-

Emerson SE8701V03-TH VI Tach CHARM

-

Emerson SE8701V02-VT VI Voltage CHARM

-

Emerson SE8701V01-PZ VI Piezo CHARM

-

Emerson SE8701-SHADE Protection from the sun Accessory Model

-

Emerson A02100WLAN External Wireless Router for outside of North America

-

Emerson Online Prediction, Protection and Process Monitor

-

Emerson The next step in your digital transformation just got easier!

-

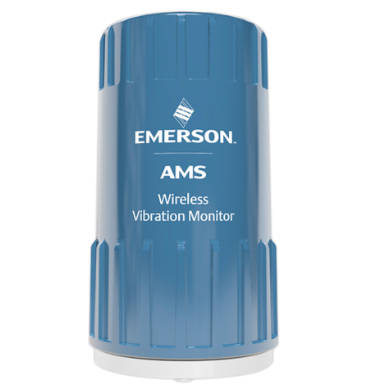

Emerson AMS Wireless Vibration Monitor

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

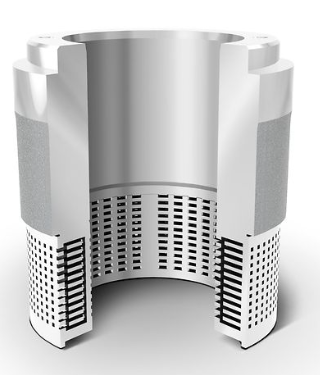

Emerson Fisher™ Whisper Trim™ I Cage

-

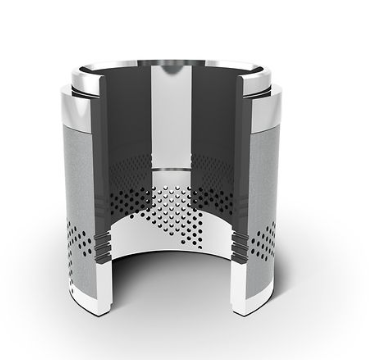

Emerson Fisher™ Whisper Trim™ III Cage

-

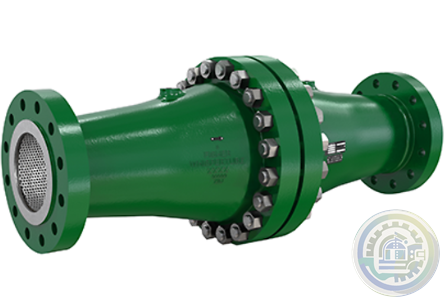

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

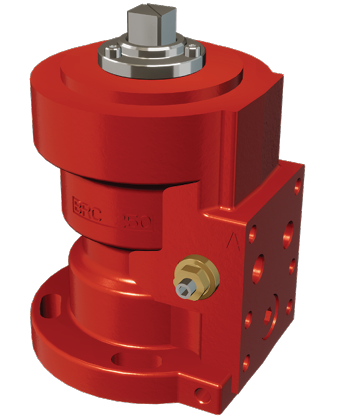

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

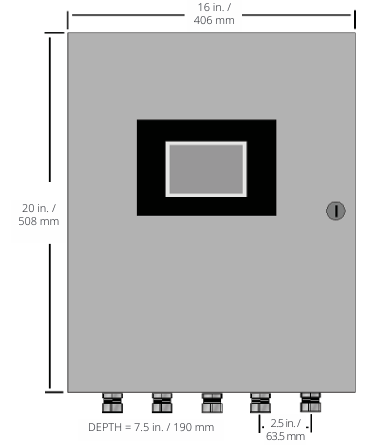

Emerson Model M250N Mounting of Rack Mount Enclosure

-

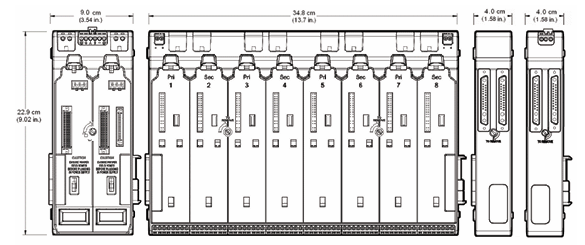

Emerson Model M250N Controlinc Network Controller System Configuration

-

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

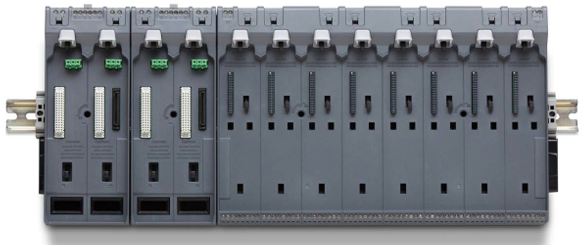

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

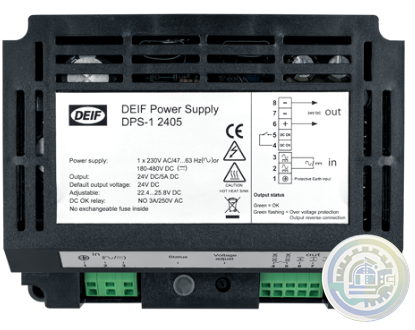

DEIF DPS-1 DC Power Supply

-

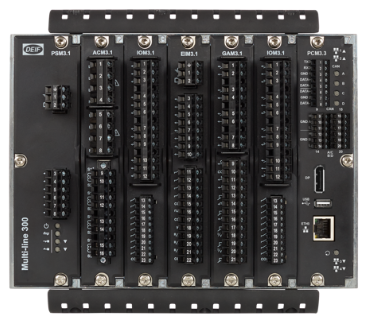

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

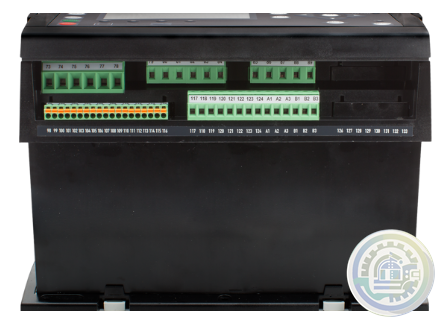

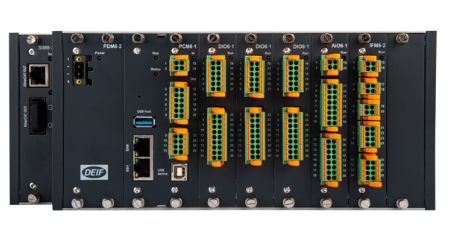

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

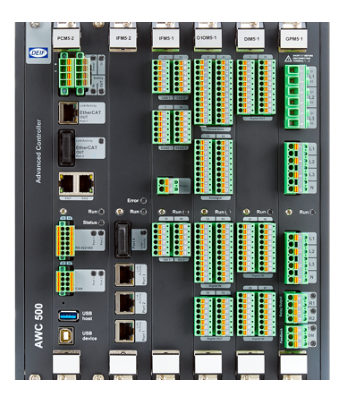

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

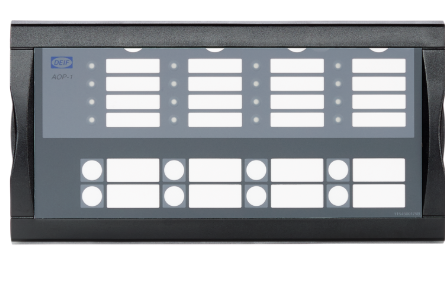

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

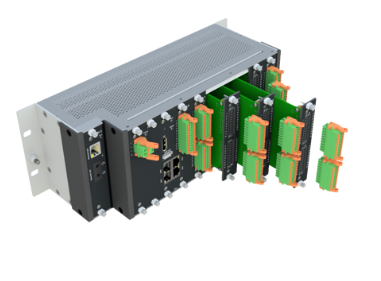

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

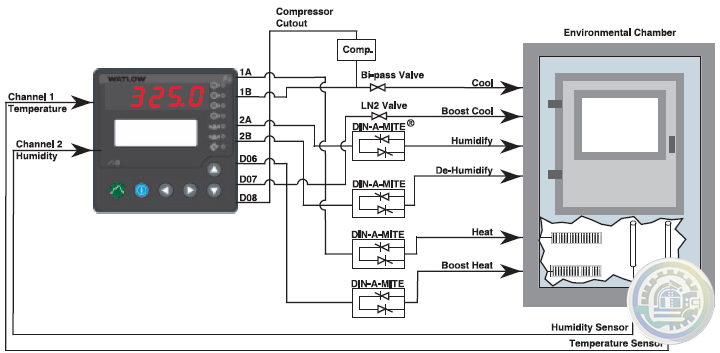

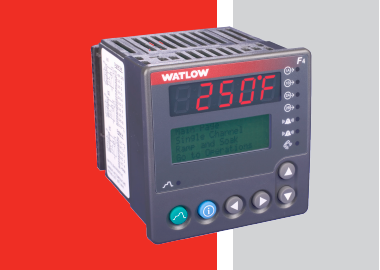

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

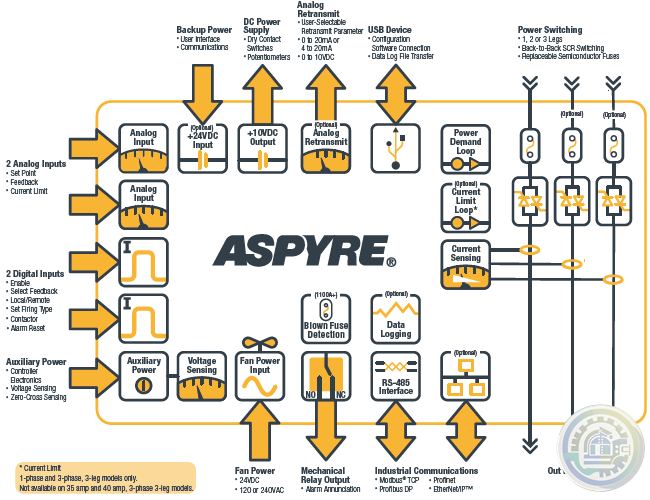

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

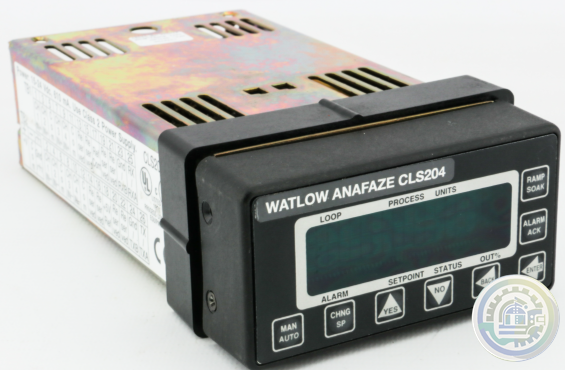

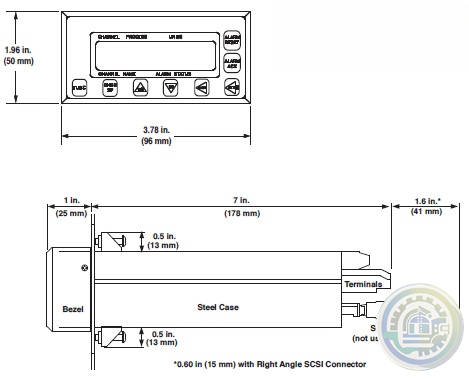

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

Current Location:

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

66

Product parameters

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Feature

**ABB DSBB110A: High-Performance Automation Solution for Power and Petrochemical Industries**

The ABB DSBB110A is a cutting-edge automation product that is engineered to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. With its robust design and advanced technical features, the DSBB110A stands out as a reliable solution for industrial automation needs.

**Key Technical Features**

The ABB DSBB110A boasts impressive input/output capacity, providing users with enhanced flexibility and control over various automation processes. With a total of 32 discrete inputs and 32 discrete outputs, this module allows for streamlined data collection and operational commands, making it an integral component for complex systems. The device operates efficiently within a temperature range of -20°C to +60°C, ensuring durability even in harsh environments.

In terms of performance metrics, the DSBB110A is designed for high-speed processing, with response times that outpace many competitors in the market. Its built-in fault tolerance capabilities reduce downtime, ensuring continuous operation critical in industries where reliability is paramount. The module also supports multiple communication protocols, allowing seamless integration with existing systems, such as ABB PLC Module 3BHE004468R0021 GDC780BE21, and ABB TA523.

**Real-World Usage Scenarios**

In the power industry, the ABB DSBB110A excels in monitoring and controlling energy distribution systems. Its ability to process real-time data enables energy operators to optimize load management and enhance grid reliability. In petrochemical applications, the DSBB110A is essential for automating complex processes like refining and chemical production, where precision and efficiency are vital. Additionally, in general automation scenarios, such as manufacturing lines or assembly processes, the DSBB110A integrates seamlessly to enhance productivity and operational efficiency.

When compared to other models within the ABB range, the DSBB110A showcases distinct advantages. For instance, unlike the ABB PM802F, which specializes in power management, the DSBB110A provides a more versatile solution applicable across various sectors. Its I/O capacity surpasses that of the ABB 560CMU05, making it a more suitable choice for large-scale applications. Furthermore, the DSBB110A’s fast processing speeds give it an edge over models like the ABB DSQC697, particularly in scenarios requiring rapid data handling and response.

**Complementary ABB Models**

The ABB DSBB110A works harmoniously with several other models within the ABB portfolio, enhancing its functionality and versatility. The ABB IMASI23, for instance, can be utilized alongside the DSBB110A to provide advanced monitoring capabilities. The ABB PM564-R-AC complements the DSBB110A by facilitating power management in conjunction with automation processes. Users can also integrate the ABB TU520-ETH for Ethernet communication, ensuring that the DSBB110A remains connected within a larger network of ABB automation products.

Additionally, the ABB 3HAB6597-1 can be paired with the DSBB110A for added control in industrial applications. The ABB AX521 serves as an excellent companion for data acquisition, while the ABB PFEA113-65 enhances the overall functionality by allowing for more extensive input/output interfaces. Other models like the ABB 3ABD00033153 and ABB DSCS131MFB can also be utilized to provide a comprehensive automation solution that meets the specific needs of various industries.

In conclusion, the ABB DSBB110A is a versatile and high-performance automation module that excels in the power industry, petrochemical applications, and general automation. Its robust technical features, coupled with its ability to integrate with a wide range of other ABB models, make it an ideal choice for organizations seeking to improve operational efficiency and reliability in their automation processes. With the ABB DSBB110A, users can confidently navigate the challenges of modern industrial environments, ensuring their systems are efficient, reliable, and future-ready.

The ABB DSBB110A is a cutting-edge automation product that is engineered to meet the demanding requirements of the power industry, petrochemical sector, and general automation applications. With its robust design and advanced technical features, the DSBB110A stands out as a reliable solution for industrial automation needs.

**Key Technical Features**

The ABB DSBB110A boasts impressive input/output capacity, providing users with enhanced flexibility and control over various automation processes. With a total of 32 discrete inputs and 32 discrete outputs, this module allows for streamlined data collection and operational commands, making it an integral component for complex systems. The device operates efficiently within a temperature range of -20°C to +60°C, ensuring durability even in harsh environments.

In terms of performance metrics, the DSBB110A is designed for high-speed processing, with response times that outpace many competitors in the market. Its built-in fault tolerance capabilities reduce downtime, ensuring continuous operation critical in industries where reliability is paramount. The module also supports multiple communication protocols, allowing seamless integration with existing systems, such as ABB PLC Module 3BHE004468R0021 GDC780BE21, and ABB TA523.

**Real-World Usage Scenarios**

In the power industry, the ABB DSBB110A excels in monitoring and controlling energy distribution systems. Its ability to process real-time data enables energy operators to optimize load management and enhance grid reliability. In petrochemical applications, the DSBB110A is essential for automating complex processes like refining and chemical production, where precision and efficiency are vital. Additionally, in general automation scenarios, such as manufacturing lines or assembly processes, the DSBB110A integrates seamlessly to enhance productivity and operational efficiency.

When compared to other models within the ABB range, the DSBB110A showcases distinct advantages. For instance, unlike the ABB PM802F, which specializes in power management, the DSBB110A provides a more versatile solution applicable across various sectors. Its I/O capacity surpasses that of the ABB 560CMU05, making it a more suitable choice for large-scale applications. Furthermore, the DSBB110A’s fast processing speeds give it an edge over models like the ABB DSQC697, particularly in scenarios requiring rapid data handling and response.

**Complementary ABB Models**

The ABB DSBB110A works harmoniously with several other models within the ABB portfolio, enhancing its functionality and versatility. The ABB IMASI23, for instance, can be utilized alongside the DSBB110A to provide advanced monitoring capabilities. The ABB PM564-R-AC complements the DSBB110A by facilitating power management in conjunction with automation processes. Users can also integrate the ABB TU520-ETH for Ethernet communication, ensuring that the DSBB110A remains connected within a larger network of ABB automation products.

Additionally, the ABB 3HAB6597-1 can be paired with the DSBB110A for added control in industrial applications. The ABB AX521 serves as an excellent companion for data acquisition, while the ABB PFEA113-65 enhances the overall functionality by allowing for more extensive input/output interfaces. Other models like the ABB 3ABD00033153 and ABB DSCS131MFB can also be utilized to provide a comprehensive automation solution that meets the specific needs of various industries.

In conclusion, the ABB DSBB110A is a versatile and high-performance automation module that excels in the power industry, petrochemical applications, and general automation. Its robust technical features, coupled with its ability to integrate with a wide range of other ABB models, make it an ideal choice for organizations seeking to improve operational efficiency and reliability in their automation processes. With the ABB DSBB110A, users can confidently navigate the challenges of modern industrial environments, ensuring their systems are efficient, reliable, and future-ready.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

66

How to install and debug this product? Matters needing attention

Open the manual and programming software, use the new version, upload the data and programs, save the computer, continue downloading! For details, please consult the technical service provider!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

Where can I download the manual and programming software?

Product official website, official hotline and contact sales or technical engineers.

Is it in stock or need to be ordered?

There will generally be inventory, but it does not rule out that the website inventory has been sold and not updated. Please consult customer service.

Can you provide technical service?

Need to see the product type and site conditions, equipment damage, humanities and other factors, please inform us, we will provide you with a suggestion!

Where can I order this series?

Please see the contact information of the website, official channels, and consulting customer service! Thank you for your cooperation!

Do you have product selection list and pre-sale service?

It can be downloaded from local agents, technical service companies, and the official website (pdf). Some special products are excluded. Please contact us as appropriate.

Let's Communicate

Call the enterprise hotline customer service consultant is waiting for you online

wechat/whatsapp:

+86-181-4410-0983

Contact Business

Talk to a customer service consultant now about what you need to know

Positive message

Leave us a message and a customer service consultant will contact you within 24 hours

Wechat

Whatsapp

Email: kongjiangauto@163.com

-

ABB 5C4045L0006 3MB030310R00001 3BH039203R0101 GVC736SE101 IGCT Module

-

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 IGCT Module

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved