-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

DEIF RMC-131D Current relay

-

DEIF MDR-2 Multi-differential relay

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

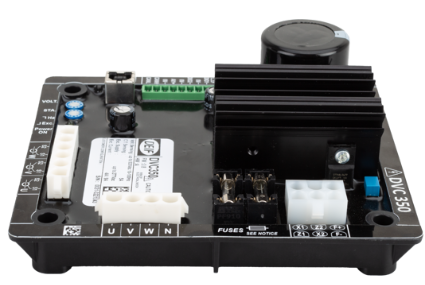

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

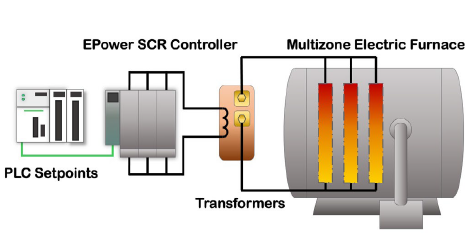

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

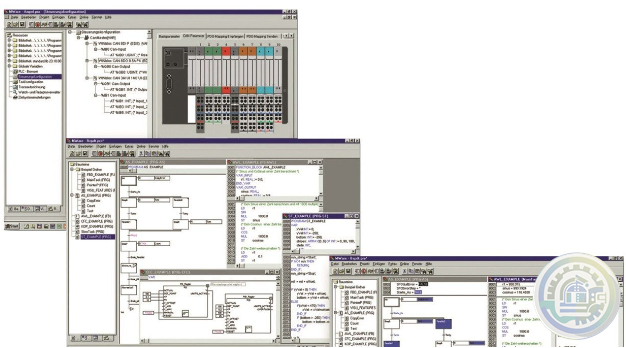

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

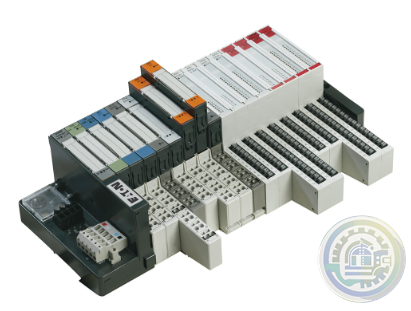

Eaton XI/ON I/O system

-

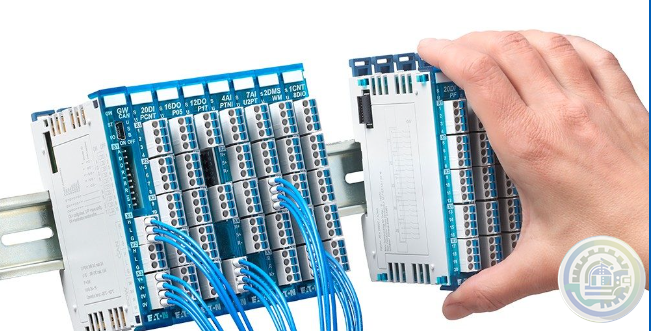

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

HIMA HIQuad Lifecycle & Modernization

-

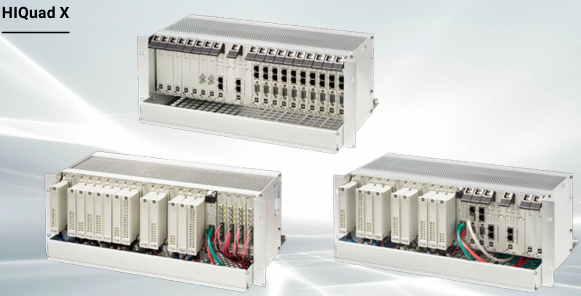

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

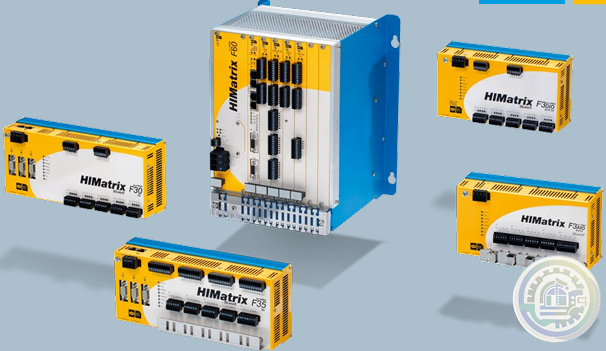

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

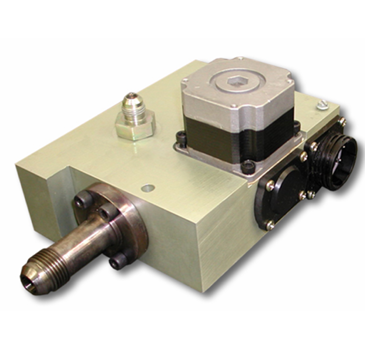

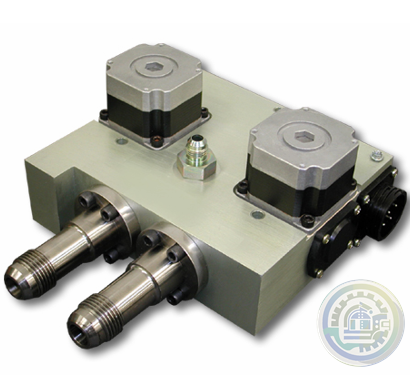

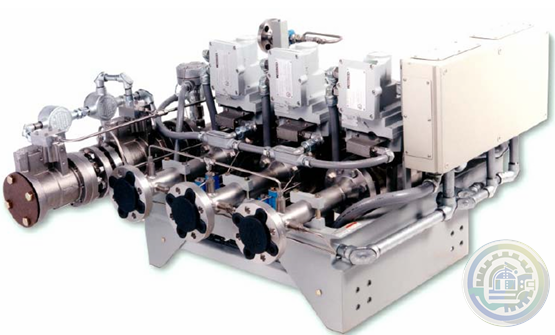

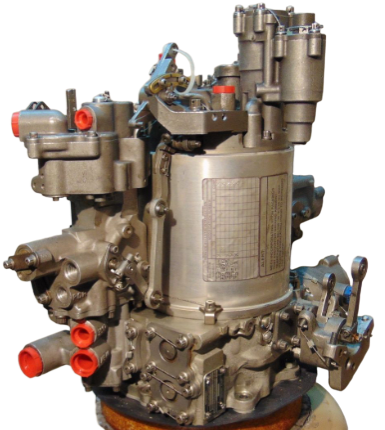

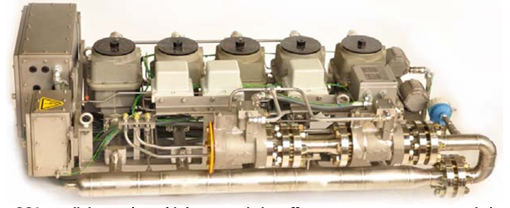

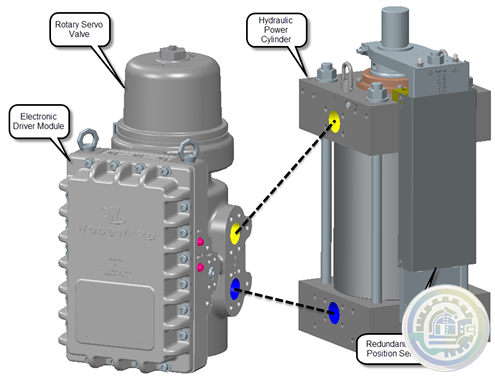

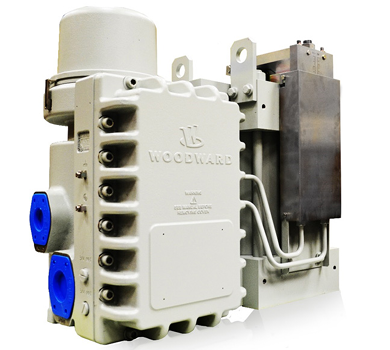

Woodward Oil Management

-

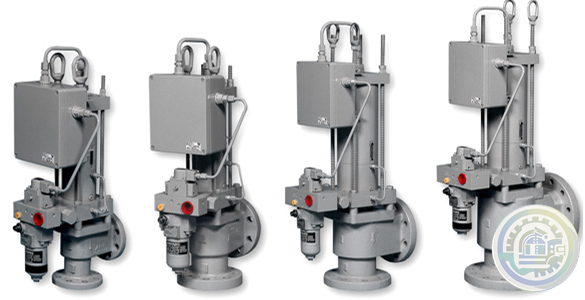

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

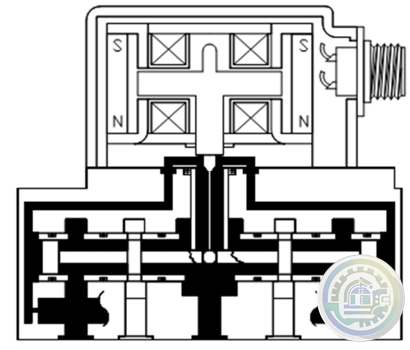

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

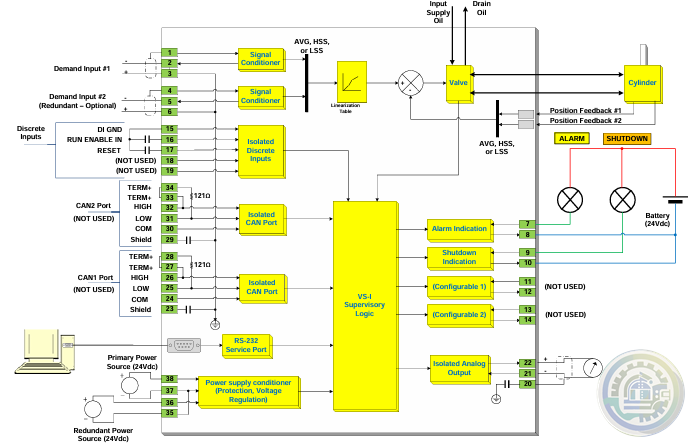

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

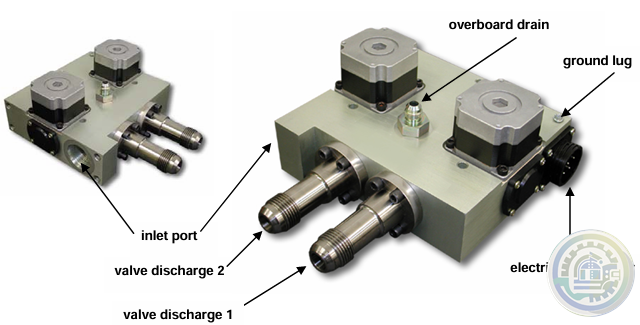

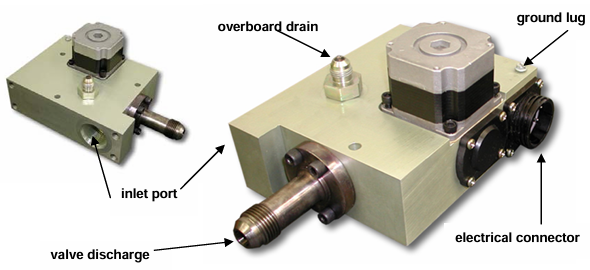

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

-

Woodward PG-07 Power Generation & Stationary Control System

-

Woodward PG‐PL Governor

-

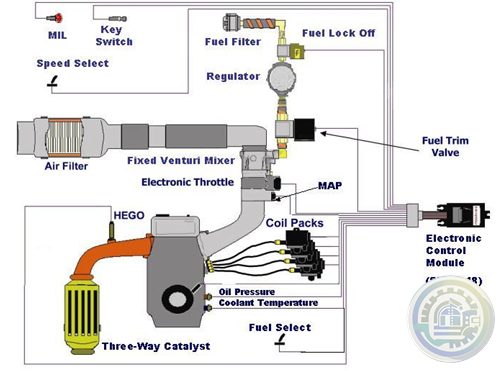

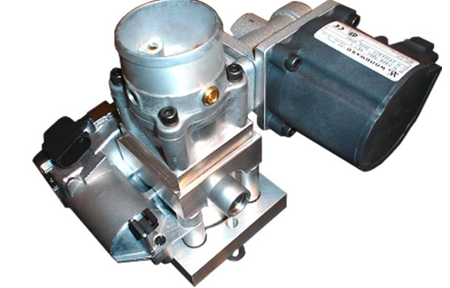

Woodward Air Management

-

Woodward Engine Actuation Systems

-

Woodward Fuel Injection and Ignition Systems

-

Woodward Fuel Control Systems

-

Woodward Smart Injector Technology Key Product Variants Include

-

Woodward P2X Features & Functionality

-

Woodward P2X Multi-Fuel Injectors

-

Woodward SOGAV Gas Valves

-

Woodward SOGAV Key Product Variants Include

-

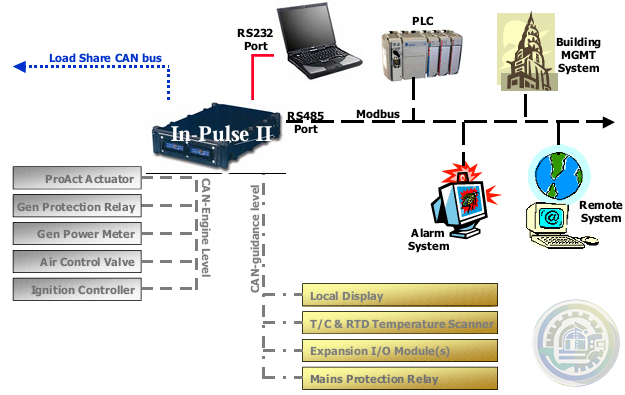

Woodward In-Pulse™ ll Self‐Diagnostics

-

Woodward In-Pulse ll Fuel Injection Control

-

Woodward Dual-Fuel Injectors

-

Woodward High-Pressure Pumps

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

ENSURING OPERATIONAL CONTINUITY AND MANAGING OPERATIONAL RISKS

Invensys is the only automation company with the experience and

track record in safety and critical control as demonstrated by our 27

years of experience in safety systems,in excess of 8.000 installed systems,

the only approved Nuclear Regulatory Commission Commercial off-the-shelf controller

for Nuclear 1E applications,large number of TÜV certified Functional Safety Experts and Engineers,

deployed world wide, and patented Triple Modular Redundant (TMR) technology.

A powerful, scalable design with assurance

of continuous operation, the Tricon system complies with international safety

standards such as IEC61508 and fulfils the requirements for applications such as

Emergency Shutdown (ESD), Fire and Gas Protection (F&G), Burner Management

(BMS), High Integrity Pressure Protection (HIPPS) and Turbomachinery Control

(TMC). The redundant high availability architecture provides a flexible, robust,

reliable and powerful solution that is ideal for clients looking to achieve

environmental and safety excellence.

The Tricon system is a must for clients who need to maximize the safety and

performance of their assets. If you are challenged with reducing investment and

lifecycle costs, meeting new safety standards, combating tough competitive

pressure in your markets as well as the welfare of your employees and the

environment, then the Tricon system is designed for you.

Managing operational risks with confidence

The Tricon fail-safe and fault-tolerant controller is used extensively in high-hazard industries

where safe operations are critical and reliable operation is paramount.

In particular, the Tricon system is the only commercial off-the-shelf controller approved by

the Nuclear Regulatory Commission for Nuclear 1E applications.

Our safety and critical control solutions are supported by a dedicated team of TÜV-certified FunctionalSafety Experts and Engineers,

deplo yed globally, ensuring that expertise is always available where and when required.

A powerful, scalable design with assurance of continuous operation,

the Tricon system complies with international standards such as IEC61508 and fulfills

the requirements for applications such as Emergency Shutdown (ESD), Fire and Gas Protection (F&G),

Burner Management (BMS),High Integrity Pressure Protection (HIPPS), and Turbo Machinery Control (TMC).

The redundant high-availability architecture provides a flexible,robust, reliable,

and powerful solution that is ideal for clients looking to achieve environmental and safety excellence.

Tricon Key capabilities

• TÜV-certified for SIL3 applications to international standard IEC61508

• High-availability architecture for continuous operation

• Fault-tolerant architecture for continuous operation even under fault conditions

• Choice of form factors

• Online module replacement ensures continuous operation and plant availability

• Online upgrade without process interruption

• Direct Integration with Foxboro®Evo process automation system

• Easily integrated with all major distributed control systems

• ISA Secure EDSA Level 1 right out of the box

• Works in both centralized and distributed applications

• HART protocol pass through to Asset Management Systems

• Fast program cycle time from 10 mS

• 1 mS SOE Digital Input

• Choice of termination options — Direct and ETP

• Expertise available from our TÜV-certified Functional Safety Experts and Engineers

• Continually current technology

• Comprehensive family of I/O modules

TRICONEX TRIPLE MODULAR REDUNDANCY

Tricon operation is based on the principle of safety and high plant availability, which identifies and

compensates for failed control system elements and allows on line replacement while continuing

its assigned task without interrupting the controlled process. Fault Tolerance is achieved through TMR technology.

TMR employs three isolated, parallel control systems and extensive diagnostics integrated into one

system. The Tricon system uses two-out-of-three (2oo3) voting to provide high integrity, error-free,

uninterrupted process operation with no single point of failure. Setting up applications is simplified

with the Tricon, because the TMR system operates as a single control system from the user’s point of

view. The extensive diagnostics are inherent and transparent to the programmer.

Use of the Tricon continues to expand into new industries and applications as customers require

increased system safety and/or high availability. Today, Invensys has delivered and installed Triconex

safety system solutions in over 70 countries, providing increased safety and high process uptime.

Related Items we have in stock

Triconex | 3604E 24VdcDigitalOutput |

Triconex | 3607E 48VdcDigitalOutput |

Triconex | 3611E 115VacDigitalOutput |

Triconex | 3617E 48VdcSupervisedDigitalOutput |

Triconex | 3623E/T 120VdcDigitalOutput |

Triconex | 3624 24VdcSupervisedDigitalOutput |

Triconex | 3625 24VdcDigitalOutput |

Triconex | 3664 24VdcDigitalOutput(Dual) |

Triconex | 3626X 24VdcSupervisedDigitalOutput |

Triconex | 3674 24VdcDigitalOutput(Dual) |

Triconex | 3636R/T RelayOutput |

Triconex | 3701 0-10VdcAnalogInput |

Triconex | 3722X 0-5VdcAnalogInput |

Triconex | 3723X 0-5VdcAnalogInput+Hart |

Triconex | 3703E 0-5,0-10VdcAnalogInput |

Triconex | 3704E 0-5,0-10Vdc(HD)AnalogInput |

Triconex | 3706A ThermocoupleAnalogInput |

Triconex | 3708E ThermocoupleAnalogInput |

Triconex | 3720 0-5VdcAnalogInput |

Triconex | 3721 0to5or–5to+5VdcAnalogInput |

Triconex | 3805E/H 4-20mAAnalogOutput |

Triconex | 3806E 4-20mAand20-320mAAnalogOutput |

Triconex | 3807 -60to+60mABipolarAnalogOutput |

Triconex | 3825X 0-20mAAnalogOutput |

Triconex | 3901X 24VdcSupervisedUniversalI/O |

Triconex | 4355XT CMModule |

Triconex | 4610XU CMModule |

Triconex | 4351BT CMModule(Copper) |

Triconex | 4352BT CMModule(Fiber) |

Triconex | 4610U CMModule |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved