-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

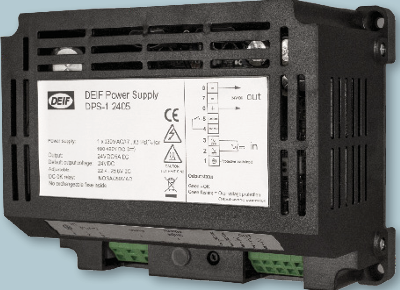

DEIF DC Power Supply, DPS-1

-

DEIF MVR-F215 Directional Feeder Protection

-

DEIF MVR-F215 Product description

-

DEIF MVR-F210 feeder protection relay Protection Functions

-

DEIF MVR-F210 Feeder Protection

-

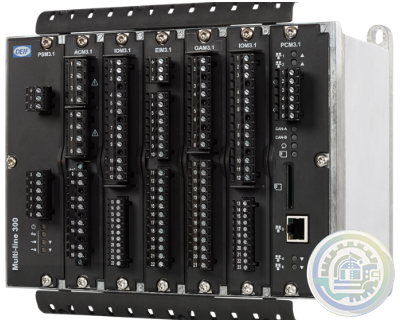

DEIF PPM 300 Shaft generator controller

-

DEIF MVR-F205 Directional Feeder Protection

-

DEIF Protection & power management PPM 300 Features

-

DEIF PPM 300 Protection & power management

-

DEIF The series of switch mode power supplies

-

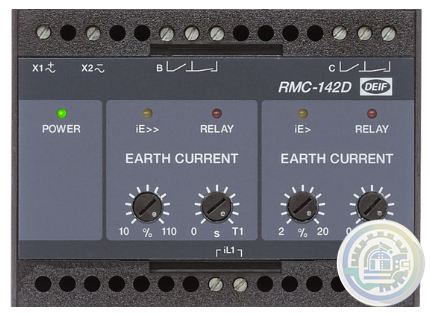

DEIF The RMC-142D is CE-marked and is applied for protection of voltage sources

-

DEIF RMC-142D Current relay

-

DEIF The GPU-3 Hydro is well-suited for PLC-controlled systems

-

DEIF GPU-3 hydro Generator protection unit

-

DEIF MVR-200 series Medium Voltage Relay

-

DEIF RMC-131D Current relay

-

DEIF MDR-2 Multi-differential relay

-

IR-TEC PPU-300 Power Pack & Controller

-

Streamline power transfer with DEIF's AGC 150 ATS controller

-

DEIF AGC 150 ATS: Advanced Generator Transfer Switch for Seamless Power Management

-

DEIF DVC 550 Automatic voltage control

-

DEIF Optimize Your Power Systems with DEIF's DVC 550

-

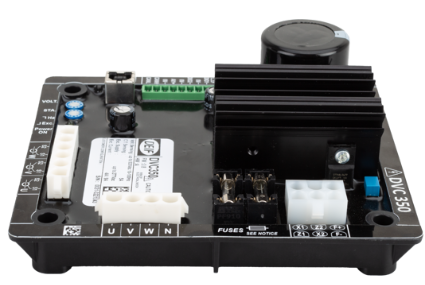

DEIF DVC 350 Digital automatic voltage regulator (AVR)

-

DEIF Advanced Features of DVC 350 Digital Automatic Voltage Regulator

-

DEIF Digital Voltage Controller DVC 550

-

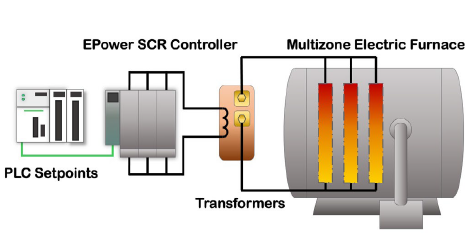

Watlow EPower™ Controller Revolutionary modularity and configurability to meet your needs

-

Watlow Eurotherm® EPower™ Controller

-

Watlow Eurotherm A standardized upgrade solution

-

Watlow Eurotherm Cost efficiency for electric furnaces

-

Watlow Eurotherm Energy efficiency for electric heat treatment furnaces

-

Watlow Solid State Relays (SSR)

-

Watlow DIN-A-MITE® D silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® C silicon controlled rectifier (SCR) power controller

-

Watlow DIN-A-MITE® B Power Controller

-

Watlow DIN-A-MITE® A Power Switching Devices

-

Watlow ASPYRE® AT Power Controllers

-

Watlow ASPYRE® DT SCR Power Controllers

-

Watlow PM PLUS™ Controller Features and Benefits

-

Watlow PM PLUS™ Controller

-

Watlow ASPYRE To Elevate Your System

-

Watlow ASPYRE® DT Power Controllers

-

Honeywell MICRO SWITCH Premium Subminiature Basic Switches

-

HIMA SILworX API (application programming interface)

-

HIMA Automated testing with SILworX Smart Safety Test

-

HIMA SILworX The world’s most advanced safety application manager

-

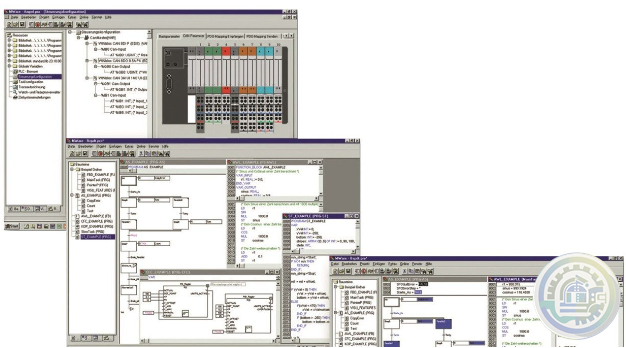

Eaton CODESYS software

-

Eaton CODESYS version 3 Integrated fieldbus configuration

-

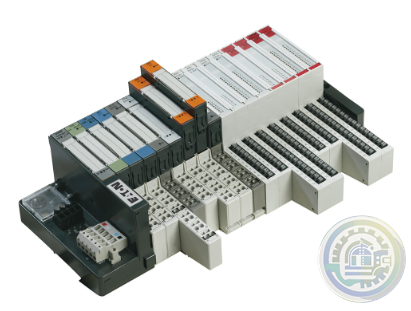

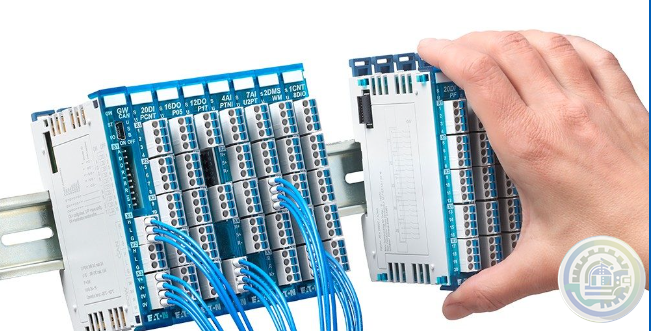

Eaton XI/ON I/O system

-

Eaton XN300 modules High modularity with a small footprint

-

Eaton XN300 I/O system

-

Eaton The XC300 modular PLC: Powerful communication

-

Eaton The three device variants of the XC300 Comprehensive functions and interfaces

-

Eaton XC300 modular programmable logic controllers

-

Eaton XC150 compact programmable logic controllers

-

Eaton XC100/200 modular programmable logic controllers

-

Eaton Multi-Function Display MFD-Titan

-

Eaton Legacy Easy programmable relays

-

Eaton easySafety Safety for people and machines

-

Eaton easySafety programmable safety relays

-

Eaton easyE4 programmable relays

-

Eaton easyE4 nano programmable logic controllers

-

Eaton COOPER POWER SERIES DirectConnect elbow arrester

-

Bently Nevada IEPE Accelerometer Series

-

Bently Nevada Velocity Sensors & Accelerometers

-

Bently Nevada ADRE - Data Acquisition & Machine Diagnostics System

-

Bently Nevada 3701/55 Emergency Shutdown Device

-

Bently Nevada Asset Condition Monitoring

-

Bently Nevada 3500 Machinery Protection Systems

-

Bently Nevada ADAPT ESD Relay Module

-

Bently Nevada Typical (and recommended) applications of the ADAPT ESD

-

Bently Nevada 3701/55 ADAPT (ESD) Emergency Shutdown Device

-

Bently Nevada Online Condition Monitoring Systems

-

Bently Nevada Trendmaster Online Condition Monitoring System

-

Bently Nevada Orbit Distributed Condition Monitoring

-

HIMA The HIJunctionBox is part of the Smart Safety Platform

-

HIMA HIJunctionBox Straightforward Safety

-

HIMA Planar4 Where Ultimate Safety Counts

-

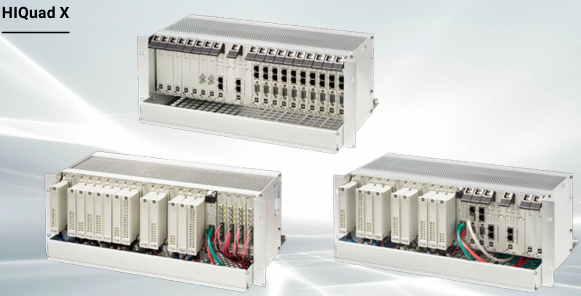

HIMA HIQuad Lifecycle & Modernization

-

HIMA HIQuad X A New Dimension of Performance for Your Safety System

-

HIMA Communication Features of HIQuad X

-

HIMA Flexible SIL 4 Controllers SYSTEM FOR THE RAIL INDUSTRY

-

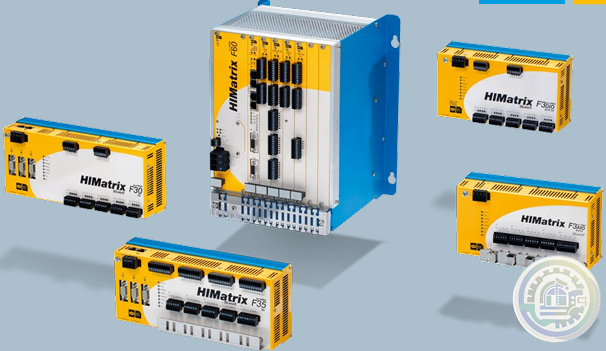

HIMA HIMatrix SYSTEMS Uniquely Fast, Uniquely Flexible

-

HIMA F35 HIMatrix Safety-Related Controller

-

HIMA HIMax Flexible Safety for Maximum Profitability

-

HIMA X-COM 01 Communication Module

-

HIMA X-DI 64 01 Digital Input Module

-

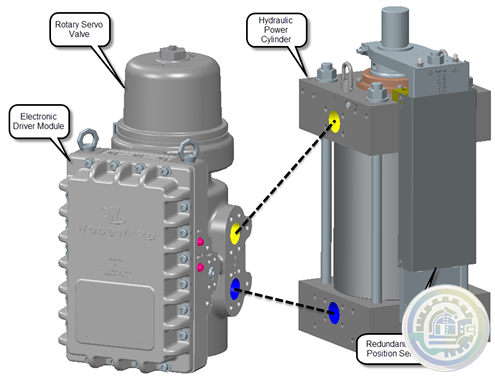

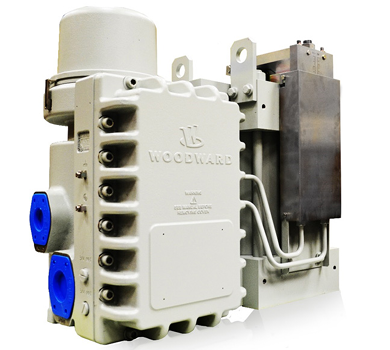

Woodward Oil Management

-

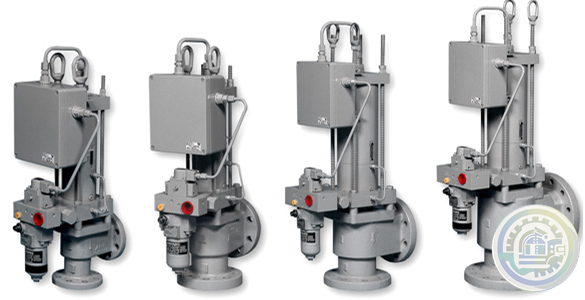

Woodward SonicFlo™ Gas Fuel Control Valve With Electric Trip

-

Woodward SonicFlo™ Gas Triple Coil Electrohydraulic Servo Valve Assembly

-

Woodward SonicFlo™ Gas Valves Hydraulically Actuated

-

Woodward Discrete Output for Driver Status Indication

-

Woodward PWM Input for Position Demand

-

Woodward The Swift valve is a sonic flow-metering valve

-

Woodward Swift™ Gas Metering System

-

Woodward LQ6 Liquid Fuel Valve with On‐board Driver

-

Woodward Fuel Metering System Integration Capabilities

-

Woodward DLE/DLN for Aeroderivative Turbine Platforms

-

Woodward Fuel Metering Systems

-

Woodward PG-07 controls Sequential spark ignition

-

Woodward PG-07 CONTROL SYSTEM FEATURES

- Glassman

- Johnson Controls

- Studer

- Watlow

- AEG

- ADVANCED

- KEBA

- Bristol Babcock

- Rolls-Royce

- Aerotech

- APPLIED MATERIALS

- Basler

- SAACKE

- BENDER

- Kollmorgen

- MEGGITT

- METSO

- MITSUBISHI

- MTL

- HIMA

- Siemens

- BACHMANN

- AMAT

- DEIF

- DELTATAU

- EATON

- ELAU

- LAM

- SCHNEIDER

- Advantest

- ABB

- GE

- Emerson

- Motorola

- A-B

- KUKA

- Abaco

- HITACHI

- SST

- Vibro-Meter

- Rexroth

- Prosoft

- DFI

- Scanlab

- Reliance

- Parker

- Woodward

- MOOG

- NI

- FOXBORO

- Triconex

- Bently

- ALSTOM

- YOKOGAWA

- B&R

- UNIOP

- KONGSBERG

- Honeywell

- Omron

- CTI

- EPRO

- Tell:+86-18144100983

- email:kongjiangauto@163.com

- Application:wind/ petroleum/ chemical/ natural gas/ Marine/ mining/ aviation/ electronics/ steel/ nuclear power/ electric power/ coking/ air separation and so on

- Series:PLC/ DCS/ servo/ analog/ Ethernet/ digital/ redundant module/ tension system/ excitation/ generator management/ human-machine interface/ detection card/ sensor/ AC drive/ etc

Fuse Protection (1746-OBP16 and 1746-OVP16 modules)

The fuse on the 1746-OBP16 and 1746-OVP16 modules (shown on page 10)

provides short-circuit protection for 13 mm2 (16 AWG) or larger wiring to external

loads. In the event of a short circuit on an output channel, it is likely that the

transistor associated with that channel will be damaged. In this event the module

should be replaced or the load moved to a spare output channel.

The fuse does not provide overload protection. In the event of an overload on an

output channel, it is likely that the fuse will not blow and the transistor associated

with that channel will be damaged. To provide overload protection for your

application, user-supplied fuses should be installed externally and properly sized to

match your individual load characteristics.

Fuse Protection (1746-OAP12 modules)

A fuse is provided on each common of the 1746-OAP12 module (shown on page

11) for a total of two fuses. The fuses are designed to protect the module from

short-circuit conditions. The fuse does not provide overload protection. In the event

of an overload on an output channel, it is likely that the fuse will not blow and the

output device associated with that channel will be damaged. To provide overload

protection for your application, user-supplied fuses should be installed externally.

The recommended fuse for overload protection is SAN-O HT. Select the fuse rating

according to your load. Do not use HT fuses rated higher than 2.0 Amps.

The Module overview will permit you to understand the basic functions of the Module and hardware requirements.

The Module, catalog number 1746–HSTP1, is an SLC 500 family compatible device. It can be used with any SLC 500 Processor.

The Module is configured through the SLC 500 backplane and requires no switch settings.

Motion can be programmed in either direction for over ±8,000,000 counts of absolute position.

An optional incremental encoder may be used to verify the position reached by the axis.

The Module does not automatically close a position loop in engineering units.

The feedback hardware can accept frequencies of up to 250 kHz for use as either loop back diagnostics or differential incremental encoder feedback devices.

The Module can be programmed for either incremental or absolute moves, depending on the application.

Command Mode Operation All stepper motor operations are performed in command mode.

This mode is entered by setting the mode flag (bit 15 in output word 0) to 0.

In command mode, the SLC Processor can issue commands and activate different operations or moves. The actions you can command are:

• Absolute Moves

• Relative Moves

• Hold Moves

• Resume Moves

• Immediate Stop Operations

• Homing Operations

• Jogging Operations

• Blend Moves

• Preset Operations

• Reset Errors

Diagnostic Mode

Use the configuration mode to select the diagnostic mode of operation. Once selected,

the diagnostic mode allows you to test your program and wiring by connecting the loop back wires at the

translator. The purpose of loop back diagnostics is to test the system wiring for electrical noise.

The number of pulses received at the feedback should equal the commanded number of pulses at the end of the move.

If they are not equal, the system may be experiencing problems due to electrical noise.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------More Model Recommendations:

1756-OB16IS module Rockwell ControlLogix 16 digital output

1756-OB32 module Rockwell ControlLogix 32 digital output

1756-OB8 module Rockwell ControlLogix 8 digital output

1756-OB8EI module Rockwell ControlLogix 8 digital output

1756-OB8I module Rockwell ControlLogix 8 digital output

1756-OC8 module Rockwell ControlLogix 8 digital output

1756-OF4 module Rockwell ControlLogix 4 analog

1756-OF6CI module Rockwell ControlLogix 6 analog

1756-OF6VI module Rockwell ControlLogix 6 analog

1756-OF8 module Rockwell ControlLogix 8 analog

1756-OF8H module Rockwell ControlLogix 8 analog

1756-OG16 module Rockwell ControlLogix 16 digital output

1756-OH8I module Rockwell ControlLogix 8 digital output

1756-ON8 module Rockwell ControlLogix 8 digital output

1756-OV16E module Rockwell ControlLogix 16 digital output

1756-OV32E module Rockwell ControlLogix 32 digital output

1756-OW16I module Rockwell ControlLogix 16 digital output

1756-OX8I module Rockwell ControlLogix 8 digital output

1756-PA72 Module Rockwell ControlLogix AC Power Supply

1756-PA75 Module Rockwell ControlLogix AC Power Supply

1756-PA75R Module Rockwell ControlLogix AC Power Supply

1756-PAR2 Module Rockwell ControlLogix AC Power Supply

1756-PAXT Module Rockwell ControlLogix XT Power Supply

1756-PB72 Module Rockwell ControlLogix DC Power Supply

1756-PB75 Module Rockwell ControlLogix DC Power Supply

1756-PB75R Module Rockwell ControlLogix DC Power Supply

1756-PBR2 Module Rockwell ControlLogix Power Supply

1756-PBXT Module Rockwell ControlLogix XT Power Supply

1756-PC75 Module Rockwell ControlLogix DC Power Supply

1756-PH75 Module Rockwell ControlLogix DC Power Supply

1756-PSCA2 Module Rockwell ControlLogix Adapter

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Please do not listen to the advice of non-professional engineers! Cause equipment damage!

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved