-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

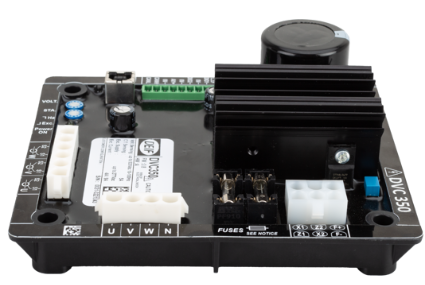

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

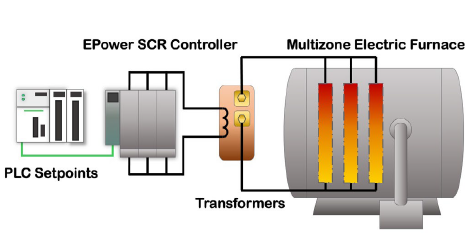

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

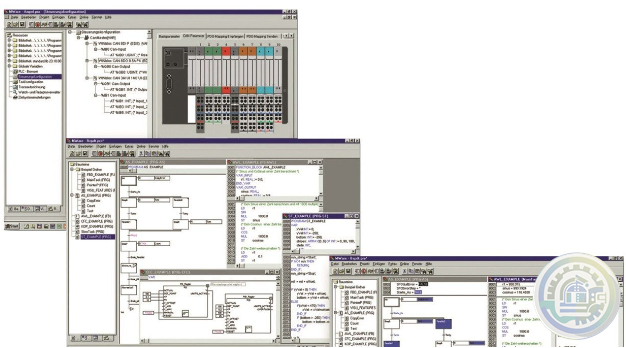

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

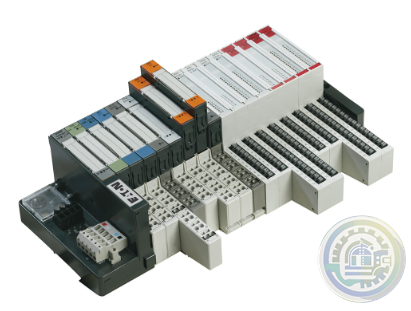

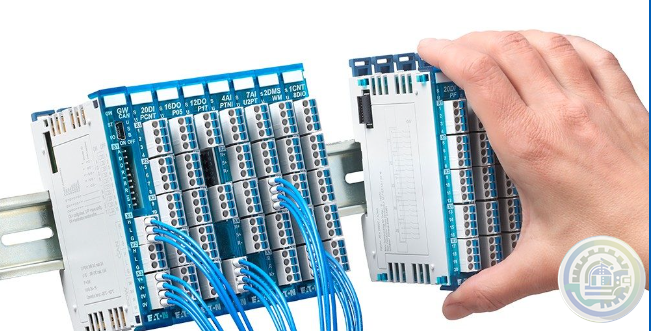

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

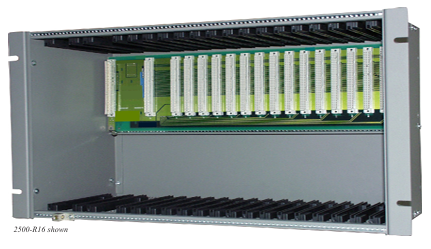

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

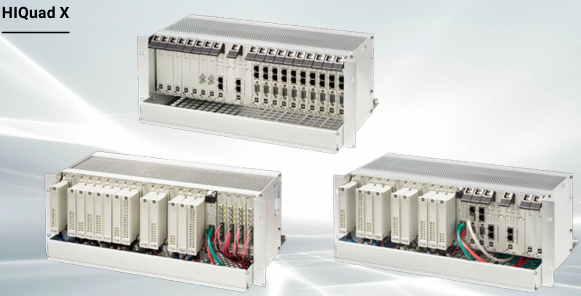

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

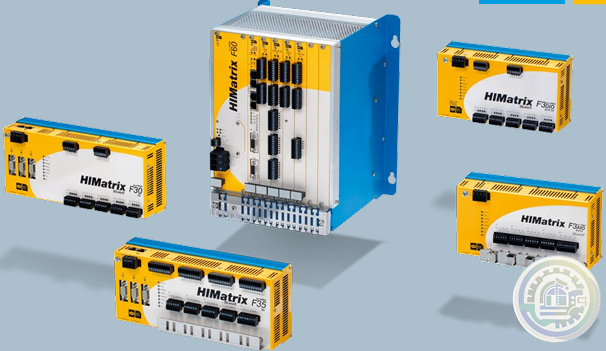

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

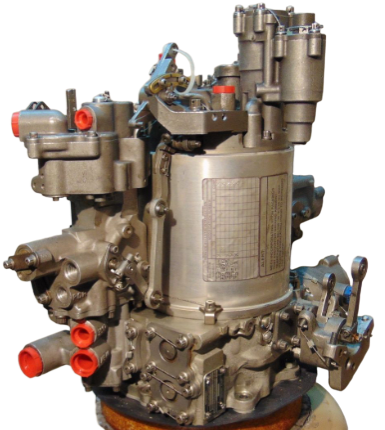

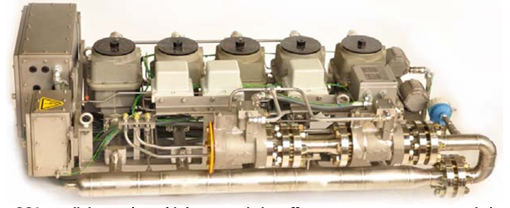

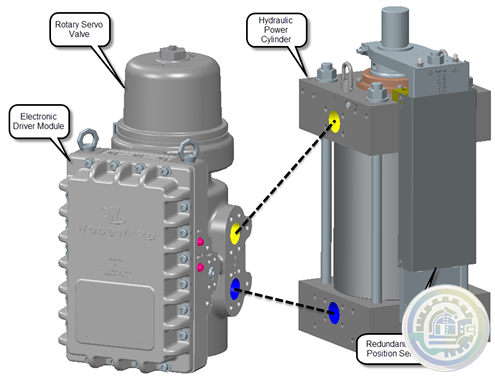

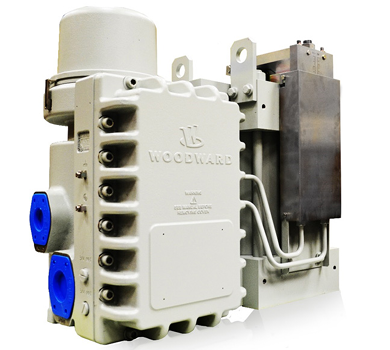

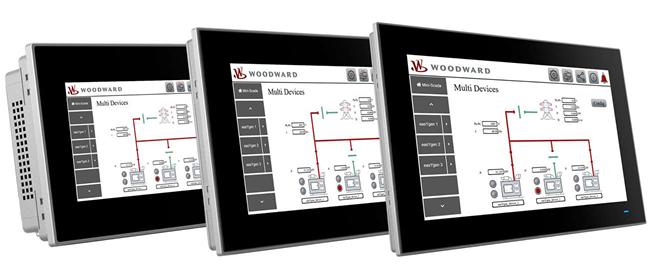

Woodward Oil Management

-

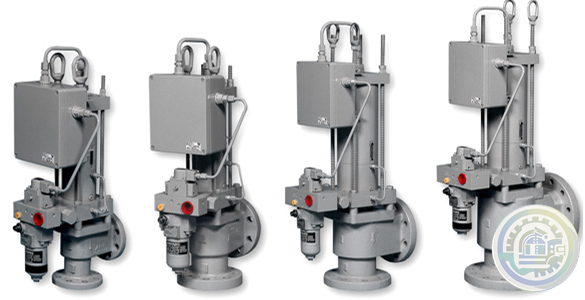

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

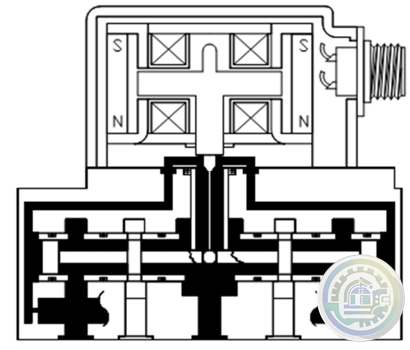

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

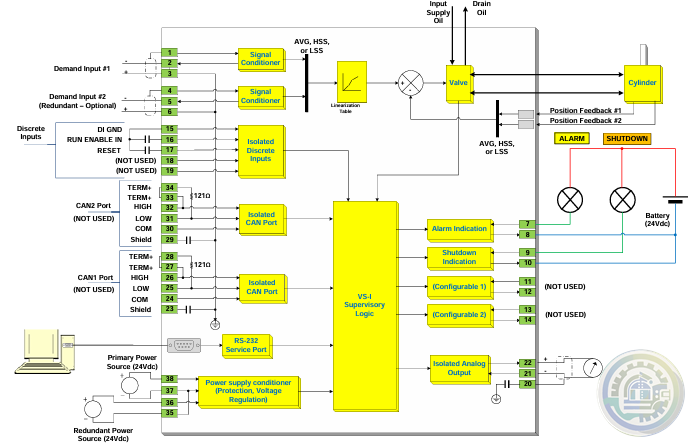

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

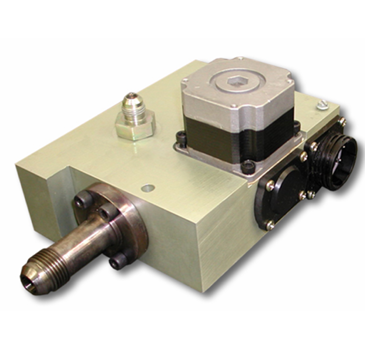

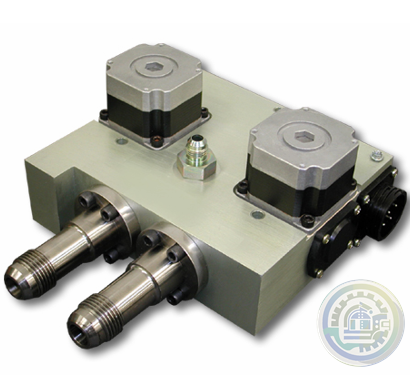

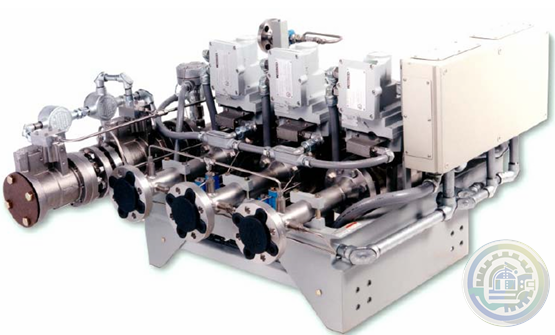

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

-

Woodward PG-07 Power Generation & Stationary Control System

-

Woodward PG‐PL Governor

-

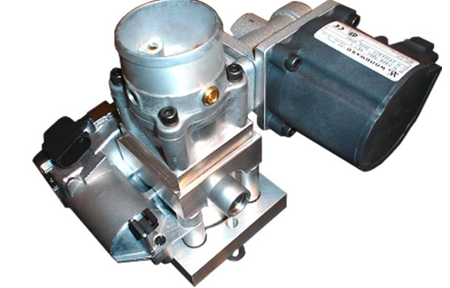

Woodward Air Management

-

Woodward Engine Actuation Systems

-

Woodward Fuel Injection and Ignition Systems

-

Woodward Fuel Control Systems

-

Woodward Smart Injector Technology Key Product Variants Include

-

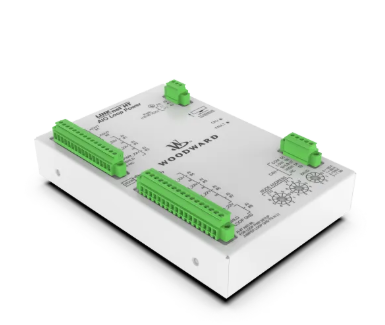

Woodward P2X Features & Functionality

-

Woodward P2X Multi-Fuel Injectors

-

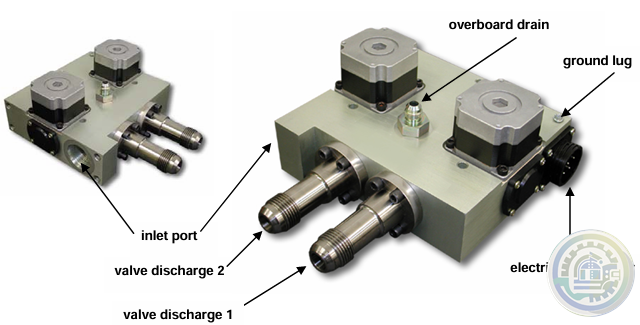

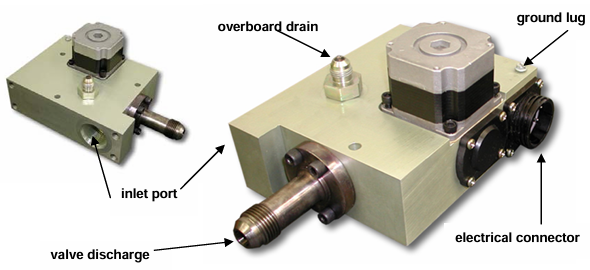

Woodward SOGAV Gas Valves

-

Woodward SOGAV Key Product Variants Include

-

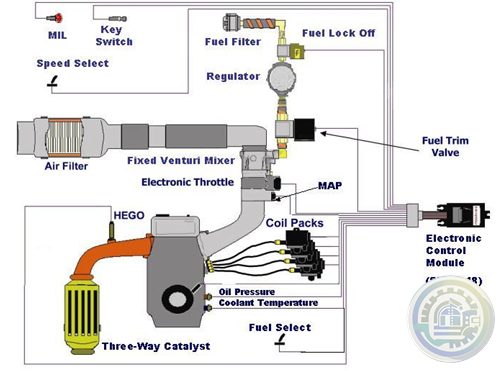

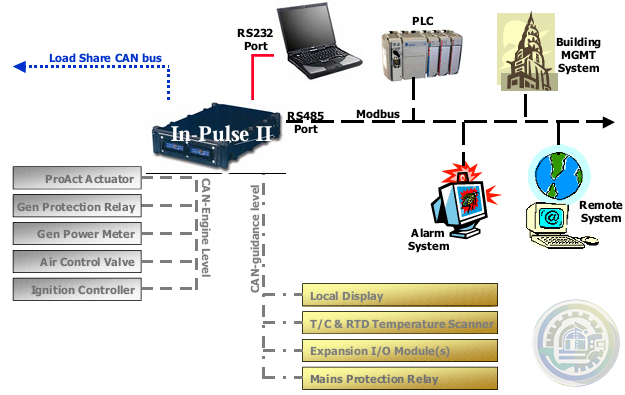

Woodward In-Pulse™ ll Self‐Diagnostics

-

Woodward In-Pulse ll Fuel Injection Control

-

Woodward Dual-Fuel Injectors

-

Woodward High-Pressure Pumps

-

Woodward offers a growing line of air valves

-

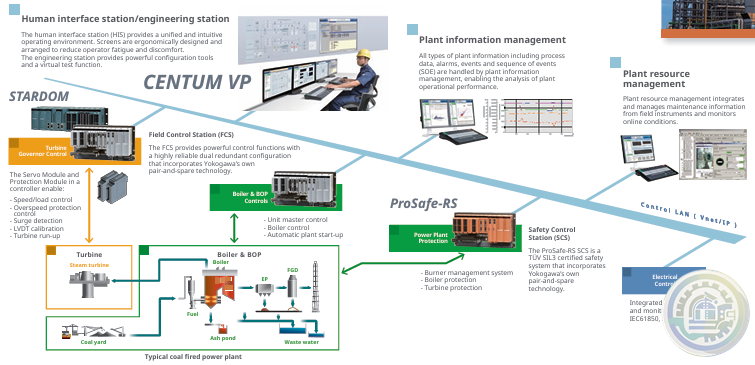

YOKOGAWA Turbine Control Solutions

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Monitor Module Footnotes

1. Only standard differential expansion capabilities provided. For ramp differential expansion and complementary

input differential expansion, use the 3500/45 Position Monitor, instead.

2. The 3500/42M provides individual 4 to 20 mA proportional outputs for each channel. The 3500/40M does NOT

provide 4 to 20 mA outputs.

3. The monitor channels are programmed in pairs and can perform up to two of these functions at a time. Channels

1 and 2 can perform one function, while channels 3 and 4 perform another (or the same) function.

4. Channels configured for velocity or acceleration provide only direct amplitude. Channels configured for Velocity

II or Acceleration II provide 1X amplitude/phase and 2X amplitude/phase and bias voltage in addition to direct amplitude.

5. Any vibration channel can be configured for conventional “pie-shaped” acceptance region alarms. When

configured for circular acceptance regions, circular (rather than pie-shaped) acceptance region alarms can be

enabled. Refer to the 3500/42M Operations/Maintenance Manual for additional information, or contact your nearest sales professional.

6. Only channels 3 and 4 can be used for Case Expansion measurements.

7. The 3500/46M provides frequency response characteristics suitable for use on machines with very slow

rotational speeds, such as hydraulic turbine/generator sets, which often operate at speeds of 100 RPM or lower.

Also, special signal conditioning and tracking filtering is provided, allowing detection of rough load zone

operation, shear pin failure, and other hydro-specific conditions.

8. The 3500/50M is not intended for use in overspeed protection applications. Use the 3701/55 Emergency

Shutdown (ESD) system, instead.

9. Both Zero Speed and Reverse Rotation channel types require both channels of the 3500/50 module, making it a

single-channel monitor when used in these configurations.

10. The 3500/60 and 3500/61 provide identical functions except the 3500/60 does not provide 4 to 20 mA

proportional outputs. When these outputs are required, use the 3500/61.

11. The 3500/62 is designed to accept static proportional signals such as 4 to 20 mA, 1 to 5 Vdc, or any static

proportional voltage signal between –10 and +10 Vdc. When dynamic signals (i.e., those where waveform

information is required) are used, a 3500/40M or 3500/42M can often be programmed as a custom channel type,

making the 3500 system compatible with virtually any static or dynamic signal from pressure, level,

temperature, vibration, flow, position, speed, or other transducers. Consult the factory or your local Bently

Nevada sales professional for more information.

12. The 3500/64M is primarily intended for monitoring combustor pressure pulsation instabilities (“humming”) in gas turbines.

Transient Data Interface (TDI)

The TDI is the 3500 Rack’s primary interface to the configuration, display, and condition monitoring

software. Each rack requires one TDI, located in the rack slot immediately adjacent to the power supply slot.

The TDI supports a proprietary protocol used by the 3500 Configuration Software to configure the rack and

the 3500 Operator Display Software to retrieve rack data and statuses.

The TDI also provides a direct interface with System 1* Condition Monitoring and Diagnostic software

without the need for an external communications processor.

The Rack OK relay is located within the TDI’s I/O module. It is driven by NOT OK conditions within the

TDI itself and within other modules in the rack.

the power supply’s front panel.

The TDI supports self-monitoring functions both for itself and for the rack, in addition to those provided by

the individual monitor, relay, communications, and other modules. While the TDI provides certain

functions common to the entire rack, it is not part of the critical monitoring path and its machinery

protection functions.

The TDI has four front-panel LEDs that provide the following indications:

Other advantageous products on sale are listed below:

| BENTLY 136711-01 I/O module with internal barrier and internal termination |

| BENTLY 136719-01 Barrier Grounding Module |

| BENTLY 146031-01 350022M chuck Transient data interface module |

| BENTLY 149992-01 Spare 16-channel relay output module |

| BENTLY 167699-02 190065A-01-01-01-00-00 Universal Device Monitor |

| BENTLY 1900 27 Vibration Monitors |

| BENTLY 1900 65A 167699-02 General Purpose Equipment Monitor |

| BENTLY 1900 65A-01-02-01-00-00 General Purpose Equipment Monitor |

| BENTLY 190055 190055-0Z-01-01-01 Fan Monitors |

| BENTLY 1900-65A General Purpose Equipment Monitor |

| BENTLY 190065A-00-02-01-01-01 General Purpose Equipment Monitor |

| BENTLY 1900-65A-01-00-01-00-00 General Purpose Device Monitor |

| BENTLY 1900-65A-01-00-01-00-00 General Purpose Device Monitor |

| BENTLY 190065A-01-01-01-00-00 General Purpose Equipment Monitor |

| BENTLY 230025-00 Vibration Monitor |

| BENTLY 3500 22M Transient Data Interface Module |

| BENTLY 3500 42M Four Channel Proximity Monitor |

| BENTLY 3500 53 133388-01 Electronic Speed Detection Module |

| BENTLY 3500_42M 176449-02 Proximity/Seismic Monitor |

| BENTLY 350005-01-02-00-00-00 14 Slot Chassis Rack |

| BENTLY 3500-05-01-02-00-00-01 System Racks |

| BENTLY 350005-01-03-00-00-00 Rack Modules |

| BENTLY 3500-05-02-04-00-00-00 DC Input Card Input Modules |

| BENTLY 3500-15 Mechanical Protection Systems AC Power Modules |

| BENTLY 350015 127610-01 AC Power Modules |

| BENTLY 350015 106M1079-01 Universal AC Power Modules |

| BENTLY 350015 106M1081-01 Universal AC Power Input Modules |

| BENTLY 3500-15 127610-01 AC/DC Power Supplies Relay Modules |

| BENTLY 350015 133292-01 Low Voltage DC Power Modules |

| BENTLY 350020 Rack Interface Modules |

| BENTLY 3500-20 125744-02 Standard Rack Interface Module |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved