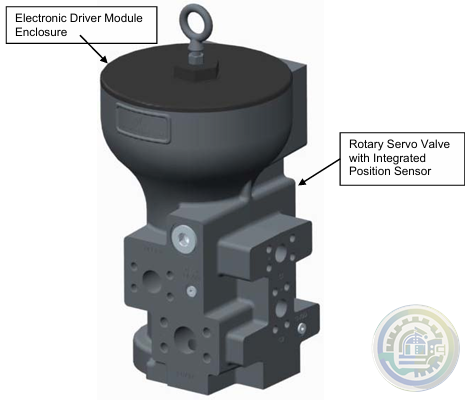

Woodward VS-I Remote Servo Only Construction

Rotary Servo Valve

The hydraulic servo valve has five ports: Supply, two Control Ports, Over Board

Drain (OVBD), and Drain/Tank. With the hydraulic valve in its middle position,

both control ports are blocked. As the valve rotates, supply pressure is

connected to a control port while simultaneously connecting the drain to the other

control port. The combined action of the servo position controller and cylinder

position controller modulate the power cylinder position as necessary to match

the input demand. OVBD is permanently connected to drain and can (optionally)

be connected to the OVBD connection on Hydraulic Power Cylinder to drain any

leakage pass the primary rod seal.

A unique function of the software is a periodic, symmetrically opposed impulse

(called "Silt Buster") which flushes silt and debris from the servo valve without

causing undue wear. At the interval and amplitude selected by the user, this

function provides a very rapid motion of the hydraulic valve, allowing any silt to

be flushed to the drain passage. This motion is followed immediately by a step of

equal amplitude in the opposite direction. The opposing symmetry of the impulse

results in no net change in fluid volume to the controlled servo valve, and thus

does not interrupt the control of the turbine. This unique function provides a

higher degree of stability, reliability, and silt resistance.

If the unit detects any diagnostic shut down condition, or if the detected

diagnostic condition prevents reliable control, or if a loss of power occurs, the

servo valve return spring forces the valve to connect the appropriate control

pressure to drain, causing the cylinder to move to the fail-safe position.

Electronic Driver Module (PCB)

The printed circuit board (PCB) is mounted on top of the housing (see Figure

1-6). The PCB performs the following tasks:

Power Supply

Isolated Input and Outputs

Dual Redundant Demand Inputs

Dual Redundant Inputs for Final Cylinder Feedback

Microprocessor-based Control

Actuator H-Bridge Drive

Current Limiting for Thermal Protection

Advanced Diagnostics

Discrete Outputs for Fault, Alarm, and Shutdown Enunciation

The shield connections for the Analog Output (terminal #20), CAN1 (terminal

#23), and CAN2 (terminal #29) are through capacitors only as indicated in the

wiring section of this manual.

The power supply section performs the EMI filtering on the (18 to 32) V (dc) input

voltage and generates controlled voltages for several electronics sub-systems.

The power supply system is monitored for proper operation. If input voltage or

internal power systems are detected outside of allowable operating ranges, a

diagnostic alarm will be enunciated.

Calibration and configuration of alarms and shut down and redundancy operation

are configurable via the PC Service Tool.

The primary demand and redundant demand / feedback input signals are

designed for a (4 to 20) mA control signal. Each input signal is EMC protected.

Discrete outputs are provided for alarm and shut down enunciation. An internal

LED also is illuminated when a fault condition is detected. Cover needs to be

removed to see this LED. The configurable discrete output can be customized to

output a variety of enunciations using the PC Service Tool. All of the discrete

outputs are configurable for normally-open or normally-closed action using the

PC Service Tool.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

- Alfa Laval

- Bachmann

-

8301A 24VDC 175W Power Module Schneider Triconex

-

Electric 24VDC Digital Input Module Triconex DI232 Schneider

-

Triconex 9101-010F Schneider PLC Module

-

DI2301 Electric Digital Input Baseplate Triconex

-

Digital Output Baseplate Triconex DO2401

-

Triconex MP2101 Digital Input Module

-

CM2201 Triconex Communication Module Baseplate

-

Control Module Triconex 4000103-546

-

Triconex 4000094-346 TMR Safety Control Module

-

Triconex 1400010-001 Schneider Electric Interface Module

-

Relay External Terminator Triconex 3000290-380

-

Interface Module Triconex 3000580-110

-

3000590-110 Interface Module Triconex

-

Triconex PS4127000 Power Supply Module

-

Triconex W2S107111516 Cooling Fan Assembly

-

Triconex SK3110000 Schneider Electric TMR Safety Module

-

Triconex PS4144110 Schneider Electric Power Supply Module

-

HFE1600-24 High-Density Power Supply Triconex

-

TMR Analog Output Module Triconex 3481S2

-

7400061-210-A3 3000110-360 Triconex Termination Panel

-

Communication Module Triconex CM3201

-

Analog Input Module AI3351 S2 Triconex

-

Interface Cable Assembly 4000206-540 Triconex

-

2000361-001 Triconex TMR System Interconnect Cable

-

Triconex EM 2281 MCIO I/O Connector

-

Internal System Interface Module Triconex EM 2291

-

Triconex EM 2292 Internal PLC Interface Module

-

8312 3000600-601 Triconex Power Supply Module

-

Remote Extender Module Triconex 4211-3

-

2770H Triconex HART Interface Module

-

Controller Module Triconex 1008FC

-

AO2481 Triconex Analog Output Module

-

Triconex SDO204 TMR Safety Digital Output Module

-

System Interface Cable Assembly 4000212-002 Triconex

-

Triconex 9662-810 3000520-380 Process Control Module

-

9662-810 4000094-350 Triconex Digital Output Termination Panel

-

Digital Input Termination Panel Triconex 9563-810 (4000093-350)

-

Triconex 3503 Digital Input Module

-

Triconex Tricon Series 4328 Network Communication Module

-

4351A/B Triconex Tricon Communication Module TCM

-

High-Density Terminal Board 7400165-380 Triconex

-

AI2351 Triconex Analog Input Module

-

Triconex 7400195-210 REV A2 Analog Input Termination Panel

-

TMR Terminal Board Interface 7400166-390 REV A2 Triconex

-

Triconex Terminal Board 7400165-380 REV A1

-

External Termination Panel Module 3000400-510 Triconex

-

ME203/CN | Bachmann Processor Module

-

Bachmann SFS236C Communication Unit

-

MP226/EW BACHMANN Processor Module

-

BACHMANN BS203 Backplane for Modular PLC Systems

-

BACHMANN AO202/SI Analog Output Module

-

AI204/4 Bachmann Analog input / output modules

-

Bachmann GIO212 Universal I/O Module

-

Bachmann CPC210 Terminal Set

-

Bachmann DMS202 Strain Gauge Input Module

-

Bachmann GM260 Grid Measurement Module

-

BACHMANN BS202 Backplane

-

BACHMANN DIO264-C CAN Slave Digital Input/Output Module

-

BACHMANN MX220 Processor Module

-

Bachmann | TI214 | Temperature Input Module

-

BACHMANN MX213 Processor Module w/ 512MB Card

-

BACHMANN MX213 Processor Module w/ 512MB Card

-

BACHMANN FS221/N FASTBUS Module

-

BACHMANN SLC284 Safety Processor Module

-

DIO248 | Bachmann Digital Input/Output Module

-

Bachmann ACR222/2 Axis Controller Module

-

MPC270 | Bachmann Programmable Logic Controller Module

-

DIO216 Bachmann Digital Input/Output Module

-

Bachmann | PTAI216 Temperature Input Module

-

MPC240 Bachmann 512MB CF Processor Module

-

FS211/N Bachmann FASTBUS Module

-

FASTBUS Module FM211 | Bachmann

-

Bachmann ISI222/8 Positioning Module

-

ISI202 Encoder Interface Module | Bachmann

-

MPC240/W | Bachmann | Processor Module

-

NT250 Bachmann Power Supply Module

-

Bus Master Module for Automation Networks CM202 BACHMANN

-

FM221 BACHMANN PLC Control Module

-

BACHMANN BS206 I/O Bus Coupler Module for Industrial Automation

-

Bachmann PCC200 Programmable Logic Controller Module

-

WT205V Bachmann Control Panel for M1 Automation Systems

-

Bachmann 00014647-00 Fieldbus Interface Module for Industrial Automation

-

Industrial Ethernet Switch SWI205 Bachmann

-

AI204/2 BACHMANN Analog Input Module

-

Bachmann BS208 Modular Backplane Rack

-

Processor Module MPC265 Bachmann

-

Bachmann 00016586-00 4GB Compact Flash Card for Devices

-

AIO288 Analog Input Output Module Bachmann Industrial

-

Honeywell XS815 Long Cross Connectors for Relay Output

-

Honeywell XS814 Aux Terminal Block

-

Honeywell XS812rO Disconnector Module relay Outputs

-

Honeywell XS812 Manual Disconnector for AI AO

-

RM7890A1015 | Honeywell 7800 Series Relay Modules

-

Honeywell Burner Control RM7800M1011

-

RM7800L1012 Burner Control by HONEYWELL

-

Honeywell RM7800L1087 burner control

-

Honeywell MC-GAIH13 galvanic isolator module

-

HONEYWELL R7849A-1023 ULTRAVIOLET FLAME

-

Honeywell XF823A Digital Input Module 25V

-

Honeywell XFR822A Pluggable Analog Output, 8 Analog Output Module

-

Honeywell XF821A HVAC Analog Input Module

-

Honeywell SIEGER 05704-A-0122 Control Module

-

HONEYWELL LG1093AA24 ULTRAVIOLET FLAME SENSOR

-

Honeywell 261A1812P012 Flame Detector

-

2104B2131 | Honeywell | Medium Range Receiver ATEX Source

-

Honeywell S2024-2POS-SW2 Two-position SPST Actuator

-

Honeywell XFR824A Panel Bus I/O Modules

-

Honeywell SC-UCMX02 51307198-276 Controller Module

-

FTA-T-02 | Honeywell | Fail-safe digital output FTA

-

HONEYWELL Carrier Channel Assy Assembly CC-MCAR02 Module

-

Honeywell FTA-T-21 Digital Input Module Brand

-

Honeywell MC-PAIH03 Analog Input Processor

-

Hitachi LYD000A Industrial Controller Module

-

HITACHI PS6000 Programmable Logic Controller

-

HITACHI LBT010A AC Drive Inverter

-

Hitachi LPD250A Advanced Process Control System

-

Hitachi LPT020A Power Supply Module

-

Hitachi LPF240F AC Drive Inverter

-

HITACHI LPU100A CPU Module

-

HITACHI PS6515 Control System Module

-

Hitachi PS6548 Industrial Power Supply Module

-

HITACHI PS6524 Industrial Control Module

-

Hitachi MPD310A High-Precision AC Drive Module

-

Hitachi MPD110A High-Precision AC Drive Module

-

Hitachi MPD060A High-Precision AC Drive Module

-

HITACHI LPP100A Industrial Power Supply

-

HITACHI LCE250B Input-output module

-

HITACHI LCE250A Input-output module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved