-

Emerson SE8701V03-TH VI Tach CHARM

-

Emerson SE8701V02-VT VI Voltage CHARM

-

Emerson SE8701V01-PZ VI Piezo CHARM

-

Emerson SE8701-SHADE Protection from the sun Accessory Model

-

Emerson A02100WLAN External Wireless Router for outside of North America

-

Emerson Online Prediction, Protection and Process Monitor

-

Emerson The next step in your digital transformation just got easier!

-

Emerson AMS Wireless Vibration Monitor

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

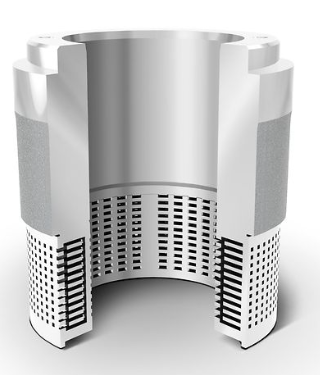

Emerson Fisher™ Whisper Trim™ I Cage

-

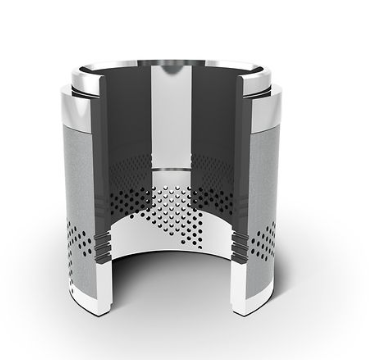

Emerson Fisher™ Whisper Trim™ III Cage

-

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

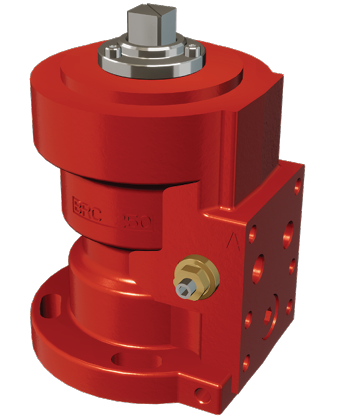

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

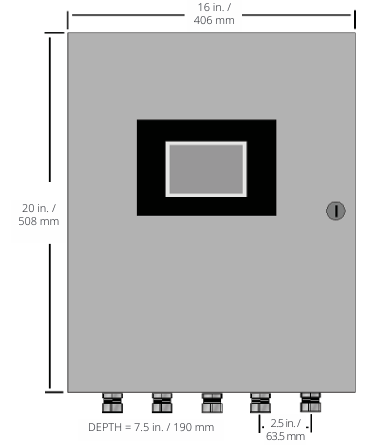

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

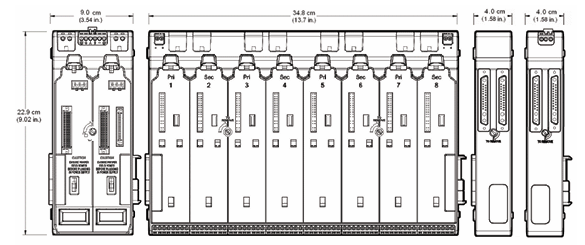

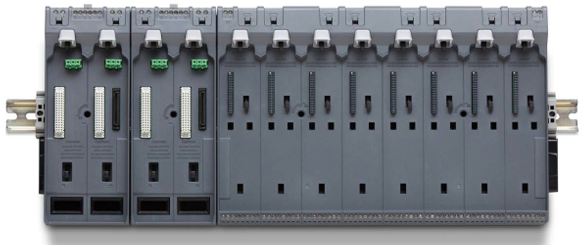

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

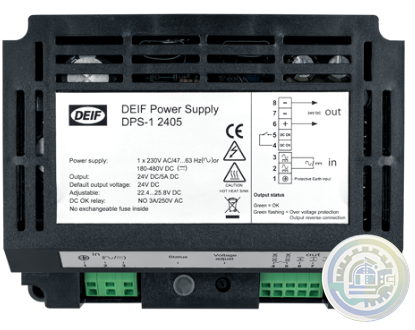

DEIF DPS-1 DC Power Supply

-

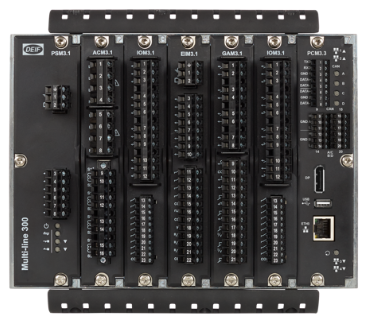

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

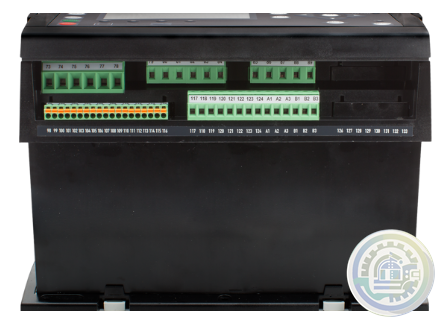

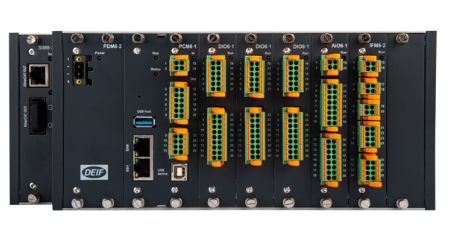

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

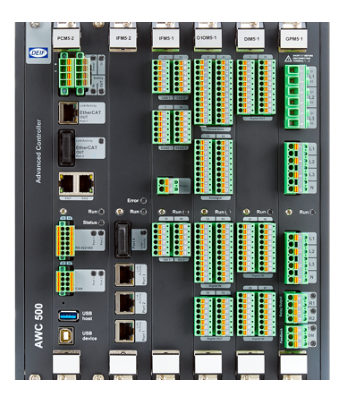

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

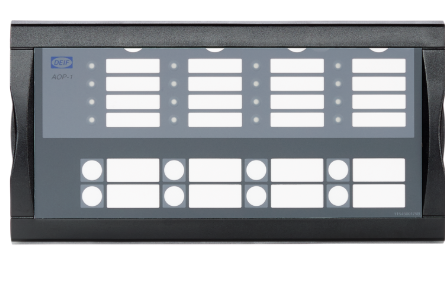

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

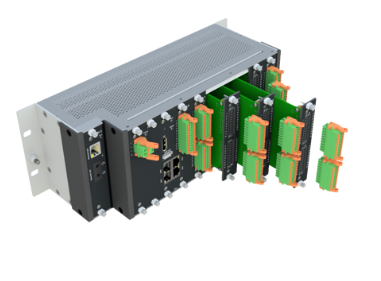

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

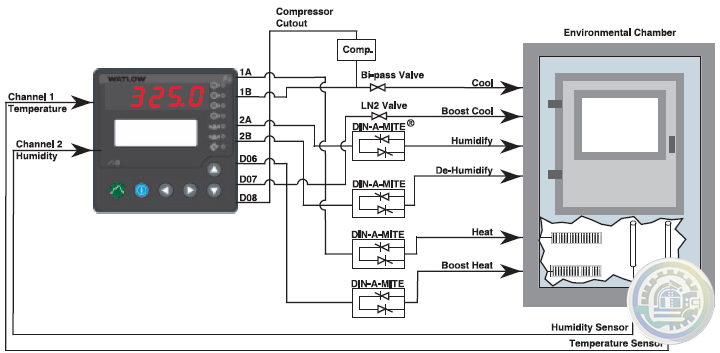

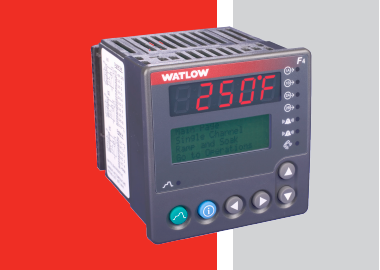

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

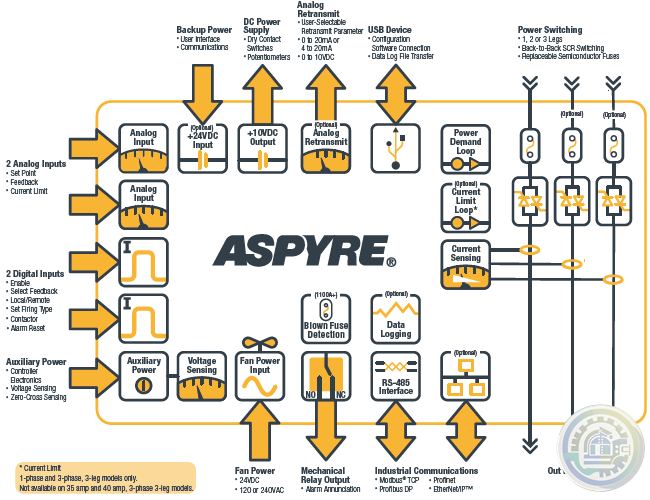

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

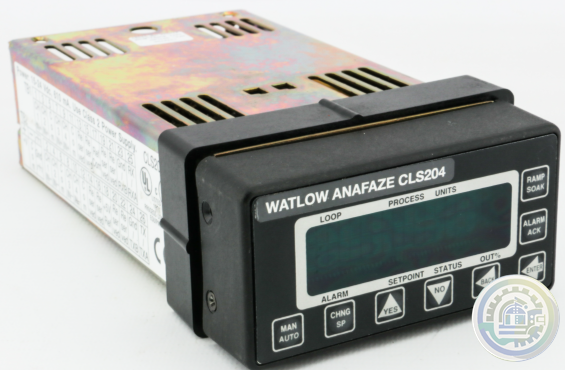

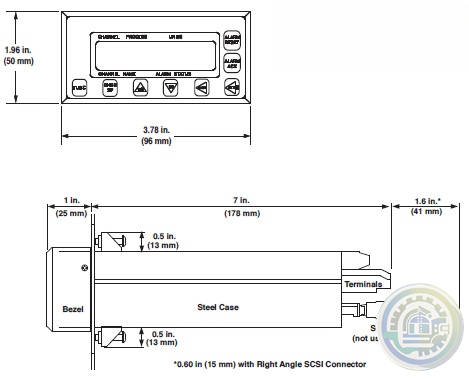

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Many years of expertise for complex tasks

This is an important task, as battery trays play a crucial role in electric vehicles.

They must be leak-proof and resilient, support the correct temperature of the batteries and help to prevent the

vehicle occupants from being endangered by the battery in the event of an accident.

A particular challenge in production is 3D welding, for which robot-based FSW technology is particularly suitable.

This also requires complex clamping technology, for which KUKA was able to contrib ute comprehensive engineering expertise.

A tool changer and a cleaning station for the FSW tools are also used for fully automatic operation.

In addition to the modern technical solution, the customer was impressed by KUKA's comprehensive expertise and

many years of experience in a wide range of areas, from process technology and engineering to good cooperation with the sales experts.

KUKA at the Battery Show Europe in Stuttgart

Modern technologies and processes such as friction stir welding are playing an increasingly important role in the complex production of electric vehicles and their batteries.

KUKA has been supporting customers here for decades with comprehensive industry and technology expertise.

At the Battery Show Europe in Stuttgart, the largest event for battery and electric vehicle technology in Europe,

industry experts and leading manufacturers will be talking about the latest developments.

KUKA will also be there from June 18 - 20. 2024 in hall 9. booth D20.

Robot-Store provides used or new industrial robot spares for KUKA robot, FANUC robot, ABB robot, MOTOMAN robot, and other manufacturers.

In addition, our expert will help to identify the parts you need If you are not sure which parts to quote.

Most of the robot parts have a unique number that will tell us exactly the robot spares you require for your robot.

The KUKA Power Pack is the drive power supply of the robot controller and generates the intermediate

circuit voltage with which the internal drive controllers and external drives are supplied.

The KPP can additionally contain axis amplifiers for one to three axes. The drive interface on the connector panel is not included.

Tailor-made services: from preventive maintenance to performance checks

Successful production is reliant on availability, output and quality of automation.

We can offer you a flexible range of services all over the world with measures tailored to

your individual needs to ensure that your machines and systems have the highest possible uptime.

With our various service level agreements, we offer everything from regular inspections and a technical hotline

to maintenance and extended warranties.

You can also benefit from our repair and replacement concepts,

the KUKA spare parts finder and a detailed analysis and performance check for your robot system.

KUKA is also responsible for the entire friction stir welding process.

In friction stir welding or FSW welding, a rotating, pin-like tool is guided between the contact surfaces of the component.

The frictional heat causes the material to plasticize, and the parts are joined together.

Even difficult-to-weld or dissimilar materials such as aluminum can be welded together with magnesium, copper, or steel.

This process consumes less energy and material and does not require shielding gas or flux cored wire as in conventional processes.

FSW welding is used in a wide variety of industries that have special requirements for welding seams,

be it battery containers, side walls of high-speed trains or tank structures of rockets.

In addition to the growth market of e-mobility, the technology is therefore also used in the aviation and electrical industries, for example.

| KUKA | Data Cable 15m X42 XS 00-132-467 | ABB | 3BHB006338R0001 UNS 0881 A-PV1 Door Driver Interface |

| KUKA | Data Cable X20 X30 15m 00-104-285 | ABB | 3BHB006338R0002 UNS 0881 A-P V2 Door Driver Interface |

| KUKA | DC POWER SUPPLY 00-171-202 | ABB | 3BHB006309R0001 UNS 0882 A-P V1 power signal interface |

| KUKA | DSE-IBS3 | ABB | 3BHB006208R0001 UNS 0883 A-PV1 fast input and output port |

| KUKA | E93CE143I4B531 | ABB | 3BHE004385R0001 UNS 0884 A-P V1 current sensor |

| KUKA | E93DA113I4B53SERVO DRIVE ( CONDITION ) | ABB | 3BHB006943R0001 UNS 0885 A-Z V1 Converter Display |

| KUKA | E93DA123I4B53Servo Drive | ABB | 3BHB006943R0002 UNS 0885 A-Z,V2 Converter Display |

| KUKA | ECMAP0D3004BE53 KPP 600-20 0019825 | ABB | 3BHB002651R0001 UNS 0874 A-PV1 Control Panel |

| KUKA | ECMAP0D3004BE53KPP 600-20 | ABB | 3BHE004059R0104 SDCS-CON 2-21 Motherboard |

| KUKA | ECMAP1D3404BE53Servo Drive 00198260 | ABB | 3ADT315100R1012 SDCS-POW 4 internal power supply |

| KUKA | ECMAS3D2224BE53 KSP 600-3x20 00192 | ABB | 3BHE006422R0001 UNS2861 C-P, V1 HGC door control unit |

| KUKA | ECMAS3D2224BE53 KSP 600-3x20 | ABB | HIEE30511 1R0001 UNS 2860 B-P Chopper stage |

| KUKA | ECMAS3D4444BE53(Slightly Damaged) | ABB | 3BHE009319R0001 UNS 2881 B-P V1 measuring cell board |

| KUKA | ECMAS3D4444BE53Ser | ABB | 3BHE003855R0001 UNS 2882 A-P V1 Extended Door Controller |

| KUKA | ECMAS3D4444BE53Servo Drive 00198268 | ABB | 3BHB005922R0002 UNS 0880 A-PV2 converter interface |

| KUKA | ECMAS3D7774BE53KSP 600-3x64 | ABB | 3BHE035495R0020 UNS 0017 A-PV1 RF board |

| KUKA | EMI Filter KRC 2 32TDRT2-Version 3 | ABB | 3BHE035495R0022 UNS 0017 A-PV1 RF board |

| KUKA | Extension Lead 15m 00-127-948 | ABB | HIEE205010R0003 UNS 3020A-Z,V3 protection relay |

| GE | IS215AEPCH1C IS215AEPCH1F AEPC - 30Nm Air Distance Control (Center/Shaft) | GE | IS215AEPAH1A IS215AEPAH1C AEPA - 20Nm Air Distance Axle Control |

| GE | IS215AEPCH1A IS215AEPCH1D AEPC -20Nm Non-ESS Air Distance Center Control | GE | IS215WEPAH1A IS215WEPAH1B WEPA - 30Nm CANBus Air Distance Axle Control |

| GE | IS215AEPCH1B IS215AEPCH1E AEPC - 20Nm ESS Air Distance Center Control | GE | IS215WEPAH2A IS215WEPAH2B WEPA - 30Nm Non-CANBus Air Distance Axle Control |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB 5C4045L0006 3MB030310R00001 3BH039203R0101 GVC736SE101 IGCT Module

-

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 IGCT Module

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved