A-B 1326AB 460V, Torque Plus Series, AC Servo Motors

Product Data

This publication provides product information about the 2.3 to 53.0 N-m (20.7 to 469.0 lb-in.) 1326AB 460V Torque Plus Series, AC Servo Motors.

This publication includes:

• Detailed lists of the features and options available for 1326AB 460V, Torque Plus Series, AC Servo Motors

• Tables that show how to determine the catalog numbers for the motors and options you need

• Performance data and speed-torque curves for all 1326AB 460V Torque Plus Series, AC Servo Motors

• Servo motor dimensions

• Details on holding brakes, shaft oil seal kits, encoder mounting adapters and junction boxes

• High-resolution feedback motors

Servo Motor Description

Torque Plus motors feature a specially engineered housing that reduces motor length and increases continuous torque ratings.

These high performance, three-phase, brushless, AC, synchronous servo motors are designed by Allen-Bradley to meet the stringent

requirements of high performance motion systems. This series of 460V, AC servo motors is intended to be used with the Allen-Bradley

1394 Motion Control System.

Each servo motor features:

• Special flux profile permanent magnets engineered by Allen Bradley to increase servo response.

• A three-phase, sinusoidal-wound stator field for smooth operation at low speeds.

• TENV construction. IP65 is standard. IP67 (-L) option is available with optional shaft seal (1326AB-MOD-SSV-xxx) installed.

• An extruded aluminum housing for improved heat transfer.

• 100% continuous-rated output torque at stall (zero rpm).

• A UL Listed insulation system (file #E57948).

• The ability to be vertically mounted at any angle with the shaft up or down.

• A normally closed thermal switch in the motor winding (rated 115V AC/ 24V DC at 1A) that provides thermal overload indication.

• A precision balance of 0.0127 mm (0.0005 in.) total peak-to-peak displacement.

• A CEI/IEC 72-1 metric flange mount with metric shafts.

• A threaded hole on the face of the shaft for securing couplings.

Feedback Options

1326AB servo motors are available with either resolver (standard) or high-resolution encoder feedback devices.

Resolver-based servo motors feature:

• A rugged, brushless resolver that provides accurate position feedback, eliminates the need for on-board electronics and can

withstand harsh shock, high operating temperatures, and vibration.

• Resolver feedback generates (2048ppr) A quad B encoder output.

High-resolution servo motors are available in single or multi-turn configurations that provide high-resolution encoder feedback for

applications requiring precise tolerance:

• Single-turn (-S) configuration provides precise machine positions of two million counts per revolution.

• Multi-turn (-M) configuration provides accurate absolute machine positions over multiple revolutions (no batteries needed) to eliminate machine re-homing on

power-up. It provides one million counts of feedback per revolution and absolute positioning within 4,096 revolutions.

• Both configurations feature on-board EEProm memory for storing motor configuration information.

Important: High-resolution feedback can only be used with the 9/440 high-resolution feedback CNC.

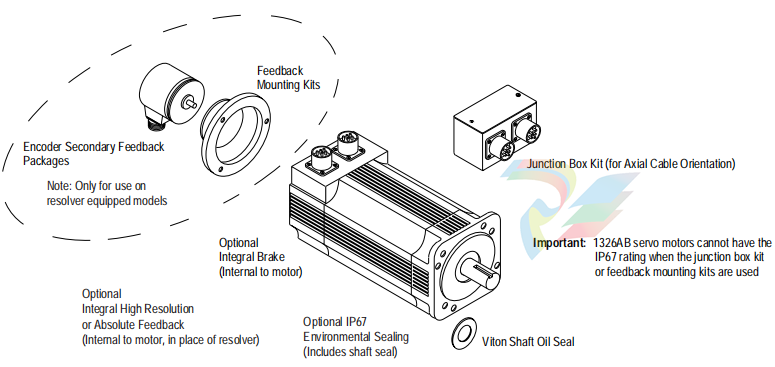

Servo Motor Options

Options available for the 1326AB 460V AC Torque Plus Series include (the option code or catalog number is in parenthesis):

• Integral Spring-Set Holding Brakes with 24V DC coils (-K4, -K5, -K7).

• A Shaft Oil Seal kit, (1326AB-MOD-SSV-xx) for installing a Viton shaft oil seal on a motor in the field. Motor disassembly is not required.

When the shaft oil seal is installed, the motor is dust tight, able to withstand pulsating water jets, and meet the IP65 requirements of the IEC 529 standard.

Important: IP67 (-L) servo motors have a factory-installed shaft oil seal and do not require the Shaft Oil Kit option.

• Secondary Feedback Mounting Kits (1326AB-MOD-Mxx) for installing an Allen-Bradley Encoder (845H) in the field.

Note: Not available for high-resolution motors.

If you are using a 1326AB-Bxxx Servo Motor with a 1394 Servo System you do not need to mount a secondary encoder because the 1394 derives A Quad B

feedback output (2048 ppr) from the motor feedback.

Important: 1326AB servo motors lose the IP65 or IP67 rating when an externally mounted encoder package is used.

• IP67 (-L) servo motors. The IP67 rating (IEC 529) provides environmental protection from the effects of temporary immersion in water.

Important: 1326AB servo motors lose the IP67 rating when the externally mounted encoder or the junction box kit options are used.

• A Junction Box Kit (1326AB-MOD-RJxxx) with axially-mounted connectors is available with either front or rear exit connections.

Right-angle connector cables are also available (refer to 1326 Cables for 460V AC Servo Motors, publication 1326A-2.11).

The junction box allows the motor connectors to be brought out axially (rather than radially) to the motor without further wiring.

Important: 1326AB servo motors lose the IP67 rating when the junction box kit option is used.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

-

Deif Du-2 / Mkiii Multil neas Ppm Protecci n Y Gesti n de Energ a 100-690vac

-

DEIF AGC 222 & IOM 220 advanced genset controller

-

Deif Delomatic 4 DGU 0005 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF PPM-3-DG PROTECTION AND POWER MANAGEMENT MEAS.VOLTAGE:100-690VAC, 0.5MA

-

DEIF AGC Plant Management (Genset Controller) 100132445.10

-

Deif Delomatic 4 DGU 0002 Generator Control System PCM 4-1, IOM 4-1, SCM 4-2

-

DEIF 879.3C Dynamic Wind Sensor with MIC-4224 Display suit Marine

-

DEIF MDR-2 MULTI DIFFERENTIAL PROTECTION RELAY

-

Generator Control Unit Deif Delomatic 4 DGU 0001

-

DEIF DELOMATIC 4 DGU 0001 CONTROLLER

-

DEIF MTR-4-415 1200510024 Multi-transducer

-

Deif DPD 04057 Printed Circuit Board 1044230020F

-

DEIF AGC 252 advanced Genset Controller 2912420010.39 Options -C2-N

-

Deif AGC/GS/3.6 Automatic genset controller 600043767.80

-

Deif GPU/2/GS Generator Protection Unit

-

DEIF AGC-4/GS/4.4 Advanced Genset Controller Option-G5-G7-I1-M12-M13.6-N-J1

-

DEIF PPU-2-GS-100033222.50 PROTECTION AND POWER MANAGEMENT SYSTEM

-

DEIF PPU/2/GS Protection & Paralleling Unit + Operator Panel + Connector cable

-

DEIF PPU-2-GS-100059909.10 WITH DISPLAY AND CABLE PROTECTION

-

DEIF PPU-2-GS 600033613.10 WITH DISPLAY GENERATOR UNIT

-

Deif Delomatic-3 Generator Control Panel System Panel CP-1 | 1044220050D

-

Caterpillar Branded DEIF MCS2 Controller

-

Deif Paralleling & Protection Unit PPU-3 100121906.10 600V

-

A-B 20G11BC1K1JN0NNNNN PowerFlex Air Cooled 755 AC Drive

-

A-B 20P41AF452RA0NNN PowerFlex 452 A DC Drive

-

A-B 20GHAJC540JN0NNNNN PowerFlex Extra Tough 755 AC Drive

-

EPRO MMS6823 9100-00001-05 Displacement Monitor Module

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

-

General Electric 1253-0003-C4 Multilin Analog & I/O Board 369-A200

-

Ge Panametrics Crs-10-Mb Ultrasonic Flow Converter

-

GE PROPRIETARY IS215WEPAH2BB With IS210BPPCH1AD CONTROL BOARD

-

GE MULTILIN / 12P0-0001-P2 / Powerr Supply Board, 870500.DWG, 870501.DWG

-

GENERAL ELECTRIC PL19A129393G4 Auxiliary Receiver in Wall-mount Cabinet

-

GE CR306F002XAAA Nema-4 Coil 115-120V 60Hz 110-50Hz 600Vac Magnetic Contactor

-

General Electric 193x190bag02 ISOL P/S Board I93XI90BAG02 Computer board GE

-

GE Multilin / G6P3CH / Front Panel, G60 Generator Management Relay

-

GE MMY30-R1D26 DewPro MOISTURE TRANSMITTER

-

GE Drive Control Board 531X302DCIBDG2

-

General Electric SKLA36AT1200B Industrial Circuit Breaker 3Pole 600V / SRPK1200

-

GE CR2962E1A4 Plugging Switch 1600 RPM Max Speed Flange Mount

-

GE IS210AEACH1ABB Platine Card Sealed

-

GE EVEREST XLG3 Industrial Videoscope Sit 100-240V 50-60 Hz

-

GE DS215DMCBG1AZZ03B / DS200DMCBG1ALG board

-

2H400489-0 REV 0 GE STATIC SENCITIVE BOARD A72 RPVM3

-

GE DM4E 1PC GE DM4E Ultrasonic Thickness Gauge Equipped with DA301 probe

-

GE DS200TCQAG1BED / DS200TCQAG1BED Analog IO Board

-

GE ENERGY PIB101C ANALOG I/O PIB MODULE PIB-101C

-

GE IC200CPUE05-HK VersaMax CPU Module IC200CPUE05

-

Ge Multilin F60 F6P3LA Feeder Protection System Brand

-

GE Intelligent IC695ALG112-DA RX3i 12 channel isolated analog input module

-

GE IS200WETBH1BBA Wind Turbine Control Panel PCB

-

GE Mark VI IS200HSLAH3A Genuine High-Speed Serial Link Interface Board

-

GE IS200TRLYH1BFD TERMINATION RELAY BOARD FOR MARK VI SYSTEM/JUA1221

-

GE XAMP-1-1-2-0 Adapter Converter With Enclosure

-

General Electric 1253-0002-C2 Multilin Upper Control Board 369-C100

-

GE Multilin 350 Feeder Protection Relay Controller Monitor Industrial Power

-

UR RHH / 12A0-0101-B4 GENERAL ELECTRIC MULTILIN POWER MODULE URRHH

-

GE MULTILIN / 12P0-0042-A5 / High-Density Input Board

-

GE MULTILIN / 12P0-0039-A1 / Digital Output Board

-

GE IS220UCSAH1A UCSA PWA Embedded Controller Mark VIe Gas Turbine Processor

-

GE RX3i PLC MODULE IC694MDL754-ED IC695MDL754

-

GE Multilin C60 Breaker Management Relay C60K03HKHF8LH6NM8LP6UUXXW7H

-

F31X139APMALG2 | GE Fanuc | Micro Application Board

-

GE HORNER ELECTRIC HE670ADC810D ANALOG INPUT MODULE

-

GE TRANSPORTATION LOCOTROL 7000069-910 REV. ZAE/D

-

GE Multilin / M6P3KH / Front Panel, M60 Motor Management Relay

-

GE 5CD124TP001B 2HP DC Motor 1750RPM 180V TEFC CD149ATC-PM

-

General Electric Ge RCC48 Lighting Controller Card

-

GENERAL ELECTRIC CR306F002XABA MAGNETIC STARTER

-

HE697THM160 GE Fanuc Series 90-70 Thermocouple Input Module, 16 Channel

-

GE 2298332 Digital Receiver and Filter II DRF2 2298333

-

GENERAL ELECTRIC DS3800NMEA1P1J CIRCUIT BOARD

-

GE 961529800 AVR Utilities Card S961529800 Prismic A30-M Controller

-

GE VMIVME 4140-000 VMEbus Analog Input I/O Module

-

GE VMIVME 3215-000 Computer module

-

GE IS215UCVFH2BB VMIVME-7650-83H 350-007650-83H C Control Module

-

GE VMIVME-7750 VMIVME-7750-834 350-027750-834 D Single Board Computer

-

GE V7668A-1310B0 350-9310007668-131020 Single Board Computer

-

GE IS220PRTDH1A 336A4940CSP6 Resistance Temperature Device

-

GE IS220PSCAH1A 336A4940CSP9 Serial Modbus Communication Interface Pack

-

GE SR745-W2-P1-G1-HI-A-L-R 745 Transformer Management Relay

-

GE SR745-W2-P1-G1-HI-A-L-R-E 745 Transformer Management Relay

-

GE WES13-3 2508-21001 Control Board Module

-

GE SR489-P5-H1-A20 Advanced Generator Protection

-

GE SR489-P5-LO-A20 Advanced Generator Protection

-

GE V7865-23003 350-9300007865-230003 M VMEbus Module

-

GE VME7865RC V7865-23003 350-9300007865-230003 M VMEbus Module

-

KEBA CU312/E Customized Controller

-

KEBA K2-200 CP253/W Input/Output Module

-

KEBA CU313 Large-Scale Complex Control Module

-

KEBA AR281 Industrial Control Module

-

KEBA CP450 Driver module

-

KEBA OP341/Y-1400 | Operator Panel

-

KEBA CP033/Y | Control Panel / Operator Interface

-

KEBA SI232 International Standard Field-Level Controller

-

KEBA PS244 Power Supply Module

-

KEBA DO321 | Digital Output Module

-

KEBA IP706 Industrial Control Module

-

KEBA CU313/B-SI/58626/09 Custom Processed Control Module

-

KEBA CU313A Large-Scale Complex Control Module

-

KEBA FB201 I/O modules

-

KEBA CP450/C Driver module

-

KEBA PS244/A Power Supply Module

-

KEBA EC100S High-Precision Industrial Controller

-

KEBA DI325 | Digital Input Module

-

Honeywell XNX-UTAV-RNIF1 XNX Universal Transmitter

-

Honeywell 51305896-200 NIM MODEM

-

HONEYWELL LG1093AA24 261A1812P012 FLAME SENSOR

-

HONEYWELL CC-TUIO41 Universal Input Output Module

-

Honeywell J-DIM00 Industrial Control Module

-

HONEYWELL 51403892-100 Carrier Channel Assy Assembly CC-MCAR01 Module

-

HONEYWELL 82408217-001 Analog Input Module

-

Honeywell J-MSC10 Output Circuit Control Module

-

Honeywell 51202329-606 I/O Link Header Cable

-

51403519-160 K4LCN-16 Honeywell 16M LCN Processor Board

-

Honeywell 05704-A-0146 5704F Fire Card

-

Honeywell SC-UCMX01 51307195-175 Controller Module

-

Honeywell FC-PUIO01 TUIO11 Universal Safety I/O

-

Honeywell CC-TCNT01 51308307-175 Input/Output Module

-

Honeywell 51196655-100 ACX633 Switchmode Power Supply

-

Honeywell Fc-psu-uni2450U V1.0 Power Supply 24Vdc

-

Honeywell SC-UCMX01 51307198-175 Remote Terminal Unit

-

Honeywell 51196653-100-RP Controller Module

-

Honeywell FTA-T-14 Digital Input Module Brand

wechat/whatsapp:

Email: kongjiangauto@163.com

-

GE LP-33 SERIES UPS DISPLAY & CONTROL PANEL LP33

-

GE CL06A300M IEC Contactor (50 Amp)

-

GE CR2962F2D Plugging Switch NIB

-

General Electric IC500A411DG2 Electrical Rectifier Semiconductor

-

GE IS200BICLH1AFE Interface Module 259B2431DB-G01 BICLH1A

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved