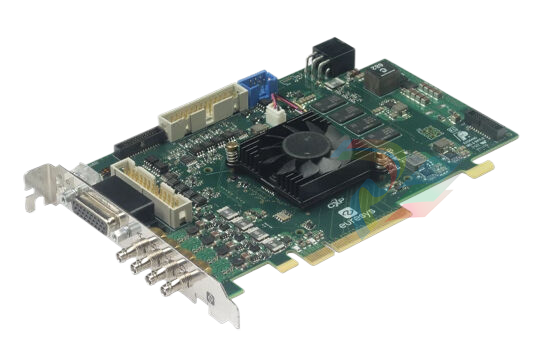

Euresys Coaxlink Quad CXP-12 Value

Advantages

PCIe 3.0 (Gen 3) x8 bus

- 7,800 MB/s peak bus bandwidth

- 6,700 MB/s sustained bus bandwidth

Connect the fastest, highest resolution cameras to capture images

- Highest data acquisition rate in the industry

- 50 Gbit/s (5,000 MB/s) bandwidth (from camera to host PC memory)

Long cable support

- 40 metres at CXP-12 speed (12.5 Gbps)

- 72 metres at CXP-6 speed (6.25 Gbps)

- 100 metres at CXP-3 speed (3 Gbps)

Power over CoaXPress

- Power over CoaXPress: The camera delivers up to 17 W per channel with 24 VDC and provides automatic device detection, measurement and overload protection.

- Total voltage and current as well as voltage and current per channel can be measured for verification and performance deviation monitoring.

Uses standard coaxial cable

- Data transfer, camera control, triggers and power supply with a single, inexpensive cable

- Top-notch reliability and flexibility for implementation in harsh environments

Micro-BNC (HD-BNC™) connectors provide reliable connections

- Trusted push-to-turn snap ring positive locking

- For quick and easy connection and disconnection

Connects up to 4 cameras to a single Coaxlink card

Memento Event Logging Tool

- Memento is an advanced development and debugging tool for Coaxlink and Grablink cards.

- Memento records an accurate log of all events related to the camera, the frame grabber card and its driver, and the application.

- For times containing timestamps, it provides developers with accurate timelines, as well as contextual information and logic analyser views.

- It can provide valuable collaboration during application development and debugging, as well as during machine operation.

Direct GPU Transfer

- Sample programs are available for AMD DirectGMA and NVIDIA (CUDA).

- GPU Direct Transfer eliminates unnecessary copies of system memory, reduces CPU overhead, and decreases latency, resulting in significant improvements in application data transfer times.

- Use AMD's DirectGMA to capture image data directly to GPU memory. Compatible with AMD FirePro W5x00 and higher and all AMD FirePro S series products.

Universal I/O Cable

- Compatible with a wide range of sensors and motion encoders

- Eight isolated current sense inputs (up to 30V, signalling up to 200kHz, individually galvanically isolated up to 250VDC and 170VAC RMS)

- Four high-speed differential inputs (quadrature motion encoder support up to 5 MHz)

- Four isolated tactile outputs (up to 30V, 100 mA, signalling up to 100 KHz)

- Four high-speed 5V-compatible TTL inputs/LVTTL outputs (signalling up to 5 MHz)

High performance DMA (Direct Memory Access)

- Direct transfers to user-allocated memory and hardware boards displaying PCI addresses

- Hardware Dispersal - Aggregation Support

- 64-bit addressing capability

Area Scan Trigger Function

- Triggers are used to initiate acquisition when a part is in place. Hardware triggers come from Coaxlink's I/O lines. Software triggers are from the application.

- Controllable delay triggers to control the point at which image acquisition is delayed.

- Trigger extraction feature allows certain triggers to be skipped.

- Camera exposure control allows the application to control the exposure time of the camera.

- When the system starts to acquire images, the Coaxlink capture card generates a signal at an appropriate point in time to control the lighting equipment connected to the output.

Line Scan Trigger Capability 1/2

Coaxlink supports both continuous roll scanning (to inspect infinite, continuously moving surfaces without losing lines) and discrete target scanning (to capture images of targets moving in front of the camera).

(to capture images of targets moving in front of the camera).

- Triggers are used to initiate acquisition when the part is in position. Hardware triggers are from the motherboard I/O lines. Software triggers come from the application.

- Once initiated, the acquisition will continue indefinitely (for rolling the network):

- Continue indefinitely (for rolled-net monitoring applications)

- continue for a programmable number of lines (to acquire a target image of known length)

- continue until an end trigger signal is received (to acquire variable length target images)

- Controllable delay trigger to delay the start of acquisition by a programmable number of lines.

Line Scan Trigger Capability 2/2

- The Coaxlink image acquisition card controls the camera scan rate based on signals received from the motion encoder. If the part is moving faster, the camera's acquisition line rate will increase.

increases. If the part is moving slower, the camera's acquisition line rate decreases.

- The Coaxlink board interprets the A/B signals from the Quadrature Motion Encoder to know in which direction (forward or backward) the part is moving.

- The Coaxlink card can also be commanded to acquire laser lines when the object is moving only forwards or only backwards.

- When a backward movement is detected, the function called ‘Backward movement cancellation’ stops the acquisition. Line acquisition is automatically resumed when forward motion is resumed at the position where acquisition was interrupted.

- The rate converter enables the camera to acquire lines at any programmable resolution below or above the resolution of the motion encoder. This provides designers with an amazing degree of freedom in the application development process.

This provides designers with amazing freedom and flexibility in the application development process.

- The rate splitter allows the camera to acquire images at a resolution higher or lower than that of the motion encoder, and is implemented by splitting the encoder input signal using a programmable integer multiple.

input signal using a programmable integer multiplier.

Line-scan Metadata insertion

When activated, this feature records metadata beside image data. Line metadata are captured every acquired image line.

Buffer metadata are only captured when the first image line of a buffer is acquired.

The metadata are composed with a configurable set of general purpose event counters, quadrature encoder

The metadata are composed with a configurable set of general purpose event counters, quadrature encoder position counters and/or I/O line status.

This feature allows line-scan applications to correlate image data with system events including motion encoder

positions.

Flexible line-scan camera operation through rate converters

- The rate converter is an intelligent, programmable frequency doubler/divider.

- Used with motion encoders and line-scan cameras, it allows the user to select the aspect ratio of pixels in that image.

- It provides a way to calibrate the acquisition chain to easily achieve square (1:1 aspect ratio) pixels.

C2C-Link Camera Synchronisation

Precise synchronisation of multiple connected facescan or linescan cameras

- Same card

- Different cards in the same PC

- Different cards in different PCs

Compatible with eGrabber

- eGrabber Studio: eGrabber's new interactive evaluation and demonstration application.

- GenICam Browser: This application provides access to the GenICam functionality in GenTL Producer.

- GenTL Console: This command line tool provides access to the functions and commands of the Euresys GenTL Producer.

Genicam compliant

Includes support for

- GenApi

- Standard Functional Naming Convention (SFNC)

- GenTL

Windows, Linux and macOS drivers available

- Support for Intel 64-bit platforms as well as ARM 64-bit platforms

Applications

Machine vision for electronics manufacturing

- High-speed image acquisition for AOI, 3D SPI, 3D lead/ball inspection machines.

- Very high resolution line scan image acquisition for flat panel display inspection and solar cell inspection

- Marker inspection

Machine vision for general manufacturing

- High frame rate image acquisition for inspection machines

- Line scan image acquisition for surface inspection machines

- Line scan image acquisition for textile inspection

- Robotic image acquisition

Machine vision for the printing industry

- High Speed Line Scan Image Acquisition for Print Inspection Machines

Video Capture and Recording

- High frame rate video capture for motion analysis and recording

Video Surveillance, Monitoring and Security

- Transmission and capture of HD video over long distance coaxial cables for traffic monitoring, surveillance and control

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA PW482-10 S2 Power Supply Module

-

Yokogawa SCP451-11 S1 Processor Module

-

YOKOGAWA SR1030B62 High-Frequency Module

-

Yokogawa CP451-50 S2 Processor Module

-

YOKOGAWA AAI143-H50 Analog I/O Modules

-

YOKOGAWA AMM42 2-Wire Transmitter Input Multiplexer Module

-

SDV144-S63 | Yokogawa | Digital Input Module

-

Yokogawa AIP830-111 Operation Keyboard for Single loop Operation

-

Yokogawa S9361DH00 Control Module / Terminal Board

-

Yokogawa ATK4A-00/S1 KS Cable Interface Adapter

-

YOKOGAWA PW701 Power Supply Module

-

YOKOGAWA Dual-Redundant V-Network Router AVR10D-A22010

-

YOKOGAWA PW441-10 Communication Module

-

YOKOGAWA VI451-10 S2 Communication Module

-

Yokogawa VC401-10 Coupler Modules

-

Yokogawa ALP121 PROFIBUS-DP Communication Module

-

Yokogawa NFAI841-S00/A4S00 Analog Input/Output Module

-

YOKOGAWA AIP591 Transceiver Control Module

-

YOKOGAWA AIP578 Transceiver Control Module

-

YOKOGAWA PW501 Power Supply Unit Brand

-

Yokogawa YNT511D-V42 Bus Repeater Module

-

YOKOGAWA AIP171 Transceiver Control Module

-

YOKOGAWA VI702 Vnet/IP Interface Card

-

2302-32-VLE-2 YOKOGAWA Data Acquisition Module

-

Yokogawa ATK4A-00 16-Channel KS Cable Interface Adapter

-

YOKOGAWA ALR121-S00 Serial Communication Module

-

CP461-50 | Yokogawa | Processor Module

-

Yokogawa AIP121-S00 Control Module

-

YOKOGAWA UR1800 Wireless Communication Module

-

Yokogawa| LC82 *A Redundant RL-Bus Interface Card

-

YOKOGAWA ST6 Industrial Control Module

-

YOKOGAWA ANR10D ER Bus Node Unit

-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

YOKOGAWA VO/E2/TCDM24/L8 High-Precision Temperature Controller

-

YOKOGAWA 16137-119 Process Control Module

-

YOKOGAWA 16114-500 I/O Module for Process Control Systems

-

Yokogawa PSCDM024DCBAN - Critical Discrete Module

-

YOKOGAWA 16137-151 Digital Input Module

-

YOKOGAWA 16137-188 Digital Input Module

-

YOKOGAWA 16137-222 Digital Input Module

-

YOKOGAWA 16137-223 Digital Input Module

-

YOKOGAWA 16137-153 Digital Input Module

-

Watlow SUB21/IV10 0-10 V input adaptor

-

Watlow ITOOLS/NONE/USB U SB configuration kit

-

Watlow CTR500000/000 100 A Current transformer

-

Watlow CTR400000/000 50 A Current transformer

-

Watlow CTR200000/000 25 A Current transformer

-

Watlow CTR100000/000 10 A Current transformer

-

Watlow SUB35/ACCESS/249R.1 2.49R Precision resistor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

-

SC200S | Yokogawa Electric Corporation

-

Yokogawa PW301 Power Supply

-

YOKOGAWA NP53*C - Precision Control Module

-

Yokogawa F3YD64-1A Basic Input/Output Modules

-

Yokogawa F3XD64-3N Basic Input/Output Modules

-

Yokogawa F3WD64-3N Input/Output Module

-

Yokogawa F3SP21-0N CPU Module

-

YOKOGAWA F3PU10-0N Power Supply Module

-

YOKOGAWA F3PU06-0N Power Supply Module

-

YOKOGAWA F3NC02-0N Positioning Module

-

YOKOGAWA F3NC01-0N Positioning Module

-

YOKOGAWA PLC F3LC21-1N MULTI-LINK MODULE

-

YOKOGAWA F3BU06-0N Base Module

-

Honeywell DC-TFB412 51307618-176 Control Module

-

Honeywell DC-TCF901 51307593-176 9-Port Control Firewall Module

-

Honeywell DC-TCF901 cutting-edge control module

-

Honeywell DC-TFB412 Circuit Board

-

LVCDJW00000750A Watlow (Temperature Limit Controller)

-

Watlow 84700-0003 Dust cover

-

Watlow 847290006 USB type A panel mount with 2 m cord

-

Watlow RJF 21N SCC RJ45 receptacle with self closing cap

-

Watlow USBBF 21N SCC USB - B receptacle with self closing cap

-

Watlow USBF 21N SCC USB - A receptacle with self closing cap

-

Watlow 0600-0097-0000 Mixed I/O Flex Modules Quick Start Guide

-

Watlow 0600-0096-0000 High Density Flex Modules Quick Start Guide

-

Watlow 0600-0095-0000 Communications Flex Modules Quick Start Guide

-

Watlow 0600-0094-0000 F4T Controller Quick Start Guide

-

Watlow 0600-0093-0000 Setup and Operations User Guide

-

Watlow 0600-0092-0000 Installation and Troubleshooting User Guide

-

Watlow 0822-0769-0000 Module slot plug (for vacant F4T slots without flex modules

-

Watlow 0830-0858-0000 Replacement battery

-

Watlow 0830-0808-0002 (CAPUSB-A) Rubber plug USB host

-

Watlow 0830-0808-0001 (CAPUSB-MB5) Rubber plug USB mini

-

Watlow 0601-0001-0000 Controller support tools (DVD)

-

Watlow 0804-0147-0000 RC supression - Quencharc®

-

Watlow 16-0246 Current transformer

-

HIMA K9212 Safety Relay Output Module

-

Watlow 0238-1245-BLUE Accent bar (brushed aluminum blue)

-

804B-1600-0000 Watlow (1/4 DIN Digital Temperature Controller)

-

EM00-GATE-0000 Computer Accessory by WATLOW

-

DC10-60F0-0000 SCR Power Control by WATLOW

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved