-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

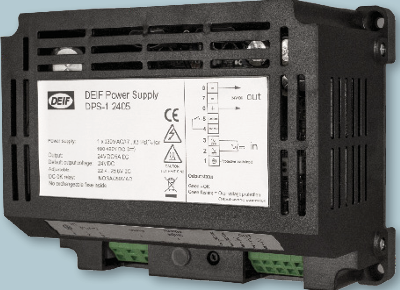

DEIF DC Power Supply, DPS-1

-

DEIF MVR-F215 Directional Feeder Protection

-

DEIF MVR-F215 Product description

-

DEIF MVR-F210 feeder protection relay Protection Functions

-

DEIF MVR-F210 Feeder Protection

-

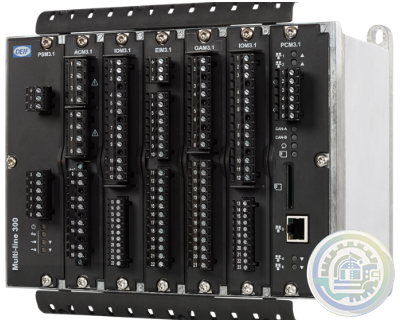

DEIF PPM 300 Shaft generator controller

-

DEIF MVR-F205 Directional Feeder Protection

-

DEIF Protection & power management PPM 300 Features

-

DEIF PPM 300 Protection & power management

-

DEIF The series of switch mode power supplies

-

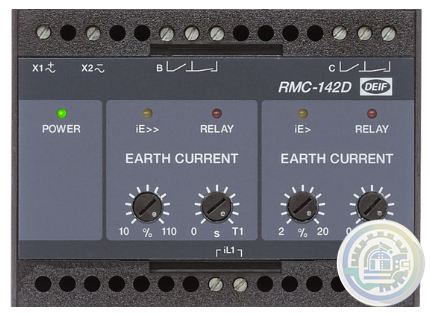

DEIF The RMC-142D is CE-marked and is applied for protection of voltage sources

-

DEIF RMC-142D Current relay

-

DEIF The GPU-3 Hydro is well-suited for PLC-controlled systems

-

DEIF GPU-3 hydro Generator protection unit

-

DEIF MVR-200 series Medium Voltage Relay

-

DEIF RMC-131D Current relay

-

DEIF MDR-2 Multi-differential relay

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

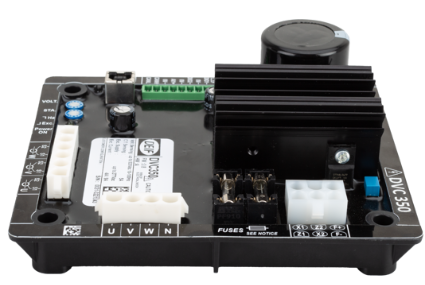

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

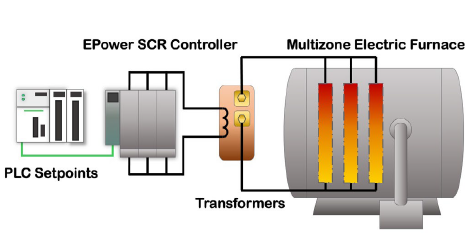

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

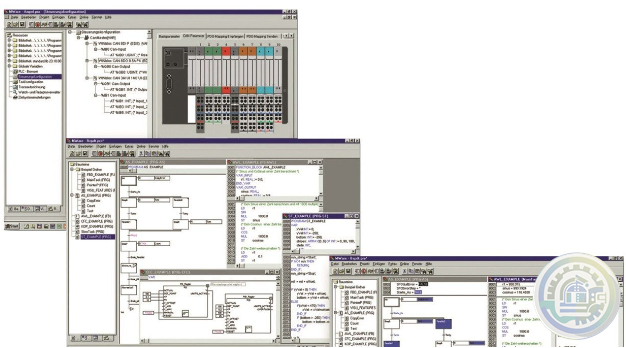

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

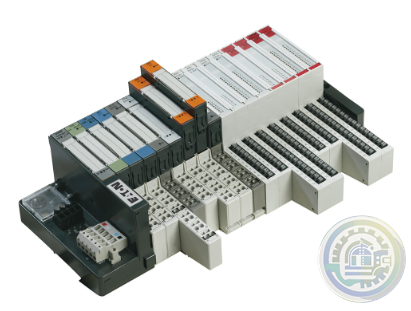

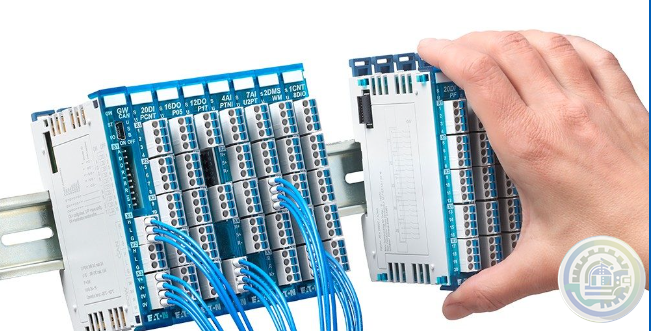

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

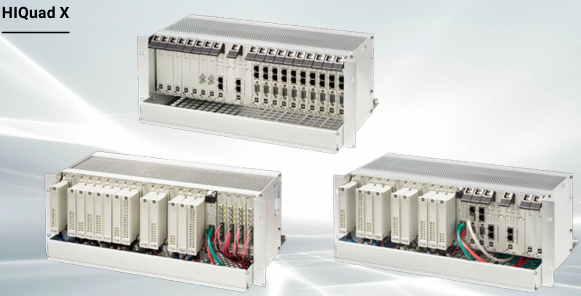

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

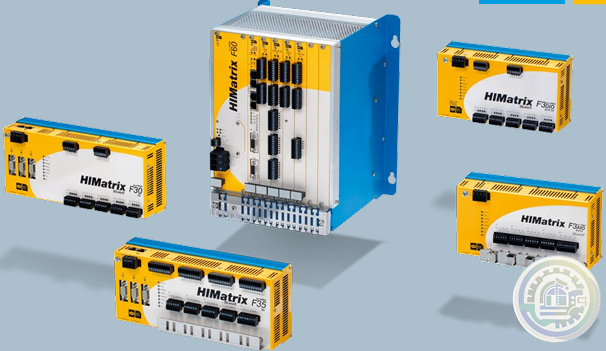

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

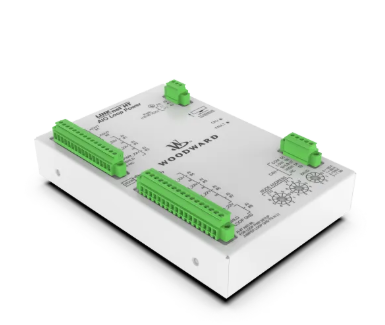

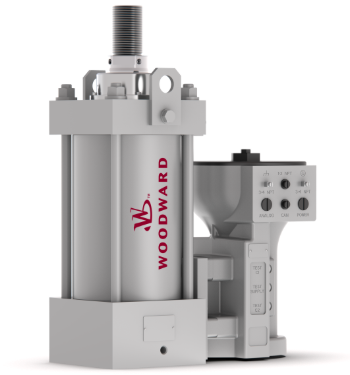

Woodward Oil Management

-

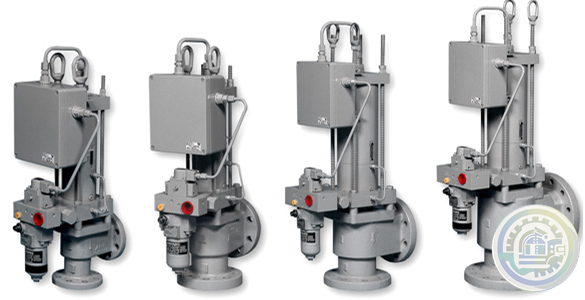

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

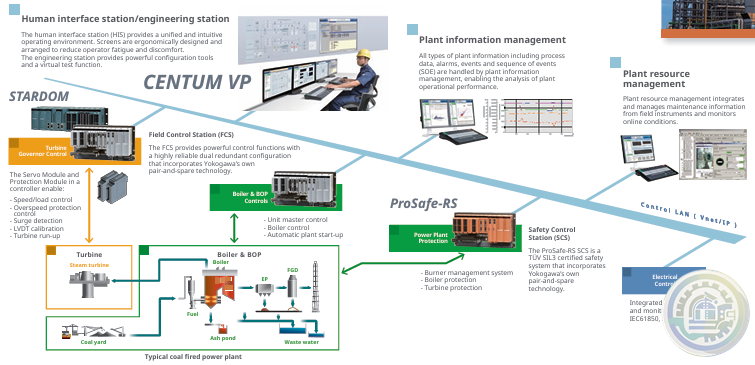

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

The DCS800 Panel Drive is a pre engineered solution for quick and easy design and installation.

All required peripheral components are included on a space-efficient back panel,

ready to be mounted into an industrial enclosure The drive is an excellent replacement for the Reliance Electric® FlexPak 3000®.

Highlights

• Space efficient multilevel panel

• Easy to maintain

• Pre-wired, pre-tested solution for smooth start ups

• Greatly simplifies the procurement process

• Module can be replaced without replacing the entire panel

• Integral ABB AC contactor

• UL Listed with 65 kA SCCR

The DCS800 Panel Drive is a preengineered solution for quick and easy design and installation.

All required peripheral components are included on a space-efficient back panel,

ready to be mounted into an industrial enclosure The drive is an excellent replacement for the Reliance Electric® FlexPak 3000®.

Voltage and Power Range

• 460 Vac, factory or field convertible to 230 Vac

• 10 to 500 HP with heavy duty overload ratings (150 pct for 60 sec.)

• 600 HP with normal duty ratings (110 pct for 60 sec.)

Applications

• Extruders

• Steel mills

• Pipe mills

• Retrofits

Options

• Integral line reactor up to 150 HP

• Circuit breaker, ABB Tmax MCP

• Blower motor contactor and overload, ABB A-line, for blowers from ½ to 15 HP

• Without AC contactor

• 230 Vac supply

Aluminium applications

• AC 800PEC Unit controller ↔ AC 800PEC Master controller communication via PEC - PEC fiberptical link (100 μs)

• Units can be controlled independent from master

• Allows emergency operation (full smooth current control, in emergency mode, without AC 800PEC,available only in combination with DCS800 premagnetization)

• Predictive maintenance features can be included

• Open circuit-, over current-, under voltage-,over voltage protection packages included in software

- A newly developed OPC (open circuit protection) stand-alone PLC (programmable logic controller), working in combination with the AC 800PEC Master controller functions or as

standalone protection, in case of the master panel maintenance

• Controlled shutdown in an event, not needing an immediate trip → less disturbance for your processes

• Potline load swing detection and load shedding function integrated in application software

• On Load Tap Changer fast tapping function in order to prevent DC current overload during disturbances

• A special potline-to-earth resistance measure ment system based on an AC 800PEC family available (PERMS)

• Maximum power regulation

- To prevent over-shooting of power consumption and to support your power generators

• Maximum DC voltage regulation for stabilizing your process

implementation

• Full integration into ABB Ability™ System 800xA

• Innovative and flexible use of FPGAs to include protocols and application functionality in the devices without creating additional

processor load

• Optical communication

• Industrial grade hardware with no moving parts

• Long life cycle, easy upgrading

• Robust reliance file system, insusceptible post power loss

Key features

• Unlimited phone support 365 days a year with

access to ABB product experts

• On-site troubleshooting dispatch prioritization

• Proactive maintenance programs

(Performance Review)

• Availability of field labor and spare parts

(discounted hourly rates and prices)

• Access to ABB University training programs

(reduced fees)

• Product Lifecycle management

• Control upgrade solutions designed to extend

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved