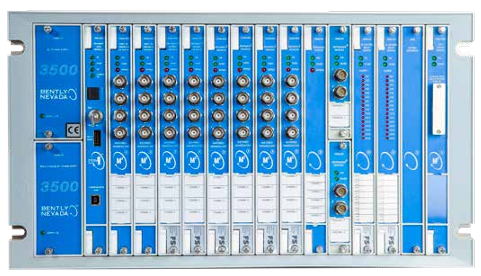

Bently Nevada 3500 series Applications and industries

Applications and industries

Service and support

The table on page 5 summarizes the enormous selection

of measurement types available in the 3500. This allows it

to be applied to an extremely wide-range of rotating and

reciprocating machinery in many industries. Below are just

a few of the more common applications that can be easily

addressed by the 3500 System.

If your specific machine doesn’t appear on the list, just

ask us. Chances are, our applications engineers have

already developed a solution that’s right for you. And,

with our extensive custom applications capabilities, we

can easily modify off-the-shelf 3500 solutions to handle

your nonstandard applications and signal processing

requirements.

• Steam turbines

• Hydraulic turbines

• Industrial gas turbines

• Aeroderivative gas turbines

• Reciprocating compressors

• Centrifugal compressors

• Axial compressors

• Screw compressors

• Gears

• Turbo-expanders

• Horizontal and vertical centrifugal pumps

• Reciprocating pumps

• Electric motors

• Generators

• Fans

• Blowers

• Agitators

• Mixers

• Centrifuges

• Pulp refiners

• Ball mills

• Crushers/pulverizers

• Extruders

• Pelletizers

• Cooling tower/heat exchanger fans

System 1

System 1†, connected to your 3500 Monitoring System,

delivers the comprehensive machinery wide diagnostic HMI

capability users need to make informed decisions on how to

proactively manage their machinery.

Connectivity

Seamless connectivity to Bently Nevada’s 3500 machinery

protection system with full access to available trend,

waveform, and event data. Standard integration to control

system PLCs through OPC DA protocol with full access to

applicable process data, first-outs, permissives, surge

control, and set points.

Visualization and management

Complete Diagnostic HMI desktop-based application,

designed to enable rich HMI overviews, extensive trend

diagnostics, vibration analysis, and proactive condition

monitoring.

Plant-wide scalability

Ability to scale connectivity beyond 3500 and the control

system to monitor more machinery leveraging other Bently

Nevada online, scanning, or portable devices in the same

System 1 platform.

Comprehensive diagnostic HMI implementation

Standardized & holistic machinery configurations based on

Bently Nevada best practices for vibration and process data.

Standard data connectivity (OPC, 3500. etc.) for overall machine

and key sub-systems (vibration, lube, seal, surge, etc.).

Optional hosted and/or remote monitoring

Access to Bently Nevada machinery experts through

standardized remote monitoring.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

-

ABB SYN 5025 Bus board for SYN 5302

-

ABB SYN 5020 System control

-

ABB SYN 5015 Bus board for SYN 520x

-

ABB SYN 5014 Extended I/O / seven parameter sets (option)

-

ABB SYN 5013 Processor for channel 2 (synchrocheck)

-

ABB SYN 5012 Basic I/O unit

-

ABB SYN 5011 Processor and power supply board

-

ABB SYN 5010 Communications board

-

ABB SYN 5009 Communications board IEC 61850

-

Bently Nevada 3500/65 145988-02 Temperature Monitor

-

CB410-EE1 T150/T155 SWL base station

-

KEBA T155 Mobile HMI / Standard T155WL-D10-EN0-W10E

-

KEBA T150WL-R10-EN0-W10E T150 Mobile HMI / Robotics

-

KEBA T155 Mobile HMI / Standard T155-MA0-AN0-W10E

-

KEBA Mobile HMI / Standard T150-MA0-AN0-W10E

-

KEBA T150-RA0-AN0-W10E Mobile HMI / Robotics

-

Honeywell FX-USI-0002 Safety Manager System Module 5 VDC/Ma.2A

-

ABB PM5052-R-ETH 1SAP124100R0172 Processor module Memory 4MB

-

ABB PM5052-T-ETH 1SAP124000R0172 Processor module Memory 4MB

-

ABB PM5032-R-ETH 1SAP123500R0172 Processor module Memory 2MB

-

ABB PM5032-T-ETH 1SAP123400R0172 Processor module

-

ABB PM5012-R-ETH 1SAP122700R0172 Processor module

-

ABB PM5012-T-ETH 1SAP122600R0172 Basic CPU

-

ABB PM5092-MC-KIT-EC-EIP 1SAP125500R0173 Motion control Kit

-

ABB PM5092-MC-KIT-EC 1SAP125400R0173 Motion control Kit

-

ABB PM5082-MC-KIT-EC-EIP 1SAP125300R0173 Motion control Kit

-

ABB PM5082-MC-KIT-EC 1SAP125200R0173 Motion control Kit

-

ABB PM5072-MC-KIT-EC-EIP 1SAP125100R0173 Motion control Kit

-

ABB PM5072-MC-KIT-EC 1SAP125000R0173 Motion control Kit

-

ABB SC560 EXC3BSE008105R1 Submodule Carrier incl local CPU

-

ABB TA5426-STAKIT 1SAP187600R0003 terminal block set, HMI CP604, programming cables

-

ABB TA5415-STAKIT 1SAP187600R0002 terminal block set, programming cable

-

ABB REB500 1MRB150071M0001 Basic bay unit

-

SIEMENS 6DP1230-8JJ FUM 230 HART Analog Module

-

ABB CMA120 3DDE300400 Basic Controller Panel Unit SYNPOL D Series

-

Bently Nevada 2300/20-CN Monitor with 4-20ma Outputs

-

Bently Nevada 2300/20-RU 2300 Vibration Monitor

-

ABB NE810 3BSE080207R1 Network switch

-

ABB NE802 Network switch 3BSE080237R1

-

A-B 4100-234-R Compact Motion Controller

-

GE IS230TNRLH1B Relay Output DINrail Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS220PAICH1B Analog I/O Module

-

GE IS230TNAIH2C - Analog I/O DIN RAIL Module

-

ABB DAPU100 3ASC25H204 Control board I/O

-

Kongsberg RCU502I 421768 Remote Control Unit (Modular I/O Processor)

-

ABB AC 800PEC PC D237 3BHE028915R0101 / PC D237 A101 CONTROLLER BOARD

-

ABB GVC704AE01 5SHX1060H0001 3BHB003230R0101 Medium voltage inverter

-

ABB Process Panel PP245 3BSC690126R2 PP245B

-

GE Mark VIe & VIeS IS230PCAAH1B - Core Analog I/O Module

-

GE Mark VIe & VIeS IS230PCAAH1A Core Analog I/O Module

-

Emerson PMCSPANA/IH PMC Carrier Installation and Use Manual

-

Emerson PMCSPAN26E-010 Secondary PMC expansion

-

Emerson PMCSPAN26E-002 Primary PMC expansion

-

Emerson PMCSPAN16E-010 Secondary PCI expansion

-

Emerson PMCSPAN16E-002 Primary PCI expansion

-

A-B 1783-HMS4C4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-RA5TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-CMS10DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-CMS20DP Stratix 5200 Ethernet Managed Switches

-

A-B 1783-HMS8S4CGN Stratix 5400 Ethernet Managed Switches

-

A-B 1783-CMS6B Stratix 5200 Ethernet Managed Switches

-

A-B 1783-RA5TGW Stratix 4300 Remote Access Routers

-

A-B 1783-RA2TGWC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US5TG/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGW Stratix 4300 Remote Access Routers

-

A-B 1783-US8T/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US6T2F/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5TG Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2TG2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US6T2TG2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US4T1H/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US14T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US7T1H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T2S Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-RA2TGC4G Stratix 4300 Remote Access Routers

-

A-B 1783-US16T/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US7T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-RA2TGB Stratix 4300 Remote Access Routers

-

A-B 1783-LMS5 Stratix 2500 Ethernet Lightly Managed Switches

-

A-B 1783-US7T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US4T1F Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US16T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US8T Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H/A Stratix 2000 Ethernet Unmanaged Switches—Series A

-

A-B 1783-US4T1F/B Stratix 2000 Ethernet Unmanaged Switches—Series B

-

A-B 1783-US8TG2GX Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US6T2H Stratix 2000 Ethernet Unmanaged Switches

-

A-B 1783-US5T 5 Port Unmanaged Switch

-

MOOG D138-002-002 Industrial Control Module

-

MOOG D138-003-001 Industrial Control Module

-

MOOG CA98502-001 Accessories for Ruggedized Motion Controller

-

MOOG D691-078D servo valve

-

MOOG CA65866-001 MSD Motion Controller

-

MOOG C43148-001 QD10 16/16 Digital l/0 module

-

MOOG D138-002-012 Main control unit

-

MOOG CA94286-001 Accessories for Ruggedized Motion Controller

-

MOOG D136-001-008 MSCI MSD Motion Controller

-

MOOG B95906-001 MSCI Motion Controller

-

MOOG B95865-001 CAN Termination Resistors

-

MOOG QEBUS-CAN Module

-

MOOG D136-003-001 Interfaces of Ruggedized Motion Controller

-

MOOG RDI0 16/16 Digital Module

-

MOOG D136-003-004 Interfaces of Ruggedized Motion Controller

-

MOOG D391-001-003 MSD MOTION CONTROLLER

-

MOOG D138-002-003 Industrial Control Module

-

MOOG MSC-R-10 16/8 Digital and PT100 Module

-

MOOG CB08987-001 Ruggedized Motion Controller

-

MOOG RDISP 22 Operator Panel DISPLAYS

-

MOOG D136-003-002 Interfaces of Ruggedized Motion Controller

-

MOOG CA65865-001 MSCl Motion Controller

-

MOOG B95863-001 CAN Connection Cables

-

MOOG QA10 16/4 Analog Module

-

MOOG D136-006-001 EtherCAT slave interface

-

MOOG D391-001-001 MSD MOTION CONTROLLER

-

MOOG D136-003-005 Interfaces of Ruggedized Motion Controller

-

MOOG D137-004-003 TFT Touch screen display

-

MOOG D138-002-003 Industrial Control Module

-

MOOG D138-003-010 Industrial Control Module

-

MOOG CB03223-001 Accessories for Ruggedized Motion Controller

-

MOOG B95864-001 CAN Termination Resistors

wechat/whatsapp:

+86-181-4410-0983

Email: kongjiangauto@163.com

-

ABB SYN 5025 Bus board for SYN 5302

-

ABB SYN 5020 System control

-

ABB SYN 5015 Bus board for SYN 520x

-

ABB SYN 5014 Extended I/O / seven parameter sets (option)

-

ABB SYN 5013 Processor for channel 2 (synchrocheck)

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved