Emerson DeltaV™ Digital Automation System Concepts

DeltaV System Concepts

The DeltaV system helps users create process control systems that are easy to set up,

easy to operate, consistent, and secure. To accomplish these goals, the DeltaV system

uses the following:

Plug-and-play technology for hardware configuration

A library of reusable control modules to simplify the initial configuration effort

Techniques like drag-and-drop to simplify system configuration and modification

Consistent graphical interface similar to that of the Microsoft Windows operating

environment

Integrated, context-sensitive help and online documentation

Hardware and software approaches to ensure system security and integrity

A Configuration Assistant that steps you through the configuration process,

configuring the system while teaching you the fundamentals

Terminology

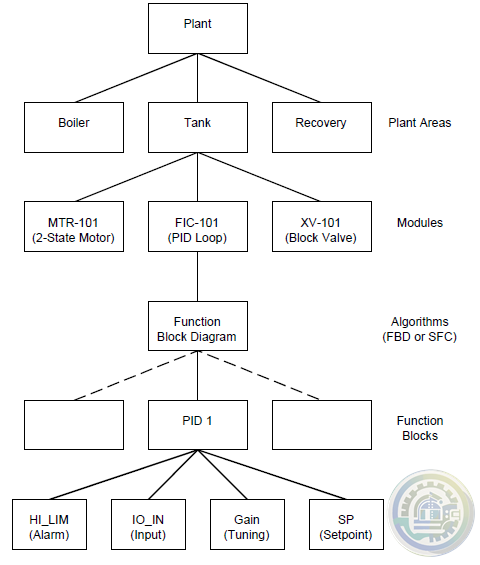

Control strategies in the DeltaV system are configured in modules. A module, which

is the smallest logical control entity in the system, contains algorithms, conditions,

alarms, displays, historical information, and other characteristics that define the

process equipment. Algorithms are the logical steps that define how the module

behaves. The DeltaV system provides control, equipment, and unit modules.

Generally, a control module contains one uniquely tagged control entity, such as a

control loop or motor, with its associated logic. Defining a module around a single

field device and its related control logic makes it easy to create, download, operate,

debug, and take a single module out of service without affecting other modules.

Equipment modules coordinate the operation of control modules and other

equipment modules that work together to control related equipment. The algorithm

for the containing equipment module manages the operation of the contained

modules.

Unit modules can be used in non-batch applications to group control modules and

equipment modules for alarm management purposes. For example, alarms for a

specific unit, such as a boiler, can be combined. All control and equipment modules

associated with the unit will be contained within the unit module.

Function blocks are building blocks for creating the continuous and discrete

algorithms that perform the control or monitoring for the process. The DeltaV

Library contains function block templates for analog control (bias/gain, lead/lag,

PID, etc.), Logical, I/O (analog and discrete input/output), and other basic functions.

Each function block contains parameters that can be modified to customize the

algorithm. Algorithms range from simple input conversions to complex control

strategies. Function blocks can be combined into composite function blocks to build

complex algorithms.

In addition to Function Block algorithms, the DeltaV system supports Sequential

Function Charts (SFCs) as well as Command-driven and State-driven algorithms

for control tasks requiring sequencing strategies.

Parameters are the user-defined data used within a module’s algorithm to perform its

calculations and logic. Parameters can be described by the type of information they

provide, such as input or output. Tables listing the parameters and their properties are

included in the Books Online information.

The DeltaV system includes a library of pre-engineered module templates with basic

characteristics. You can customize these library modules or create your own modules

from scratch. Your customized modules can be added to the library, making them

available for reuse in the development of your control strategy.

Modules that work closely together to perform a specific process control function are

typically grouped in an area. An area is a logical division of a plant. Areas typically

represent plant locations or main processing functions. The configuration engineer

determines how to logically divide the plant into areas.

Nodes are physical pieces of equipment on the control network, such as a controller

or a workstation. You control your process by downloading modules in the controller

nodes. The configuration tells the node how to act and what information to receive or

save from the process.

Device Tags represent the instruments, valves, and other field devices. A Device

Signal Tag consists of a specific signal from a device.

Alarms alert the operator that an event has occurred. (Alarms are assigned to

modules.) Typically, you want the operator to perform some action and respond to the

alarm. Alarms can be both visible and audible.

The database contains configuration information and lets you make off-line changes

without affecting the process. Online control algorithm monitoring and modification

are also available.

Following is a diagram showing the DeltaV system’s hierarchical structure.

- Informations

- Industry information

- ABB

- A-B

- GE

- MOOG

- NI

- YOKOGAWA

- FOXBORO

- BENTLY

- B&R

- UNIOP

- Abaco

- KONGSBERG

- Triconex

- HITACHI

- Emerson

- Honeywell

- Motorola

- Omron

- CTI

- Woodward

- Eaton

- EPRO

- KOLLMORGEN

- SST

- Scanlab

- Reliance

- DFI

- Prosoft

- Rexroth

- Vibro-Meter

- Mitsubishi Power

- Parker

- GEA

- MAN

- ALSTOM

- SBS

- PCH Engineering

- ZYGO

- HIMA

- BIFFI

- Advantest

- KUKA

- Full-V

- DEIF

- IBA

- Euresys

- Vishay

- Meggitt

- Aerotech

- Merlin Embedded

- Baker Hughes

- Horner

- Control Wave

- Schneider

- Siemens

- KEBA

- TEWS

- MERSEN

- Panasonic

- Ingersoll Rand

- Watlow

- Johnson Controls

- irtec

- Baldor

-

Kongsberg TRX32 FILTER (303067B) | Elektro Marine

-

Kongsberg MRU-M-MB3 | Motion Reference Unit

-

Kongsberg TRX32 303088 | eight-channel I/O module

-

Kongsberg MRU2 Motion Reference Unit

-

KONGSBERG MRU-M-SU1 Industrial Measurement Unit

-

Kongsberg RMP201-8 Versatile Remote Input/output System

-

Kongsberg dPSC 8100183 Dual Process Segment Controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable indicating controller

-

YOKOGAWA YS1700-100/A06/A31 Programmable Indicating Controller

-

KS9-5*A | Yokogawa | MXL DSC Cabl

-

KS8-5*A | Yokogawa | MXL DSC Cabl

-

KS2-05*A | Yokogawa | MXL DSC Cabl

-

YOKOGAWA PW482-10 S2 Power Supply Module

-

Yokogawa SCP451-11 S1 Processor Module

-

YOKOGAWA SR1030B62 High-Frequency Module

-

Yokogawa CP451-50 S2 Processor Module

-

YOKOGAWA AAI143-H50 Analog I/O Modules

-

YOKOGAWA AMM42 2-Wire Transmitter Input Multiplexer Module

-

SDV144-S63 | Yokogawa | Digital Input Module

-

Yokogawa AIP830-111 Operation Keyboard for Single loop Operation

-

Yokogawa S9361DH00 Control Module / Terminal Board

-

Yokogawa ATK4A-00/S1 KS Cable Interface Adapter

-

YOKOGAWA PW701 Power Supply Module

-

YOKOGAWA Dual-Redundant V-Network Router AVR10D-A22010

-

YOKOGAWA PW441-10 Communication Module

-

YOKOGAWA VI451-10 S2 Communication Module

-

Yokogawa VC401-10 Coupler Modules

-

Yokogawa ALP121 PROFIBUS-DP Communication Module

-

Yokogawa NFAI841-S00/A4S00 Analog Input/Output Module

-

YOKOGAWA AIP591 Transceiver Control Module

-

YOKOGAWA AIP578 Transceiver Control Module

-

YOKOGAWA PW501 Power Supply Unit Brand

-

Yokogawa YNT511D-V42 Bus Repeater Module

-

YOKOGAWA AIP171 Transceiver Control Module

-

YOKOGAWA VI702 Vnet/IP Interface Card

-

2302-32-VLE-2 YOKOGAWA Data Acquisition Module

-

Yokogawa ATK4A-00 16-Channel KS Cable Interface Adapter

-

YOKOGAWA ALR121-S00 Serial Communication Module

-

CP461-50 | Yokogawa | Processor Module

-

Yokogawa AIP121-S00 Control Module

-

YOKOGAWA UR1800 Wireless Communication Module

-

Yokogawa| LC82 *A Redundant RL-Bus Interface Card

-

YOKOGAWA ST6 Industrial Control Module

-

YOKOGAWA ANR10D ER Bus Node Unit

-

YOKOGAWA SDV144-S13 S1 Digital Input Module

-

YOKOGAWA NFAI143-H00 analog I/O module

-

YOKOGAWA EB501 Bus Interface Module

-

Yokogawa CP451-10-S2 High-Performance Processor Module

-

YOKOGAWA V0/E1/TCAM/L08 High-Precision Temperature Controller

-

YOKOGAWA VO/E2/TCDM24/L8 High-Precision Temperature Controller

-

YOKOGAWA 16137-119 Process Control Module

-

YOKOGAWA 16114-500 I/O Module for Process Control Systems

-

Yokogawa PSCDM024DCBAN - Critical Discrete Module

-

YOKOGAWA 16137-151 Digital Input Module

-

YOKOGAWA 16137-188 Digital Input Module

-

YOKOGAWA 16137-222 Digital Input Module

-

YOKOGAWA 16137-223 Digital Input Module

-

YOKOGAWA 16137-153 Digital Input Module

-

Watlow SUB21/IV10 0-10 V input adaptor

-

Watlow ITOOLS/NONE/USB U SB configuration kit

-

Watlow CTR500000/000 100 A Current transformer

-

Watlow CTR400000/000 50 A Current transformer

-

Watlow CTR200000/000 25 A Current transformer

-

Watlow CTR100000/000 10 A Current transformer

-

Watlow SUB35/ACCESS/249R.1 2.49R Precision resistor

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

-

Vibro-meter VM600 RLC16 200-570-000-111 200-570-101-015 Relay Card

-

Vibro-meter VM600 RPS6U 200-582-600-013 cutting-edge monitoring module

-

Vibro-meter VM600 CMC16 200-530-025-014 200-530-111-013 input/output card

-

Vibro-meter 200-570-000-014 200-570-101-013 VM600 Protection Module

-

Vibro-meter 620-002-000-113 620-003-111-112 VM600 XIO16T input/output card

-

Vibro-meter 600-003 620-001-001-116 VM600 XMV16 input/output card

-

Vibro-Meter 444-680-000-511 Level Detector & Proximity Sensor

-

Vibro-meter VM600 MPC4 200-510-111-034 200-510-070-113 Module

-

Vibro-Meter IOCN 200-566-000-113 | I/O Communication Node

-

Vibro-meter VM600 IOC16T 200-565-000-013 / 200-565-101-013 Industrial Control Module

-

Vibro-Meter 200-566-000-012 VM600 IOCN Communication board

-

Vibro-meter 200-560-000-113 VM600 power supplies Module

-

VIBRO 573-935-202C - High-Accuracy Interface Module

-

Vibro-meter 200-595-002-011 Modular Safety Relays

-

200-560-000-016 VIBRO I/O Module

-

YOKOGAWA 8662570000 Terminal Module

-

YOKOGAWA 8596020000 Terminal Module

-

YOKOGAWA 8662560000 Terminal Module

-

YOKOGAWA PSCAMAAN | Process Control Analog Input Module

-

YOKOGAWA DR1030B60 High-Precision Pressure Transmitter

-

Yokogawa adv551 Digital I/O Modules

-

Yokogawa aai543 Analog I/O Modules (for FIO)

-

YOKOGAWA LR 4220E Level Controller Module

-

Yokogawa SR1008B62 Signal Relay Module

-

SC200S | Yokogawa Electric Corporation

-

Yokogawa PW301 Power Supply

-

YOKOGAWA NP53*C - Precision Control Module

-

Yokogawa F3YD64-1A Basic Input/Output Modules

-

Yokogawa F3XD64-3N Basic Input/Output Modules

-

Yokogawa F3WD64-3N Input/Output Module

-

Yokogawa F3SP21-0N CPU Module

-

YOKOGAWA F3PU10-0N Power Supply Module

-

YOKOGAWA F3PU06-0N Power Supply Module

-

YOKOGAWA F3NC02-0N Positioning Module

-

YOKOGAWA F3NC01-0N Positioning Module

-

YOKOGAWA PLC F3LC21-1N MULTI-LINK MODULE

-

YOKOGAWA F3BU06-0N Base Module

-

Honeywell DC-TFB412 51307618-176 Control Module

-

Honeywell DC-TCF901 51307593-176 9-Port Control Firewall Module

-

Honeywell DC-TCF901 cutting-edge control module

-

Honeywell DC-TFB412 Circuit Board

-

LVCDJW00000750A Watlow (Temperature Limit Controller)

-

Watlow 84700-0003 Dust cover

-

Watlow 847290006 USB type A panel mount with 2 m cord

-

Watlow RJF 21N SCC RJ45 receptacle with self closing cap

-

Watlow USBBF 21N SCC USB - B receptacle with self closing cap

-

Watlow USBF 21N SCC USB - A receptacle with self closing cap

-

Watlow 0600-0097-0000 Mixed I/O Flex Modules Quick Start Guide

-

Watlow 0600-0096-0000 High Density Flex Modules Quick Start Guide

-

Watlow 0600-0095-0000 Communications Flex Modules Quick Start Guide

-

Watlow 0600-0094-0000 F4T Controller Quick Start Guide

-

Watlow 0600-0093-0000 Setup and Operations User Guide

-

Watlow 0600-0092-0000 Installation and Troubleshooting User Guide

-

Watlow 0822-0769-0000 Module slot plug (for vacant F4T slots without flex modules

-

Watlow 0830-0858-0000 Replacement battery

-

Watlow 0830-0808-0002 (CAPUSB-A) Rubber plug USB host

-

Watlow 0830-0808-0001 (CAPUSB-MB5) Rubber plug USB mini

-

Watlow 0601-0001-0000 Controller support tools (DVD)

wechat/whatsapp:

Email: kongjiangauto@163.com

-

Vibro-meter vmf-RLC16-V111 200-570-101-015 200-570-000-111 Relay Card

-

Vibro-meter vmf-IOC4T 200560-101-017 200-560-000-111 I/O module

-

vmf cpum vmf-cmc16 200-530-111-013 200-530-100-014 Vibro-meter Monitoring system Modulee

-

Vibro-meter 200-595-045-114 | CPUM | Vibration Processor Module

-

Vibro-meter SIM-275A 200-582-500-013 state-of-the-art protection and monitoring module

Copyright © 2009 - 2024 Cld , All Rights Reserved K-JIANG All rights reserved