-

Emerson SE8701V03-TH VI Tach CHARM

-

Emerson SE8701V02-VT VI Voltage CHARM

-

Emerson SE8701V01-PZ VI Piezo CHARM

-

Emerson SE8701-SHADE Protection from the sun Accessory Model

-

Emerson A02100WLAN External Wireless Router for outside of North America

-

Emerson Online Prediction, Protection and Process Monitor

-

Emerson The next step in your digital transformation just got easier!

-

Emerson AMS Wireless Vibration Monitor

-

Emerson Fisher™ WhisperFlo™ Aerodynamic Noise Attenuation Trim

-

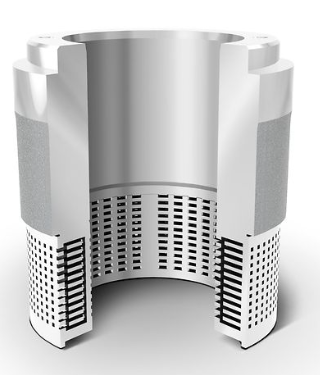

Emerson Fisher™ Whisper Trim™ I Cage

-

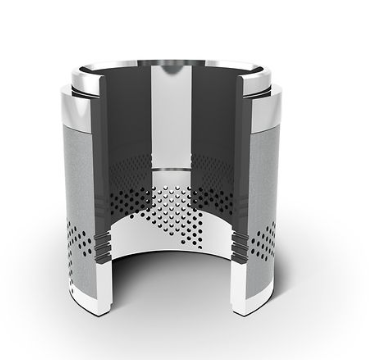

Emerson Fisher™ Whisper Trim™ III Cage

-

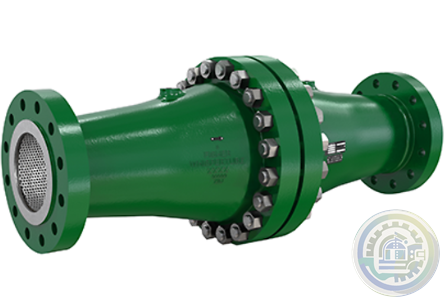

Emerson Fisher™ 6060 WhisperTube Modal Attenuator

-

Emerson Fisher™ easy-e™ EA SERIES Control Valve

-

Emerson Rosemount 8700 Series Magnetic Flowmeter Systems

-

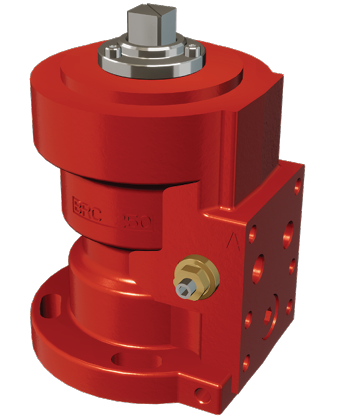

Emerson Damcos™ BRC 250 Hydraulic Double-acting Balanced Rotary Actuator 90° (Quarter-turn)

-

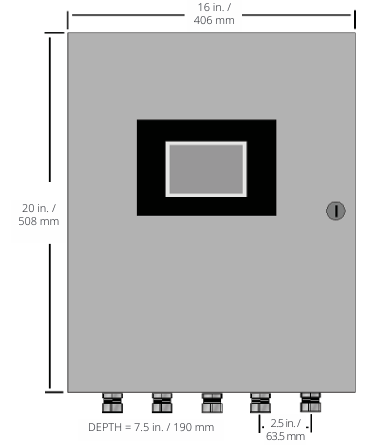

Emerson Model M250N Mounting of Rack Mount Enclosure

-

Emerson Model M250N Controlinc Network Controller System Configuration

-

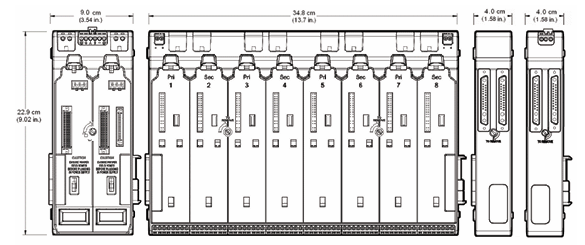

Emerson Controlinc Network Master Model M250 Version 5.2

-

Emerson DCMlink Software

-

Emerson M250 Controlinc Network Master

-

Emerson AMS Trex Device Communicator

-

Emerson AMS Trex™ Device Communicator with embedded Bluetooth® connectivity

-

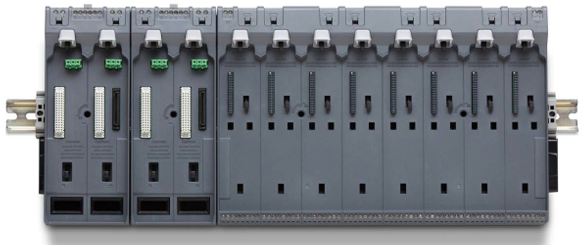

Emerson S-series Horizontal Carriers Product Description

-

Emerson S-series Horizontal Carriers Modular design allows flexible installation

-

Emerson S-series Horizontal Carriers

-

DEIF TAS-331DG AC transducer for active or reactive power

-

DEIF RMV-112D Undervoltage and overvoltage relay, U< and U>

-

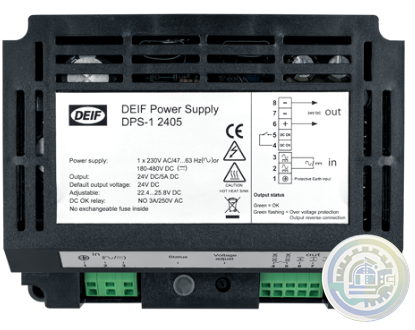

DEIF DPS-1 DC Power Supply

-

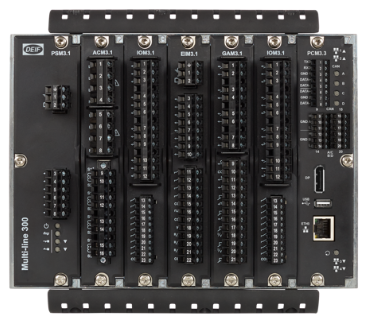

DEIF DM 400 hydro Integrated systems

-

DEIF DBC-1 Battery charger

-

DEIF CSQ-3 Multi-function synchroscope

-

DEIF CODESYS Programming editor and debug

-

DEIF CODESYS Features Software - AWC 500 development package

-

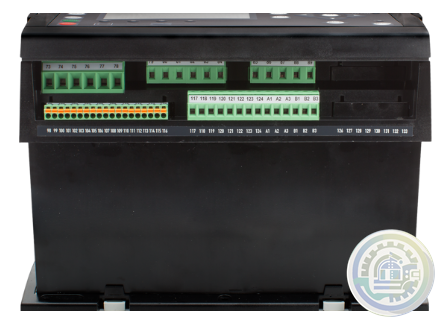

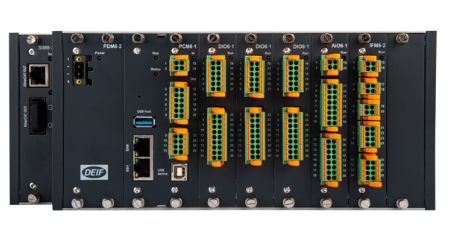

DEIF AMC 300 Features Advanced Programmable Controller

-

DEIF AMC 300 Performance and system design freedom

-

DEIF AMC 300 Flexible solution design options

-

DEIF AMC 300 Advanced Programmable Controller

-

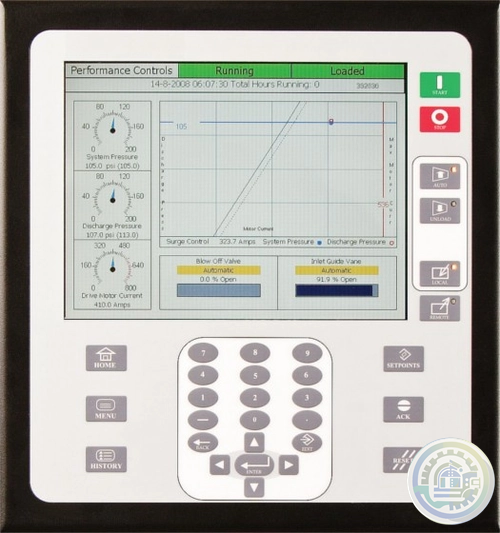

DEIF AGI 400 Features Advanced graphical interface

-

DEIF AGI 400 Advanced graphical interface

-

DEIF BRW-2 & BW Analogue illuminated bridge wing indicators

-

DEIF Basic control package for mobile generators

-

DEIF AWC 500 - G59/3 Integrated G59/3 protection turbine controller unit

-

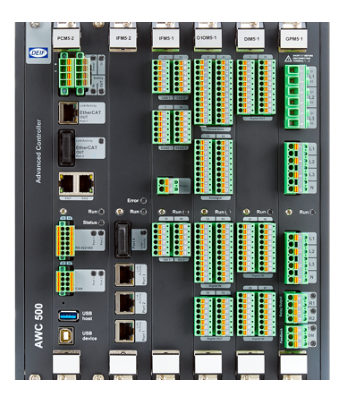

DEIF AWC 500 Advanced Controller

-

DEIF ASK & ASR Measuring transformer

-

DEIF ASC-4 Battery Energy source, power source, or droop mode

-

DEIF ASC-4 Battery Automatic Sustainable Controller

-

DEIF ASC plant management Ideal for self-consumption applications

-

DEIF ASC plant management Automatic sustainable controller

-

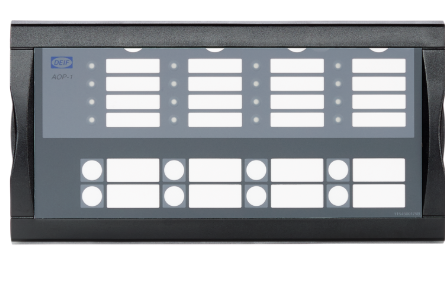

DEIF AOP Additional operator panel

-

DEIF AMC 600 Fast, fail-safe, and secure system software

-

DEIF AMC 600 Wide range of protocols supported

-

DEIF AMC 600 Programmable automation controller with EtherCAT based I/O

-

DEIF AL8-2 Alarm panel

-

DEIF AGC 150 Hybrid Advanced Genset Controller

-

DEIF AGC 150 PMS Lite Simple power management controller

-

DEIF AGC 150 Generator Advanced Genset Controller

-

DEIF AGC 150 Remote Display Remote access and control unit

-

DEIF MVR-250 series Medium Voltage Relay

-

DEIF MVR-210 series Medium Voltage Relay

-

DEIF The SGC series

-

DEIF Advanced paralleling and power management controllers

-

DEIF Engine and single genset controllers

-

DEIF iE 350 Marine Highly flexible and cybersecure intelligent energy controller

-

DEIF iE 250 Marine Versatile and cybersecure intelligent energy controller for maritime applications

-

DEIF iE 150 Marine Simple and effective power management

-

DEIF iE 150 Marine Cost-effective and flexible controller for coastal, harbour, and inland vessels

-

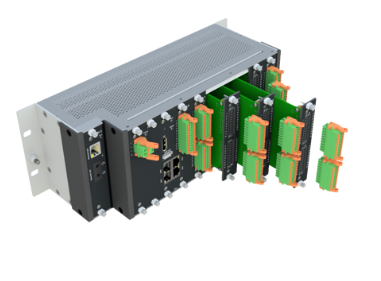

DEIF iE 650 PLC Fast, fail-safe, and secure system software

-

DEIF iE 650 PLC Performance and flexibility with module concept

-

DEIF iE 650 PLC Extreme robust Programmable Automation controller with EtherCAT based I/O

-

DEIF iE 350 PLC Performance and system design freedom

-

DEIF iE 350 PLC Robust right out of the box

-

DEIF Advanced Features of the iE 350 PLC Controller

-

DEIF iE 250 PLC Versatile and modular intelligent energy PLC controller

-

DEIF XL / BW / BRW-2 Illuminated indicators

-

DEIF SGC 120/121 Single Genset Controllers

-

DEIF Load Sharing Unit LSU-112DG

-

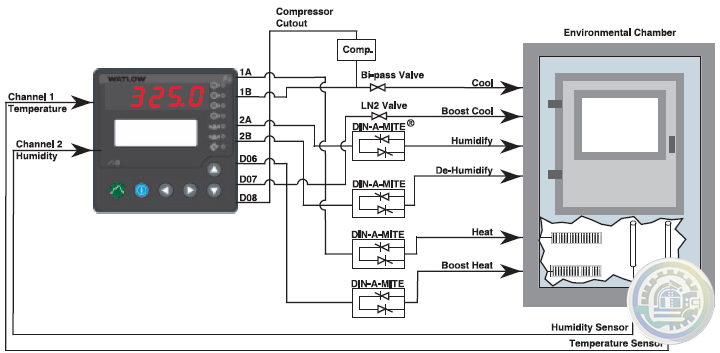

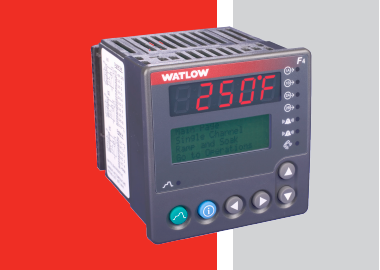

Watlow F4T Base Specifications

-

Watlow F4T Key Features and Options 1/4 DIN Process Controller

-

Watlow F4T 1/4 DIN Process Controller Features and Benefits

-

Watlow F4T 1/4 DIN Process Controller

-

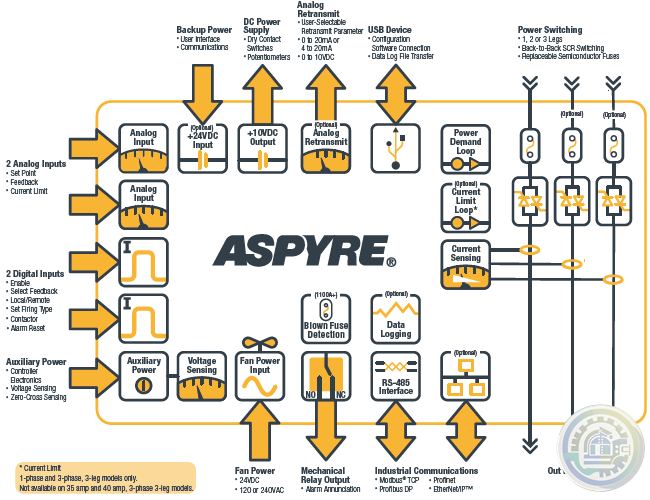

Watlow ASPYRE® AT Power Controllers Specifications

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT Power Controllers Features and Benefits

-

Watlow ASPYRE® DT Power Controllers

-

Watlow ASPYRE® Power Controllers Features and Benefits

-

Watlow ASPYRE® Power Controllers

-

Watlow SERIES F4 Specifications 1/4 DIN Ramping Controllers

-

Watlow SERIES F4 1/4 DIN Ramping Controllers Features and Benefits

-

Watlow SERIES F4 1/4 DIN Ramping Controllers

-

ABB CI869 Ability™ System 800xA® hardware selector

-

CI867A ABB Ability™ System 800xA® hardware selector

-

CI860 ABB Ability™ System 800xA® hardware selector

-

ABB CI855 Ability™ System 800xA® hardware selector

-

ABB Single drive modules ACS880-01, frame sizes R1, R8 and R5, IP20

-

ABB Single drive modules, ACS880-01 with option +P940

-

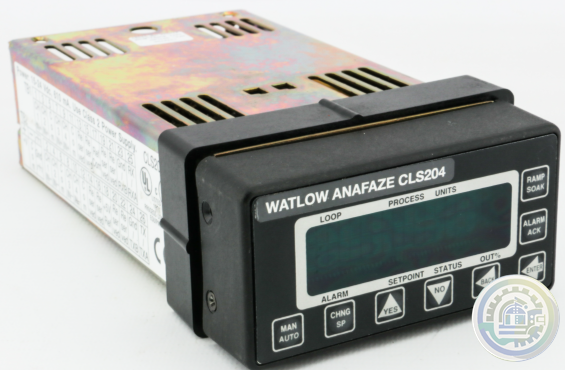

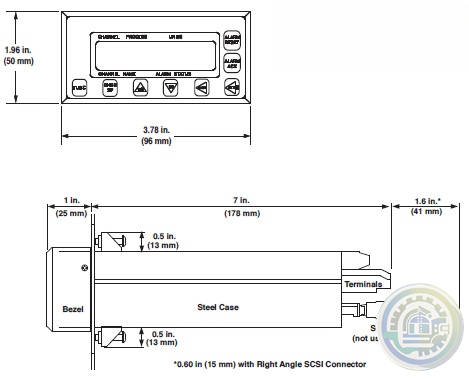

Watlow Anafaze CLS200 Controller 204-1200000

-

Watlow SERIES CLS200 Specifications

-

Watlow SERIES CLS200 DAC and SDAC Modules

-

Watlow SERIES CLS200 Powerful line of controllers

-

ALSTOM ALSPA®MV500 Drive Dependable Drives – Reliable Support

-

ALSTOM ALSPA®MV500 Drive Small in Size – Big on Features

-

ALSTOM ALSPA®MV500 Drive Easy to use – Simple to install

-

ALSTOM Common Programming Tools for all Drives and Automation

-

ALSTOM Drives ALSPA DRIVE RANGE Drive solutions for all applications

-

ALSTOM Power Conversion ALSPA DRIVE RANGE Drive solutions for all applications

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Tricon and Tricon CX High-integrity + high-availability system

The TriconTM high-integrity/high-availability system meets the needs of safety and critical

control applications in oil and gas, power, refining, chemicals, pharmaceutical, and biotech industries.

It is based on industry-leading TMR technology, is easy to operate and maintain, and provides a higher value of ownership.

KEY CAPABILITIES

• TÜV Certified up to SIL3 applications in accordance with International standard IEC61508

• Easily integrated with all major Distributed Control Systems

• On-line module replacement ensures plant availability by hot-swapping of modules

• Works with both centralized and distributed applications

• Comprehensive family of I/O modules

• HART protocol pass through to Asset Management Systems

• Fast program cycle time for TMC applications

• Expertise available from our TÜV certified Functional Safety Experts and Engineers

• Certified for use in non-incendive applications

TRICONEX TRIPLE MODULAR REDUNDANCY

Tricon operation is based on the principle of safety and high plant availability, which identifies and

compensates for failed control system elements and allows on line replacement while continuing

its assigned task without interrupting the controlled process. Fault Tolerance is achieved through

TMR technology.

TMR employs three isolated, parallel control systems and extensive diagnostics integrated into one

system. The Tricon system uses two-out-of-three (2oo3) voting to provide high integrity, error-free,

uninterrupted process operation with no single point of failure. Setting up applications is simplified

with the Tricon, because the TMR system operates as a single control system from the user’s point of

view. The extensive diagnostics are inherent and transparent to the programmer.

Use of the Tricon continues to expand into new industries and applications as customers require

increased system safety and/or high availability. Today, Invensys has delivered and installed Triconex

safety system solutions in over 70 countries, providing increased safety and high process uptime.

variables

• Safe-state (FAILOPT) behaviors configurable on a

per channel basis

• Output read-back and alarm on discrepancy

• Non-incendive output

Series 8 I/O Overview

This document provides technical information to configure the Series 8 I/O.

The following Series 8 I/O items are included in this document.

• TC/RTD

• Analog Input – Single Ended

• Analog Input with HART – Single Ended

• Analog Input with HART – Differential

• Analog Output

• Analog Output with HART

• Digital Input Sequence of Events (SOE)

• Digital Input, 24 VDC

• Digital Input Pulse Accumulation

• Digital Output, 24 VDC

• DO Relay Extension Board

Related Items we have in stock

| Analog Input Module |

| Model 3351 Analog Input Module |

| Model 2351Analog lnput Baseplate |

| Model 2352 Analog input External Termination Panel Baseplate |

| Model 9764-310 RTD/TCIAl Termination Panel |

| Analog Output Modules |

| Model 3481 Analog Output Module |

| Model 3482 High-Current Analog Output Module |

| Model 2481 Analog Output Baseplate |

| Digital lnput Module |

| Model 3301 Digital Input Module |

| Model 2301 Digital Input Baseplate |

| Digital Output Module |

| Model 3401 Digital Output Module |

| Model 2401 Digital Output Baseplate |

| Model 2402 Digital Output Baseplate |

| Pulse Input Module |

| Model 3381 Pulse Input Module |

| Model 3381 Pulse Input Module Specifications |

| Model 2381 Pulse Input Baseplate |

| Solid-State Relay Output Module |

| Model 3451 Solid-State Relay Output Module |

| Model 2451 Solid-State Relay Output Baseplate |

| IO Extender Modules |

| Model 2281 IO Extender Module Kit |

| Model 2291 IO Extender Module Kit |

| Model 2292 VO Extender Module Kit |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB 5C4045L0006 3MB030310R00001 3BH039203R0101 GVC736SE101 IGCT Module

-

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 IGCT Module

-

Alstom 029.232 446 Central Unit VME A32/D32 | COP 232.2

-

ABB REF610B11LCNP Feeder Protection and Control

-

General Electric 029.381208 Converteam Controller Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved