-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

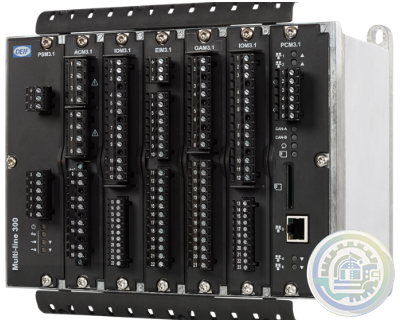

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

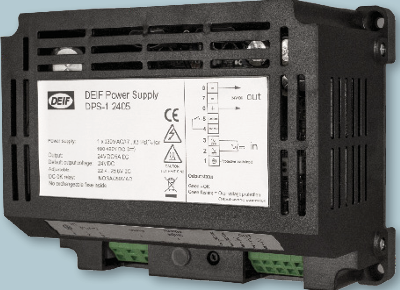

DEIF DC Power Supply, DPS-1

-

DEIF MVR-F215 Directional Feeder Protection

-

DEIF MVR-F215 Product description

-

DEIF MVR-F210 feeder protection relay Protection Functions

-

DEIF MVR-F210 Feeder Protection

-

DEIF PPM 300 Shaft generator controller

-

DEIF MVR-F205 Directional Feeder Protection

-

DEIF Protection & power management PPM 300 Features

-

DEIF PPM 300 Protection & power management

-

DEIF The series of switch mode power supplies

-

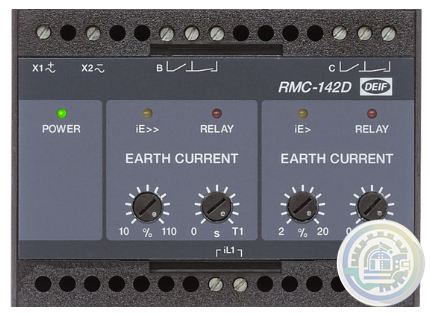

DEIF The RMC-142D is CE-marked and is applied for protection of voltage sources

-

DEIF RMC-142D Current relay

-

DEIF The GPU-3 Hydro is well-suited for PLC-controlled systems

-

DEIF GPU-3 hydro Generator protection unit

-

DEIF MVR-200 series Medium Voltage Relay

-

DEIF RMC-131D Current relay

-

DEIF MDR-2 Multi-differential relay

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

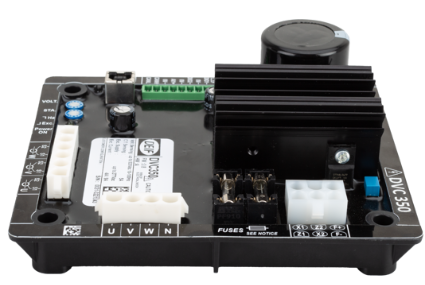

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

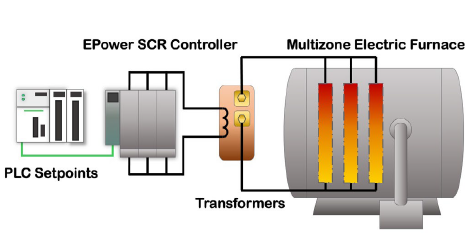

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

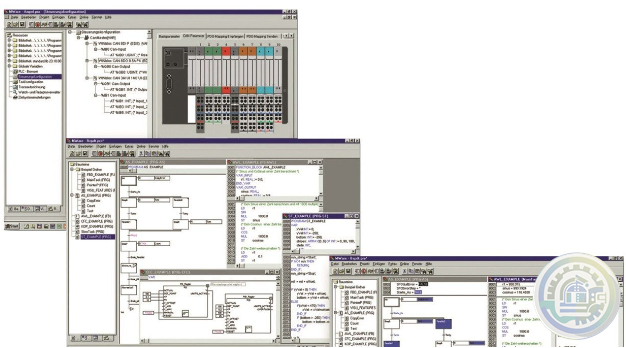

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

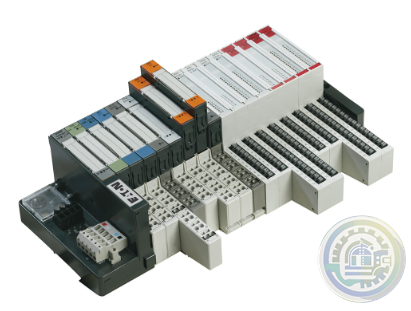

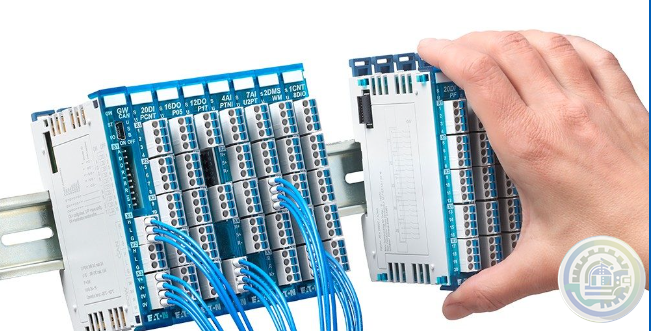

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

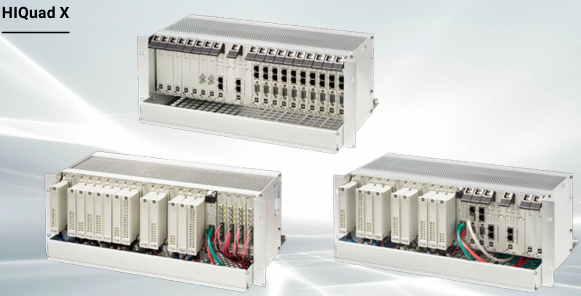

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

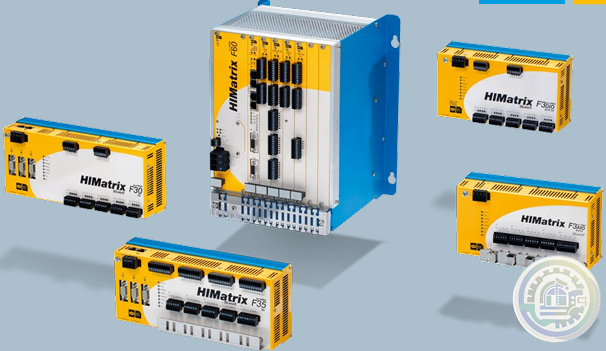

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

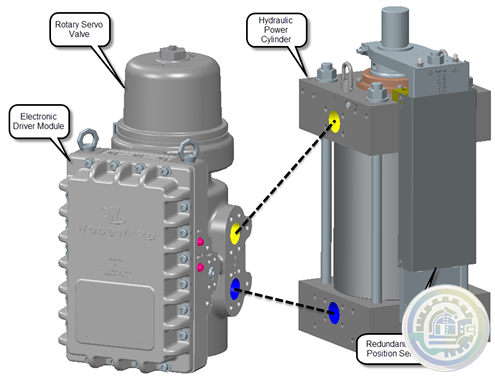

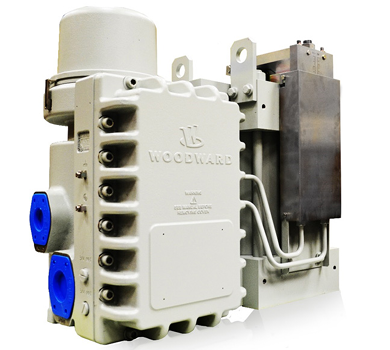

Woodward Oil Management

-

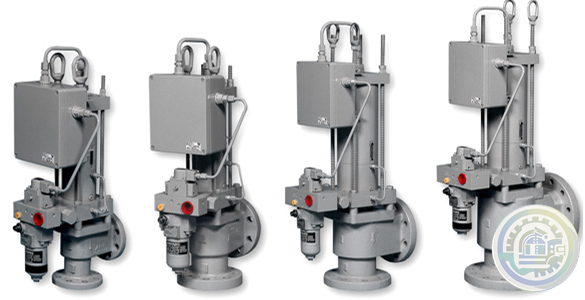

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Features

All Series C components feature an innovative design that supports enhanced heat management.

This unique look provides a significant reduction in overall size for the equivalent function.

The unique features of Series C I/O include:

• I/O Module and field terminations are combined in the same area. The I/O Module is plugged

into the IOTA to eliminate the need for a separate chassis to hold the electronics assemblies.

• Two level “detachable” terminals for landing the field wiring in the enclosure, providing easier

plant installation and maintenance.

• Field power is supplied through the IOTA, with no need for extra power supplies and the

associated craft wired marshalling.

• Redundancy is available directly on the IOTA without any external cabling or redundancy control

devices, by simply adding a second IOM to an IOTA.

• The Series C innovative styling is one of its unique features. This styling includes features to

facilitate the effective use of control hardware in a systems environment. These features include:

• Vertical mounting for more effective wiring since most field wiring applications require entry from the top or bottom of

the systems cabinet.

• An “information circle” for a quick visual cue to draw the Maintenance Technician’s eye to important status

information.

• “Tilted” design for effective heat management within the cabinet enclosure. Since Series C allows for a significant

increase in cabinet density, an effective heat management system is critical for high systems availability.

• Input and output circuits are protected from shorts to alleviate the need for in-line fusing, reducing installation and

maintenance costs.

Overview

Plants running the TotalPlant™ Solution (TPS) system need to avoid obsolescence by employing modern technology.

TPS, introduced in 1998, helped establish open plant automation with a host of advanced applications.

However, its users are now dealing with compliance issues related to new safety regulations as well as increasing system support challenges.

With Experion LCN, existing control strategy, field terminations, applications, history and graphics can be retained,

allowing users to focus on high value improvements.

It minimizes operating disruptions, maintains overall consistency and delivers optional lifecycle advantages with virtualization.

It also opens the door to Industrial Internet of Things (IIoT) by Honeywell, an approach that connects people to assets,

automates predictive analytics, and enables increased collaboration.

Analog Output with HART – CC-PAOH01

Function

The Analog Output (AO) Module delivers high-level constant current to actuators and recording/indicating devices.

Notable Features

• Extensive self-diagnostics

• Optional redundancy

• HART-capable, multivariable instruments

• Multiple moems for fast collection of control

How Does It Work?

Expanding on the Enhanced TPS Node capabilities, the Experion LCN further enables continuous innovation for Honeywell customers.

Using the proven Experion Fault Tolerant Ethernet (FTE) infrastructure, a new ELCN Bridge connects Experion to Classic Coax LCN.

Once this connection is established, the LCN coax connection can be removed one LCN node at a time.

Instead of a hardware connection for every Experion TPS Node, only one redundant ELCN Bridge pair is needed to enable virtualization.

Related Items we have in stock

Honeywell CC-PAOH01 Analog Output Module | Honeywell FC-SAI-1620M 4 Point Analog Input Module |

Honeywell CC-PAON01 Analog Output Module | Honeywell FC-SDI-1624 16 Point Input Module |

Honeywell CC-PAOX01 Analog Output Module | Honeywell FC-SDO-0824 8 Point Output Module |

Honeywell CC-PCF901 Control firewall module | Honeywell FC-TSAI-1620M 0-20ma Analog Module |

Honeywell CC-PCNT01 Processor Module | Honeywell FF-SB12E04K-S2 Grating Device Kits |

Honeywell CC-PCNT02 Processor Module | Honeywell FF-SB12R04K-S2 Grating Device Kits |

Honeywell CC-PDIL01 Digital Input Module | Honeywell K4LCN-16 Processor Upgrade Module |

Honeywell CC-PDOB01 Digital Output Module | Honeywell LCNP4E communication interface card |

Honeywell CC-PDOD51 Digital Output Module | Honeywell MC-PAIH03 TDC3000Analog Input Module |

Honeywell CC-PFB401 Fieldbus Interface Module | Honeywell MC-TAMR04 Interface Module |

Honeywell CC-TAID01 Analog Input Module | Honeywell SAI-1620M Analog Input Module |

Honeywell CC-TAIN01 Analog Input Module | Honeywell TC-CCR014 Compatible Communication Module |

Honeywell CC-TAIX01 Analog Input Module | Honeywell TC-FPCXX2 Compatible Power Module |

Honeywell CC-TAOX01 Analog Output Module | Honeywell TC-IAH161 Compatible Analog Input Module |

Honeywell FC-QPP-0002 Processor Module | Honeywell TC-OAV081 Compatible Analog Output Module |

Honeywell FC-SAI-1620M 4 Point Analog Input Module | Honeywell TC-ODK161 Compatible Digital Output Module |

Honeywell FC-SDI-1624 16 Point Input Module | Honeywell TC-PPD011 Compatible Redundancy Module |

Honeywell FC-SDO-0824 8 Point Output Module | Honeywell TC-PRR021 Compatible Redundancy Module |

Honeywell FC-TSAI-1620M 0-20ma Analog Module | Honeywell TC-PRS021 Compatible Redundancy Module |

Honeywell FF-SB12E04K-S2 Grating Device Kits | Honeywell TK-FPDXX2 Compatible Power Module |

Honeywell FF-SB12R04K-S2 Grating Device Kits | Honeywell TK-FTEB01 Compatible Redundancy Module |

Honeywell K4LCN-16 Processor Upgrade Module | Honeywell TK-IOLI01 Compatible Redundancy Module |

Honeywell LCNP4E communication interface card | Honeywell TK-PRR021 Compatible Redundancy Module |

Honeywell MC-PAIH03 TDC3000Analog Input Module | Honeywell TK-RPCXX1 Compatible Redundancy Module |

Honeywell MC-TAMR04 Interface Module | Honeywell 51404172-175 51404170-175 rackmount |

Honeywell SAI-1620M Analog Input Module | Honeywell TK-PRS021 Compatible Redundancy Module |

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved