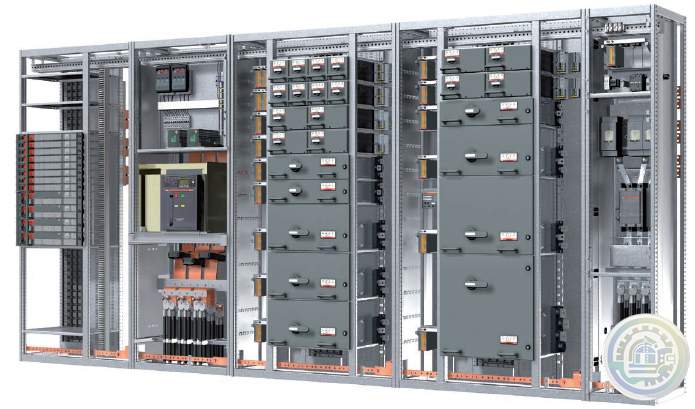

ABB MNS iS motor control center system overview

MNS iS system overview

MNS iS – Value inside

High protection and safety

MNS iS and its clear segregation of power and

control compartments offers highest personal,

system and supervision safety possibilities.

Standardization

Maximum simplicity due to standardized power

modules – fully assembled and ready to use for

a wide range of motor starter and energy

distribution modules.

Lower lifecycle costs

These are defined in three ways; less downtime,

less fault finding and less inventory.

Information variety

MNS iS offers latest HMI technology, remote

management, innovative plug and produce

technology and real time plant condition

monitoring.

Complete solution

ABB offers the possibility to provide an all in

one solution when MNS iS is used in conjunction

with other power and automation technologies

from ABB.

Pro-active maintenance

MNS iS with Condition Monitoring indicates

conditions before a failure occurs, enabling

pro-active maintenance possibilities.

User friendliness

MNS iS provides integrated user tasks, like

module supervision, lifecycle management,

contact temperature supervision and

power loss supervision.

Less engineering complexity

MNS iS is the easiest way to plan, engineer and

manage a low voltage switchgear system.

Project implementation

MNS iS helps you to reduce your project costs by

offering a shorter project duration due to high

standardization and reduced engineering.

MNS iS retains the best of MNS technology and

evolves it into the next level of operational

handling benefits for customers’ low voltage

motor control center applications.

The distinct elements in MNS iS are:

Power and control part operational safety

Physically separated and independent

operational handling of power and

control parts.

Standard power modules

Fully assembled, ready to use and offered for

a wide range of motor starter and energy

distribution modules.

Flexible control modules

Scalable for basic to complex motor starter types,

protection functions and field input/output

signal requirements.

Integrated control schematics

All starter level interlocking scheme between

control and power module is built in.

No hardwiring or input/output assignment

required. The control schematic is reduced to

assigning field I/O signal contacts only.

Measurement variables

Selectable temperature, current and voltage

measurement for various protection needs

for both motor and the switchgear itself.

No traditional transformers are utilized

for any measurements.

Information distribution as required

Industry standard communication interfaces,

such as Profibus DP, ProfiNet, Modbus RTU,

Modbus TCP and OPC are available, enabling site

wide distribution of information (operator,

maintenance, management).

System accessibility with ‘off the shelf’

web browser based devices

With an inbuilt web server functionality, the user

can select any web browser based device to

interrogate the system.

User friendliness

Self supervision of module location, module type,

power rating and automatic installation onto the

communication network.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

- Alfa Laval

-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

METSO D201505 / D201463 network controller

-

METSO ntel D33025 Motherboard

-

METSO ACN MR D201463 DCS Controller

-

METSO ACN MR D201505R DCS Controller

-

METSO ACN MR D201380 DCS Controller

-

METSO ACN MR D201139 DCS Controller

-

METSO ACN MR D202214 DCS Controller

-

METSO ACN MR D202275 DCS Controller

-

Metso D201376 Industrial Analog Input Module

-

Metso D201134 Process Control Module

-

Metso d200175 ver: 2.04 personality module

-

Metso D200137 ACN RT Node with D200175

-

METSO ACN CS CONTROLLER D201925 VER 2.15

-

METSO D100644 Electrical Automation Module

-

Kollmorgen CB06560 PRD-B040SAIB-62 Control Module

-

Servostar 310 Kollmorgen Servo Amplifier

-

Kollmorgen S20330-SRS Digital AC Servo Drives

-

Kollmorgen S22460-SRS Digital AC Servo Drives

-

Kollmorgen S70602-NANANA S700 Servo Driver

-

BJRL-20012-110001 Kollmorgen Goldline Smart Drives

-

Kollmorgen SAM-DA-400-07B-P4N-F SAM Servo Amplifiers

-

Kollmorgen CP320260 Servo Drive

-

Kollmorgen S72402-NANANA - AC servo drives

-

Kollmorgen E33NRHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen S20360-SRS Servo Drive

-

Kollmorgen E33NCHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen CR06200-000000 Servo Drive

-

Kollmorgen DIGIFAS7201 Digital Industrial Servo

-

CB06251 Kollmorgen Servo Drive

-

Kongsberg TRX32 FILTER (303067B) | Elektro Marine

-

Kongsberg MRU-M-MB3 | Motion Reference Unit

-

Kongsberg TRX32 303088 | eight-channel I/O module

-

Kongsberg MRU2 Motion Reference Unit

-

KONGSBERG MRU-M-SU1 Industrial Measurement Unit

-

Kongsberg RMP201-8 Versatile Remote Input/output System

-

Kongsberg dPSC 8100183 Dual Process Segment Controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA PW482-10 S2 Power Supply Module

-

Yokogawa SCP451-11 S1 Processor Module

-

YOKOGAWA SR1030B62 High-Frequency Module

-

Yokogawa CP451-50 S2 Processor Module

-

YOKOGAWA AAI143-H50 Analog I/O Modules

-

YOKOGAWA AMM42 2-Wire Transmitter Input Multiplexer Module

-

SDV144-S63 | Yokogawa | Digital Input Module

-

Yokogawa AIP830-111 Operation Keyboard for Single loop Operation

-

Yokogawa S9361DH00 Control Module / Terminal Board

-

Yokogawa ATK4A-00/S1 KS Cable Interface Adapter

-

YOKOGAWA PW701 Power Supply Module

-

YOKOGAWA Dual-Redundant V-Network Router AVR10D-A22010

-

YOKOGAWA PW441-10 Communication Module

-

YOKOGAWA VI451-10 S2 Communication Module

-

Yokogawa VC401-10 Coupler Modules

-

Yokogawa ALP121 PROFIBUS-DP Communication Module

-

Yokogawa NFAI841-S00/A4S00 Analog Input/Output Module

-

YOKOGAWA AIP591 Transceiver Control Module

-

YOKOGAWA AIP578 Transceiver Control Module

-

YOKOGAWA PW501 Power Supply Unit Brand

-

Yokogawa YNT511D-V42 Bus Repeater Module

-

YOKOGAWA AIP171 Transceiver Control Module

-

YOKOGAWA VI702 Vnet/IP Interface Card

-

2302-32-VLE-2 YOKOGAWA Data Acquisition Module

-

Yokogawa ATK4A-00 16-Channel KS Cable Interface Adapter

-

YOKOGAWA ALR121-S00 Serial Communication Module

-

CP461-50 | Yokogawa | Processor Module

-

Yokogawa AIP121-S00 Control Module

-

YOKOGAWA UR1800 Wireless Communication Module

-

Yokogawa| LC82 *A Redundant RL-Bus Interface Card

-

YOKOGAWA ST6 Industrial Control Module

-

YOKOGAWA ANR10D ER Bus Node Unit

-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

YOKOGAWA VO/E2/TCDM24/L8 High-Precision Temperature Controller

-

YOKOGAWA 16137-119 Process Control Module

-

YOKOGAWA 16114-500 I/O Module for Process Control Systems

-

Yokogawa PSCDM024DCBAN - Critical Discrete Module

-

YOKOGAWA 16137-151 Digital Input Module

-

YOKOGAWA 16137-188 Digital Input Module

-

YOKOGAWA 16137-222 Digital Input Module

-

YOKOGAWA 16137-223 Digital Input Module

-

YOKOGAWA 16137-153 Digital Input Module

-

Watlow SUB21/IV10 0-10 V input adaptor

-

Watlow ITOOLS/NONE/USB U SB configuration kit

-

Watlow CTR500000/000 100 A Current transformer

-

Watlow CTR400000/000 50 A Current transformer

-

Watlow CTR200000/000 25 A Current transformer

-

Watlow CTR100000/000 10 A Current transformer

-

Watlow SUB35/ACCESS/249R.1 2.49R Precision resistor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved