ABB helps making hydrogen production robust

ABB helps making hydrogen production

robust, simple and cost efficient by offering solutions that successfully

address the challenge of water electrolysis

Every plant is unique, and so are our customers

and their needs for electrification.

Whether you want to produce hydrogen for re

sale, for on- or off-site industrial utilization, as a

reserve for electricity generation or you are sup

porting customers in building such plants – get

ting ABB on board ensures an optimal electrical

subsystem. We take a holistic approach to system

design, so that all possible eventualities are fully

considered. The solution we propose for you is

tailor made to meet your requirements and based

on close collaboration with you as our client. We

always strive for a perfect understanding of your

needs, your process and the surrounding condi

tions to configure the optimum solution, which

you can trust 100%.

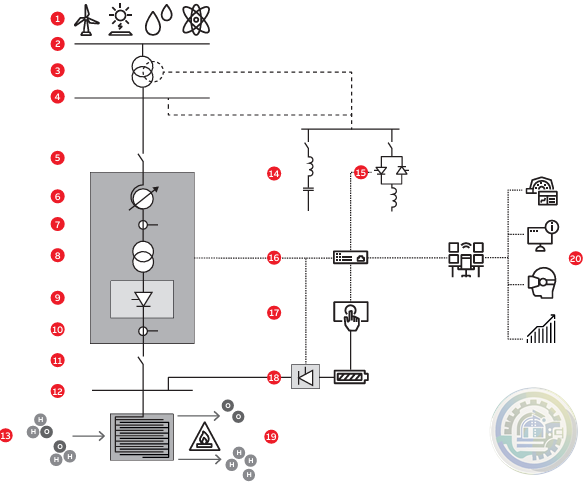

Here are some of the places where ABB fits into

the H₂ electrolysis process. We know it well and

have the track record to prove it.

1.Grid/on-site generation integration

2.HV connection and grid compliance

3.HV/MV substation

4.Medium voltage distribution

5.Medium voltage circuit breaker

6.Regulating transformer (optional)

7.AC current metering

8.Rectifier transformer

9.Rectifier

10.DC current metering

11.DC isolator

12.DC bus

13.Electrolyzer stack

14.Passive power quality systems

15.Active power quality systems (as required)

16.Local rectifier control system

17.HMI & distributed control system

18.Back-up power supply & polarization rectifier

19.Expertise in flammable environments

20.Full digital portfolio with ABB Ability™

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

-

CTI 2572-B - Fast Ethernet TCP/IP Adapter

-

CTI 2515-A - 100W AC PS w/redundancy support

-

CTI 2500-C400 CPU with 3072K User Memory

-

CTI 2500P-WB-USB CTI Janus Workbench Software Integrated Development Environment -- "JSoft"

-

CTI 2500-SSB - Single-slot blank front panel

-

CTI 2580 - 16-point Isolated 95-132 VAC Input Module

-

CTI 2500-RFC - CPU to RF Modem Cable

-

CTI 2500-C300 CPU with 512K User Memory

-

CTI 2500-C100 CPU with 128K User Memory

-

CTI 2500-TAP - RS485 Network Tap

-

CTI 2500P-ECC1 - Ethernet Communications Coprocessor

-

CTI 2500P-J450 Janus PAC with 2MB Project Memory

-

CTI 2582 - 16-point Isolated 125VDC Input Module

-

CTI 2541 - Redundant Processor Manager Module

-

CTI 2500P-JACP Janus Application Co-Processor

-

CTI 2500P-R16 Sixteen-Slot Base with High-Speed Channel

-

CTI 2500P-R4 - Four-slot base

-

CTI 2559-FPC I/O Connectors for the 2556-A

-

CTI 2500-40F 40-Position Standard Screw-Terminal Connector

-

CTI 2502 - High-speed Counter Encoder Module

-

CTI 2598 - 8/16-point 11-240 VAC Output Module

-

CTI 2531 - 32-point Form-A Relay Output Module

-

CTI 2562 - 8-Channel Analog Output Module

-

Foxboro P0700HU Termination Cable

-

Foxboro FBM42 Input Interface Module

-

FOXBORO P0700TT Embedded System Module

-

Foxboro P0500RU Termination Assembly 3 Wire

-

Foxboro P0500RG I/A Series Termination Cable

-

Foxboro P0903QF Fiber Optic Modem (End Bus) I/A Series

-

FBM214B P0924JH | Input Module | Foxboro Supplier

-

Foxboro C0136-HZ Pressure transmitter

-

Foxboro FBM201 Input Interface Module

-

FOXBORO FBM206 Channel Isolated 8 Input Supplier

-

Foxboro IMT25-PEATB1-0N-AB Magnetic Flow Transmitter

-

Foxboro AD207AV Pressure transmitter

-

Foxboro FBM39 Input Interface Module

-

Foxboro FBM44 Input Interface Module

-

Foxboro FBI10E P0972AJ Fieldbus Isolator

-

Foxboro FBM207B Input Interface Module

-

Foxboro FBM241 Input Interface Module

-

Foxboro FBM05 Input Interface Module

-

Honeywell USI-00001 Communication Card

-

Honeywell Cisco 9200 Cisco switch(With configuration parameters)

-

Honeywell SAKSI4(1A) fuse terminal

-

Honeywell FS-SICC-0001/LX X=3.25 m,5 m,6 m,8 m,10 m,15 m, 20 m,25 m and 30 m

-

Honeywell FC-TSGAS-1624 Safe gas /flame detector input FTA(0-20 mA, 16 channels)

-

ALSTOM N895609510K N895609010R E32OUT N895609100P Industrial Manufacturing module

-

ALSTOM N897163510Q N897163050Q MODEM N897163100U interface board module

-

ALSTOM N895600512D N895600051C ECPU_1 N895600200Q Industrial Manufacturing module

-

ALSTOM N897093511D N897093051D DIAGNOSTICA N897093400H Industrial Manufacturing module

-

ALSTOM N897066510E N897066010M AOVD N897066000A controller interface board module

-

Johnson Controls MS-NCE2566-0 Metasys Network Control Engine Controller

-

Johnson Controls Metasys NAE MS-NAE5510-3 Ver 10.0 Rev K Controller

-

Johnson Controls DRP-24V 48W 1AZ (rev04) CliQ DIN Rail 24 VDC Power Supply

-

Johnson Controls FIELD EQUIPMENT CONTROLLER MS-FEC2611-0ET 24VAC REV

-

Johnson Controls MS-NAE5510-ER2 Panel consisting of the Secure Network Automation Engine

-

Johnson Controls MS-NCE2560-0 NCE2560 Network Control Engine

-

Johnson Controls PAN-PWRSP-0 96 VA 120/24 VAC Power Assembly

-

MS-NCE2510-0 Networking Router by JOHNSON CONTROLS

-

Johnson Controls MS-NAE551S-702 Replacement secure NAE-S

-

Johnson Controls MS-DIS1710-0 Local Controller Display

-

Johnson Controls MS-BAT1010-0 Replacement data protection battery for secure NAE-S

-

Johnson Controls MS-FEC2621-0 17-Point FEC Field Equipment Controller

-

Johnson Controls IOM3723 INSTALLATION MANUAL

-

Johnson Controls MS-IOM2711-0 Input/Output Module

-

Johnson Controls IOM3731-0A INSTALLATION MANUAL

-

Johnson Controls DIS1710 INSTALLATION INSTRUCTIONS MANUAL

-

Johnson Controls MS-FEC1611-1 B-ASC 10-Point Field Equipment Controller

-

Johnson Controls MS-NAESCBL-0 Diagnostic cable and non-metallic reset probe

-

Johnson Controls MS-NAE551S-2 Secure NAE-S Network Automation Engine

-

Johnson Controls METASYS FEC2621 FIELD EQUIPMENT CONTROLLER MS-FEC2621-0

-

Johnson Controls MS-FAC3613-0 Field Equipment Controller

-

Johnson Controls YK-FEC2611-110 Controller

-

Johnson Controls MS-NCE2516-0 NETWORK CONTROL ENGINE

-

Rexroth HNC100-NIB-23/W-24-P-D-E23-A012 Drive module

-

Rexroth HNC100-NIB-23/W-24-P-D-E23-A012 Drive module

-

GE VME-PMC-CADDY VME-Carrier Board

-

GE IC698PSD300 Power Supply Module

-

GE HWA143-TDM-PMC-V20 Industrial TDM Module

-

GE VG5SK8I052311 PM0N2000 Digital Input Module

-

GE SR745-W3-P5-G5-HI 745 Transformer Management Relay

-

GE ESM10A Industrial Control Module

-

GE ITM11A8XJ036645 Industrial Control Module

-

GE IC695CPE310-ABAB Central Processing Unit

-

GE IC754CSX06CTD QuickPanel HMI Most Favorable

-

GE IS215VCMIH2BB IS200VCMIH2BCC VMEbus Communication Interface Card

-

GE SR745-W2-P5-G5-HI 745 Transformer Management Relay

-

GE CP238TA Multi-purpose PMC Expansion Card

-

GE PCH1026 Vibration Monitor

-

GE WES5123-1200 Substation Controller

-

GE IS420UCSCH2A-C-V0.1-A Controller Module

-

GE PRG-MODEM Multi-protocol communication

-

GE DL-1200/RTU Remote Terminal Unit

-

GE IS200EGDMH1ADF Ethernet communication module

-

GE D20 MIC 10BASE-T Communication Interface Module

-

GE IS200TRPAH2AHE Mark VIe Turbine Control Relay Module

-

GE 369-HI-0-M-F-E-0 Motor Management Relay

-

GE R-TPD3 High-Performance Industrial Control Module

-

GE 94-164136-001 Industrial Control Module

-

GE SW1-31 Control Module

-

GE 531X303MCPBDG1 AC Power Supply Card

-

GE 0880001-01 Motor Management Relay

-

GE IC660TSA100 Terminal Assembly Block

-

GE IC660ELB921M Enhanced logic bus interface module

-

GE 369-C101 Multilin Lower Control Board

-

GE IS230TVBAH2A Enhanced intelligent communication module

-

GE IS220PDIIH1B 336A5026ADP1 Discrete I/O Module

-

GE CM400RGICH1ACB gas turbine control I/O module

-

GE WES5302-150 Digital I/O / Output Interface Board

-

GE H200I Industrial Control Module

-

GE IC670MDL240K Digital Input Module

-

GE IC670CHS101 I/O Carrier Module

-

GE IC697ALG440 16-Channel Analog Input Expander Module

-

GE IC660BBD023 Bus Baseplate Module

-

GE WESCOM D200 VME Communication processor

-

GE WESTERM D20 M++ Industrial Control Module

-

GE IS200SAMBH1ABA Acoustic Monitoring Terminal PCB

-

GE BK698CPA15B0 versatile single board computer

-

GE IS200HSLAH2ADE HS Serial Link Interface Board

-

GE MS90376-12Y server driver module

-

GE IS230SNIDH1A MRP689579 isolated digital DIN-rail module

-

GE IS200SDIIH1ADB MRP683026 Digital Input Module

-

GE IC660TBA026 Terminal Assembly

-

GE DS200LDCCH1AGA Drive Control/LAN Communications Board

-

GE 369-A200 369 Motor Management Relay

-

GE IC670CBL001 I/O Carrier Module

-

GE 511-0101-08B I/O Carrier Module

-

GE IC660ELB912G MicroGENI daughterboard

wechat/whatsapp:

Email: kongjiangauto@163.com

-

ALSTOM N895609510K N895609010R E32OUT N895609100P Industrial Manufacturing module

-

ALSTOM N897163510Q N897163050Q MODEM N897163100U interface board module

-

ALSTOM N895600512D N895600051C ECPU_1 N895600200Q Industrial Manufacturing module

-

ALSTOM N897093511D N897093051D DIAGNOSTICA N897093400H Industrial Manufacturing module

-

ALSTOM N897066510E N897066010M AOVD N897066000A controller interface board module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved