-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

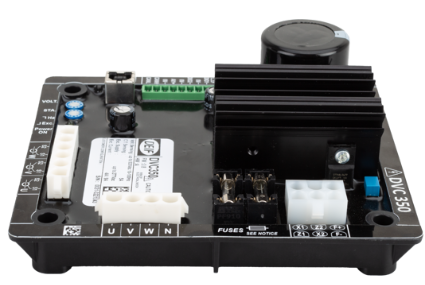

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

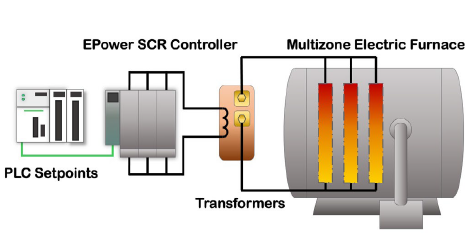

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

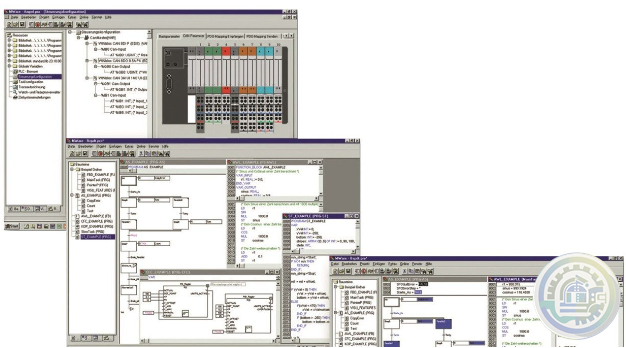

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

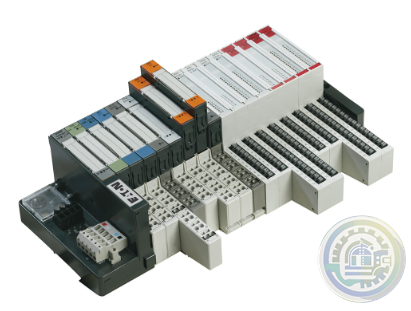

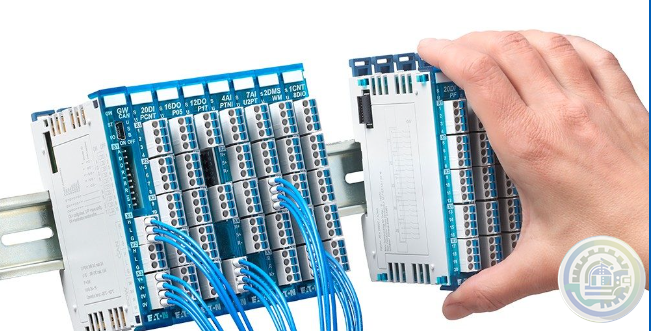

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

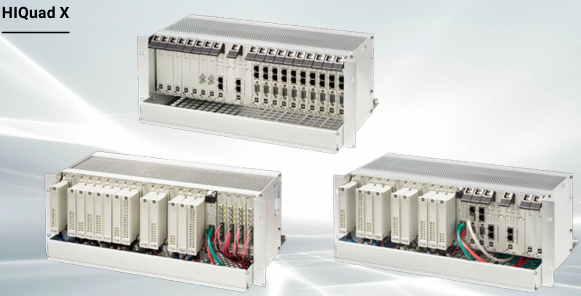

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

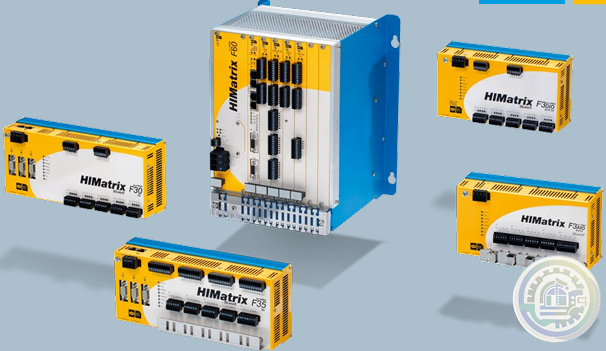

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

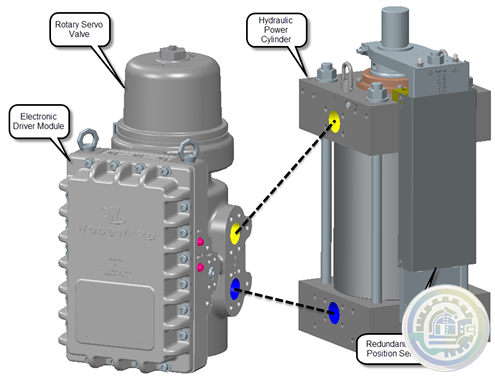

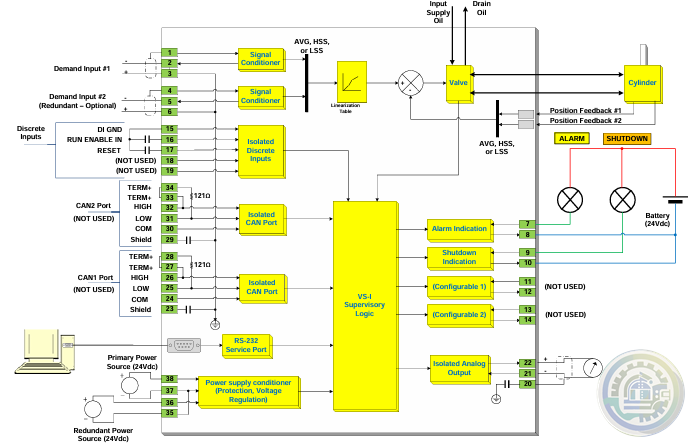

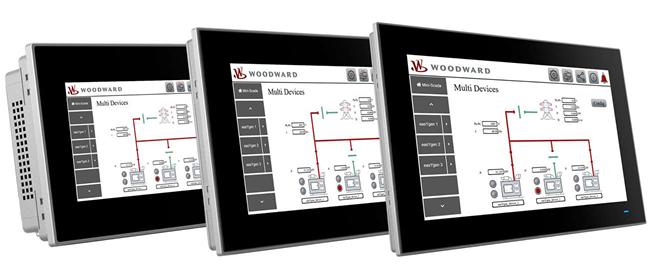

Woodward Oil Management

-

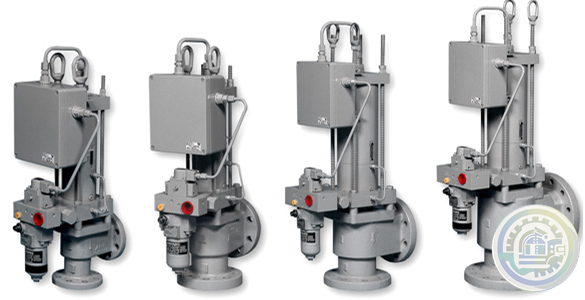

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

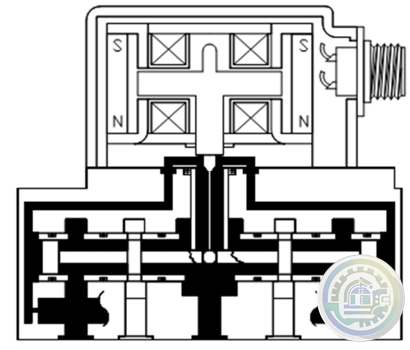

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

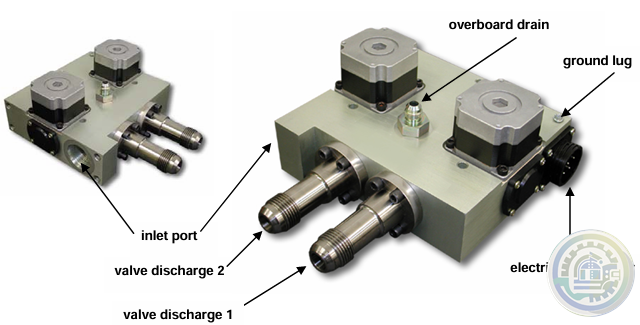

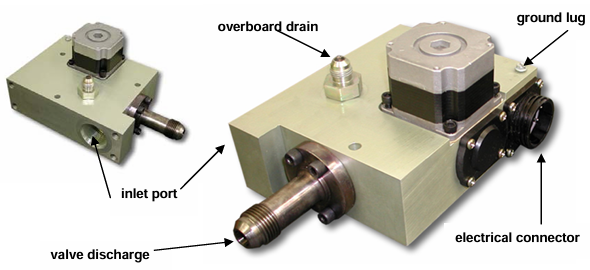

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

-

Woodward PG-07 Power Generation & Stationary Control System

-

Woodward PG‐PL Governor

-

Woodward Air Management

-

Woodward Engine Actuation Systems

-

Woodward Fuel Injection and Ignition Systems

-

Woodward Fuel Control Systems

-

Woodward Smart Injector Technology Key Product Variants Include

-

Woodward P2X Features & Functionality

-

Woodward P2X Multi-Fuel Injectors

-

Woodward SOGAV Gas Valves

-

Woodward SOGAV Key Product Variants Include

-

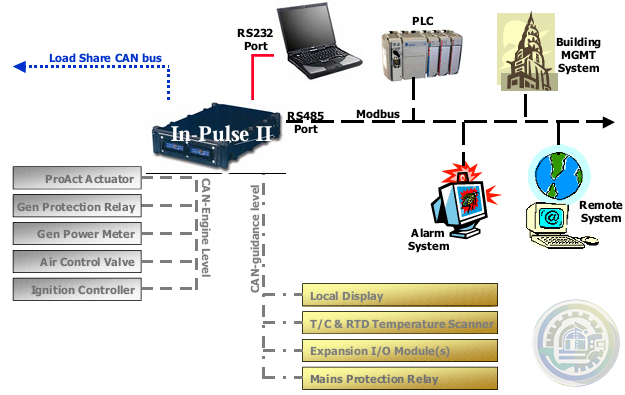

Woodward In-Pulse™ ll Self‐Diagnostics

-

Woodward In-Pulse ll Fuel Injection Control

-

Woodward Dual-Fuel Injectors

-

Woodward High-Pressure Pumps

-

Woodward offers a growing line of air valves

-

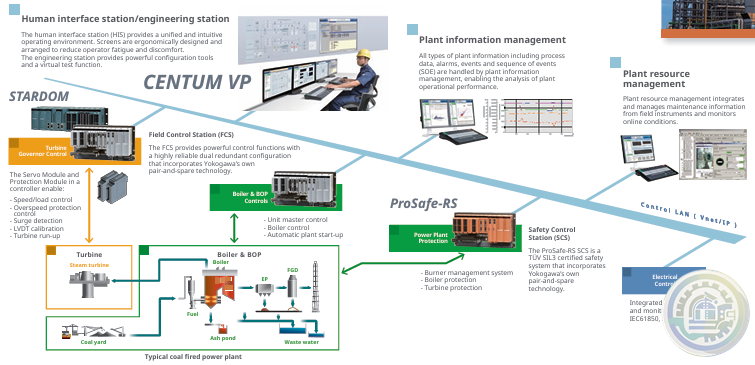

YOKOGAWA Turbine Control Solutions

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

The EL operating mechanism of the Advac circuit breakers (in all versions) is fitted with a mechanical anti-pumping

device which prevents re-closing due to either electrical or mechanical commands.

Should both the closing command and any one of the opening commands (local or remote) be active at the same time,

there would be a continuous succession of opening and closing operations.

The anti-pumping device avoids this situation, ensuring that each closing operation is only followed

by a single opening operation and that there is no closing operation after this.

To obtain a further closing operation, the closing command must be released and then re-launched.

Furthermore, the anti-pumping device only allows circuit-breaker closure if the following conditions

are present at the same time:

1. Closing spring fully charged

2. Opening mechanical pushbutton and/or opening release coils (-MO1/-MO2) are not active.

3. The circuit breaker is in the Open position.

Below is a side internal view of the EL mechanism and the associated anti-pumping component.

When the opening pushbutton or coils are activated the opening shaft lever pushes down on point C of the anti-pump device.

This causes the device to side down slot D in direction of arrow B.

Then the trigger portion A moves out from between the closing push-button and the closing shaft lever.

So if the closing button or signal is held active and the opening button or signal is then activated.

The trigger A will pull out from between closing shaft lever and the closing push button.

Once the open signal is released the trigger A will come to rest under the closing push-button and will

not return between the closing shaft lever and closing push-button until the button or closing command is released.

The closing push button is operated by the closing coil (MC) directly by the shaft closing device.

This allows the anti-pumping device to prohibit closing by manual or electrical means.

The SD (Symphony DIN) Series is a green portfolio of completely scalable control

and I/O products that work in any environment or geographic location,

Through seamless interconnections with smart field and electrical devices and higher level applications,

these rugged control and I/O products deliver lower energy consumption,

an extreme operating temperature range, and a scalable architecture in a compact, modular footprint,

making SD Series the best automation solution for your new installation, upgrade or expansion.

Powerful, scalable controller family for high-end (SPC800/HPC800), mid-range (SPC700)

and small (SPC600/SPC700) applications from discrete and continuous,

to batch and advanced control applications.

Simultaneous support for SD Series, HR Series and S800 I/O subsystems.

SD Series controllers communicate with S+ Operations, S+ Engineering and other higher level applications via a high-speed,

high-throughput, and high-security Fast Ethernet-based redundant plant network.

Environmental management

OT-switches are manufactured at the Finish plant,

which has been certified according to ISO 14001 since 1997

(the plant has been also certified according to the ISO 9001 quality management standard since 1993).

Life cycle assessment is applied continuously to all product development.

The HBR01-CJC the mounting base is for RAI04, Redundant, 16-CH, TC & mV analog input modules.

The base includes a built-in RTD that can be used for Cold Junction Compensation.

Two (2) 16-point headers on the base provide connections to either (2) pluggable

16-point terminal blocks for direct connection of field signal wires or to SPK0x_-yy marshaling

cables when field signal wires are landed on 3rd party termination hardware.

Features and benefits

Termination for up to sixteen (16) analog I/O process signals within a horizontal row.

All SD I/O modules & bases of all types (Singular or Redundant) AND (Compact or Full-size), are 100% fully compatible with each other.

Thus, Singular & Redundant, Compact or Full-size I/O modules can be mounted within a single, common HN800 I/O bus.

Optional mechanical keying can be implemented to prevent insertion of the wrong I/O module type.

Latching device on the base locks the base into position on DIN-Rail.

Industry standard 35-mm DIN rail, Horizontal row mounting.

You may need the following additional products:

ABB DO02 DO module 16-CH 24 / 48 VDC OC Prot. |

ABB DO02A DO module 16-CH 24 / 48 VDC OC Prot. |

ABB DRMP-19 DIN-Rail Mtg Panel 19 inch Generic HW |

ABB DRMP-19SD DIN-Rail Mtg Panel 19 inch SD Series |

ABB HAI805 Analog Input Module 8-CH HART |

ABB HAI805A Analog Input Module 8-CH HART |

ABB HAO805 Analog Output Module 8-CH HART |

ABB HAO805A Analog Output Module 8-CH HART |

ABB HBS01-CJC Horiz. Base Single Cold Junction Comp. |

ABB HBS01-CJCA Horiz. Base Single Cold Junction Comp. |

ABB HBS01-EPD Horiz. Base Single Ext. Pwr Inputs |

ABB HBS01-EPDA Horiz. Base Single Ext. Pwr Inputs |

ABB HBS01-FPH Horiz. Base Single Field Pwr Hot |

ABB HBS01-FPHA Horiz. Base Single Field Pwr Hot |

ABB HBS01-FPN Horiz. Base Single Field Pwr Neutral |

ABB HBS01-FPNA Horiz. Base Single Field Pwr Neutral |

ABB HBX01K02 HN800 Bus Extender Kit Horizontal |

ABB HBX01K02A HN800 Bus Extender Kit Horizontal |

ABB HBX01L HN800 Bus Extender Horizontal Left |

ABB HBX01LA HN800 Bus Extender Horizontal Left |

ABB HBX01R HN800 Bus Extender Horizontal Right |

ABB HBX01RA HN800 Bus Extender Horizontal Right |

ABB ITU805 HART I/O Module Mounting Base |

ABB ITU805A HART I/O Module Mounting Base |

ABB PI01 Pulse/Frequency Input module 8-CH |

ABB PI01A Pulse/Frequency Input module 8-CH |

ABB SPK01B-02 I/O Cable Bottom Flying Leads 2.0 M |

ABB SPK01B-03 I/O Cable Bottom Flying Leads 3.0 M |

ABB SPK01B-04 I/O Cable Bottom Flying Leads 4.0 M |

ABB SPK01B-05 I/O Cable Bottom Flying Leads 5.0 M |

ABB SPK01B-06 I/O Cable Bottom Flying Leads 6.0 M |

ABB SPK01B-10 I/O Cable Bottom Flying Leads 10.0 M |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved