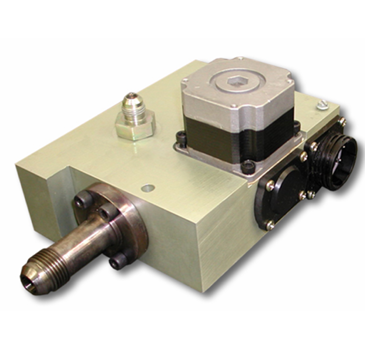

Woodward The Swift valve is a sonic flow-metering valve

Description

The system is available in two primary configurations. The "Swift" configuration

provides either single- or dual-metering valves in a single housing. This

configuration can be integrated into a new or existing gas metering system to

provide low-cost, accurate, reliable control. The Swift Model 200 system, sizes

65. 36. and 20. have been designed to provide system mass flow accuracy of 2%

of point at 100% of rated flow across the entire temperature range. The Swift

Model 200 system, size 11. has been designed to provide system mass flow

accuracy of 6.2% of point between 50 and 100% of rated flow, across the entire

temperature range.

The Swift gas metering system components include one or two metering valves

and one valve driver (see Figure 1-1). For fuel systems requiring two

independently modulated fuel flows, the primary valve can be integrated with a

secondary metering valve. The primary valve can accommodate this integration

without duplicating either electrical or mechanical connections.

Swift Valve

The Swift valve is a sonic flow-metering valve. The valve has a

converging/diverging nozzle and a moving needle to adjust the valve flow area.

An open loop step motor through a rack and pinion drive positions the needle. A

return spring is included to remove the effects of gear backlash and to minimize

closed-valve leakage. A mechanical stop allows the valve to re-zero the valve

position during start-up. After the re-zero, the driver counts the step motor steps

and monitors the step motor position.

Swift Driver

The driver is effectively a positioner that will accept a desired position signal from

another device in the system, such as a speed control, and drive the valve to that

position. The position controller software is executed on dual Texas Instruments

16-bit DSPs, operating at 40 MHz, onboard the Swift Driver. The driver can be

commanded to a position via 4–20 mA, PWM, or CAN/DeviceNet interfaces. The

driver monitors all available signals, internal and external, and annunciates any

detected shutdown conditions through the discrete output. A discrete input is

available to remotely shut down the actuator and to reset shutdown conditions.

Features of the driver include dual (2) model-based position control loops, on-line

diagnostics, CAN communications, and service port communications (described

in detail in Chapter 5). A Windows-based Service Tool software program is

available for monitoring, troubleshooting, and parameter adjustments. The

Service Tool software is loaded on a PC and communicates serially to the driver

via RS-232. Refer to Chapter 7 (Service Tool) for installation instructions.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

-

SC200S | Yokogawa Electric Corporation

-

Yokogawa PW301 Power Supply

-

YOKOGAWA NP53*C - Precision Control Module

-

Yokogawa F3YD64-1A Basic Input/Output Modules

-

Yokogawa F3XD64-3N Basic Input/Output Modules

-

Yokogawa F3WD64-3N Input/Output Module

-

Yokogawa F3SP21-0N CPU Module

-

YOKOGAWA F3PU10-0N Power Supply Module

-

YOKOGAWA F3PU06-0N Power Supply Module

-

YOKOGAWA F3NC02-0N Positioning Module

-

YOKOGAWA F3NC01-0N Positioning Module

-

YOKOGAWA PLC F3LC21-1N MULTI-LINK MODULE

-

YOKOGAWA F3BU06-0N Base Module

-

Honeywell DC-TFB412 51307618-176 Control Module

-

Honeywell DC-TCF901 51307593-176 9-Port Control Firewall Module

-

Honeywell DC-TCF901 cutting-edge control module

-

Honeywell DC-TFB412 Circuit Board

-

LVCDJW00000750A Watlow (Temperature Limit Controller)

-

Watlow 84700-0003 Dust cover

-

Watlow 847290006 USB type A panel mount with 2 m cord

-

Watlow RJF 21N SCC RJ45 receptacle with self closing cap

-

Watlow USBBF 21N SCC USB - B receptacle with self closing cap

-

Watlow USBF 21N SCC USB - A receptacle with self closing cap

-

Watlow 0600-0097-0000 Mixed I/O Flex Modules Quick Start Guide

-

Watlow 0600-0096-0000 High Density Flex Modules Quick Start Guide

-

Watlow 0600-0095-0000 Communications Flex Modules Quick Start Guide

-

Watlow 0600-0094-0000 F4T Controller Quick Start Guide

-

Watlow 0600-0093-0000 Setup and Operations User Guide

-

Watlow 0600-0092-0000 Installation and Troubleshooting User Guide

-

Watlow 0822-0769-0000 Module slot plug (for vacant F4T slots without flex modules

-

Watlow 0830-0858-0000 Replacement battery

-

Watlow 0830-0808-0002 (CAPUSB-A) Rubber plug USB host

-

Watlow 0830-0808-0001 (CAPUSB-MB5) Rubber plug USB mini

-

Watlow 0601-0001-0000 Controller support tools (DVD)

-

Watlow 0804-0147-0000 RC supression - Quencharc®

-

Watlow 16-0246 Current transformer

-

HIMA K9212 Safety Relay Output Module

-

Watlow 0238-1245-BLUE Accent bar (brushed aluminum blue)

-

804B-1600-0000 Watlow (1/4 DIN Digital Temperature Controller)

-

EM00-GATE-0000 Computer Accessory by WATLOW

-

DC10-60F0-0000 SCR Power Control by WATLOW

-

DC21-60F0-0000 SCR Power Control by WATLOW

-

DC22-60F0-0000 Power Control Watlow

-

Watlow PC20-F30B-0000 Power Supply

-

Watlow DC10-20L0-0000 Solid State Power Control

-

Watlow 0238-1245-REDD Accent bar (brushed aluminum red)

-

Watlow 0238-1245-ALUM Accent bar (brushed aluminum gray)

-

Watlow 0847-0400-0000 USB 2.0 to RJ45 Ethernet adapter

-

Watlow 0216-1285-0000 Flush mount - mounting adapter plate

-

Watlow 0822-0705-0000 F4T 1/4 DIN mounting collar - thru front panel mount

-

Watlow 0830-0870-0000 Protective screen cover (2 per pack)

-

Watlow EZ-ZONE PM Panel Mount Controller

-

Watlow PM Plus PID Control | West Coast Plastics

-

Watlow ASPYRE® Intelligent Power Controllers - HEATCON Composite Systems

-

Watlow ASPYRE DT Power Controller | Power Controllers

-

Watlow Distributors | Watlow Heaters, Sensors and Controllers

-

Watlow DUAL-5JRG-1100 Dual Controller Console, 1/32-Din, J Thermocouple Input

-

Watlow MINI-K5R1-0000 Mini. Single Controller Console, 1/32-Din, K Thermocouple Input

-

Watlow SNGL-7KRG-1100 Single Controller Console, 1/16-Din, K Thermocouple Input

-

Watlow 96 Temperature Controller W/ Watlow SNGL-CRBB-1100

-

POWERGLIDE® controller | Watlow

-

Watlow ASPYRE SCR Power Controller DT1480352B05AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480404A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480601A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT3480602A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480904B10AAA - Thermal Devices

-

Watlow Thyristor Power Controllers - 3 Phase Thyristor Power Controller

-

Watlow PID Temperature Controllers: Everything You Need to Know

-

Watlow F4T | Integrated Process Controller

-

Watlow PM PLUS PID & Limit Controller | Temperature Controllers

-

Watlow SELECT™ Visual Designer™

-

Watlow LLS200212 E257034 CLS208 208-1200000 temperature controller

-

Watlow 997D-11CC-JURG Temperature Controller Series

-

Watlow CLS2163C1-110200000/CLS204204-C10000AA/CLS2082 controllers

-

Watlow PPC-TB50 3C1-110200000 Temperature/Process Control

-

Watlow MLS300-CIM316 Control Interface Module

-

Watlow MLS300 Analog Input Module

-

ABB CP555 1SBP260179R1001 Industrial Control Panel

-

ABB 500BIM01 1MRB160024R0002 Binary Input Signal Interface Module

-

ABB 500BIO01 1MRB150005R0001 1MRB200060/E Digital Input Output Interface Module

-

ABB 500BIO01 1MRB150005R1/J Binary Input Output Interface Module

-

ABB 500BOM01 1MRB150023R0002 Bus Organization Module

-

ABB 500CIM05 1MRB150077R1/B Communication Interface Module

-

ABB 500CMP04 HE401314/0001 1MRB150051R1 Communication Management Processor Module

-

ABB 500CPU03 1HDF700003R5122 Central Processing Unit Modul

-

ABB 500CPU05 1MRB150081R1/E Central Processing Unit Module

-

ABB 500CSP04 HE401314/0002 1MRB150051R2 Communication System Processor Module

-

ABB 500MBA02 1MRB150003R000/B Memory Backup Module

-

ABB 500MBA01 1MRB150003R0002 1MRB200053/L Memory Backup Module

-

ABB 500MBA02 1MRB150003R0003 1MRB200053/M

-

ABB 500MTM02 1MRB150020R1102 1HDF 930512 X010 Measurement and Termination Module

-

ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010 Measurement and Termination Module

-

ABB 500PB101 1MRB178009R0001 1MRB200064/C Processor Bus Module

-

ABB 500PSM02 1MRB150015R1 AD-272.100.20-01 AZ:C Power Supply Module

-

ABB 500PSM03 1MRB 150038 R1 894-030375D 136-011100H Power Supply Module

-

ABB 500SCM01 1MRB200059/C 1MRB15004R0001 Serial Communication Module

-

ABB 500SCM01 1MRE450004R1 Serial Communication Module

-

ABB 500TRM02 1MRB150011R0001 Temperature Relay Module

-

ABB 500TRM02 1MRB150011R1 Temperature Relay Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved