-

A-B 20G11BC1K1JN0NNNNN PowerFlex Air Cooled 755 AC Drive

-

A-B 20P41AF452RA0NNN PowerFlex 452 A DC Drive

-

A-B 20GHAJC540JN0NNNNN PowerFlex Extra Tough 755 AC Drive

-

EPRO MMS6823 9100-00001-05 Displacement Monitor Module

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

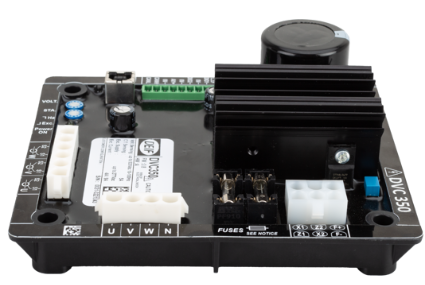

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

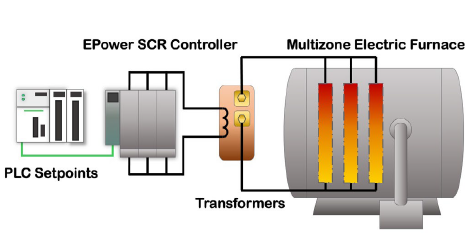

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

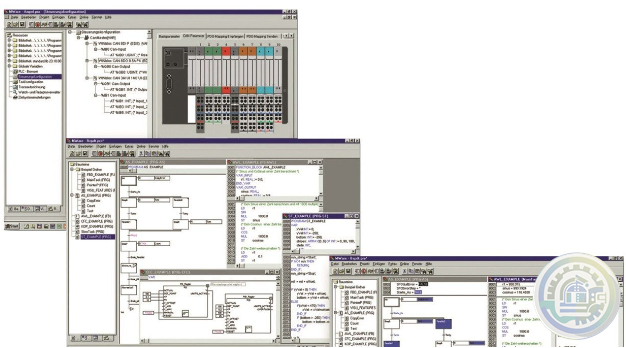

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

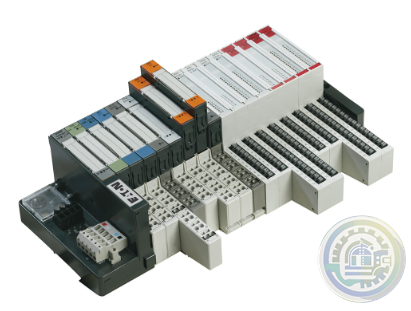

Eaton XI/ON I/O system

-

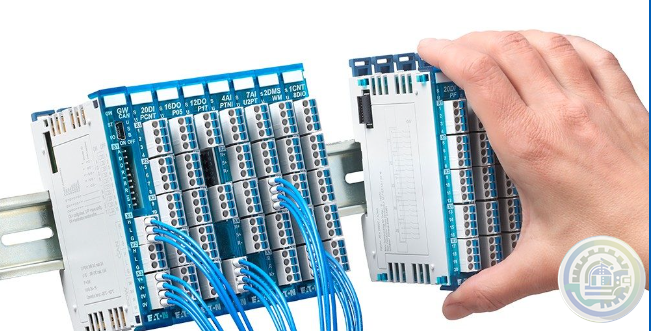

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

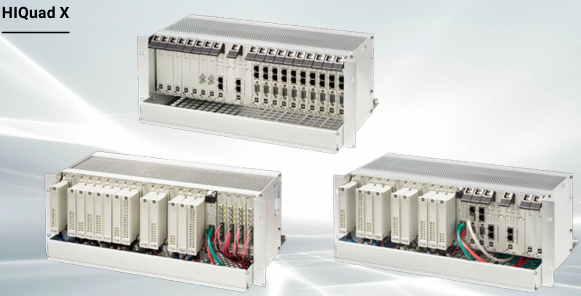

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

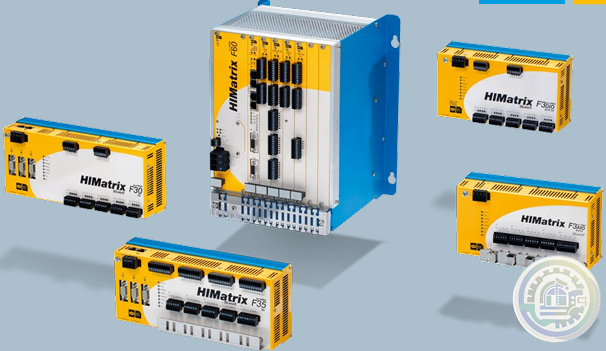

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

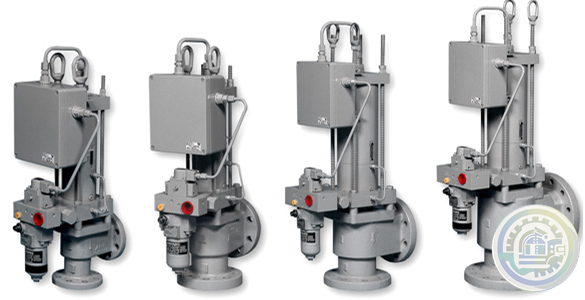

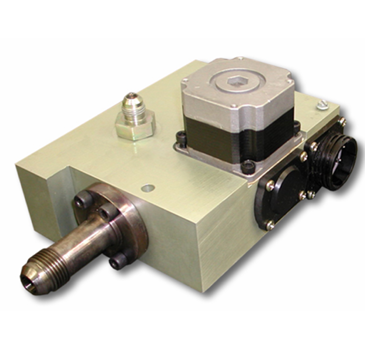

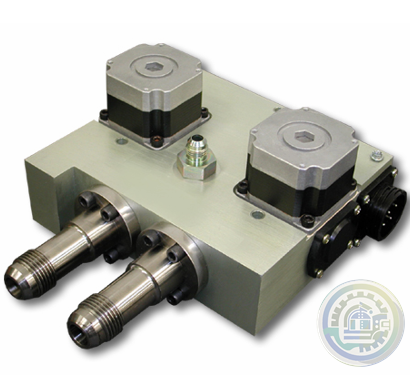

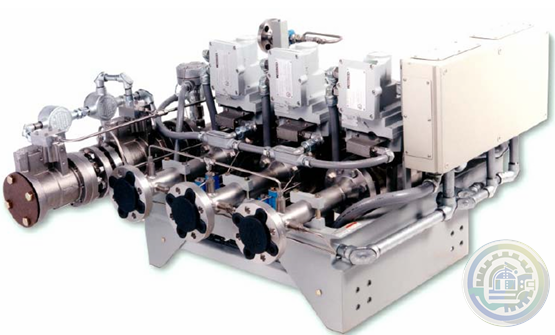

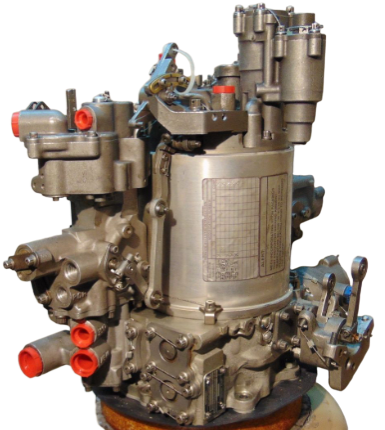

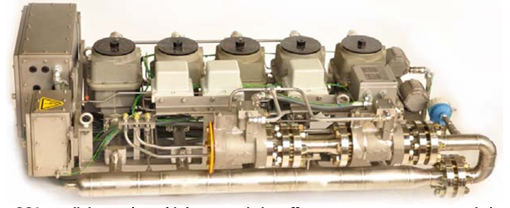

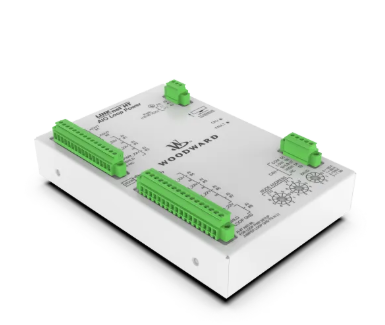

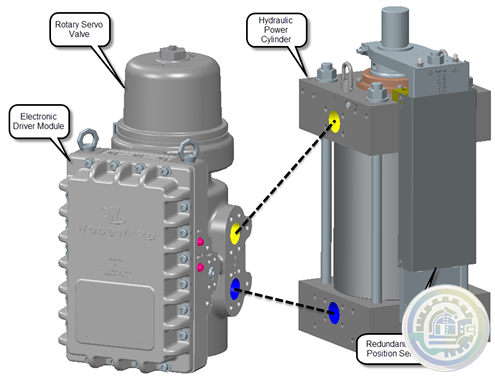

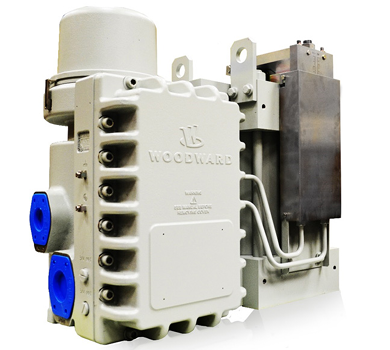

Woodward Oil Management

-

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

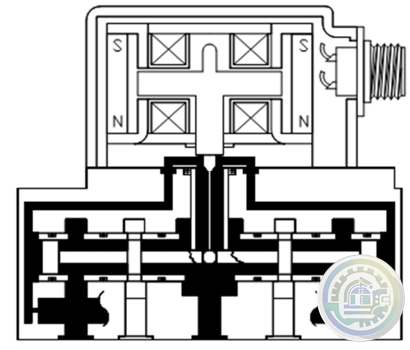

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

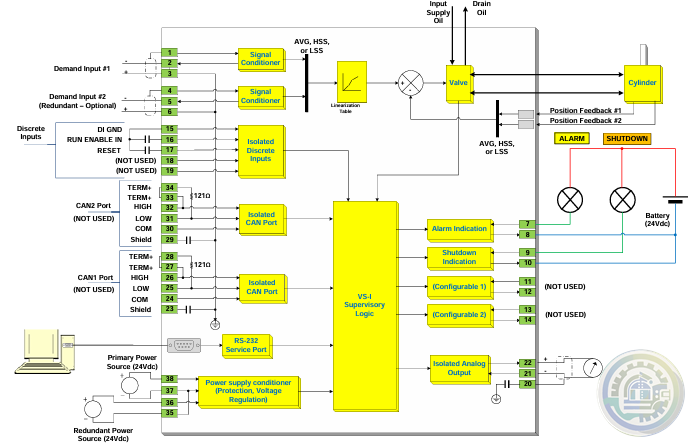

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

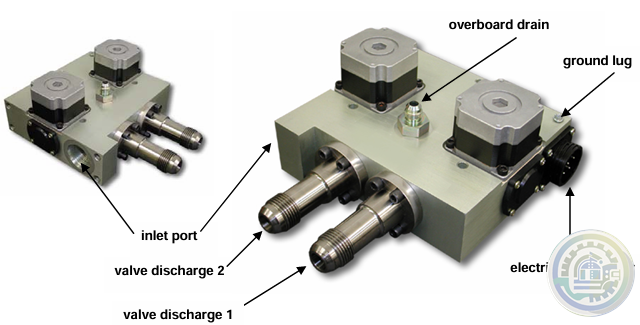

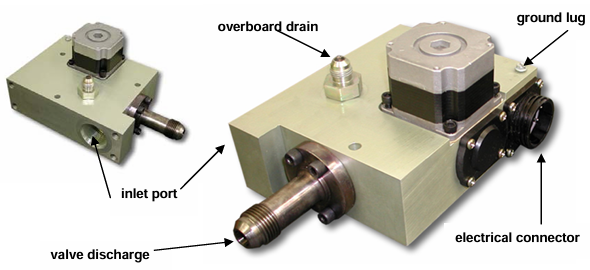

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

-

Woodward PG-07 Power Generation & Stationary Control System

-

Woodward PG‐PL Governor

-

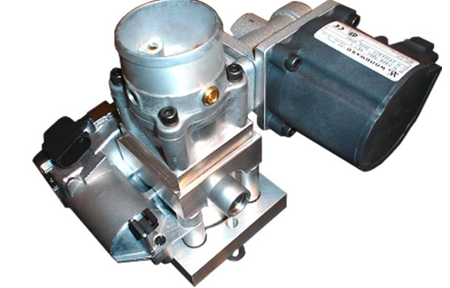

Woodward Air Management

-

Woodward Engine Actuation Systems

-

Woodward Fuel Injection and Ignition Systems

-

Woodward Fuel Control Systems

-

Woodward Smart Injector Technology Key Product Variants Include

-

Woodward P2X Features & Functionality

-

Woodward P2X Multi-Fuel Injectors

-

Woodward SOGAV Gas Valves

-

Woodward SOGAV Key Product Variants Include

-

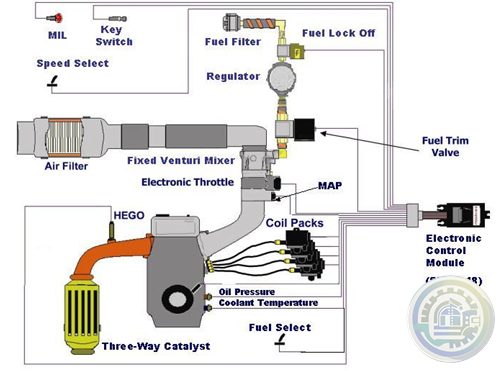

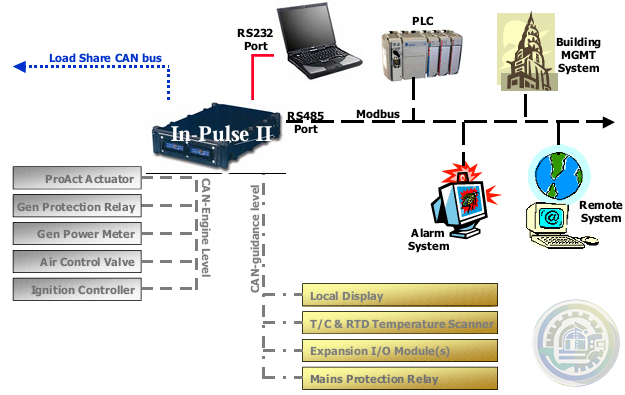

Woodward In-Pulse™ ll Self‐Diagnostics

-

Woodward In-Pulse ll Fuel Injection Control

-

Woodward Dual-Fuel Injectors

-

Woodward High-Pressure Pumps

-

Woodward offers a growing line of air valves

-

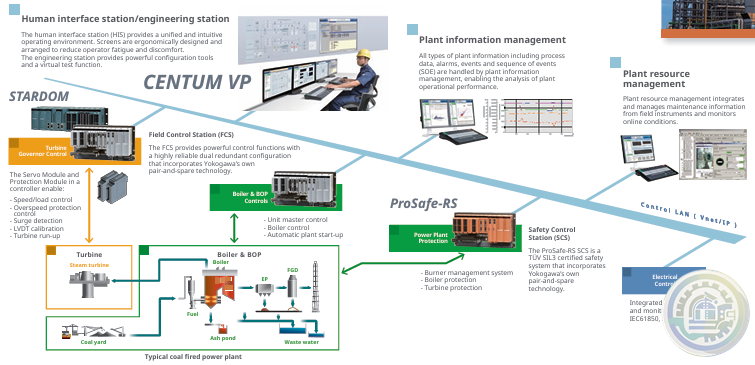

YOKOGAWA Turbine Control Solutions

-

Emerson Turbine Control

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

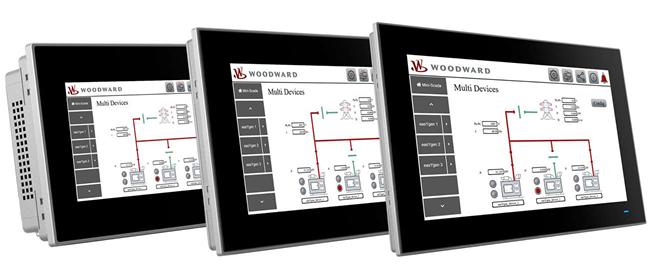

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

S-Series Servo Motor Power and Brake Wiring and Grounding

Motor power and brake cables as shown in Table 3-13 are available from GE Fanuc for the S2K

Series Servo Controllers. Cables for S-Series motors with brakes include two 18 AWG leads for

connection of a 24Vdc brake power supply (see section 2.1.9, Servo Motor Specifications, for brake

power requirements) and brake control logic. The brakes are of a fail-safe design, engaged by internal

springs and disengaged by the application of 24 Vdc power.

The motor cable must have a motor ground wire that connects one of the frame ground terminals on

the controller to the frame ground pin on the motor connector. Tables to 3-13 show the proper wire

size and Figure 3-25 shows the motor connector pin-out for each S-Series motor model. For noise

sensitive applications, a shielded motor power cable may be necessary.

Note

A shielded motor power cable is required in CE marked systems. When used, the

power cable shield should connect to the frame ground stud on the bottom of the

controller and to the connector at the motor end. GE Fanuc’s standard motor power

cables do not include a shield.

On the 30–750 Watt S-Series motors, the power connectors shown in the following figure are wired

to the motors with short leads and include a separate connector (and require a separate brake cable)

when the optional holding brake is included. On the 1.0–5.0 kW motors, the MS-style connectors

shown are mounted directly on the motor’s frame and the brake connections are included in the same

connector and cable.

FAULT CONDITIONS — In the event of a shortedload, shorted winding, or stalled motor, the load current will attempt to increase.

As described above, the drive current to the output stage is diverted (limiting the load current to about1 A), causing the output stage to go linear. As the junction

temperature of the output stage increases, the thermal limit circuit will become operational, further decreasing the drivecurrent.

The load current (junction temperature) is then a function of ambient temperature, state of remaining drivers,supply voltage, and load resistance.

If the fault condition is corrected, the output driver will return to its normal saturated condition.

Short circuit protection is provided for each output for supply voltages up to 25 V.

Any program can start and stop any other program, and all programs can utilize common motion blocks.

Engineering time is reduced and integration is simplified due to configuration and programming wizards for the controller software.

We have the same series of models in stock.

If you don't find the model you need, please contact us and we will provide you with an official quotation!

GE IC800VMCB2030 Motion Control Cables |

GE IC800VMCB2050 Motion Control Cables |

GE IC800VMCB2100 Motion Control Cables |

GE IC800VMCB2200 Motion Control Cables |

GE IC800VMCB3030 Motion Control Cables |

GE IC800VMCB3050 Motion Control Cables |

GE IC800VMCB3100 Motion Control Cables |

GE IC800VMCB3200 Motion Control Cables |

GE IC800VMCE006A Motion Control Cables |

GE IC800VMCE050 Motion Control Cables |

GE IC800VMCE100 Motion Control Cables |

GE IC800VMCE1030 Motion Control Cables |

GE IC800VMCE1050 Motion Control Cables |

GE IC800VMCE1100 Motion Control Cables |

GE IC800VMCE1200 Motion Control Cables |

GE IC800VMCE200 Motion Control Cables |

GE IC800VMCI010 Motion Control Cables |

GE IC800VMCI030 Motion Control Cables |

GE IC800VMCP030 Motion Control Cables |

GE IC800VMCP050 Motion Control Cables |

GE IC800VMCP100 Motion Control Cables |

GE IC800VMCP1030 Motion Control Cables |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved