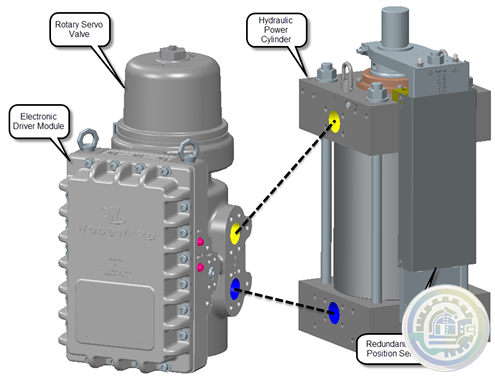

Woodward VariStroke-II (VS-II) Valve Rack Linearization (not currently available)

Valve Rack Linearization (not currently available)

Because steam flow through single and staged inlet steam valves tends to be non-linear throughout their

flow range, turbine controls must be de-tuned to compensate for instability or sluggish control points

throughout this range. As a way of allowing turbine control optimization without detuning, the VariStroke-II

includes an 11-point linearization table to allow turbine OEMs or users to compensate for poor valve

linearization by digitally linearizing the control-to-valve flow relationship.

Side Load Capability

A common problem with turbine actuators is oil leaking from their output shaft due to connection to valve

rack linkages which have an arc-type of motion. This motion results in side loading of the actuator shaft,

and after long periods may result in shaft-seal wear and resultant oil leakage. Designed for a continuous

side load of up to 10% of actuator output, the VariStroke-II actuator incorporates a high-force precision

bearing and triple-seal technology on its output shaft to solve this typical application problem.

Silt Buster

A patented self-cleaning feature that flushes silt and debris from the servo valve. At the interval and

amplitude selected by the user, this function provides a very rapid motion of the servo valve spool,

allowing any silt to be flushed to the drain passage. This motion is followed immediately by a step of

equal amplitude in the opposite direction. The opposing symmetry of the impulse results in no net change

in fluid volume to the hydraulic power cylinder, and thus does not interrupt the control of the turbine. This

unique feature provides a high degree of stability, reliability, and silt resistance.

Valve Rack Linearization (not currently available)

Because steam flow through single and staged inlet steam valves tends to be non-linear throughout their

flow range, turbine controls must be de-tuned to compensate for instability or sluggish control points

throughout this range. As a way of allowing turbine control optimization without detuning, the VariStroke-II

includes an 11-point linearization table to allow turbine OEMs or users to compensate for poor valve

linearization by digitally linearizing the control-to-valve flow relationship.

Side Load Capability

A common problem with turbine actuators is oil leaking from their output shaft due to connection to valve

rack linkages which have an arc-type of motion. This motion results in side loading of the actuator shaft,

and after long periods may result in shaft-seal wear and resultant oil leakage. Designed for a continuous

side load of up to 10% of actuator output, the VariStroke-II actuator incorporates a high-force precision

bearing and triple-seal technology on its output shaft to solve this typical application problem.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

-

Honeywell CC-TUI041 51306873-176 Temperature and humidity transmitter

-

Honeywell CC-TUI041 51306873-176 Temperature and humidity transmitter

-

HONEYWELL FS-USI-0001 ANALOG INPUT MODULE

-

HONEYWELL QPP-0001 Quad Processor Pack QPP Module

-

Honeywell PSU-2405 Redundant 24VDC power unit

-

Honeywell CPB-0001 CPCHAS-0001 Single Channel Control Module

-

Honeywell FS-CPB-0001 Control processor backplane module

-

Honeywell FS-DCOM-232/485 Industrial Interface Module

-

Honeywell CPB-0001 CPCHAS-0001 Single Channel Control Module

-

IO-0001 CCV1.0 HONEYWELL I/O Extended Module

-

Honeywell FC-IOCHAS-0001R Chassis 100% Original Brand

-

HONEYWELL FC-IOCHAS-0001S I/O Chassis Brand

-

Honeywell FC-SAI-1620M V1.4 Safety Manager System

-

Honeywell EG1033AA EG1033AA01 261A1812P002 EG Flame Amplifiere

-

Honeywell XS824-25 Panel Bus I/O Modules

-

Honeywell 51120841-201 Single SPDT Control Relay

-

Honeywell 51120841-101 Single SPDT Control Relay

-

Honeywell CC-PUIO01 51454205-175 Universal I/O Module

-

Honeywell 0571-A-0325 MODBUS Interface Module

-

Honeywell 0571-A-0328 MODBUS Interface Module

-

Honeywell 05701-A-0282 MODBUS Interface Module

-

Honeywell 10310/1/109701 High-Performance Control Module

-

Honeywell TC-CCN014 redundant network interface module

-

Honeywell GR-2C-DC24V Single Channel Control Module

-

Honeywell GR-2C-AC230V Single Channel Control Module

-

Honeywell GR-4C-DC24V | Single Channel Control Module

-

Honeywell SPS5713 51199930-100 Industrial Control Module

-

Honeywell 05074-A-0122 05704-A-0121 05704-A-0131 PLC Module

-

Honeywell 05074-A-0122 05704-A-0121 05704-A-0131 PLC Module

-

Honeywell 05704-A-0131 PLC Module

-

Honeywell SC-TCMX01 51307198-175 Remote Terminal Unit

-

Honeywell SC-PCMX01 51307195-175 Remote Terminal Unit

-

Honeywell CC-IP0101 51410056-175 Profibus Dp Gateway Module

-

Honeywell SPS5785 51198651-100 HPM Power Supply Module

-

Honeywell 51402455-100 MP-DNCF02-201 PLC Module

-

Honeywell 51402455-100 MP-DNCF02-200 PLC Module

-

Honeywell 51403645-100 SBHM Card Module

-

Honeywell 51401583-100 EPNI I/O Card

-

Honeywell 51306673-100 EPNI I/O Card

-

K4LCN16 - Honeywell 16M LCN Processor Board

-

GR-4C-AC230V Honeywell LCSC Electronics

-

HONEYWELL PGR-4C-E High-Frequency Control Module

-

Honeywell CC-TCNT01 Input/Output Termination Assembly

-

Honeywell CC-TAON01 HART Analog Output IOTA

-

51400700-100 | TDC 3000 | Honeywell - DCS Center

-

HONEYWELL 97-4698 REV.A Control Module

-

FF-SR05936G Honeywell - Industrial Relays

-

Honeywell 51195066-100 / HF-75632-F Analog Input Module

-

51305072-300 - Honeywell CLCN-B LCN I/O Card CE

-

HONEYWELL 51404223-001 Safety Explosion-Proof Module

-

Honeywell 620-0041C 620 - 10/15 Power Supply Module

-

Honeywell CC-PAON01 Advanced Analog Output Module

-

Honeywell CC-PAON01 Advanced Analog Output Module

-

GE VMIVME-5565-010000 332-015565-010000P Processing Module

-

GE VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J Controller Module

-

GE IS420ESWBH3AX IONET Switch Module

-

GE IS200AEPAH1BKE IS215WEPAH2BB Printed Circuit Board

-

GE PMC-0247RC-282000 350-93750247-282000F Industrial Storage Module

-

GE IC200PWR012D AC power supply module

-

GE EVPBDP0001 EVPBDP032 Controller Module

-

GE MVR1600-4601 Air-cooled rectifier module

-

GE IS200SPROH1AAB MRP663860 Turbine Protection Relay Module

-

GE 760-P1-G1-S1-LO-A20-R Feeder Management Relay

-

GE IS210MACCH1AGG Single-Axis Motion Control Module

-

GE 369B1860G0031 Input output module

-

GE SR489-P1-HI-A20-E Multilin 489 Advanced Generator Protection

-

GE 369-HI-0-M-0-E-0 Motor Management Relay

-

GE 369B1859G0021 Input output module

-

GE 208D9845P0008 Motor Management Relay

-

GE D20EME10BASE-T 820-0474 Ethernet interface module

-

GE IS200AEPGG1AAA Drive Control Module

-

GE CK11CE300 CK contactor with electronic module

-

GE IC800SS1228R02-CE Motor Controller

-

GE IC695CHS016-CA Universal Controller and I/O Back

-

GE MPU55 Microprocessor Unit

-

GE IS200TTURH1CCC S1DF00Z terminal turbine board

-

GE DS200DCFBG2BNC MRP445970 DC Feedback Board

-

GE TED134050WL Thermal Magnetic Circuit Breakers

-

GE PQMII-T20-C-A PQMII Power Quality Meter

-

GE IC200ALG327H Analog Input/Output Module

-

GE IS200AEADH4A 109W3660P001 Analog Input Module

-

GE IC695PSD140A DC power module

-

GE QPJ-SBR-201 Remote I/O Module

-

GE FS16 Management Relay Module

-

GE DS3800NB1F1B1A Termination Board

-

GE 369B1859G0022 Turbine Control Module

-

GE D20 EME210BASE-T Ethernet Communication Module

-

GE IC697CPM790-GD Controller Module

-

GE 369B1860G0030 relay module

-

GE IC800SSI228RD2-EE DeviceNet S2K Servo Controller

-

GE 369-HI-R-M-F-E-H-E Motor Management Relay

-

GE CIFX50-C0 Industrial Control Module

-

GE DS200SI0CG1A6A VME Stand I/O Board

-

GE IS200AEPAH1ACB AEPA card

-

GE IS200WREAS1ADB Turbine Emergency Trip option board

-

GE IS210MACCH2AGG Communication Adapter Module

-

GE IS200BPPBH2CAA Mark VIe Power Supply Module

-

GE WESDAC D20ME 18-MAR-13 D20 Control Output Module

-

GE IS200WEMAH1AEA Wind Energy Main Assembly

-

GE DS200SI0CG1AEA Instantaneous Overcurrent Card

-

GE DS200SI0CG1AEA Instantaneous Overcurrent Card

-

GE IS200AEPAH1AFD Printed Circuit Board

-

GE IC695CPE400-ABAB Central Processing Unit

-

GE IC697VDD100 Isolated Digital Input Board

-

GE IS220YAICS1A L Mark VIe Safety Analog I/O Pack

-

GE IS200TSVCH1AED Servo Input/Output Terminal Board

-

GE IS200JPDMG1ACC S1AT005 Discrete input/output (I/O) module

-

GE PC000087524/01 Control Board Module

-

GE D20MIC10BASE-T 820-0756 Ethernet Media Interface Card

-

GE 2400-21004 2010-3101-0442 Reusable Blood Pressure Cuff

-

GE IS200AEPAH1AHD PLC Module Brand

-

GE 760-P1-G1-S1-LO-A20-R-E Feeder Management Relay

-

GE D20 EME 2400-21004 Substation Controller

-

GE D20 EME 27-APR-13 Substation Controller

-

GE DS200DCFBG2BNC MRP569662 DC Feedback Board

-

GE DS200SHVMG1AGE High Voltage M-Frame Interface Board

-

GE IS210BPPCH1AEC Mark VIe Power Supply Module

-

GE 760-P5-G5-S5-HI-A20-R-E Feeder Management Relay

-

GE IS230TNDSH2A Mark VIe Terminal Board

-

GE IS200TDBSH2ACC Terminal Base Module

-

GE WEA13-13 2508-21001 Substation Controller

-

GE DS200PCCAG1ACB Power Connect Card

-

GE IS210MACCH2AEG Printed Circuit Board

-

CTI 2572-B - Fast Ethernet TCP/IP Adapter

-

CTI 2515-A - 100W AC PS w/redundancy support

-

CTI 2500-C400 CPU with 3072K User Memory

-

CTI 2500P-WB-USB CTI Janus Workbench Software Integrated Development Environment -- "JSoft"

-

CTI 2500-SSB - Single-slot blank front panel

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE VMIVME-5565-010000 332-015565-010000P Processing Module

-

GE VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J Controller Module

-

GE IS420ESWBH3AX IONET Switch Module

-

GE IS200AEPAH1BKE IS215WEPAH2BB Printed Circuit Board

-

GE PMC-0247RC-282000 350-93750247-282000F Industrial Storage Module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved