Woodward PG-07 CONTROL SYSTEM FEATURES

Gasoline engines (up to 4 cylinders)

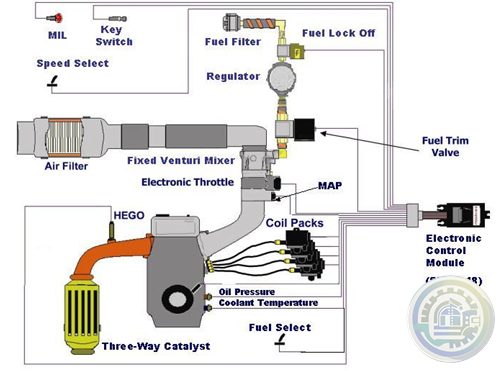

The ECM and sensors provide the computational power, algorithm logic, sensor

inputs and control outputs to control the system. The ECM receives signals from

the sensors, digitizes these signals, and then through algorithms and

calibration maps computes the desired output response to manage

fuel, spark and air to the engine. The ECM also provides a variety of other

functions and features, including system monitoring and diagnostics to aid

in maintaining efficient system operation and auxiliary control.

All gasoline specific components are automotive production parts and

validated to strict automotive standards.

PG-07 CONTROL SYSTEM FEATURES

Closed-loop control of air-fuel ratio improves equipment durability by reducing

maintenance, fuel consumption, and engine component wear.

Control strategy ensures optimal transient performance for efficient system response.

Comparisons of actual engine operation to expected values allow the system to

compensate for wear, tolerances and adverse operating environments.

This improvement in operating economics is a result of the sophisticated software

models in the PG-07 system.

Programmable idle speed control includes speed setpoint modifications for

coolant temperature and speed selector switch input.

Monitoring and diagnostic communication via two CAN Bus interfaces

(J1939 protocol) allows immediate assessments and corrections either on-site or remotely.

Individual diagnostic codes detect functional faults, intermittent faults, sensor

and actuator failures, and engine protection problems.

Malfunction indicator lamp (MIL) annunciator allows instant analysis and troubleshooting.

Extensive engine protection features include monitoring of engine coolant

temperature, oil pressure, and overspeed.

Fault conditions can be calibrated to trigger a limited operating mode for

diagnostics and troubleshooting.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

-

SC200S | Yokogawa Electric Corporation

-

Yokogawa PW301 Power Supply

-

YOKOGAWA NP53*C - Precision Control Module

-

Yokogawa F3YD64-1A Basic Input/Output Modules

-

Yokogawa F3XD64-3N Basic Input/Output Modules

-

Yokogawa F3WD64-3N Input/Output Module

-

Yokogawa F3SP21-0N CPU Module

-

YOKOGAWA F3PU10-0N Power Supply Module

-

YOKOGAWA F3PU06-0N Power Supply Module

-

YOKOGAWA F3NC02-0N Positioning Module

-

YOKOGAWA F3NC01-0N Positioning Module

-

YOKOGAWA PLC F3LC21-1N MULTI-LINK MODULE

-

YOKOGAWA F3BU06-0N Base Module

-

Honeywell DC-TFB412 51307618-176 Control Module

-

Honeywell DC-TCF901 51307593-176 9-Port Control Firewall Module

-

Honeywell DC-TCF901 cutting-edge control module

-

Honeywell DC-TFB412 Circuit Board

-

LVCDJW00000750A Watlow (Temperature Limit Controller)

-

Watlow 84700-0003 Dust cover

-

Watlow 847290006 USB type A panel mount with 2 m cord

-

Watlow RJF 21N SCC RJ45 receptacle with self closing cap

-

Watlow USBBF 21N SCC USB - B receptacle with self closing cap

-

Watlow USBF 21N SCC USB - A receptacle with self closing cap

-

Watlow 0600-0097-0000 Mixed I/O Flex Modules Quick Start Guide

-

Watlow 0600-0096-0000 High Density Flex Modules Quick Start Guide

-

Watlow 0600-0095-0000 Communications Flex Modules Quick Start Guide

-

Watlow 0600-0094-0000 F4T Controller Quick Start Guide

-

Watlow 0600-0093-0000 Setup and Operations User Guide

-

Watlow 0600-0092-0000 Installation and Troubleshooting User Guide

-

Watlow 0822-0769-0000 Module slot plug (for vacant F4T slots without flex modules

-

Watlow 0830-0858-0000 Replacement battery

-

Watlow 0830-0808-0002 (CAPUSB-A) Rubber plug USB host

-

Watlow 0830-0808-0001 (CAPUSB-MB5) Rubber plug USB mini

-

Watlow 0601-0001-0000 Controller support tools (DVD)

-

Watlow 0804-0147-0000 RC supression - Quencharc®

-

Watlow 16-0246 Current transformer

-

HIMA K9212 Safety Relay Output Module

-

Watlow 0238-1245-BLUE Accent bar (brushed aluminum blue)

-

804B-1600-0000 Watlow (1/4 DIN Digital Temperature Controller)

-

EM00-GATE-0000 Computer Accessory by WATLOW

-

DC10-60F0-0000 SCR Power Control by WATLOW

-

DC21-60F0-0000 SCR Power Control by WATLOW

-

DC22-60F0-0000 Power Control Watlow

-

Watlow PC20-F30B-0000 Power Supply

-

Watlow DC10-20L0-0000 Solid State Power Control

-

Watlow 0238-1245-REDD Accent bar (brushed aluminum red)

-

Watlow 0238-1245-ALUM Accent bar (brushed aluminum gray)

-

Watlow 0847-0400-0000 USB 2.0 to RJ45 Ethernet adapter

-

Watlow 0216-1285-0000 Flush mount - mounting adapter plate

-

Watlow 0822-0705-0000 F4T 1/4 DIN mounting collar - thru front panel mount

-

Watlow 0830-0870-0000 Protective screen cover (2 per pack)

-

Watlow EZ-ZONE PM Panel Mount Controller

-

Watlow PM Plus PID Control | West Coast Plastics

-

Watlow ASPYRE® Intelligent Power Controllers - HEATCON Composite Systems

-

Watlow ASPYRE DT Power Controller | Power Controllers

-

Watlow Distributors | Watlow Heaters, Sensors and Controllers

-

Watlow DUAL-5JRG-1100 Dual Controller Console, 1/32-Din, J Thermocouple Input

-

Watlow MINI-K5R1-0000 Mini. Single Controller Console, 1/32-Din, K Thermocouple Input

-

Watlow SNGL-7KRG-1100 Single Controller Console, 1/16-Din, K Thermocouple Input

-

Watlow 96 Temperature Controller W/ Watlow SNGL-CRBB-1100

-

POWERGLIDE® controller | Watlow

-

Watlow ASPYRE SCR Power Controller DT1480352B05AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480404A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480601A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT3480602A00AAA - Thermal Devices

-

Watlow ASPYRE SCR Power Controller DT2480904B10AAA - Thermal Devices

-

Watlow Thyristor Power Controllers - 3 Phase Thyristor Power Controller

-

Watlow PID Temperature Controllers: Everything You Need to Know

-

Watlow F4T | Integrated Process Controller

-

Watlow PM PLUS PID & Limit Controller | Temperature Controllers

-

Watlow SELECT™ Visual Designer™

-

Watlow LLS200212 E257034 CLS208 208-1200000 temperature controller

-

Watlow 997D-11CC-JURG Temperature Controller Series

-

Watlow CLS2163C1-110200000/CLS204204-C10000AA/CLS2082 controllers

-

Watlow PPC-TB50 3C1-110200000 Temperature/Process Control

-

Watlow MLS300-CIM316 Control Interface Module

-

Watlow MLS300 Analog Input Module

-

ABB CP555 1SBP260179R1001 Industrial Control Panel

-

ABB 500BIM01 1MRB160024R0002 Binary Input Signal Interface Module

-

ABB 500BIO01 1MRB150005R0001 1MRB200060/E Digital Input Output Interface Module

-

ABB 500BIO01 1MRB150005R1/J Binary Input Output Interface Module

-

ABB 500BOM01 1MRB150023R0002 Bus Organization Module

-

ABB 500CIM05 1MRB150077R1/B Communication Interface Module

-

ABB 500CMP04 HE401314/0001 1MRB150051R1 Communication Management Processor Module

-

ABB 500CPU03 1HDF700003R5122 Central Processing Unit Modul

-

ABB 500CPU05 1MRB150081R1/E Central Processing Unit Module

-

ABB 500CSP04 HE401314/0002 1MRB150051R2 Communication System Processor Module

-

ABB 500MBA02 1MRB150003R000/B Memory Backup Module

-

ABB 500MBA01 1MRB150003R0002 1MRB200053/L Memory Backup Module

-

ABB 500MBA02 1MRB150003R0003 1MRB200053/M

-

ABB 500MTM02 1MRB150020R1102 1HDF 930512 X010 Measurement and Termination Module

-

ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010 Measurement and Termination Module

-

ABB 500PB101 1MRB178009R0001 1MRB200064/C Processor Bus Module

-

ABB 500PSM02 1MRB150015R1 AD-272.100.20-01 AZ:C Power Supply Module

-

ABB 500PSM03 1MRB 150038 R1 894-030375D 136-011100H Power Supply Module

-

ABB 500SCM01 1MRB200059/C 1MRB15004R0001 Serial Communication Module

-

ABB 500SCM01 1MRE450004R1 Serial Communication Module

-

ABB 500TRM02 1MRB150011R0001 Temperature Relay Module

-

ABB 500TRM02 1MRB150011R1 Temperature Relay Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved