Bently Nevada 3500 series Machinery protection system

3500 – Simply the best

Beginning with the 5000 Series in the 1960s, we’ve introduced

seven successive generations of highly successful

monitoring platforms. Today, that experience is embodied

in the most advanced, powerful, and reliable system we

have ever offered: The Bently Nevada 3500 Series Machinery

Protection System.

Certified

The 3500 is designed to fully comply with the American

Petroleum Institute’s Standard API 670. the world’s most

widely used specification for machinery protection systems.

For reciprocating compressor applications, the 3500 meets

API 618 requirements as well. It can also be ordered with DNV

and Class NK certifications for maritime applications such as

offshore platforms and ship propulsion. And, when used as

part of a safety instrumented system, third party Functional

Safety Certification can be supplied for applications requiring

up to Safety Integrity Level (SIL) 2. In addition, the 3500 is

approved to meet relevant Canadian Standards Association

(CSA), Factory Mutual (FM), GOST, ATEX, and CE requirements.

Bently Nevada follows closely the development and changes

in these standards and continually demonstrates our

capacity and commitment to be in sync with them as they

change and evolve. This continued focus and investment

in regulatory excellence ensures our customers don’t have

to worry about deploying a non-compliant solution that

may later require significant update or replacement. A

compliance miss has the potential for exposure to not only

catastrophic consequences, but also can lead to fines from

governments and inspection agencies as well as impact on

insurance rates and reputation. Baker Hughes Bently Nevada

is committed to continued compliance leadership and full

regulatory excellence.

Reliable

We understand that our systems are routinely used not just

for indication, but to provide auto-shutdown protection.

That’s why – even in simplex mode – the 3500 is the most

reliable monitoring system we have ever offered with

extensive self-checking and fault tolerant design features.

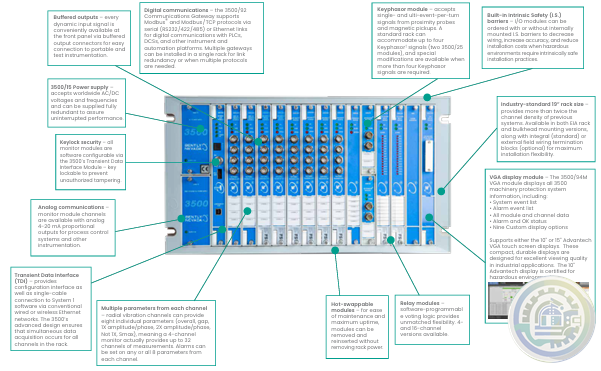

Connected

Connecting to condition monitoring and diagnostic software

has never been easier. With the 3500 there are no bulky

external modules, no additional wiring, and no extra rack

slots required. Simply use the Ethernet port in the 3500/22M

Transient Data Interface Module and a single network cable

to communicate with our System 1† software. Connecting

to plant control and automation systems is straightforward

as well. Simply add a communication gateway module.

You can even add multiple gateways when communication

redundancy is required or when multiple systems must be

supported with differing protocols.

Flexible

The 3500 Series features the industry’s most extensive

selection of machinery measurement parameters combined

with software configuration for virtually all monitor options.

Local or remote mounted displays are available, or you can

operate the 3500 without a display. The result is unparalleled

flexibility to address almost any application.

Field-proven

The 3500 Series system has proven its value and

dependability with customers everywhere, year after year,

with more than 100.000 racks installed globally.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

-

ABB SYN 5025 Bus board for SYN 5302

-

ABB SYN 5020 System control

-

ABB SYN 5015 Bus board for SYN 520x

-

ABB SYN 5014 Extended I/O / seven parameter sets (option)

-

ABB SYN 5013 Processor for channel 2 (synchrocheck)

-

ABB SYN 5012 Basic I/O unit

-

ABB SYN 5011 Processor and power supply board

-

ABB SYN 5010 Communications board

-

ABB SYN 5009 Communications board IEC 61850

-

Bently Nevada 3500/65 145988-02 Temperature Monitor

-

CB410-EE1 T150/T155 SWL base station

-

KEBA T155 Mobile HMI / Standard T155WL-D10-EN0-W10E

-

KEBA T150WL-R10-EN0-W10E T150 Mobile HMI / Robotics

-

KEBA T155 Mobile HMI / Standard T155-MA0-AN0-W10E

-

KEBA Mobile HMI / Standard T150-MA0-AN0-W10E

-

KEBA T150-RA0-AN0-W10E Mobile HMI / Robotics

-

Honeywell FX-USI-0002 Safety Manager System Module 5 VDC/Ma.2A

-

ABB PM5052-R-ETH 1SAP124100R0172 Processor module Memory 4MB

-

ABB PM5052-T-ETH 1SAP124000R0172 Processor module Memory 4MB

-

ABB PM5032-R-ETH 1SAP123500R0172 Processor module Memory 2MB

-

ABB PM5032-T-ETH 1SAP123400R0172 Processor module

-

ABB PM5012-R-ETH 1SAP122700R0172 Processor module

-

ABB PM5012-T-ETH 1SAP122600R0172 Basic CPU

-

ABB PM5092-MC-KIT-EC-EIP 1SAP125500R0173 Motion control Kit

-

ABB PM5092-MC-KIT-EC 1SAP125400R0173 Motion control Kit

-

ABB PM5082-MC-KIT-EC-EIP 1SAP125300R0173 Motion control Kit

-

ABB PM5082-MC-KIT-EC 1SAP125200R0173 Motion control Kit

-

ABB PM5072-MC-KIT-EC-EIP 1SAP125100R0173 Motion control Kit

-

ABB PM5072-MC-KIT-EC 1SAP125000R0173 Motion control Kit

-

ABB SC560 EXC3BSE008105R1 Submodule Carrier incl local CPU

-

ABB TA5426-STAKIT 1SAP187600R0003 terminal block set, HMI CP604, programming cables

-

ABB TA5415-STAKIT 1SAP187600R0002 terminal block set, programming cable

-

ABB REB500 1MRB150071M0001 Basic bay unit

-

SIEMENS 6DP1230-8JJ FUM 230 HART Analog Module

-

ABB CMA120 3DDE300400 Basic Controller Panel Unit SYNPOL D Series

-

Bently Nevada 2300/20-CN Monitor with 4-20ma Outputs

-

Bently Nevada 2300/20-RU 2300 Vibration Monitor

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

A-B 4100-234-R Compact Motion Controller

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

-

Kongsberg RCU502I 421768 Remote Control Unit (Modular I/O Processor)

-

ABB AC 800PEC PC D237 3BHE028915R0101 / PC D237 A101 CONTROLLER BOARD

-

ABB GVC704AE01 5SHX1060H0001 3BHB003230R0101 Medium voltage inverter

-

ABB Process Panel PP245 3BSC690126R2 PP245B

-

GE Mark VIe & VIeS IS230PCAAH1B - Core Analog I/O Module

-

GE Mark VIe & VIeS IS230PCAAH1A Core Analog I/O Module

-

Emerson PMCSPANA/IH PMC Carrier Installation and Use Manual

-

Emerson PMCSPAN26E-010 Secondary PMC expansion

-

Emerson PMCSPAN26E-002 Primary PMC expansion

-

Emerson PMCSPAN16E-010 Secondary PCI expansion

-

Emerson PMCSPAN16E-002 Primary PCI expansion

-

A-B 1783-HMS4C4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-RA5TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-CMS10DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-HMS8S4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-CMS6B Stratix 5200 Ethernet Managed Switches

-

A-B 1783-RA5TGW Stratix 4300 Remote Access Routers

-

A-B 1783-RA2TGWC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US5TG/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGW Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US6T2F/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5TG Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2TG2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US6T2TG2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US4T1H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US14T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US7T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-RA2TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US16T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US7T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGB Stratix 4300 Remote Access Routers

-

A-B 1783-LMS5 Stratix 2500 Ethernet Lightly Managed Switches

-

A-B 1783-US7T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US8T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US8TG2GX Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T 5 Port Unmanaged Switch

-

MOOG D138-002-002 Industrial Control Module

-

MOOG D138-003-001 Industrial Control Module

-

MOOG CA98502-001 Accessories for Ruggedized Motion Controller

-

MOOG D691-078D servo valve

-

MOOG CA65866-001 MSD Motion Controller

-

MOOG C43148-001 QD10 16/16 Digital l/0 module

-

MOOG D138-002-012 Main control unit

-

MOOG CA94286-001 Accessories for Ruggedized Motion Controller

-

MOOG D136-001-008 MSCI MSD Motion Controller

-

MOOG B95906-001 MSCI Motion Controller

-

MOOG B95865-001 CAN Termination Resistors

-

MOOG QEBUS-CAN Module

-

MOOG D136-003-001 Interfaces of Ruggedized Motion Controller

-

MOOG RDI0 16/16 Digital Module

-

MOOG D136-003-004 Interfaces of Ruggedized Motion Controller

-

MOOG D391-001-003 MSD MOTION CONTROLLER

-

MOOG D138-002-003 Industrial Control Module

-

MOOG MSC-R-10 16/8 Digital and PT100 Module

-

MOOG CB08987-001 Ruggedized Motion Controller

-

MOOG RDISP 22 Operator Panel DISPLAYS

-

MOOG D136-003-002 Interfaces of Ruggedized Motion Controller

-

MOOG CA65865-001 MSCl Motion Controller

-

MOOG B95863-001 CAN Connection Cables

-

MOOG QA10 16/4 Analog Module

-

MOOG D136-006-001 EtherCAT slave interface

-

MOOG D391-001-001 MSD MOTION CONTROLLER

-

MOOG D136-003-005 Interfaces of Ruggedized Motion Controller

-

MOOG D137-004-003 TFT Touch screen display

-

MOOG D138-002-003 Industrial Control Module

-

MOOG D138-003-010 Industrial Control Module

-

MOOG CB03223-001 Accessories for Ruggedized Motion Controller

-

MOOG B95864-001 CAN Termination Resistors

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB SYN 5025 Bus board for SYN 5302

-

ABB SYN 5020 System control

-

ABB SYN 5015 Bus board for SYN 520x

-

ABB SYN 5014 Extended I/O / seven parameter sets (option)

-

ABB SYN 5013 Processor for channel 2 (synchrocheck)

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved