-

Emerson SE8701V03-TH VI Tach CHARM

-

Emerson SE8701V02-VT VI Voltage CHARM

-

Emerson SE8701V01-PZ VI Piezo CHARM

-

Emerson SE8701-SHADE Protection from the sun Accessory Model

-

Emerson A02100WLAN External Wireless Router for outside of North America

-

Emerson Online Prediction, Protection and Process Monitor

-

Emerson The next step in your digital transformation just got easier!

-

Emerson AMS Wireless Vibration Monitor

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

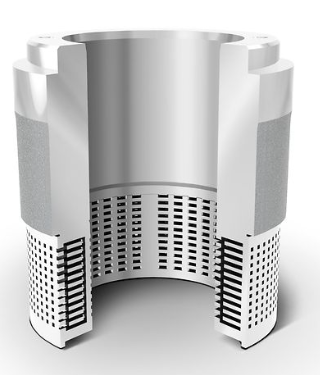

Emerson Fisher™ Whisper Trim™ I Cage

-

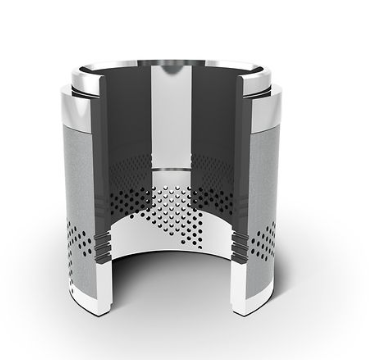

Emerson Fisher™ Whisper Trim™ III Cage

-

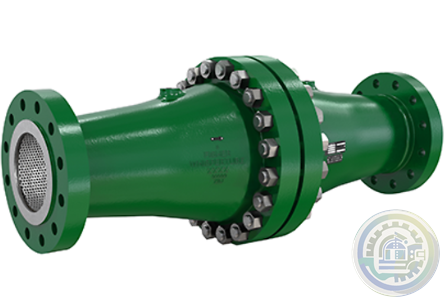

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

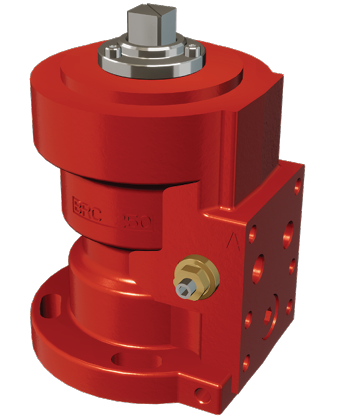

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

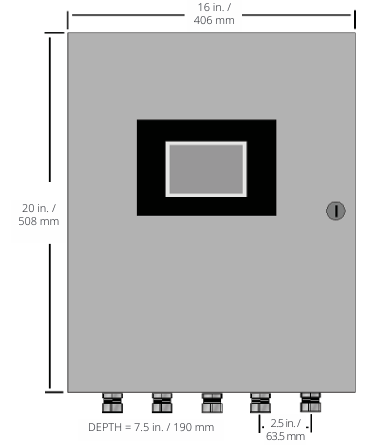

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

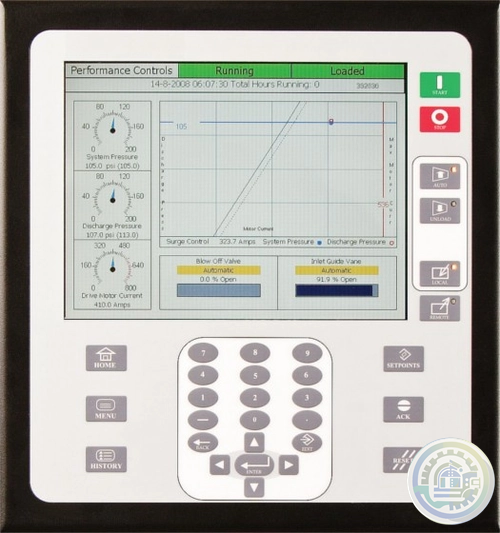

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

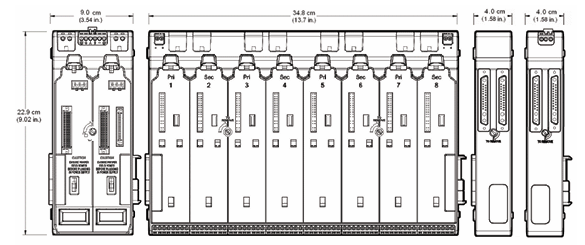

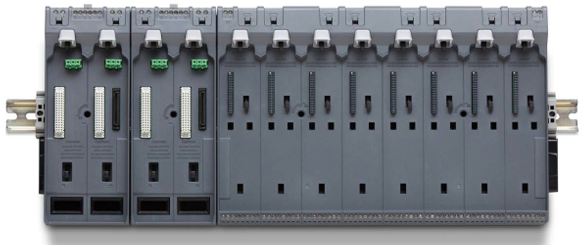

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

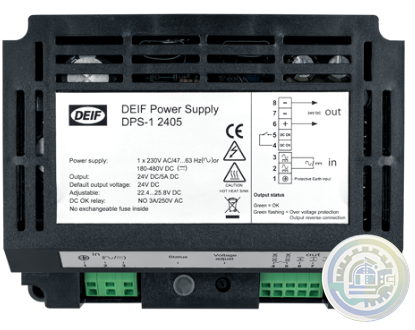

DEIF DPS-1 DC Power Supply

-

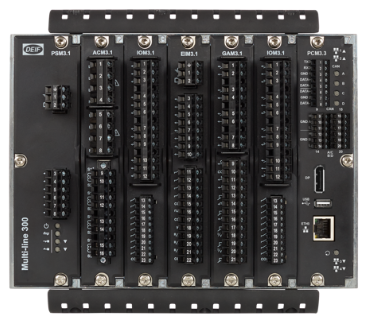

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

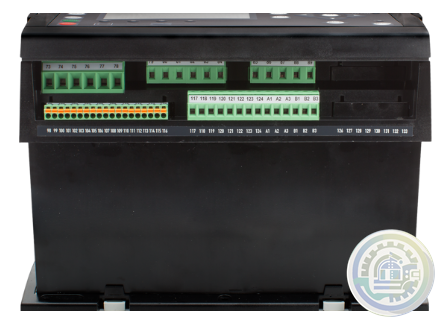

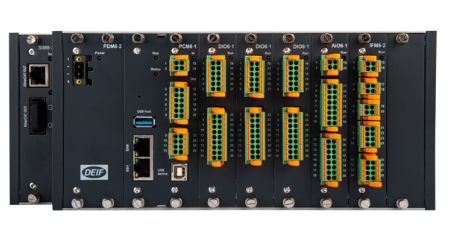

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

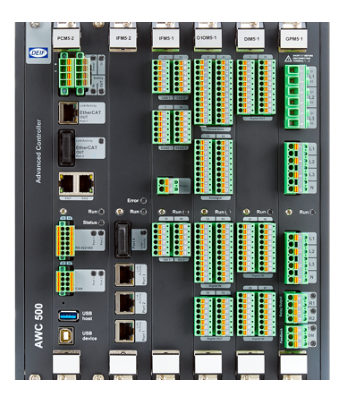

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

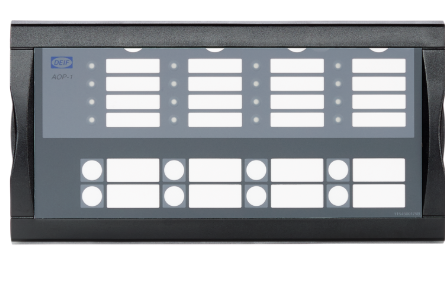

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

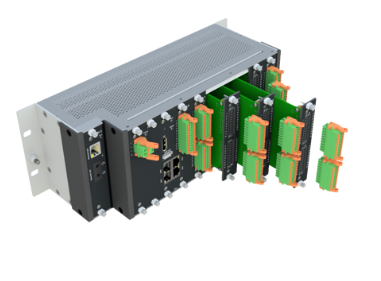

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

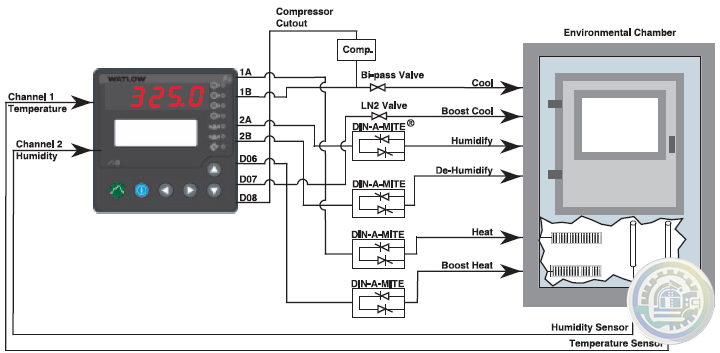

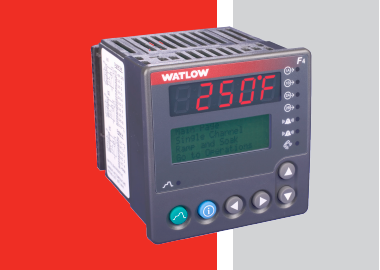

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

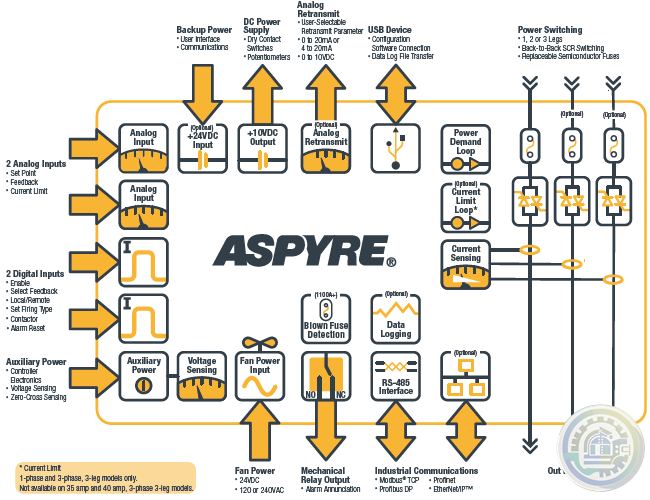

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

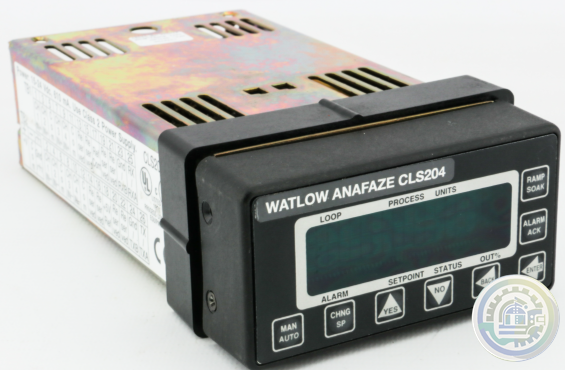

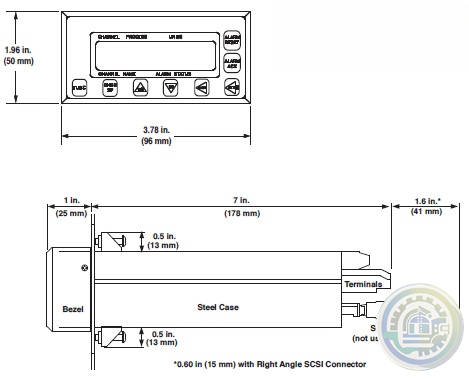

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

The S-series H1 with integrated power provides local LED indicators to assist in trouble shooting:

2 Yellow LED’s: One per port Indicating the port is enabled and communicating with devices.

2 Red LED’s: One per port indicating to health of power supply as well as monitoring voltage or short circuit faults on the physical layer.

Fault LED: Indicates internal fault with the H1 card.

Power LED: Indicates available LocalBus power.

The Fieldbus I/O Card meets ISA G3 corrosion specifications by using superior electronic components and conformal coating.

One of the most powerful features of FOUNDATION Fieldbus devices is their diagnostic data.

Using AMS Device Manager, you can access all of the necessary information to configure,commission, monitor,

and troubleshoot all your FOUNDATION Fieldbus smart devices. Improved device diagnostics can lead to increased product quality and minimize unplanned downtime.

Improve the productivity and profitability of your process control system with FOUNDATION Fieldbus.

Leveraging Digital Intelligence

The Ovation PlantWeb digital plant architecture begins with a strong foundation of intelligent field devices from industry leaders such as Fisher and Rosemount.

With their digital capabilities — including onboard microprocessors, embedded software, and openstandard communications — these field devices can…

• Deliver precise measurement and control to reduce process variability.

• Handle multiple variables to reduce the number of devices required.

• Perform diagnostics to monitor device health, predict problems, and avoid downtime.

Ovation Simulation

Emerson offers Ovation Simulation solutions using virtual technology that faithfully replicates the

Ovation DCS within a simulator configuration by using a few desktop workstations.

This approach reduces hardware costs and footprint, allows easy portability for use throughout the facility,

and greatly simplifies ongoing simulator maintenance and upgrades to track ongoing control system modifications.

Ovation simulation is a valuable and flexible tool to improve plant operations.

Typical applications include DCS validation prior to its installation, operator training programs, engineering upgrades,and control changes to improve plant performance.

Comprehensive Support for the Life of the System

That support begins with our customer training programs.

Conducted by experienced engineers at your facility or ours, our training programs provide your operators, engineers,

and technicians with the knowledge and skills they need to effectively operate and maintain your systems.

Our training programs are tailored for your needs and can include custom-designed plant simulators that employ the same software and graphics used on the actual system.

We also understand the pressures to minimize plant staffs while maximizing plant performance.

With that understanding, we have structured our service and support programs to provide the flexibility and responsiveness necessary to meet your needs.

Benefits

Increase I/O capacity while reducing wiring.

Use FOUNDATION Fieldbus I/O instead of Classic I/O to increase the I/O density and quality of information of your

field devices. Take advantage of FOUNDATION Fieldbus digital communications to access additional information from your

smart devices. Get more information over one wire with up to 16 Ff devices per H1 segment, and 2 segments per card for up

to 32 devices per H1 card.

Product Description

FOUNDATION™ fieldbus I/O is a modular subsystem that communicates digitally with field devices,

increases your input/output capacity, and gives you access to more information about your process than conventional I/O subsystems.

It greatly enhances device diagnostics that affect your control strategy and alerts operators to device malfunctions.

If you want an efficient, economical, and secure process control system, use DeltaV™ FOUNDATION fieldbus I/O.

Maximize smart device capabilities. Increase your quality and throughput by taking advantage of the added diagnostics

of FOUNDATION Fieldbus I/O devices. Field device status is updated continuously using FOUNDATION Fieldbus I/O.

For multi-variable devices, all process variables are available on the single fieldbus at the cost of a single Device Signal Tag.

Redundant H1 cards provide increased availability.

The DeltaV system offers redundant H1 interfaces. The two H1

interfaces are connected with a redundant terminal block to

provide back-up link active schedule (LAS) capability that also

maintains communication with the host system.

Transfer to the standby card is automatic and requires no special configuration.

Ongoing diagnostics ensure the standby H1 card is available on demand.

This process requires no user interaction.

Prerequisites

A fieldbus power supply is required for each bus segment.

Each fieldbus segment must be terminated at both ends.

A fieldbus brick and terminator for each segment are recommended.

Contact your local sales office for more information on complementary Fieldbus components.

Recommended Products P/N:

EMERSON 24VDC System Power Supply SE5009

EMERSON S-series AS-i Interface Card

EMERSON S-series Actuator Sensor Interface Card, includes terminal block SE4009

EMERSON S-series 4-port Foundation™ Fieldbus I/O

EMERSON SE4019P0 Simplex H1 4-port Plus; Fieldbus I/O Interface with Terminalblock

EMERSON SE4039P0 Redundant H1 4-port Plus; Fieldbus I/O Interface with Terminalblock

EMERSON DeltaV SISTM Logic Solver

EMERSON VS3202 DeltaV SLS 1508 Redundant Logic Solver

EMERSON DeltaV™ MX Controller VE3007

EMERSON VE3006 M-series MD Plus Controller MD-PLUS Controller

EMERSON DeltaV™ Wireless I/O Card SE4801T01 SE4801T02

EMERSON Ethernet I/O Card (EIOC)

EMERSON SE4100 Simplex Ethernet I/O Card (EIOC) Assembly

EMERSON SE4101 Redundant Ethernet I/O Card (EIOC) Assembly

EMERSON MODBUS TCP Interface for Ethernet connected I/O (EIOC) VE4103

EMERSON EtherNet/IP Control Tag Integration for Ethernet connected I/O (EIOC) VE4104

EMERSON EtherNet/IP Interface for Ethernet connected I/O (EIOC) VE4105

EMERSON OPC-UA client for Ethernet connected I/O (EIOC) VE4106

EMERSON IEC 61850 MMS Interface for Ethernet connected I/O (EIOC) VE4107

EMERSON Ethernet connected I/O (EIOC and PK): nn Physical Devices VE4109Sxxx

EMERSON Ethernet I/O card KL2001X1-BD1

EMERSON Ethernet Isolation Port for Twisted Copper KL1604X1-BA1

EMERSON Dual Horizontal Carrier KL4104X1-BA1

EMERSON Universal Carrier Protection Cover SE6106

EMERSON DeltaV™ SX Controller SE3007

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB 5C4045L0006 3MB030310R00001 3BH039203R0101 GVC736SE101 IGCT Module

-

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 IGCT Module

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved