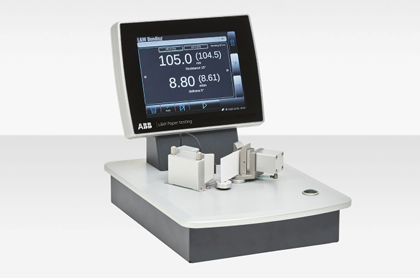

ABB L&W Bending Tester Testing and industry-specific instruments

ABB’s L&W Bending Tester is an easy-to-use and reliable instrument

that measures bending resistance and stiffness of paper and board.

Enhanced automation and digitalization allow mills to meet target

specifications and ensure product performance in converting and

end-use operations.

Overview

The L&W Bending Tester offers the best available features for

ease-of-use, automation, customiza tion, and digitalization,

for easy, fast, operator independent testing that gives reliable

and repeat able measurement results that mills require to

ensure customer specifications are being met.

Benefits

• Easy to use and customize

• Ergonomic operation

• Fast, operator-independent testing

• Reliable and repeatable results

• Streamlined lab data management

Features

• Large touchscreen with user-friendly interface

• Test piece support and automatic clamping for easy and precise

test piece loading

• Enhanced auto-touch function with improved post-processing

for faster, operator independent testing

• Ergonomically placed start button

• Quick overview of results

• Graphical display of bending curve with break angle/force indication

for analysis

• Bending length detection for ensuring correct program settings

• Adjustable bending angle

• Adjustable angular testing speed

• Easy instrument check and calibration

• Bending lengths of 1. 5. 10. 15. 20. 25 and 50 mm

• Available with 1N, 5N or 10N load cells

• Optional 25 mm sample support available

Ease of operation

L&W Bending Tester is easy to use with a large touchscreen interface

and intuitive menus, saving operator time and effort. Operators can

quickly change settings from the screen, with correct authorization.

It provides easy calibration and simple instrument check with included

check plate and gives a quick overview of results for an entire series.

The bending curve with break angle/force in dication allows quick analysis

of the test to identify any erroneous measurements.

Operation is automated once the operator hits start. First, the instrument

is connected to power and pressurized air, and the operator selects either

a standard or pre-set, custom program. The pre cisely cut test piece can

be easily loaded in the measuring clamps and correctly aligned with the

loadcell with the help of sample support.

The operator simply places the test piece inside the clamp with one hand,

while the other hand starts operation with the ergonomically placed start

button. The clamps are automatically closed with fixed pressure for precise

measurement.

Bending length detection ensures that the bending length selected in program

settings matches the manually set bending length, or otherwise warns the

operator with an error message.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

- Alfa Laval

-

Foxboro P0917XV Compression Termination

-

Foxboro FBM206 Input Interface Module

-

Foxboro P0961BS Buss Connector

-

Foxboro FBM216 Input Interface Module

-

Foxboro p0903nu 1X8 Cell Sub Assembly

-

Foxboro P0911SM Industrial Control Module

-

Foxboro CM902WM I/A Series Industrial Power Module

-

Foxboro CM902WL I/A Series Industrial Power Module

-

Foxboro P0972VA Address Translation Station

-

Foxboro P0916Js Terminal Block Brand

-

Foxboro FBM203 Input Interface Module

-

Foxboro P081000000FF IPM02 Power Supply/Switching Board

-

Foxboro ZCP270 Control Processor Module

-

Foxboro PO961BC/ CP40B Industrial Control Module

-

Foxboro PO916JS Control Module

-

Foxboro PO911SM Field bus module

-

Foxboro P0972PP-NCNI Network Interface Module

-

Foxboro P0971XU I/A Series Control Module

-

Foxboro P0971QZ Control Module

-

Alfa Laval i-OC-XL Modular composite boiler

-

Alfa Laval i-OC-L Modular composite boiler

-

Alfa Laval i-OC-M Modular composite boiler

-

Alfa Laval i-OC-S Modular composite boiler

-

Kollmorgen AKT2G-AC-FAN-001 fan cartridge

-

Kollmorgen AKT-AN-820-000 8-Channel Analog Input Terminal

-

Kollmorgen 4-Channel Analog Input Terminal (AKT-AN-420-000)

-

METSO D201379 PC Board PLC & ADD-ON Board

-

Metso PDP403 Distributed Processing Unit

-

METSO D201505 / D201463 network controller

-

METSO ntel D33025 Motherboard

-

METSO ACN MR D201463 DCS Controller

-

METSO ACN MR D201505R DCS Controller

-

METSO ACN MR D201380 DCS Controller

-

METSO ACN MR D201139 DCS Controller

-

METSO ACN MR D202214 DCS Controller

-

METSO ACN MR D202275 DCS Controller

-

Metso D201376 Industrial Analog Input Module

-

Metso D201134 Process Control Module

-

Metso d200175 ver: 2.04 personality module

-

Metso D200137 ACN RT Node with D200175

-

METSO ACN CS CONTROLLER D201925 VER 2.15

-

METSO D100644 Electrical Automation Module

-

Kollmorgen CB06560 PRD-B040SAIB-62 Control Module

-

Servostar 310 Kollmorgen Servo Amplifier

-

Kollmorgen S20330-SRS Digital AC Servo Drives

-

Kollmorgen S22460-SRS Digital AC Servo Drives

-

Kollmorgen S70602-NANANA S700 Servo Driver

-

BJRL-20012-110001 Kollmorgen Goldline Smart Drives

-

Kollmorgen SAM-DA-400-07B-P4N-F SAM Servo Amplifiers

-

Kollmorgen CP320260 Servo Drive

-

Kollmorgen S72402-NANANA - AC servo drives

-

Kollmorgen E33NRHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen S20360-SRS Servo Drive

-

Kollmorgen E33NCHA-LNN-NS-00 Precision Motion Control Module

-

Kollmorgen CR06200-000000 Servo Drive

-

Kollmorgen DIGIFAS7201 Digital Industrial Servo

-

CB06251 Kollmorgen Servo Drive

-

Kongsberg TRX32 FILTER (303067B) | Elektro Marine

-

Kongsberg MRU-M-MB3 | Motion Reference Unit

-

Kongsberg TRX32 303088 | eight-channel I/O module

-

Kongsberg MRU2 Motion Reference Unit

-

KONGSBERG MRU-M-SU1 Industrial Measurement Unit

-

Kongsberg RMP201-8 Versatile Remote Input/output System

-

Kongsberg dPSC 8100183 Dual Process Segment Controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA PW482-10 S2 Power Supply Module

-

Yokogawa SCP451-11 S1 Processor Module

-

YOKOGAWA SR1030B62 High-Frequency Module

-

Yokogawa CP451-50 S2 Processor Module

-

YOKOGAWA AAI143-H50 Analog I/O Modules

-

YOKOGAWA AMM42 2-Wire Transmitter Input Multiplexer Module

-

SDV144-S63 | Yokogawa | Digital Input Module

-

Yokogawa AIP830-111 Operation Keyboard for Single loop Operation

-

Yokogawa S9361DH00 Control Module / Terminal Board

-

Yokogawa ATK4A-00/S1 KS Cable Interface Adapter

-

YOKOGAWA PW701 Power Supply Module

-

YOKOGAWA Dual-Redundant V-Network Router AVR10D-A22010

-

YOKOGAWA PW441-10 Communication Module

-

YOKOGAWA VI451-10 S2 Communication Module

-

Yokogawa VC401-10 Coupler Modules

-

Yokogawa ALP121 PROFIBUS-DP Communication Module

-

Yokogawa NFAI841-S00/A4S00 Analog Input/Output Module

-

YOKOGAWA AIP591 Transceiver Control Module

-

YOKOGAWA AIP578 Transceiver Control Module

-

YOKOGAWA PW501 Power Supply Unit Brand

-

Yokogawa YNT511D-V42 Bus Repeater Module

-

YOKOGAWA AIP171 Transceiver Control Module

-

YOKOGAWA VI702 Vnet/IP Interface Card

-

2302-32-VLE-2 YOKOGAWA Data Acquisition Module

-

Yokogawa ATK4A-00 16-Channel KS Cable Interface Adapter

-

YOKOGAWA ALR121-S00 Serial Communication Module

-

CP461-50 | Yokogawa | Processor Module

-

Yokogawa AIP121-S00 Control Module

-

YOKOGAWA UR1800 Wireless Communication Module

-

Yokogawa| LC82 *A Redundant RL-Bus Interface Card

-

YOKOGAWA ST6 Industrial Control Module

-

YOKOGAWA ANR10D ER Bus Node Unit

-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

YOKOGAWA VO/E2/TCDM24/L8 High-Precision Temperature Controller

-

YOKOGAWA 16137-119 Process Control Module

-

YOKOGAWA 16114-500 I/O Module for Process Control Systems

-

Yokogawa PSCDM024DCBAN - Critical Discrete Module

-

YOKOGAWA 16137-151 Digital Input Module

-

YOKOGAWA 16137-188 Digital Input Module

-

YOKOGAWA 16137-222 Digital Input Module

-

YOKOGAWA 16137-223 Digital Input Module

-

YOKOGAWA 16137-153 Digital Input Module

-

Watlow SUB21/IV10 0-10 V input adaptor

-

Watlow ITOOLS/NONE/USB U SB configuration kit

-

Watlow CTR500000/000 100 A Current transformer

-

Watlow CTR400000/000 50 A Current transformer

-

Watlow CTR200000/000 25 A Current transformer

-

Watlow CTR100000/000 10 A Current transformer

-

Watlow SUB35/ACCESS/249R.1 2.49R Precision resistor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved