-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

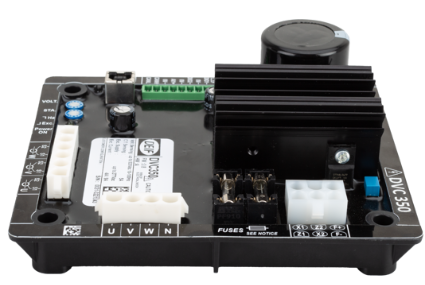

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

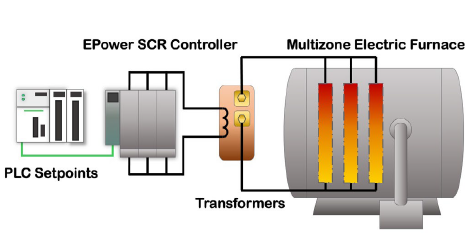

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

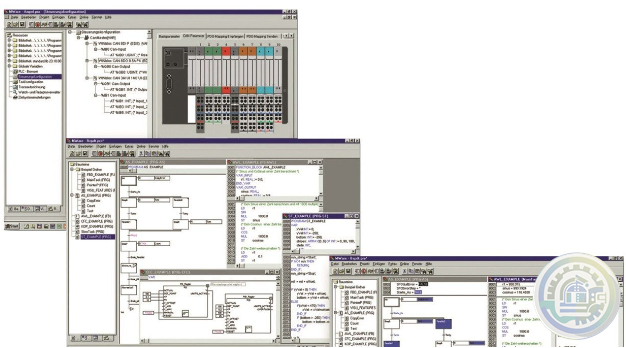

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

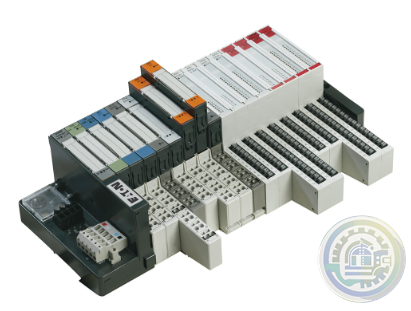

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

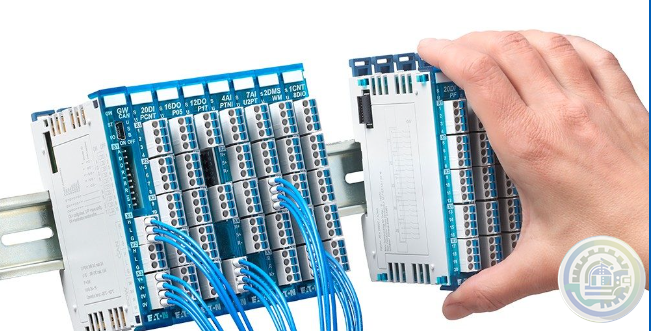

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

HIMA HIQuad Lifecycle & Modernization

-

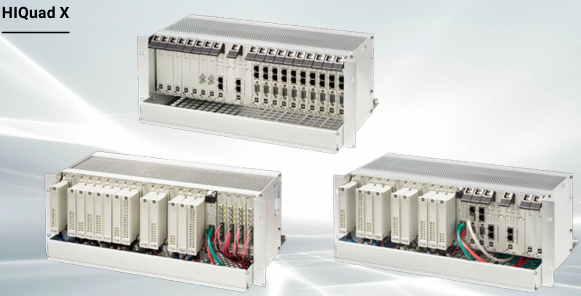

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

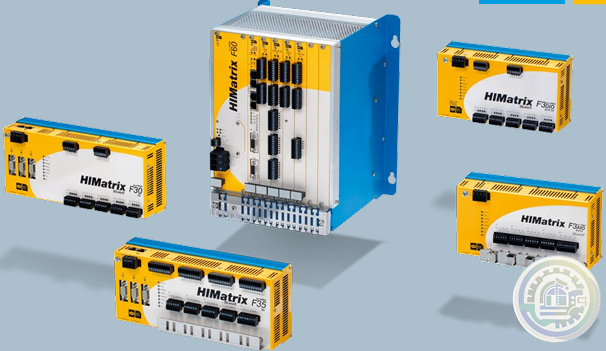

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

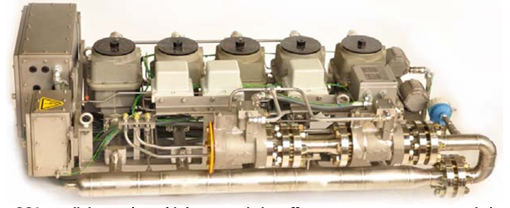

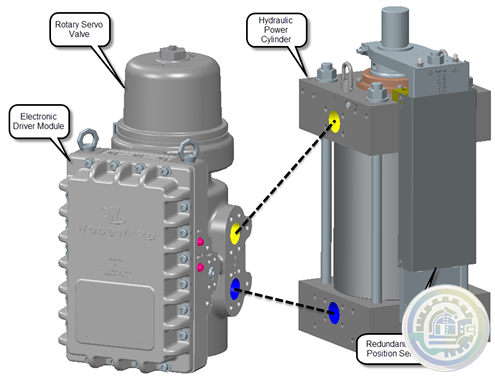

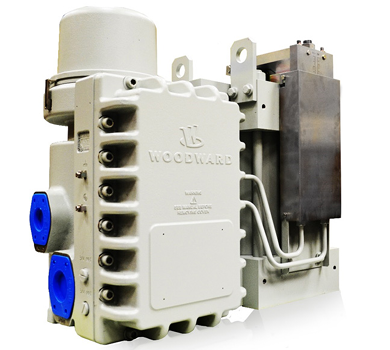

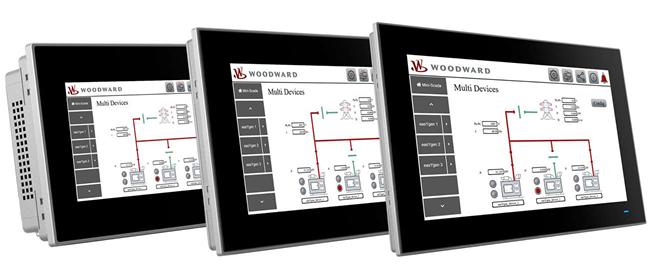

Woodward Oil Management

-

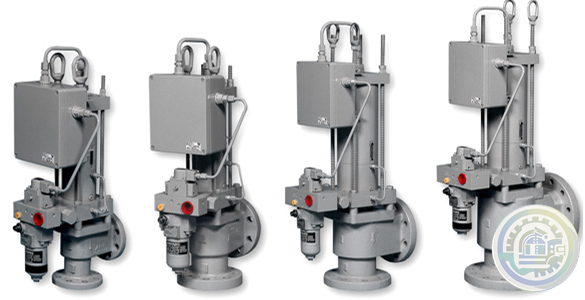

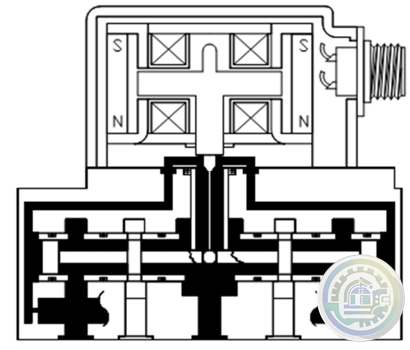

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

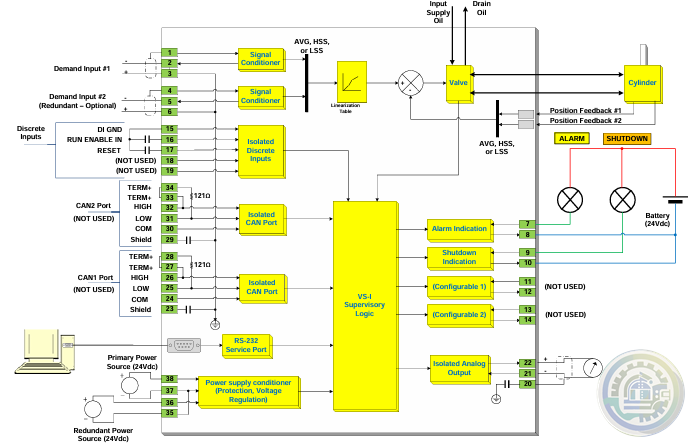

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

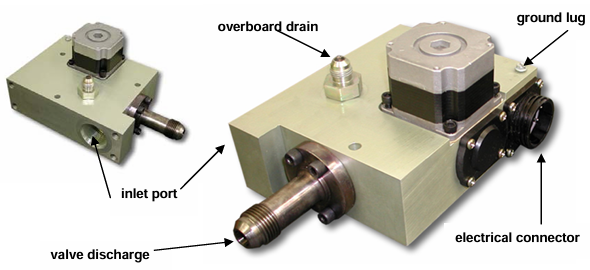

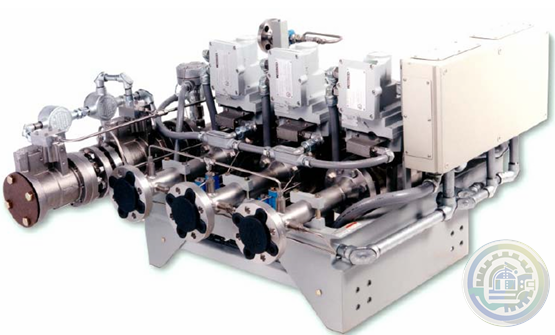

Woodward The Swift valve is a sonic flow-metering valve

-

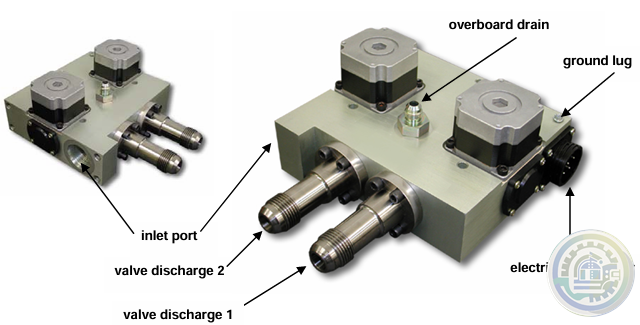

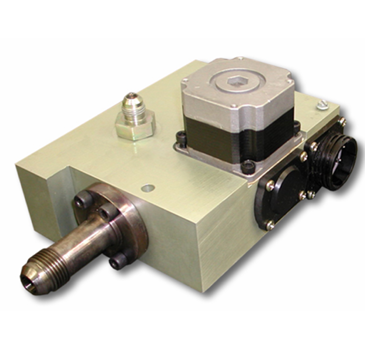

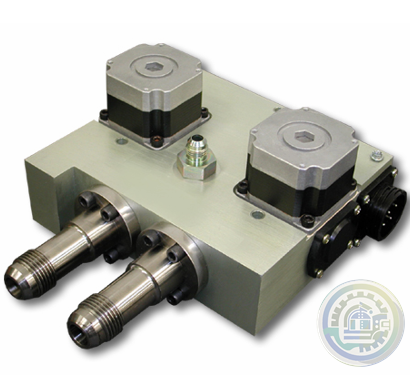

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

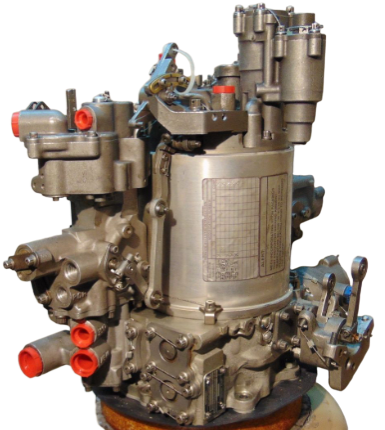

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

-

Woodward PG-07 Power Generation & Stationary Control System

-

Woodward PG‐PL Governor

-

Woodward Air Management

-

Woodward Engine Actuation Systems

-

Woodward Fuel Injection and Ignition Systems

-

Woodward Fuel Control Systems

-

Woodward Smart Injector Technology Key Product Variants Include

-

Woodward P2X Features & Functionality

-

Woodward P2X Multi-Fuel Injectors

-

Woodward SOGAV Gas Valves

-

Woodward SOGAV Key Product Variants Include

-

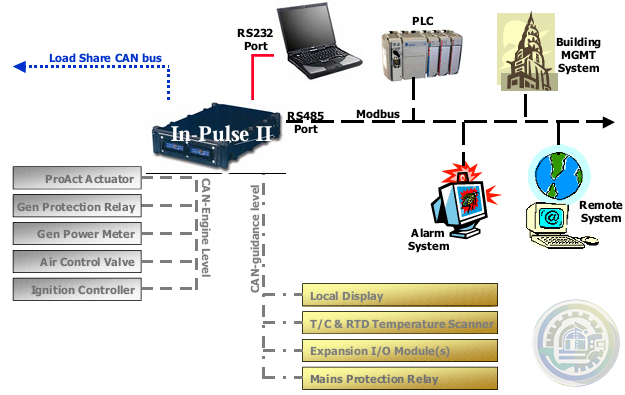

Woodward In-Pulse™ ll Self‐Diagnostics

-

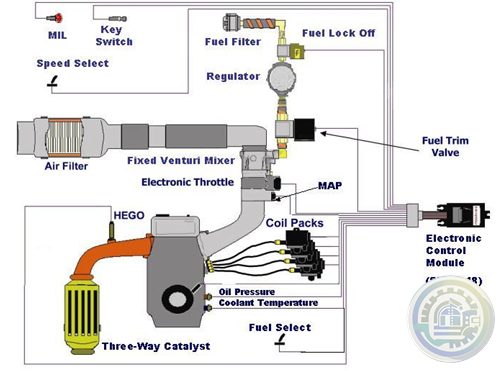

Woodward In-Pulse ll Fuel Injection Control

-

Woodward Dual-Fuel Injectors

-

Woodward High-Pressure Pumps

-

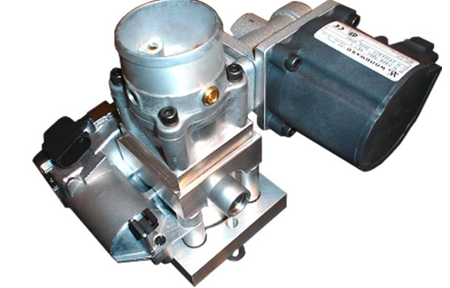

Woodward offers a growing line of air valves

-

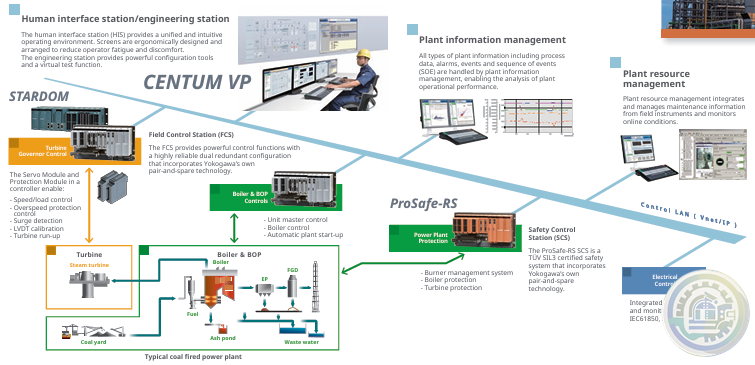

YOKOGAWA Turbine Control Solutions

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Analog Module Termination Cable Manufacturers ABB Model(s) ABB Bailey Infi 90

ABB Bailey Infi 90 and Net 90

Additional Information 33 foot length

Estimated Shipping Size Dimensions: 16.0" x 4.0" x 96.0" (40.6 cm x 10.2 cm x 243.8 cm)

Weight: 3 lbs 10.0 oz (1.4kg )

Tariff Code: 8544429000

Country of Origin: United States Ships from Webster NY, USA

Analog Module Termination Cable

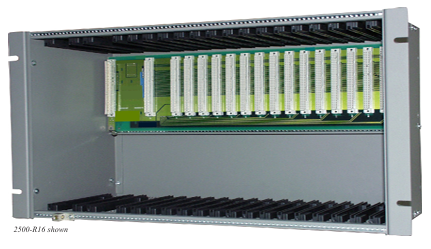

• Termination for up to sixteen (16) TC / mV process signals within a Vertical column.

• All SD I/O modules & bases of all types (Singular or Redundant) AND (Compact or Full-size), are 100% fully compatible with each other.

Thus, Singular & Redundant, Compact or Full-size I/O modules can be mounted within a single, common HN800 I/O bus.

• Optional mechanical keying can be implemented to prevent insertion of the wrong I/O module type.

• Latching device on the base locks the base into position on DIN-Rail.

• Industry standard 35-mm DIN rail, Vertical Column mounting.

Features and benefits

Termination for up to sixteen (16) analog I/O process signals within a horizontal row.

All SD I/O modules & bases of all types (Singular or Redundant) AND (Compact or Full-size), are 100% fully compatible with each other.

Thus, Singular & Redundant, Compact or Full-size I/O modules can be mounted within a single, common HN800 I/O bus.

Optional mechanical keying can be implemented to prevent insertion of the wrong I/O module type.

Latching device on the base locks the base into position on DIN-Rail.

Industry standard 35-mm DIN rail, Horizontal row mounting.

Furthermore, the anti-pumping device only allows circuit-breaker closure if the following conditions

are present at the same time:

1. Closing spring fully charged

2. Opening mechanical pushbutton and/or opening release coils (-MO1/-MO2) are not active.

3. The circuit breaker is in the Open position.

Below is a side internal view of the EL mechanism and the associated anti-pumping component.

When the opening pushbutton or coils are activated the opening shaft lever pushes down on point C of the anti-pump device.

This causes the device to side down slot D in direction of arrow B.

Then the trigger portion A moves out from between the closing push-button and the closing shaft lever.

So if the closing button or signal is held active and the opening button or signal is then activated.

The trigger A will pull out from between closing shaft lever and the closing push button.

Once the open signal is released the trigger A will come to rest under the closing push-button and will

not return between the closing shaft lever and closing push-button until the button or closing command is released.

The closing push button is operated by the closing coil (MC) directly by the shaft closing device.

This allows the anti-pumping device to prohibit closing by manual or electrical means.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved