-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Industry-leading

-

Kollmorgen S200 High Performance Compact Brushless Servo Drives Benefits

-

Emerson 00813-0100-0112 VersaMax Modular Input/Outputs and Controls Ease of Use

-

Emerson 00813-0100-0161 Compact Programmable Automation Controller Open communication

-

Emerson 00813-0100-0115 RXi - Industrial Monitor Designed for Visualisation

-

HIMA X-CPU 01 Processor Module Function

-

HIMA launches the fourth generation of its central module HIQuad X benefits

-

KEBA KeControl C5 - FE 560 Multi-protocol fieldbus expansion card

-

KEBA KeControl C5 - FE 571, FE 573 EtherCAT master expansion card

-

KEBA KeControl C5 - NE 551 Gbit Ethernet expansion card

-

KEBA KeDrive D3 controls – D3-DU 3x5 Control modules with built-in safety control

-

KEBA KeDrive D3 controls - D3-DU 3x0 Control modules

-

KEBA KeControl C1 Control modules

-

KEBA KeControl C5 - CP 5x0 Control modules

-

KEBA KeControl C5 - CP 50x Controls / Control units

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Performance

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Value

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller Features

-

Emerson Fisher™ FIELDVUE™ DPC2K Digital Process Controller

-

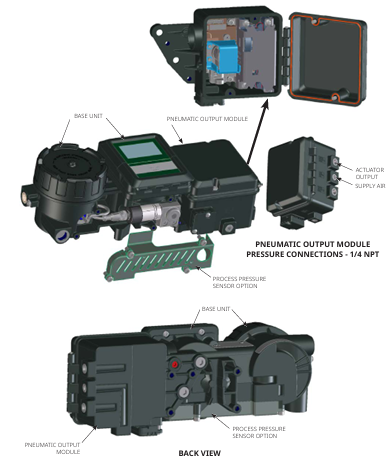

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Device Alerts

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Value

-

Emerson Fisher™ FIELDVUE™ DVC6200p Digital Valve Controller Features

-

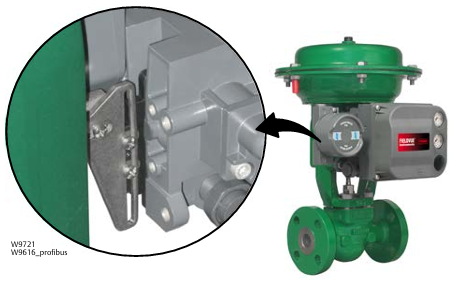

Emerson Fisher DVC6200 Digital Valve Controller Features

-

Emerson Fisher DVC6200 Digital Valve Controller Specifications

-

Emerson Fisher DVC6200 Digital Valve Controller

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Instrument Shutdown

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller General Information

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Restart Control Mode

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller Detailed Setup

-

Emerson Fisher™ FIELDVUE™ DVC2000 Digital Valve Controller

-

Kongsberg RDIO400 Remote Digital Inputs and Outputs Technical Specifications

-

Emerson CSI A6120 Enclosure Seismic Vibration Monitor Features

-

Kongsberg RL542A Radio Link Features

-

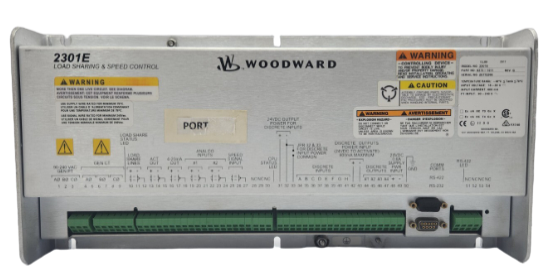

Woodward 2301E Digital Load Sharing and Speed Controller four modes of operation

-

ABB AC 800PEC High Performance Control System Modular structure

-

ABB AC 800PEC High Performance Control System Aluminium applications

-

GE IC693CMM321 Ethernet Interface Module Board Indicators

-

ABB Preventive maintenance for AF1350 ... AF2650 contactors Benefits

-

ABB DC switching contactors, type GAF A compact contactor up to 1000 V DC Features

-

Kongsberg RMP420-Remote Multipurpose Input/Output

-

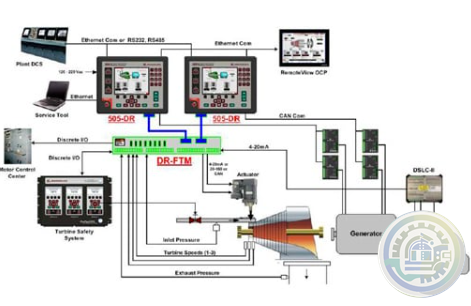

Woodward 505DR Dual Redundant Turbine Controller Control specifications

-

Woodward 505DR Dual Redundant Turbine Controller Communication

-

Woodward 505DR Dual Redundant Turbine Controller Description

-

Emerson M-Series DC to DC System Power Supplies Product Description

-

ABB M4M Network Analyser Transmission method

-

ABB FAU 810 Flame Analyser Unit Remote Monitoring

-

Honeywell 91MCE Series MICRO SWITCH Miniature Compact Limit Switches Features

-

MOOG Dual PWM Amplifier G123-814 Wiring

-

MOOG Dual PWM Amplifier G123-814 Applying this amplifier

-

Emerson A6410 Dual Channel Valve and Enclosure Expansion Monitor Features

-

Emerson A6630 Temperature Monitor Machine Monitoring System sensor types

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive main application scenarios

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive applications

-

Parker C3S063V2F12I31T11M00 Compax3S Single Axis Servo Drive

-

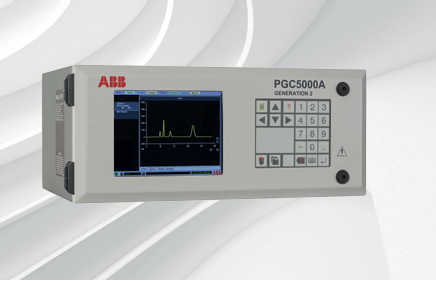

ABB PGC5000 Temperature programmed gas chromatograph Gas Control

-

ABB PGC5000 Temperature programmed gas chromatograph Safety area classification

-

ABB PGC5000 Temperature programmed gas chromatograph Introduction

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Application flexibility

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller Features

-

ABB PGC5000 Series gas chromatographs PGC5000A Generation 2 master controller

-

ABB Time Synchronization in PGC5000 Series Data System

-

ABB VistaSTAR with PGC5000 Version 4 Data System Interface

-

ABB PGC5000 Series gas chromatographs ATEX Directive

-

ABB PGC5000 Series gas chromatographs PGC Certification

-

ABB PGC5000 Series gas chromatographs Introduction

-

Honeywell BW™ ICON Multi-Gas Detector FEATURES AND BENEFITS

-

HONEYWELL BW™ RIGRAT Transportable Multi-gas Area Monitor FEATURES AND BENEFITS

-

HONEYWELL BW™ SOLO Repairable Single Gas Detector FEATURES

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System User Experience

-

Honeywell Touchpoint Plus Easy-to-configure Wall Mount Control System Flexible Capabilities

-

ABB ACS800-07 (+V992) is a cabinet-mounted drive Controls of the supply unit

-

Emerson A6110 Shaft Relative Vibration Monitor Features

-

GE Multilin 489 Generator Protection System SR Series Relays features

-

GE Multilin 489 Generator Protection System SR Series Relays Applications

-

ABB Motor Protection Relay REM610 Product Features

-

FOXBORO FBM233 Redundant Field Device System Integrator (FDSI) Module Features

-

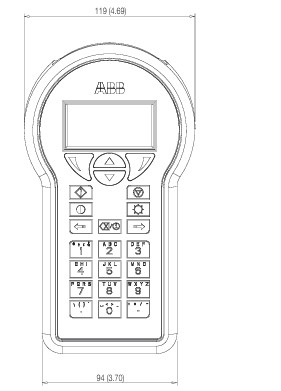

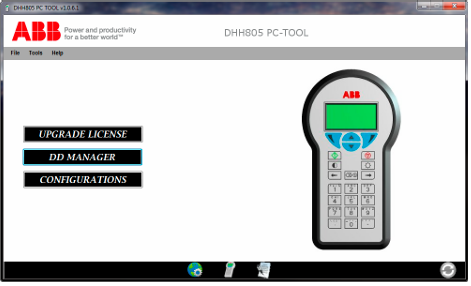

ABB Model DHH805 Handheld communicator Physical specifications

-

ABB Model DHH805 Handheld communicator Functional specifications

-

ABB Model DHH805 Handheld communicator Use cases

-

ABB Model DHH805 Handheld communicator Device Functions

-

ABB Model DHH805 Handheld communicator OVERVIEW

-

GE Multilin™ M60 Motor protection system EnerVista Launchpad

-

GE Multilin™ M60 Motor protection system Multi-Language

-

GE Multilin™ M60 Motor protection system Direct I/O Messaging

-

GE Multilin™ M60 Motor protection system Communications

-

GE Multilin™ M60 Motor protection system Role Based Access Control

-

GE Multilin™ M60 Motor protection system Fault and Disturbance Recording

-

GE Multilin™ M60 Motor protection system Advanced Device Health Diagnostics

-

GE Multilin™ M60 Motor protection system Scalable Hardware

-

GE Multilin™ M60 Motor protection system IEC 61850 Process Bus

-

GE Multilin™ M60 Motor protection system Underpower Protection

-

GE Multilin™ M60 Motor protection system Breaker Failure Protection

-

GE Multilin™ M60 Motor protection system Acceleration Time

-

GE Multilin™ M60 Motor protection system Protection and Control

-

GE Multilin™ M60 Motor protection system APPLICATIONS

-

GE Multilin™ M60 Motor protection system KEY BENEFITS

-

GE Multilin D485 Modbus to DeviceNet Converter

-

GE Multilin™ C30 Substation Hardened Programmable Logic Controller EnerVista Integrator

-

GE Multilin™ C30 Substation Hardened Programmable Logic Controller Viewpoint Monitoring

-

GE Multilin™ C30 Substation Hardened Programmable Logic Controller EnerVista Software

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Emerson Ovation - 1C31113G02 Analog Input Module

The Emerson Ovation system exemplifies advanced automation technology designed to meet the demanding needs of the power industry, petrochemical plants, and general automation applications. Built with robustness and precision in mind, the Ovation platform offers a comprehensive suite of features that ensure reliable operation, high performance, and seamless integration within complex control environments. Its key technical features include extensive input/output (I/O) capacity, high-speed data processing, and exceptional durability in harsh industrial conditions.

The Ovation system supports a wide range of I/O modules, enabling it to handle complex control tasks with ease. For instance, it accommodates numerous analog and digital inputs and outputs, essential for monitoring and controlling critical plant processes. Its modular architecture allows for flexible expansion, supporting additional I/O modules such as the Emerson OVATION 5X00070G04 Analog Input Module and Emerson OVATION 5X00226G01 to tailor the system precisely to project requirements. Durability is a hallmark of the Ovation platform, with ruggedized

components and advanced thermal management ensuring consistent performance even in extreme environments—be it high-temperature petrochemical facilities or outdoor power generation sites.

Performance metrics of the Emerson Ovation include rapid response times, high data throughput, and reliable operation over extended periods. Its sophisticated control algorithms and real-time data processing capabilities enable precise regulation of complex processes, minimizing downtime and maximizing efficiency. The system's compatibility with other Emerson automation products, such as the Emerson MMS6100 multivariable controllers, Emerson PR6423/003-030 Eddy Current Sensors, and Emerson KJ2002X1-CA1 logic solvers, enhances its overall functionality. This interconnected ecosystem allows for comprehensive automation solutions that are scalable and adaptable to evolving operational demands.

In practical applications, the Emerson Ovation excels in power generation plants where precise control of turbines and generators is critical. Its robust I/O modules facilitate reliable data acquisition from sensors like the Emerson PR6423/00R-131 Eddy Current Sensor, ensuring optimal operational conditions. Similarly, in petrochemical facilities, Ovation's high-speed processing supports real-time monitoring of process variables, contributing to safety and efficiency. Its ability to interface seamlessly with other control components, such as the Emerson VE4002S1T2B1 or the Emerson KJ4110X1-BA1, makes it an ideal choice for complex automation tasks requiring high reliability and performance.

Compared to other Emerson models, the Ovation system offers superior scalability and integration capabilities. While models like the Emerson MMS6100 focus on multivariable control, the Ovation platform provides a broader array of I/O options and enhanced modularity, making it suitable for large-scale, mission-critical applications. Additionally, its rugged design surpasses many standard controllers, ensuring continuous operation in challenging industrial environments.

Alongside the Emerson Ovation, we also offer complementary automation devices such as the Emerson PR6426/010-040 Series I/O modules and the Emerson KJ3003X1-EA1 controllers for specialized control functions. The Emerson VE4003S5B1 and Emerson 12P0631X012 Delta Cable facilitate seamless communication and integration across the automation network. For sensor integration, models like Emerson PR6423/013-130 and PR6423/011-131 Eddy Current Sensors are ideal for precise measurement and process control.

In conclusion, the Emerson Ovation stands out as a premier automation solution that combines high I/O capacity, rugged durability, and advanced processing performance. Its application in the power industry, petrochemical sector, and general automation underscores its versatility and reliability. When selecting Emerson automation products, the Ovation system offers a comprehensive, scalable platform designed to optimize plant performance, reduce downtime, and ensure operational excellence across a wide range of industrial environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved