-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

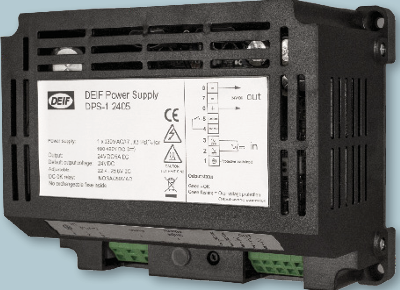

DEIF DC Power Supply, DPS-1

-

DEIF MVR-F215 Directional Feeder Protection

-

DEIF MVR-F215 Product description

-

DEIF MVR-F210 feeder protection relay Protection Functions

-

DEIF MVR-F210 Feeder Protection

-

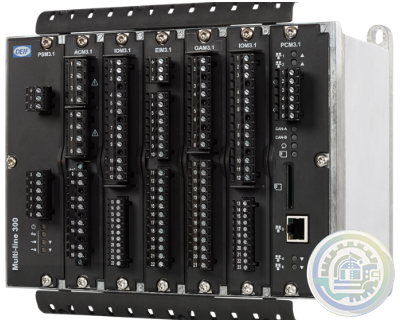

DEIF PPM 300 Shaft generator controller

-

DEIF MVR-F205 Directional Feeder Protection

-

DEIF Protection & power management PPM 300 Features

-

DEIF PPM 300 Protection & power management

-

DEIF The series of switch mode power supplies

-

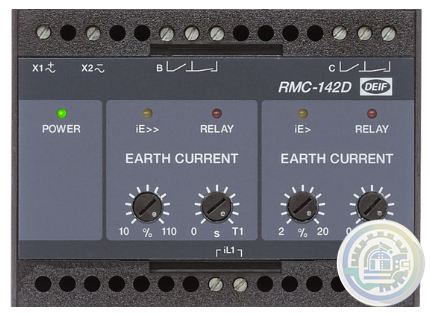

DEIF The RMC-142D is CE-marked and is applied for protection of voltage sources

-

DEIF RMC-142D Current relay

-

DEIF The GPU-3 Hydro is well-suited for PLC-controlled systems

-

DEIF GPU-3 hydro Generator protection unit

-

DEIF MVR-200 series Medium Voltage Relay

-

DEIF RMC-131D Current relay

-

DEIF MDR-2 Multi-differential relay

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

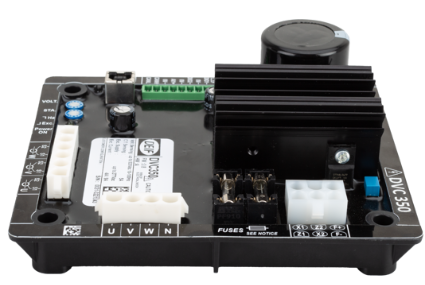

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

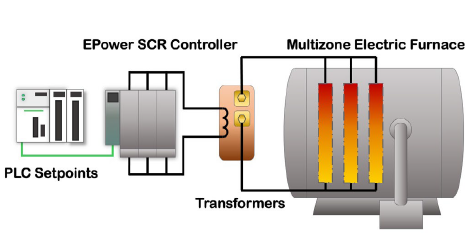

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

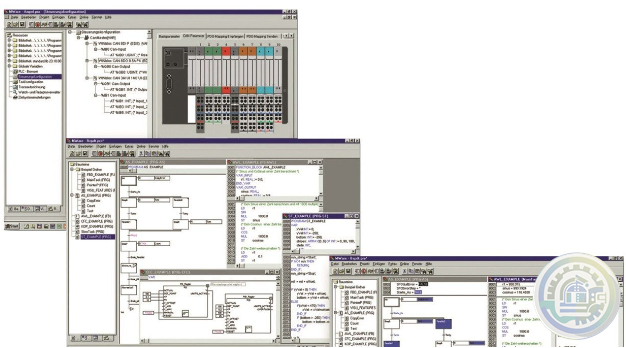

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

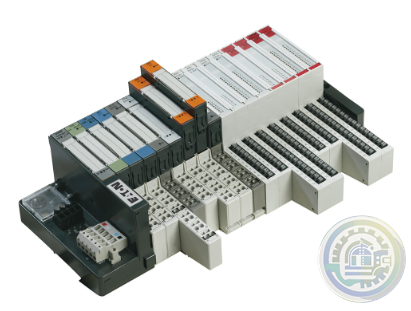

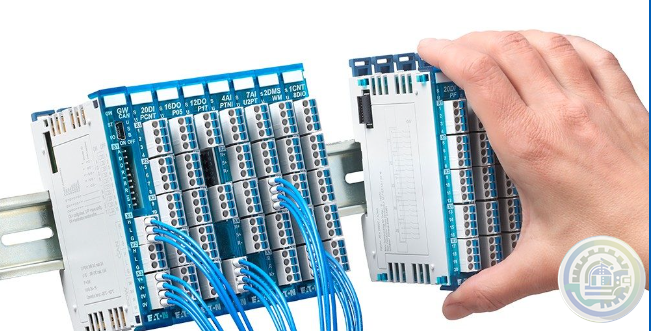

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

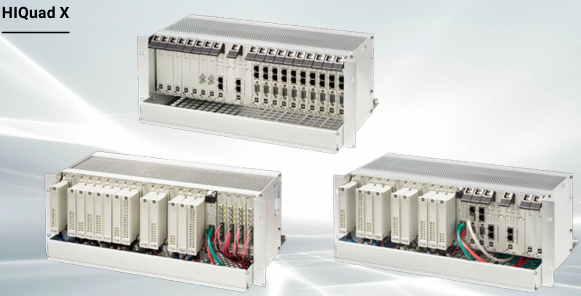

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

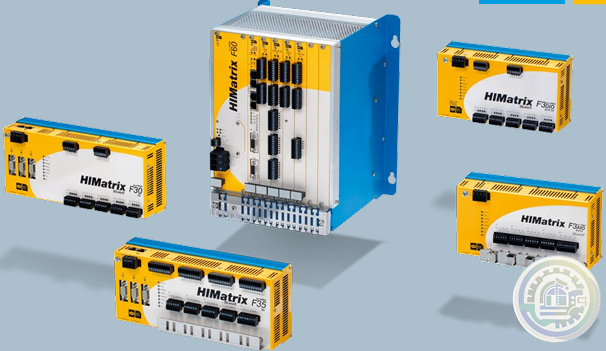

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

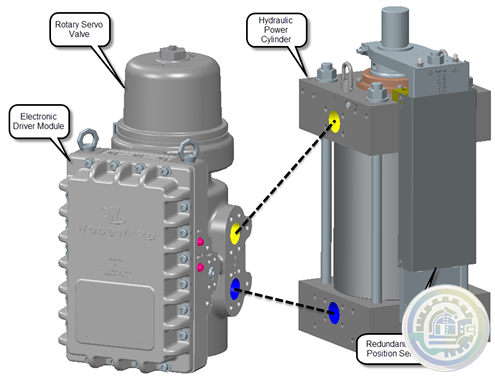

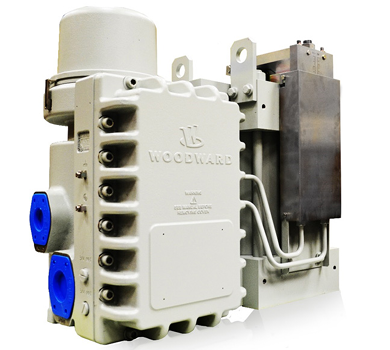

Woodward Oil Management

-

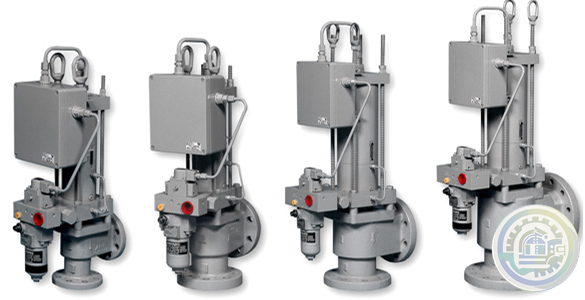

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Isolated Analog Input Module Manufacturers ABB, Bailey Model(s) ABB Bailey Infi 90, ABB Bailey Infi 90 and Net 90

Estimated Shipping Size Dimensions: 3.0" x 8.0" x 8.0" (7.6 cm x 20.3 cm x 20.3 cm)

Weight: 2 lbs 2.1 oz (1.0kg )

Isolated Analog Input Module

Bailey DCS Overview

The Net 90 DCS and the INFI 90 DCS are products of Elsag Bailey Process

Automation N.V., now ABB, and are marketed and installed worldwide.

Net 90 and INFI 90

The Net 90 DCS, introduced in the 1980, and the INFI 90 DCS, introduced in

the 1988, are widely used for process control in process oriented plants, in

industries such as pulp and paper, power generation, cement making, glass,

chemical and many others. In these industries the Bailey DCS system are

respected for the high level of process automation reliability that they bring.

Data Highways

All DCS systems on the marketplace rely on a “data highway” for high speed

data communications between all of the distributed components of the DCS

system. Over the life of the Net 90 and INFI 90 product lines, three primary

data highways have been used: Plant Loop , Super Loop and INFI Net.

Connecting to Bailey DCS

The Driver may be connected to any Bailey DCS via a gateway device, variously

called a Computer Interface Unit (CIU), an INFI-NET to Computer Interface

(ICI) or a Plant Loop to Computer Interface (PCI). These interfaces, designed

for connection of external devices to the Bailey DCS, allow the OPC Data Server

to communicate with the Bailey DCS modules.

Applications

The binary input board 23BE40 performs the following processing functions for different types of signals:

Digital filtering to suppress contact jumping

Suppression of technically induced chattering signals

Intermediate position suppression and double indication monitoring

Consistency check of all binary input channels assigned to digital measurement values

The 23BE40 has a buffer for temporarily storing 50 time-stamped event messages in chronological order, designated for transmission to the communication unit.

The board's microcontroller handles all time-critical tasks for the parameterized processing functions. In addition, it communicates interactively with the RTU560 system bus.

All configuration data and processing parameters are transmitted via the RTU560 system bus.

All configuration data and processing parameters are loaded from the communication unit via the RTU560 bus.

The board is equipped with a serial interface to the RTU560 system bus.

During initialization and operation, the board performs a series of tests. If a fault occurs, it is reported to the communication unit.

All fault conditions affecting the board's functionality are indicated as general fault signals by means of light emitting diodes (ST).

Faults in the board are detected by the communication unit.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved