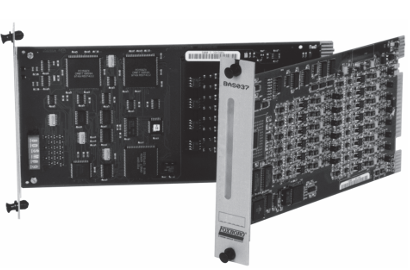

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

Alfa Laval EPC 60 Retrofit kit

-

ABB Digital annunciator unit SACO 64D4

-

ABB Model 264DD Differential/Gauge

-

ABB Alarm annunciators

-

ABB SACO 16 A3 Analog Annunciator Unit

-

Kollmorgen AKD PDMM® Programmable Drive, Multi-Axis Master

-

Kollmorgen PCMM: Programmable Controller, Multi-Axis Master

-

Kollmorgen PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

-

Kollmorgen P80630 Stepper Drive

-

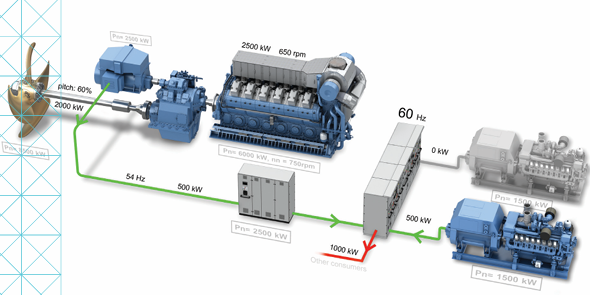

Kongsberg Maritime System and vessel conversions

-

ADLINK CPCI-3840 3U CompactPCI Intel® Pentium® M Processor Module

-

ABB Digital Annunciator Unit SACO 16D1

-

ABB SACO16D1-AA Digital Annunciator Unit

-

Kongsberg HIPAP® 352P PORTABLE HIGH PRESICION ACOUSTIC POSITIONING

-

Kongsberg MRU 5 Motion Reference Unit

-

Kongsberg MRU 5+ Motion Reference Unit

-

Kongsberg KONGSBERG MARITIME PROPULSION SYSTEMS Active Front End (AFE)

-

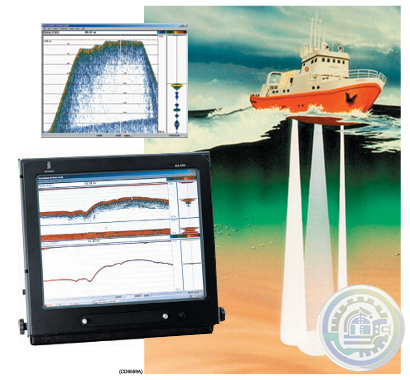

Kongsberg HiPAP 352P Portable acoustic positioning system

-

Kongsberg EA600 New generation precision hydrographic echo sounder

-

Kongsberg Digital Governor Unit (DGU) AutoChief® 600

-

Kongsberg AutoChief® 600 Propulsion Control System

-

Kongsberg K-Chief Vessel Automation System

-

Kongsberg AIS BS600 Automatic Identification System - Base Station

-

Kongsberg K-Chief 600 Alarm and Command Panel

-

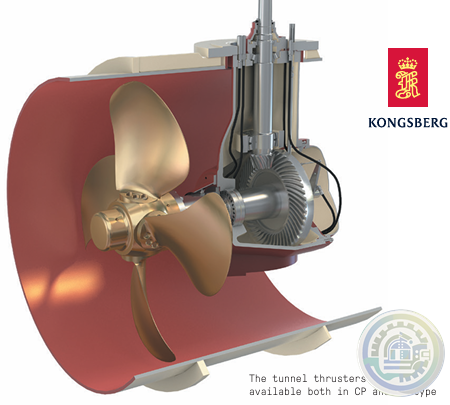

Kongsberg Tunnel Thrusters Type TT FP

-

Kongsberg AutoChief®600 Lever Telegraph Unit (LTU11)

-

YOKOGAWA Model AW810D Wide Area Communication Router

-

Watlow Eurotherm® 3200 Temperature/Process Controller

-

Watlow EtherCAT®, Fiber Optic Temperature Measurement and Control System

-

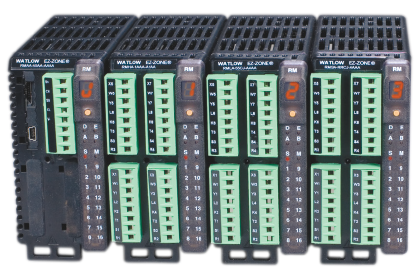

Watlow EZ-ZONE® RM Modular Controller Family

-

Watlow EFit SCR Power Controller

-

Watlow Basic Temperature and Limit Controllers

-

Watlow’s New WATCONNECT® Control Panels

-

Watlow EPack-2PH Compact SCR Power Controllers

-

Watlow Large and Extra-Large WATCONNECT® Panels

-

Watlow Eurotherm® EPack™ compact SCR power controllers-1PH -2PH -3PH

-

Watlow Eurotherm® EPack™ Lite Compact SCR Power Controllers

-

Watlow EPack™ Lite-1PH Compact SCR Power Controllers

-

Watlow’s new SERIES LS offers fixed limit set point temperature values

-

Watlow The SERIES LV limit family

-

Watlow’s family of microprocessor- based limit controllers SERIES LF

-

Watlow The EZ-ZONE RM controller simplifies thermal system management

-

Watlow The PM LEGACY™ series panel mount controller

-

Watlow EZ-ZONE® Remote User Interface (RUI)

-

Watlow Silver Series EM Operator Interface Terminal

-

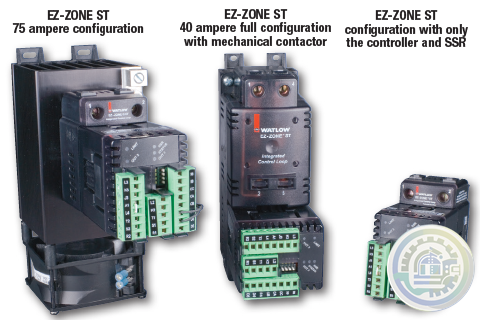

The EZ-ZONE® ST integrated solid state controller from Watlow®

-

YOKOGAWA Cooling Water Pump Failure Prediction Monitoring

-

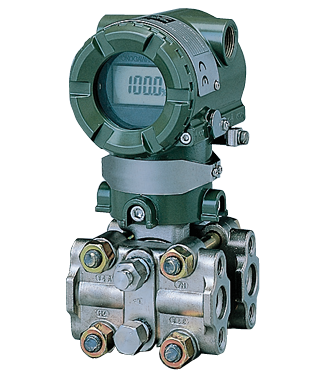

YOKOGAWA EJA Series Differential Pressure and Pressure Transmitters

-

YOKOGAWA EJA110E Diff erential Pressure Transmitter

-

YOKOGAWA AXF Magnetic Flowmeter Series

-

YOKOGAWA Turbomachinery Controller Overview (FCN-500/FCN-RTU)

-

YOKOGAWA STARDOM FCN-RTU Autonomous Controller

-

YOKOGAWA FCN Autonomous Controller Hardware (FCN-100)

-

YOKOGAWA STARDOM FCN-500 Autonomous Controller

-

CTI 2500-R4 Four-Slot Base with High-Speed Channel

-

CTI 2500P-J750 Janus PAC with 3MB Project Memory

-

CTI 2500C-J750“Janus”Compact Programmable Automation Controller

-

CTI 2500 Series® Compact Programmable Controllers

-

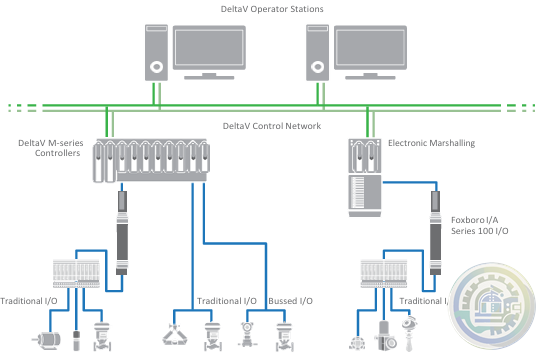

Emerson DeltaV™ Flex.Connect Solutions for Foxboro™ I/A Series 100 I/O

-

Emerson Modernization of Foxboro I/A Series® Systems to the DeltaV™ System

-

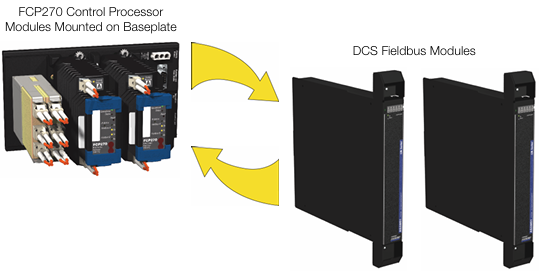

Foxboro DCS Fieldbus Modules for APACS+™ Automation Systems

-

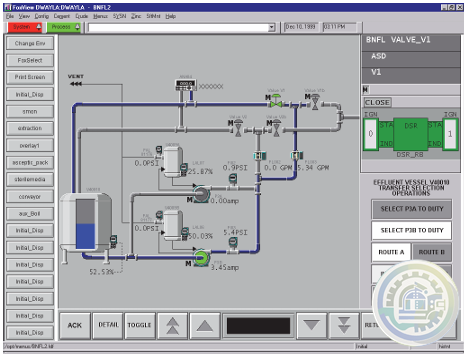

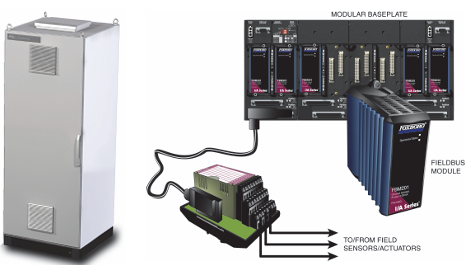

Foxboro Evo™ Process Automation System

-

Foxboro™ DCS G61 Tricon Termination Enclosure

-

Foxboro G60 Tricon System Enclosure I/A Series® HARDWARE

-

Foxboro G62 and G72 Tricon System and Termination Enclosures

-

Foxboro I/A Series® Hardware DIN Rail Mounted Fieldbus Module Baseplate

-

Kongsberg K-Chief 600 Marine automation system

-

Kongsberg WCC 600 Watch Call Panels

-

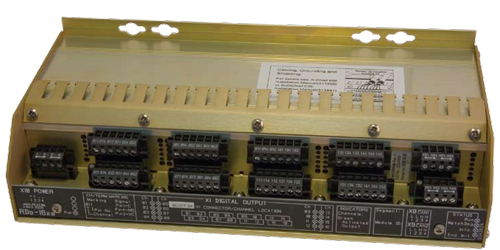

Kongsberg Distributed Processing Units Remote Digital Output (RDo-16xe)

-

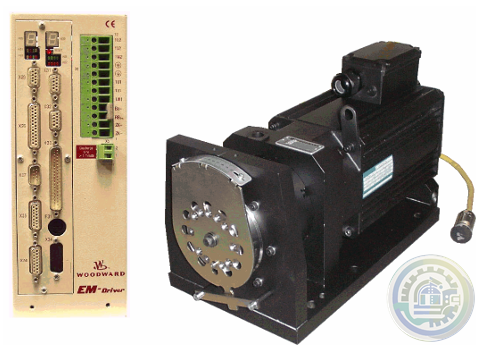

Woodward EM‐80 and EM‐300 Actuators All‐Electric Actuator System

-

Foxboro DCS FBM for Migration of Bailey® Systems

-

Foxboro Migration with FCP280 and DCS FBMs

-

Foxboro DCS Fieldbus Modules for Siemens APACS+™ Automation Systems

-

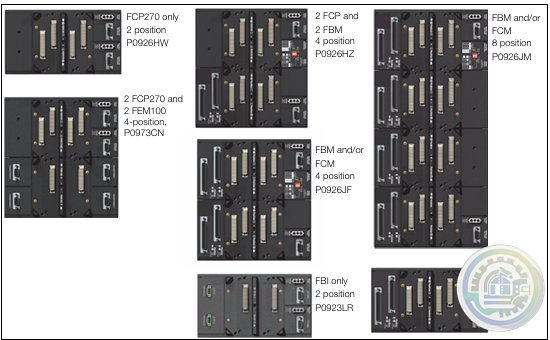

Foxboro 200 Series Baseplate Module Mounting

-

Foxboro Standard 200 Series Subsystem Overview

-

Foxboro Field Control Processor 270 (FCP270)

-

Johnson Controls DIS1710 Local Controller Display Installation Instructions

-

Johnson Controls FX-DIS Local Controller Display

-

Johnson Controls WRZ Series Wireless Room Sensors

-

Woodward EM-80/EM-300 Actuator System

-

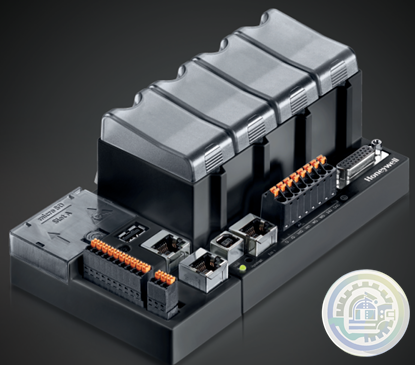

Honeywell ControlEdge™ PLC Modular Controllers

-

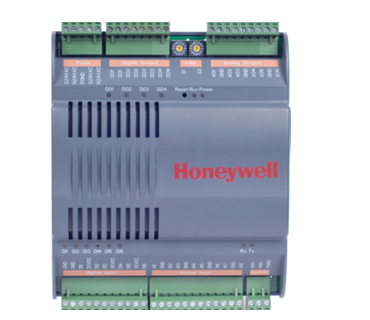

Honeywell CONTROLEDGE PCD Compact, Cyber Secure Control System

-

Honeywell M6410A, M7410F Non-Spring Return Cartridge Globe Valve Actuator

-

Honeywell ControlEdge™ HC900 How Does It Work?

-

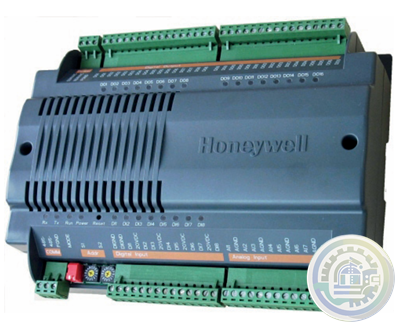

Honeywell ControlEdge HC900 controller

-

Honeywell HC900 Functional Overview

-

Honeywell Optimizer Advanced Controllers are a family of next generation integration & plant controllers

-

Honeywell Optimizer Advanced Controller

-

Honeywell Excel Web II Control System

-

Honeywell CPO-PLANT Controller area of the site

-

Honeywell ComfortPoint Niagara T1L VAV Controller

-

Honeywell ComfortPoint™ Open Plant Controller

-

Honeywell ComfortPoint Open CP-EXPIO (EXPANSION IO BOARD)

-

Honeywell ComfortPoint Open CPO-VAV2A-US (UNITARY CONTROLLER)

-

Honeywell ComfortPoint™ Open CPO-PC400 Plant Controller

-

Honeywell I/O MODULES EXPANSION MODULES & WIRING ADAPTER

-

Honeywell CPO-DIO ComfortPoint Open (DIGITAL I/O CONTROLLER)

-

Honeywell CP-Core ComfortPoint Open

-

Honeywell CPO-IO830A ComfortPoint Open MIXED I/O MODULE

-

Honeywell Sensepoint XCD

- Baldor

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

Barrel Control

Select barrel control for multiple–zone applications in which there is

thermal conduction between the zones. Injection molding and

extrusion are good example applications because they use multiple

heater bands (zones) mounted on one thermal conductor (the metal

barrel). The barrel conducts heat between different zones. If you

select barrel control, also select between inner and outer zones (word

1, bit 13 for channel 1). A barrel loop is autotuned as the temperature

rises from a cold start to a temperature setpoint during startup.

Non–barrel control

Select non–barrel control for applications with independent loops and

no thermal conduction between zones. If you select non–barrel

control, the inner/outer zone selection doesn’t apply.

Switching the barrel control

For some applications, even though the loops are independent with

no thermal conduction between zones, barrel control might provide

better performance than non–barrel control. If a loop has any of these

characteristics, you might want to use barrel control if the:

• time constant is greater than 10 - 30 seconds

• loop has a problem of overshooting the setpoint

• loop output is saturating (CV is at 100%) for a significant duration

Output response

When the slot for this module is disabled, configuration words in the

SLC processor’s output image table are held in their last state and not

transferred to the module. When the slot is re–enabled, output image

table words are transferred to the module during the subsequent scan.

Installing and Wiring

This document gives you information about:

• avoiding electrostatic damage

• compliance with European Union directive

• determining the module’s chassis power requirement

• planning for sufficient enclosure depth

• choosing a module slot in a local I/O chassis

• installing the module

• wiring the module

TC Break Control

Word 4 or O:e.8 for Channel1

If a loop input circuit becomes open (open wire) the loop can not

measure temperature. In automatic mode, the lack of temperature

feedback makes it impossible to control the temperature. To guard

against this condition, the BTM module provides TC break detection.

When a break is detected, the module responds in one of these ways:

• disables the loop

• forces CV to this (TC Break Control) value (word 4 for loop 1)

• forces the CV to the manual %–output value (O:e.8 for loop 1)

Once the thermocouple break has been repaired you must disable the

loop and then re-enable it (through the input image table O:e.0/0 loop 1).

Module Addressing

When you enter the module ID in processor configuration (off-line),

the processor automatically reserves the required number of I/O

image table words. In the figure below, that section of the I/O image

table is designated by “slot e”. Its location in the I/O image table is

determined by the module’s slot location “e” in the I/O chassis. Slot

location “e” is a required addressing unit when referring to the

module in ladder logic. For the sample program’s data table layout

A-B 1756-OB32 module Rockwell ControlLogix 32 digital output

A-B 1756-OV32E module Rockwell ControlLogix 32 digital output

A-B 1756-OW16I module Rockwell ControlLogix 16 digital output

A-B 1756-OX8I module Rockwell ControlLogix 8 digital output

A-B 1756-PA72 Module Rockwell ControlLogix AC Power Supply

A-B 1756-PA75 Module Rockwell ControlLogix AC Power Supply

A-B 1756-PA75R Module Rockwell ControlLogix AC Power Supply

A-B 1756-PAR2 Module Rockwell ControlLogix AC Power Supply

A-B 1756-PAXT Module Rockwell ControlLogix XT Power Supply

A-B 1756-OB8 module Rockwell ControlLogix 8 digital output

A-B 1756-OB8EI module Rockwell ControlLogix 8 digital output

A-B 1756-OB8I module Rockwell ControlLogix 8 digital output

A-B 1756-OC8 module Rockwell ControlLogix 8 digital output

A-B 1756-OF4 module Rockwell ControlLogix 4 analog

A-B 1756-OF6CI module Rockwell ControlLogix 6 analog

A-B 1756-OF6VI module Rockwell ControlLogix 6 analog

A-B 1756-OF8 module Rockwell ControlLogix 8 analog

A-B 1756-OF8H module Rockwell ControlLogix 8 analog

A-B 1756-OG16 module Rockwell ControlLogix 16 digital output

A-B 1756-OH8I module Rockwell ControlLogix 8 digital output

A-B 1756-ON8 module Rockwell ControlLogix 8 digital output

A-B 1756-OV16E module Rockwell ControlLogix 16 digital output

A-B 1756-PB72 Module Rockwell ControlLogix DC Power Supply

A-B 1756-PB75 Module Rockwell ControlLogix DC Power Supply

A-B 1756-PB75R Module Rockwell ControlLogix DC Power Supply

A-B 1756-PBR2 Module Rockwell ControlLogix Power Supply

A-B 1756-PBXT Module Rockwell ControlLogix XT Power Supply

A-B 1756-PC75 Module Rockwell ControlLogix DC Power Supply

A-B 1756-PH75 Module Rockwell ControlLogix DC Power Supply

A-B 1756-PSCA2 Module Rockwell ControlLogix Adapter

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved